|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Junior Member

Join Date: April 24, 2009

Posts: 6

|

New to Reloading, Made First Bullets, Need Advice

Well I finally received my Square Deal B reloading machine from Dillion and after getting everything set up I made my first two bullets. I am reloading .45 ACP ammo. Maybe it's just me, but I think there is something wrong with my bullets I made. They look a little short (bullets pressed too far into the case), and they also have a slight bulge where the end of the bullet meets the case.

About them looking short ... the dies were set by the factory for .45 ACP ammo so maybe it's just me but I swear they look short. I measured them with some calipers and they were under the maximum length the bullet should be. They cycle through both my .45's fine which makes me think they are ok. I will post some pictures of the bullets very soon so everyone will know what I am talking about. As for the bulge, I don't know what to do about that. Is that normal? It's a very slight bulge, hardly noticeable but it bothers me and makes me a little afraid of firing them. The brass I used has been reloaded once before if that makes any difference. I checked the dimensions of the brass before I reloaded it and all the dimensions were exact with Hornady Reloading book I have. I think pictures will help more than any explaining I can do about what I am talking about. I'll post some today. Thanks for your help! |

|

|

|

|

#2 |

|

Senior Member

Join Date: November 7, 2008

Location: North Florida

Posts: 172

|

You need to adjust your Bullet Seating Die. If you have a Factory round of 45 use that to set your OAL. Back the die out also back the seating adjuster all the way out, put the factory round in the shell holder, screw the die back in until it stops, then screw the seating adjuster down until it contacts the bullet. That should get you close you can make small adjustment from there.

|

|

|

|

|

#3 |

|

Member

Join Date: July 4, 2007

Location: Virginia

Posts: 45

|

The seating die is not adjusted at the factory, because the adjustment depends on the bullet type/weight. Every new die I've ever gotten the seating adjustment was screwed most of the way in, you need to back that out all the way then adjust it down as needed so your cartridge over all length (COAL) is correct, as RickV described.

You say it is less than the maximum length, but COAL is not a maximum length, it is THE length. Seating the bullet deeper decreases the case volume and will cause pressures the case, and maybe the chamber, were never intended to handle. |

|

|

|

|

#4 |

|

Member

Join Date: January 14, 2009

Location: Washington (the state)

Posts: 29

|

In fact, depending on how short they are they may be unsafe to fire.

|

|

|

|

|

#5 |

|

Senior Member

Join Date: July 28, 2007

Location: Ohio

Posts: 11,775

|

Jeeper, you need to get yourself a reloading manual and read it cover to cover before you load another round.

A bullet seated too deeply in the case is an obvious problem. Before you ever build any ammo, you need to know some of the pitfalls that can make for horribly unsafe conditions. If you have a bullet seated much too deeply, you have reduced the internal space of the case. When you reduce the internal space, you raise pressures exponentially. As a new reloader, you shouldn't be expected to know every little detail. But as any kind of reloader, you must know the most important parts of the ballgame, or you could get hurt and destroy some firearms in the process.

__________________

Attention Brass rats and other reloaders: I really need .327 Federal Magnum brass, no lot size too small. Tell me what caliber you need and I'll see what I have to swap. PM me and we'll discuss. |

|

|

|

|

#6 |

|

Senior Member

Join Date: November 7, 2008

Location: North Florida

Posts: 172

|

I agree with Sevens says I just assumed you had read some manuals I read the Lee Modern Reloading 2nd Edition before I made my first round. That being said I am not sure if Dillion offers help videos on their website but here is a link to Lee's showing how to set the bullet seating die. I am reasonably sure it is the same for Dillion. There are other videos on Lee's site that show how to set all the dies. I use a Lee Progressive but setting the dies in any loader should be about the same. Hope this helps and if you haven't read a manual yet do it first. I would hate to see you come on here talking about destroying a gun and losing a finger or two.

http://www.leeprecision.com/html/Hel...justment-1.wmv |

|

|

|

|

#7 |

|

Senior Member

Join Date: January 17, 2008

Location: Pennsylvania

Posts: 214

|

When in doubt give Dillon a call. They have an exellant customer service dept.

|

|

|

|

|

#8 |

|

Senior Member

Join Date: January 21, 2009

Location: Louisville Ky

Posts: 312

|

Get a manual and a couple recipes. They should include COL min and max. You cannot take a stock round and use it for measurements. A hollow point will have a different COL then a RN. Get a manual, read it, understand it or this will be a short lived hobby I fear. Make sure your powder thrower is throwing correct for your recipe. It also is not set at the factory, just to be clear.

