|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#26 |

|

Senior Member

Join Date: February 13, 2002

Location: Canada

Posts: 12,453

|

"...Bought from a pawn shop..." Chances are they didn't look at it either. If it hasn't been too long take it back. 'Too long' being whatever the pawn shop says it is.

Springfield's warrantee applies to the original owner only. |

|

|

|

|

#27 |

|

Senior Member

Join Date: March 18, 2019

Location: Texas

Posts: 477

|

I'm 2/2 for sending back pistols to the OEM for repair/replacement from pawn shops. I bought a Ruger SR1911 that would constantly stove pipe. Sent it back. They said the frame was way out of spec. Sent a brand new one. Bought a Sig P229. It had cracked grip screw holes. Sig swapped my parts onto a new frame and sent it back.

The last thing a gun manufacturer wants (especially now when sales are in a slump) is an unhappy user ranting all over the place about how their brand is a POS. Especially Springfield Armory. A replacement slide probably costs them $50. And if the part isn't completely destroyed out of misuse/neglect they'll likely help you out and make you a XDM fanboy. |

|

|

|

|

#28 |

|

Member

Join Date: August 12, 2019

Posts: 16

|

Trash, better safe than sorry.

|

|

|

|

|

#29 | |

|

Senior Member

Join Date: October 22, 2016

Posts: 3,962

|

Quote:

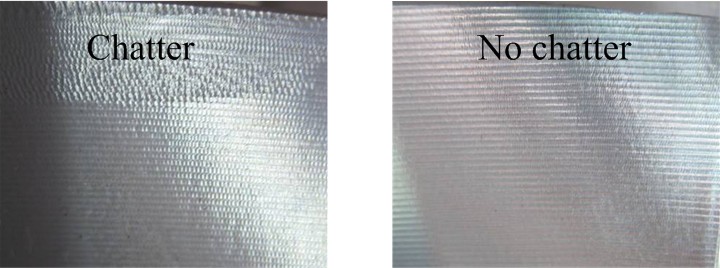

Chatter wouldn't cause such visible ridges, it would just leave a poor surface finish.

__________________

"We always think there's gonna be more time... then it runs out."

|

|

|

|

|

|

#30 |

|

Staff

Join Date: February 12, 2001

Location: DFW Area

Posts: 25,567

|

If you machine through thin and somewhat brittle metal too fast, the metal will break and chip at the edges of the cut instead of cutting through smoothly. Especially if the tool is dull.

__________________

Do you know about the TEXAS State Rifle Association?

|

|

|

|

|

#31 |

|

Senior Member

Join Date: October 22, 2016

Posts: 3,962

|

I don't work with thin material that much, so probably. I can tell the tool would be a ball end mill and when the radius portion of it gets dull, it looks bad.

Regardless, should have been caught before leaving factory, but quality in gun manufacturing plays second fiddle to customer service nowadays.

__________________

"We always think there's gonna be more time... then it runs out."

|

|

|

|

|

#32 |

|

Staff

Join Date: March 11, 2006

Location: Upper US

Posts: 30,486

|

I informed one of my "minions" about this thread, and they went to the local shop, and examined two different pistols of the same make & model as the OP, and in both cases the cut looked like the one in post #6, with smooth edges, not like the gun the OP has.

And, for what its worth, the shop owner stated that if a customer brought him a gun like the one the OP has, he would send it back to the maker and say "fix it!" am curious to see what Springfield says and does about it...

__________________

All else being equal (and it almost never is) bigger bullets tend to work better. |

|

|

|

|

#33 |

|

Senior Member

Join Date: February 15, 1999

Location: Winston-Salem, NC USA

Posts: 6,348

|

Nymero? Have you heard from Springfield.

|

|

|

|

|

#34 |

|

Senior Member

Join Date: August 9, 2007

Location: Oregoncoast

Posts: 1,793

|

I guess I've been living dangerously, I'd have just trimmed the edges of that in less time than it took to read all the posts here.

__________________

CNC produced 416 stainless triggers to replace the plastic triggers on Colt Mustangs, Mustang Plus II's, MK IV Government .380's and Sig P238's and P938's. Plus Colt Mustang hardened 416 guide rods, and Llama .32 and .380 recoil spring buttons, checkered nicely and blued. |

|

|

|

|

#35 |

|

Senior Member

Join Date: December 11, 2004

Location: Redwood City, Ca.

Posts: 4,114

|

If John is right and it's a standard design feature it's an odd way to design a slide. It's a standard Browning tilt barrel right? Common enough. How many guns handle that in this way?

This gun is also not a new design. Seems folks would have been asking about this if common. I know nothing about this Springfield so have no real opinion, but seems odd. tipoc

__________________

1. All guns are always loaded. 2. Never let the muzzle cover anything you are not willing to destroy. 3. Keep your finger off the trigger till you are ready to shoot. 4. Identify your target and know what is beyond it. |

|

|

|

|

#36 |

|

Staff

Join Date: February 12, 2001

Location: DFW Area

Posts: 25,567

|

I don't think the rough edges are a standard feature at all. I'd say that's the result of dull tools, or maybe someone pushing a cutter too fast. I don't see it as being a functional problem or a safety issue (the gun should still work and be safe to fire even with the rough edges), but the edges should be smooth.

But the cut through does seem to be standard. There has to be some provision for the barrel to tilt and if the channels for the barrel and recoil spring are close together (to keep the bore axis as low as possible) the cut in the barrel channel to allow the barrel tilt will go through into the channel for the recoil spring. The break through will leave a profile that is elliptical and since the edges of the cutout will be thin because of the geometry, if the tool is dull or being pushed too fast, it won't be nice and smooth. If the barrel channel and recoil spring assembly channel are farther apart, then the cut in the barrel channel won't go through into the recoil spring channel and the cutout won't occur. Also, if the slide design doesn't include a barrel channel and recoil spring channel (as with Glocks) then this "feature" won't be there. I've seen this cutout on other guns (just don't ask me which ones) over the years, and I did find a picture of another XDM showing the cutout (albeit with smooth edges) and we also have other folks indicating that other XDMs show the same cutout but with smooth edges.

__________________

Do you know about the TEXAS State Rifle Association?

|

|

|

|

|

#37 |

|

Staff

Join Date: March 11, 2006

Location: Upper US

Posts: 30,486

|

The cutout is a design feature, the rough edges are a flaw. Several other pistols of the same make model and caliber have been examined, and they don't have the rough edges the OP's gun has. It's a flaw.

Its not in a critical area, the gun is safe to shoot and does function. The OP has contacted the maker, and we're waiting to hear back from him, about what they said.

__________________

All else being equal (and it almost never is) bigger bullets tend to work better. |

|

|

|

|

|