|

|

|

#51 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

I can't for the life of me remember what the technical term is for press hesitation,

I think I only heard it once, all other times it was simply called hesitation rings. Anyway, no outward signs, but the brass is basically two pieces pressed together really hard, the brass (and copper, aluminum, etc) separates when the draw stops & restarts. Metals act under a completely different set of rules when they go 'Plastic' under pressure forming. I don't understand then reason why the rings form or why there is such a week bond between the two parts on either side of the hesitation ring, if anyone knows please elaborate. I've seen it several times, but it was my old press causing it, it's a one in a million with commercial brass since they have been aware of it since the mid 1800s, well known problem with them, but when I stared I had no idea. Now, consider this, The military used outdated equipment until very recently, Milbrass often did it more frequently, and the military still issues broken case extractors when they DO NOT reload brass... By the way, The brass engineer that helped me pointed that out, and since he worked for ATK/Federal I listened. Personally, before I screwed up manufacture, I think I only saw one or two separated cases in 3 decades... Last edited by JeepHammer; June 5, 2017 at 10:19 AM. |

|

|

|

|

#52 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

Found my shop notes, it's called "Dislocation Density".

Hesitations cause "Twinning", fault lines formed during re-crystallization, "...when atoms shift under great force" is the metallurgical definition. Pretty good definition of the drawing process. Last edited by JeepHammer; June 5, 2017 at 01:12 PM. |

|

|

|

|

#53 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

He wanted to borrow a hammer in 10 words or less. F. Guffey |

|

|

|

|

|

#54 | |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

Quote:

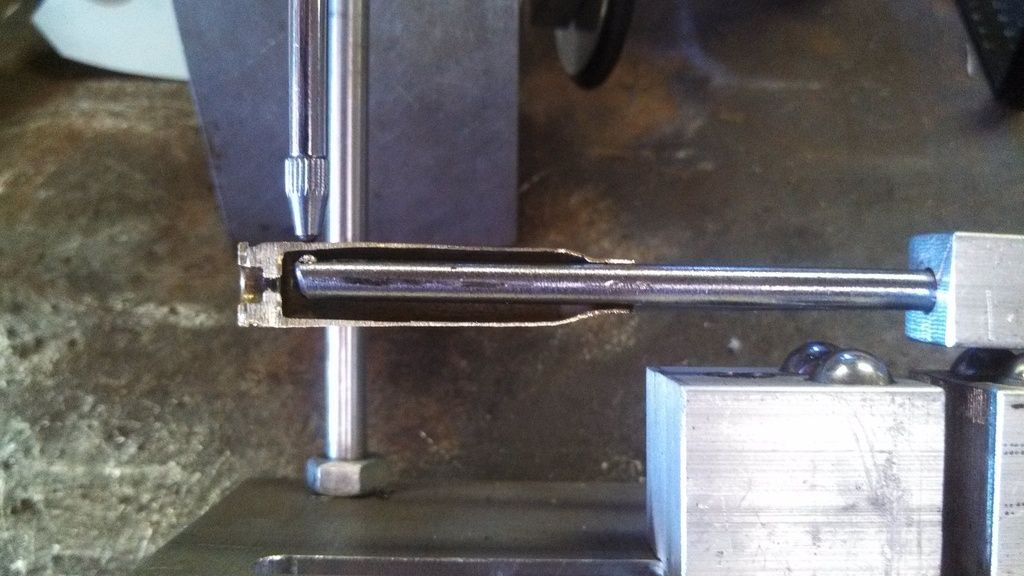

When you purchase "once fired" brass you should just think "at least once fired". If you are buying it already sized and trimmed you are not going to get any signs that something is wrong with it but where there is one bad apple, others are near by. On the concentricity gauge I built I added an arm with a bearing in the tip that lines up with the dial indicator.  It allows me to non destructively measure case wall thickness.  Had you shoved your separated case onto it before you loaded it and slowly slid the case towards the mouth, you could have seen the needle start at the thickest point, go low where it was thin where it was stretched and then back up to normal thickness. You could have scrapped it at that point. If another case started thick and was uniform with the thinnest part being the mouth, it would be ok. |

|

|

|

|

|

#55 | |

|

Senior Member

Join Date: August 26, 2016

Location: North Dakota

Posts: 1,636

|

jmorris:

That is a pretty neat device, but I don't need it....A dental pick will accomplish the same task. A sharp, hard, dental pick will easily feel a pressure ring. I have culled plenty of cases using the dental pick from range pickup brass. However, as some have pointed out, there doesn't need to be excessive headspace in some situations for there to be casehead cracking/separation. Quote:

Furthermore, I have checked over 500 of the other cases by now, and they show no ring...or at least nothing a dental pick can feel. Which means there are no red flags. Sometimes, stuff just happens. If you reload enough, it is likely all of the quirky little failures that are possible will happen to you at some point. |

|

|

|

|

|

#56 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

F. Guffey |

|

|

|

|

|

#57 | |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

Quote:

There are various causes from damaged brass open bolt beltfed 308's like the M240 make it hard to be "out of time" though. The likely source is the barrel, they can only handle sustained fire for about 2 min before they have to be swapped and it's not uncommon to have a barrel in service that is at the end of its life. FWIW If your waiting on the case to get so bad you can feel the ring from the inside with a paper clip or dental pick, you could be firing cases that are already separating and go "thick, thin, thick" and you just can't tell. Often by the time you can "feel" it from the inside you can see it from the outside. |

|

|

|

|

|

#58 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Yes, it is fundamental. the shell holder has a deck height of .125", I know, it is alleged the manufacture of the shell holder must match the manufacturer of the die and I never understood that. I measure the deck height of the shell holder' if the deck height is .125" that is all it can do. But! If the deck height is not .125" I place the shell holder in the box of high esteem. I purchased a set of Redding Competition shell holders at a gun show, it was a #6 set, I paid $5.00 for it, I thought there had to be something wrong with the set. Sure enough, the #2, 3 and 4 shell holders were off by .001" each.

F. Guffey |

|

|

|

|

#59 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

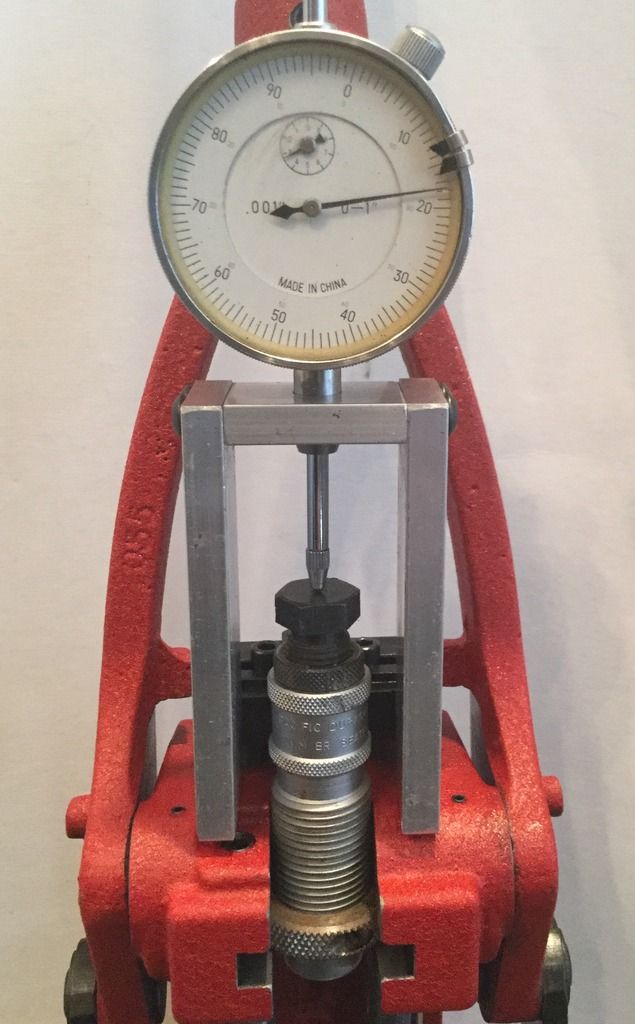

Redding competition shell holders come in sets of five. +.002, +.004, +.006, +.008, +.010 and are marked for how much they will reduce headspace accordingly.

http://www.redding-reloading.com/onl...ellholder-sets You can adjust a die with better precision than .002" for less than a $56 set of shell holders, for one specific case head, with an easy to make fixture and a dial indicator.

|

|

|

|

|

#60 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,903

|

I found my Garand's headspace correlated with a jiiiust-close case headspace dimension of 2.049" as measured with the Hornady comparator.

Unfortunately, the Redding die set I was using was sizing cases down to 2.036-ish (  ) )So now I simply cam-over (ensuring consistency with that "body-supporting" die  ) using a 0.010" feeler gauge between the shellholder deck and the die for a final case dimension of 2.047" ) using a 0.010" feeler gauge between the shellholder deck and the die for a final case dimension of 2.047"(see Guffy? I do listen)

|

|

|

|

|

#61 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

So I ask how did that Redding die reduce the length of the case from the datum to the case head .014" shorter than a minimum length full length sized case. .014"? I can do that but I would have to use a Lee shell holder. I would have to use a lee shell holder because my RCBS shell holders fit like a hand-me-down short and Lee fit like a worn out shirt. There are time I find the loose shell holder necessary when forming cases for short chambers. One more time, I create work that is necessary for forming cases for short chambers, it is not something I go looking for, for me it is something that is important to be able to do. When working with a chamber I want to know the length of the chamber before I start. You will never read and or hear me bragging about having a tighter and or smaller chamber than anyone else  jmorris, it appears the grease worms have gotten to your die. F. Guffey Last edited by F. Guffey; June 9, 2017 at 06:15 AM. Reason: change 2 ds to 2 gs, change works to worms |

|

|

|

|

|

|