|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Junior Member

Join Date: June 14, 2011

Posts: 4

|

brass is very tight in rifle

I am reloading 22-250 I bought the brass from a guy that said it had only been shot once maybe twice. I have F/L re-sized it, trimmed it, and de-bured it. The brass looks great no bulges and no discolorations. When I place the brass in the chamber and close the bolt the action is tight or stiff to close. When you eject the round you can see smear marks on the rim of the bottom of the case running through the size and brand markings. The brass is Winchester brass. I have used other brands without problems. I have tried to place this brass in three other makes of rifle’s having the same problem. Any ideas or suggestions why this is happening.

Thanks |

|

|

|

|

#2 |

|

Senior Member

Join Date: May 9, 2000

Location: SLC,Utah

Posts: 2,704

|

Just brainstorming here:

Is it possible that your sizing die has gotten out of adjustment and is not fully sizing the Winchester brass? Do you have a fired case of a different brand that you can try sizing now to see if the problem carries over to the different brand? Is it possible that the web of the Winchester cases is a bit thicker and the decapping pin is contacting the web, making it feel like the ram has reached full stroke when it really hasn't? Backing out the decapping pin one full turn would serve to check this and make it simple to return it to the previous position. Have you blacked the case shoulder with a Magic Marker or similar marker to verify that the case shoulder is contacting the chamber shoulder? One more thing: Have you double-checked that the trim length is correct and not too long? |

|

|

|

|

#3 |

|

Senior Member

Join Date: February 9, 2005

Location: Owego, NY

Posts: 2,000

|

Assuming your die is adjusted down as far as it will go and the case is still too long (shoulder hitting chamber), you might try a small piece of aluminum foil as a shim under the brass when it is in your shell holder and see if the extra .001" - .002" gives enough added shoulder bump to make a better fit in the chamber. You can achieve the same affect if you take a couple thou off the bottom of your die or the top of your shell holder. I have several shell holders I have sanded thinner with fine emery paper.

__________________

,,, stupidity comes to some people very easily. 8/22/2017 my wife in a discussion about Liberals. Are you ready for civil war? |

|

|

|

|

#4 |

|

Senior Member

Join Date: August 2, 2007

Location: Tabor City , NC.

Posts: 1,969

|

Tite !!! you don`t know what tite is until ya try to size some machine gun 30-06 brass

RCBS lube II all the way !!! RCBS lube II all the way !!!I had to do as flashhole suggested I ground alittle (600 grit on a peice of glass) ~bout .015"to get it to chamber in my 700 Loaded pistol alot more than rifle over the yrs. & got caught with the decapper too deep on some 7mm-08 dies , talk `bout a DUH moment  Good responses though & I`ve really added nothing except my experiences which were very complexing when they were actually happening  Now I`m older & wiser , but can`t remember any of it

|

|

|

|

|

#5 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

You need to anneal your brass, it is getting "work hardened" and springing back after full length resizing.

Jimro |

|

|

|

|

#6 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

moonall, before I start to reload for a chamber I determine the length of the chamber, I would not know what it would be like to size a case then attempt to chamber...only to find the case did/will not chamber, that to me is reloading without a plan. I make all my tools, that does not mean I do not have tools, I just do not use them.

Again, I have never found it necessary to alter a die and or shell holder, I did purchase a set of Redding composition shell holders, #6, a set of 5 for $5.00 dollars at the Big Town Gun Show in Mesquite, TX as an alternative to the Redding Shell holders I use the companion tool to the press, the feeler gage, with a standard RCBS shell holder I have 10 options between .125 deck height and .135 deck height, the shell holders from Redding are nice and that is about it. I form cases for short chambers, that would be .017 thousands shorter than a go-gage length chamber or .012 thousands shorter than a full length sized/minimum length sized case, why? comes in handy when cutting a chamber and I never say "When reaming a chamber no one knows where they are so 'check often'. To form short cases I use the feeler gage between the deck of the shell holder and the head of the case, to form cases for long chambers I use the feeler gage to adjust the die off the shell holder, again, I have a M1917 Eddystone with .016 thousands head space, I adjust the gap between the bottom of the die and top of the shell holder to .014 thousands. Moving the shoulder forward, not a problem, I find cases that are long between the head of the case and shoulder 'WITHOUT FIRE FORMING' I use 280 Remington new Remington 280 cases with a shoulder forward of the 30/06 by .051 thousands, that is a can not miss. Again, cases can have resistance to being sized,, sometimes the press wins and whips the case, other times the case wins and whips the press, when I have my press adjusted and the press, die and shell holder fail to size the case because the case is tougher than my press, I can use a feeler gage to determine the amount of case that does not get stuffed into the die by the shell holder by measuring the gap between the top of the shell holder and bottom of the die before lowering the ram, I do not need cases that are that tough, I do not need the hassle, and datums, I am THE fan of datums, without datums I could not determine the length of the chamber, I could not transfer the difference in length to the press, die and shell holder, again I make my tools and I am THE fan of DATUMS. F. Guffey |

|

|

|

|

#7 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I had two problems over the years that might relate. Once I used brass that had been fired in an extremely over sized chamber. I could not re-size it down to the proper specs. As some one mentioned earlier, the brass just sprung back to the over sizes length. The other condition, and you described it perfectly, is brass from a rifle that was out of alignment. The face of the bolt is not at 90* with the bore and the base of the brass is at an angle when fired. When you turn the bolt it cams brass off the base of the case. If you set some emptys on a flat surface you can usually see the difference.