__________________

"And finally, the Baby Bear looked and he said, "Somebody's sleeping in my bed, and the bastard's still there!" But Goldylocks had a Remington semi-automatic, with a scope and a hair-trigger!" |

|

|

|

|

#9 |

|

Senior Member

Join Date: October 28, 2006

Location: South Central Michigan...near

Posts: 6,501

|

A loaded round is a cartridge, not "bullet".

A bullet is the part of a cartridge that is propelled down the barrel when a cartridge is fired. Primer + case + powder + bullet = cartridge or round. |

|

|

|

|

#10 |

|

Junior Member

Join Date: April 24, 2009

Posts: 6

|

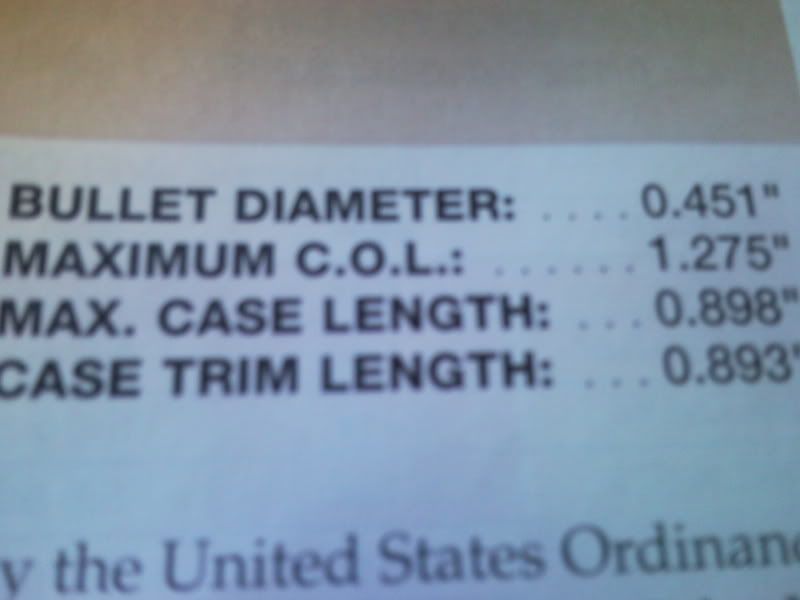

Here are some pictures. In the first and second pictures you should be able to see the line I was talking about where the case expanded. Also, in the second and third pictures you can see what I meant by "maximum C.O.L" and what my C.O.L. is. I was told not to go over that and it is ok to be a little under that number. I was also told the best way to find out if the length will work is to cycle it through the gun a couple of times to see if it jams. Maybe that's not exactly correct. I don't know. As I said, I was new to reloading. Anyways, in the fourth picture you should be able to see what my overall "cartridge" length is.

So based on these pictures most of you agree I should loosen the die that seats the bullet correct? That will fix the line on the case where it expanded and give me the correct C.O.L? And on the topic of the correct C.O.L, most of you say I should try to match my C.O.L to the Maximum C.O.L stated in the book? Also, I forgot to say that I have read my Hornady Reloading Handbook almost from cover to cover as well as many threads on this forum. It's not like I don't know how to adjust the bullet seating depth or anything, but more like what the overall cartridge length should be. I was told never to go over the max C.O.L, not to make my measurements exactly by what the book says the MAX overall cartridge length should be. I compared my two cartridges that I made to other self-defense .45 ammo I had and they were exactly the same length. That is why I didn't know what the C.O.L should be. Even though I thought it looked a little short, it measured to be the exact length as factory manufactured ammo I already had so I didn't know what to base the length on. Which is why I asked and why I would like people who are more experienced in reloading than I am to give me their advice. And I thank everyone who has given me advice on this subject since improperly reloading a cartridge could lead to very hazardous results. Last edited by Jeeper906; April 24, 2009 at 02:20 PM. |

|

|

|

|

#11 |

|

Senior Member

Join Date: November 7, 2008

Location: North Florida

Posts: 172

|

I would not shoot those!!!!!!!!!!! They look like "Danger Will Robinson" rounds.

Follow some of the advice given by others in this thread. You don't necessarily have to use Max OAL lengths but those look WAY under Min OAL. |

|

|

|

|

#12 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,732

|

Jeeper 906,

Hardball should be seated 1.265-1.275" COL (mil-spec hardball is usually about 1.270" on average). You can go over that if it still feeds OK in your gun? Maximum COL numbers are just to ensure fitting into a SAAMI compliant magazine, but many allow you a bit more leeway. More blunt shaped bullets like hollow points are often seated shorter because they don't feed well at the maximum COL, but their weight distribution is different from round nose ball, too, and their powder charges will be adjusted for the seating depth used. You've got your hardball about 0.054" deeper than normal. You didn't say what the powder charge was, so I have no way to know whether that is still safe or not? The bulge looks a little exaggerated, perhaps because .45 ACP case walls get thicker below normal hardball seating depths, though they usually have a little leeway with that. If the cartridges have trouble fitting in your chamber, then you went too far. Some amount of bulge is normal, but the photo doesn't tell me if it is actually over spec or not? I can tell you that with the old standard hardball load of 5.0 grains of Bullseye, the pressure at the correct seating depth is about 16,500 psi, but at your seating depth is about 20,000 psi, which is right near SAAMI maximum for the cartridge. But again, I don't know what your powder or charge are?

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#13 |

|

Senior Member

Join Date: January 21, 2009

Location: Louisville Ky

Posts: 312

|

When you say you compared them to other self defense ammo, is it hollow points you compared them to? If so hollow points are shorter then RN or ball. If the recipe you are working on is with that bullet or projectile, then try and get it as close to max COL as possible.

Also may want to adjust your crimping die as it does not look like your getting a crimp at all. I would do this only after you get the bullet seating right. Beat way to get it right is to back it out substantially, then get a bullet seated. Check the bullet and turn the seator in and check again. Keep doing so til you get to your COL.

__________________

"And finally, the Baby Bear looked and he said, "Somebody's sleeping in my bed, and the bastard's still there!" But Goldylocks had a Remington semi-automatic, with a scope and a hair-trigger!" |

|

|

|

|

#14 |

|

Senior Member

Join Date: November 17, 2008

Location: NW Ohio

Posts: 1,399

|

I agree, they are way too short. Pull them apart and adjust your seating die. Make sure you double check your powder charge as well.

|

|

|

|

|

#15 |

|

Senior Member

Join Date: October 25, 2001

Location: Alabama

Posts: 19,163

|

The maximum C.O.L. is the MAXIMUM that will go in the magazine and run through the action, it is not the usual or the optimum. I load 230 grain FMJ to 1.260-1.265". Or seat to equal a round of factory ammuntion.

|

|

|

|

|

#16 | |

|

Senior Member

Join Date: February 21, 2005

Location: Minnesota

Posts: 2,084

|

You look to have some fine equipment and are getting top notch advice to your very honest and nessesary questions.

You posted, Quote:

. .

__________________

Gbro CGVS For the message of the Cross is foolishness to those who are perishing, But to us who are being saved, It Is The Power Of God. 1Corinthians 1-18 |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: March 5, 2009

Location: Marysville, Washington

Posts: 195

|

Also, the slight bulge you are talking about, where the bullet meets the case, might be an indicator of too much crimp. If you are using the Dillon taper crimp die, you may need to back it off a little, too. Your reloading manual should have the diameter measurement of that part of the cartridge, too.

|

|

|

|

|

#18 |

|

Junior Member

Join Date: April 24, 2009

Posts: 6

|

Unclenick, thank you for the information about what the overall cartridge length should be. That is the information that I needed in order to continue reloading and solve this problem. So, as you said, as long as my C.O.L. is 1/100 or less under the Maximum C.O.L. then my overall cartridge length is fine correct?

Also, Jim Watson gave me helpful advice about the C.O.L of a .45 cartridge loaded with 230 grain FMJ which is what I am using as well. Both Jim's and Unclenick's information were about the same which makes me much more confident their information is correct. Thank you for helping me with that. Gbro, both of those cartridges are primed. I know it looks a little funny in the picture but they are both primed and neither are in backwards. When making these two cartridges I did put a powder charge in them, primed them, and crimped them. When reading the manual from Dillion it specifically stated stage 3 and stage 4 are "easy ones." Dillion's manual went on to say both the bullet seating depth and crimp were adjusted by Dillion specifically for .45 cartridges. That is why I made two completely assembled cartridges. After reading the manual, I thought once I got my powder charge exact I would be home free on the rest of the reloading stages. Also, someone asked me what my powder charge was I put in these two cartridges. I put 4.6 grains in the cartridges and with that charge I was aiming for around 750 FPS. So, I need to pull these bullets apart and start all over. Is it safe to use the bullet puller that you whack on the ground on a primed and ready cartridge? Even after crimping? I know it looks like these two cartridges haven't been crimped but I did run them through the crimping stage. I will have to work on that as well. |

|

|

|

|

#19 | |

|

Senior Member

Join Date: February 21, 2005

Location: Minnesota

Posts: 2,084

|

Quote:

When you posted the powder charge you didn't include the powder you used. that is just as important as the amount of charge, they go hand in hand. Making up dummy loads for chambering tests is a good practice. The neighbors will sleep better knowing you are cycling dummy through your pistol tonight. Then you have a sample round for re-setting your die should you load another brand of bullet. Greg

__________________

Gbro CGVS For the message of the Cross is foolishness to those who are perishing, But to us who are being saved, It Is The Power Of God. 1Corinthians 1-18 Last edited by Gbro; April 25, 2009 at 12:41 AM. |

|

|

|

|

|

#20 | |

|

Senior Member

Join Date: March 24, 2006

Location: Northern Utah

Posts: 705

|

Quote:

If your are seeing a slight bulge on the case where the bottom of the bullet would be, this is normal. When you resize the casing it makes it smaller, but seating the bullet expands the brass a bit, and this is what gives the brass a good firm grip on the bullet. As the others have said, we need to each adjust our own dies to suit our needs. I would never depend on anyone else, even the factory, to send them set up right. They can't anticipate the components, and a different bullet will likely change the seating depth. Here is a bit more reading: http://donce.lofthouse.com/jamaica/crimping.html Have fun! |

|

|

|

|

|

#21 |

|

Junior Member

Join Date: April 24, 2009

Posts: 6

|

Jamaica, I did see finally the C.O.L for each bullet under each bullets picture. I don't know why I missed it before but thanks for the tip.

Also, I am glad to have somebody tell me that the slight bulge is okay. I made two more cartridges last night after I made adjustments to the bullet seating depth and crimping die and I still had a slight bulge even though I triple checked the bullet was sitting square on the case before seating it. This time I made sure my C.O.L matched the recommended C.O.L. in the Hornady Reloading Manual and I think I made two good cartridges. I am going to make about eight more tonight and tomorrow I am going to test them with a chronograph to make sure they are firing at the correct fps before I make a bunch of them. Gbro, the powder I am using is Hodgdon Titegroup. Sorry I didn't post it earlier. |

|

|

|

|

#22 |

|

Senior Member

Join Date: January 19, 2009

Location: Powder Springs, GA

Posts: 213

|

With you being brandnew to reloading the one suggestion of safety that I will give ya is to make sure you keep a very close eye on your powder charge while using Titegroup. In a 45 you could double charge that in the blink of an eye. I want to move to Titegroup but currently use Universal which would allow me to see a double charge much easier.

|

|

|

|

|

#23 |

|

Senior Member

Join Date: March 7, 2009

Location: South East Queensland, Australia

Posts: 1,513

|

I dont know if anyone else noticed

In the pics, the bulge where the projectile is inside the case, seems to be worse on one side than the other (projectile is in crooked)?

I would be pulling them apart, resize and start again, paying attention to the projectile depth, start with the projectile depth too long, then ajust down a little at a time, til it is right. I truely recommend you get some advice from someone you know who reloads, just to be safe..... And like someone else said, the primer appears to be in back to front (or missing)? Be real careful not to overcharge the powder.... easy to get hurt (or worse)

|

|

|

|

|

#24 |

|

Junior Member

Join Date: April 24, 2009

Posts: 6

|

About the bulge, I know the pictures are bad and it's hard to see but the bulge is on the outside and it is pretty uniform all the way around the case. I did pull the cartridge apart, resize the case, and reseat the bullet at least 10 times. Every time know matter how square the bullet was on the case I still had a little bulge in the case. Maybe it's just the case even though I have made four cartridges now and everyone has a bulge in them. I'll make some more today and will count how many have bulges. The cases I am using have been reloaded once before if that makes any difference.

I also have been very careful about the overcharging. Almost to the point where it could be called obsessive. I have measured the powder charge at least 15 times if not 20 before I made one cartridge. I wrote down every powder charge out of the 15 times and then took the average of my numbers. My average turned out to be 4.6 grains which was what I was wanting. My powder charges were pretty precise getting 4.5, 4.5, 4.6, 4.6, 4.5, 4.7, 4.6, etc. so I am pretty confident my fps will be exactly what I thought it should be. Thank you for the advice though. Putting double the amount of powder in a cartridge would be bad I am sure. |

|

|

|

|

#25 |

|

Junior Member

Join Date: April 24, 2009

Posts: 6

|

Well I shot my first 10 cartridges through a chronograph today. The powder charge in the cartridges was set at just a hair over 750 fps. My average fps of the 10 cartridges shot was 768 fps. Now that I know everything is where it's supposed to be I am going to make a couple boxes. Thanks for everyone's help!

|

|

|

|

|

|