|

|

|

|

|

#8 |

|

Senior Member

Join Date: December 1, 2002

Posts: 2,832

|

Resize your cases properly and all will be well; "oversized" chambers are not a problem when the cases are sized correctly. I routinely make .22-250 from .30-06 cases and you can't get a more oversized chamber than that.

I have a near full cigar box of unused datums in various sizes, pay the postage and they are yours.

|

|

|

|

|

#9 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,732

|

The guys have got you covered, but I think you'll discover that once you've fired the rounds in your chamber, they are straightened up to match and the usual resizing will then work just fine. The only exceptions would be if they've been fired so many times they are in sever need of annealing, or they have been fired in a chamber so long that the pressure ring stretch is so severe that they should be pitched out (you can feel for that inside the case with a dental probe or the bent-over tip of a straightened paperclip; you are feeling for a dip at the thin spot, which is usually near the head and occassionally in the middle of the brass (odball foreign stuff with very thick walls near the head)).

If the head smearing is bothering you, take a rag and burnish a little graphite powder into the loaded case heads and it will mitigate that problem while you get through the first firing. After that it should no longer be needed.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#10 |

|

Junior Member

Join Date: June 14, 2011

Posts: 4

|

Thanks guys for the advice I have tried most of you suggestions with no luck.

1. I have readjusted my die twice 2. I have painted the shoulder of the brass and it doesn’t seem in be the problem. 3. After shooting some of it and resizing it still the same other brand no problems. It is very frustrating… |

|

|

|

|

#11 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

wncchester....

You are wrong. I am the king of making one case out of a different case and that is not the same. You can stretch a case to the point where it actually has to be swaged down to be of the correct dimension again and a hand press will not do it. I had some old .22 Hi-Power brass I could not size down. With a bolt action you can force and might not feel it. A lever action tells all. The odd thing about this is that of the "Big three" ammo makers, Winchester always has the smallest body dimensions.

|

|

|

|

|

#12 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,732

|

Moonyall,

Do you have a fired case from your chamber that started out as new ammunition and is not yet resized? If so, let's compare it to one of the resized ones that don't fit. If you don't have a gauge, use the method in the photo below. For .22-250, you want a hole through the spacer that is ideally 0.347". I think you'll find spacers that are sized for 5/16" bolts are going to be close enough to that size inside. You only have to be close to get a comparison. Measure the fired case and one of your troublesome resized cases. What you are interested in is the difference, not the absolute number. If the resized case is not shorter than the fired case, you still have a problem with the sizing die not pushing the shoulder back far enough. If it is already shorter, then something else is going on. One other thought: have you measured the head diameters of the difficult cases? You can also smoke or mark the case with dry-erase pen all around the head and going up a half inch, then chamber and withdraw it. The scraping should let you see if the sizing die is failing to get the diameter near the head down. That can be a problem if the sizing die has too much radius at the mouth for these cases. Since Winchester cases tend to be thinned more than average in the head to accommodate their semi-balloon head design, they can expand a bit lower down than the average for other brands, so that is a possibility. If the shoulder turns out just not to have been pushed back as much as the fired case shoulder position, that's a sign the original chamber was very long. You can repeat the foil trick with three layers of foil instead of one. You can remove the decapping pin from your sizing die and use Mr. Guffey's favorite trick of slipping an automotive feeler gauge in under the head and thereby choose the number of thousandths of additional shoulder push-back that way.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#13 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I'm with you Unclenick. There is something weird about over size Winchester brass. I don't know if anyone mentioned it, but you could drop a re-sized case in the chamber with out a bullet or primer in. Probably won't change anything but when you have these situations it is usually something really obvious.

|

|

|

|

|

#14 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

"....the brass in the chamber and close the bolt the action is tight or stiff to close. When you eject the round you can see smear marks on the rim of the bottom of the case running through the size and brand markings"

It is not fair, when I attempt chambering a round and I find it will not chamber (allow the bolt to close) I have all the tools I need to determine "by how much" the bolt fails to close, for me when the bolt closes the the light does not go out nor does the chamber get dark inside. F. Guffey Did I leave out the part where I can check head space as in go, no and beyond with a field (reject) gage. |

|

|

|

|

#15 |

|

Senior Member

Join Date: July 26, 2011

Location: USA

Posts: 1,757

|

The web area of your used brass might be expanded/oversize from excess pressure. Standard dies do not resize this area. Scrap it.

|

|

|

|

|

#16 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Around here there is no shortage of dies, neck, versatile full length sizer dies, small base dies then there is the cut off saw with the v-block clamp, and the grinder, it is a butt grinder, angle grinder and an in-line grinder with a chuck,I can make tapered gages, guides and head space gages.

When sizing a case the bottom of the case is not sized, the limiter to sizing the case is the shell holder, one more time, the deck height of the shell holder is .125, then there is the radius on the bottom of the die, there is no difference between the amount of sizing between the full length (versatile) sizer die and the small base die from the head of the case up, there could be a difference in diameter of the case that is sized with some small base dies used by other reloaders, I am never in need for something to measure with and there is no limit when it comes to measuring down to .000,0005, it is a waste of time and effort but it can be done. As to case head expansion, if the shooter/reloader did not measure the case before and after the reloader is wasting their time. If they can not determine the length of the chamber and it's effect the chamber will have on the case when fired, they should learn. It will not happen but a good reloading practice when purchasing new/bulk case as in 50 or 100 a few cases should be saved and never fired for a reference, if the new cases, store bought, over the counter minimum length/minimum length cases chamber the new/saved/unfired cases will allow the reloader to have a reference, weight, length diameter, volume etc.. F. Guffey |

|

|

|

|

#17 |

|

Junior Member

Join Date: June 14, 2011

Posts: 4

|

Well guys I got it thanks for all the help. I went and got a new die today put it in the press set it up grabbed a piece of that brass re-sized it same problem. So that told me its something I am doing wrong. So I began thinking about my die set up and started screwing it down (more than normal). This die really needs to cam over HARD in the press but it worked?

|

|

|

|

|

#18 |

|

Senior Member

Join Date: August 11, 2009

Location: SW Idaho

Posts: 1,497

|

Perhaps I missed the post, but did you check the trim length? I see that Don H mentioned this and he is absolutely right.

__________________

Keltec P15 at 1200 rounds |

|

|

|

|

#19 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

You are not paying attention. Read "243winxb" and "Gunplummer". Your brass is ****. It seems the only way to explain it to you. If you have to crank that hard on the press, then the brass was fired in a way oversize chamber at excessive pressure. The only other explanation would be military brass and they never made 22-250 that I know of.

|

|

|

|

|

#20 |

|

Senior Member

Join Date: February 9, 2005

Location: Owego, NY

Posts: 2,000

|

I ensure there is a lot of fiber in my diet. It keeps my disposition in check.

__________________

,,, stupidity comes to some people very easily. 8/22/2017 my wife in a discussion about Liberals. Are you ready for civil war? |

|

|

|

|

#21 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

"This die really needs to cam over HARD in the press but it worked?"

I will never understand "cam over HARD" when sizing a case, just how tough is the case, without a die to support the case I crush cases into accordions/bellows, it would take a week to explaining how and why I find it necessary, but before I start telling someone a case has the ability to whip a press, I test the case for it's ability to resist sizing, most of the effort used when camming over goes to putting a strain on the press. Cases do not whip my presses,but sometimes the press whips the case and other times the case whips the press, reloaders do have bad habits. F. Guffey |

|

|

|

|

#22 |

|

Senior Member

Join Date: November 9, 2005

Location: Ohio, Appalachia's foothills.

Posts: 3,779

|

Screw the die in another 1/4 turn.

|

|

|

|

|

#23 |

|

Senior Member

Join Date: June 15, 2006

Posts: 246

|

I also have to go with Don H and say to double check your trim length.

|

|

|

|

|

#24 |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

You have big brass and your sizing die is not swaging it down to where it will fit the chamber.

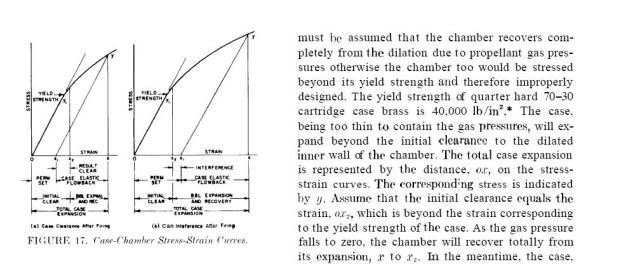

Brass is always operating above its yield strength, the stuff deforms during firing, and you have to reduce it below the dimensions of your chamber. Why is that so hard to believe? Standard sizing dies do not always provide sufficient case reduction. With really ballooned brass, sometimes small base dies cannot reduce the case size to a useable level. I have been told that commercial reloading companies have huge hydraulic machines that swage case heads between steel plates to reduce the brass to minimum dimensions.

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

|