|

|

|

#1 |

|

Member

Join Date: March 1, 2005

Posts: 31

|

Forster CoAx Press?

I would like to get this press, but Midway and Cabelas never seem to have it in stock. This could be of the high demand, but thinking it might be worth the $$ for precision reloading.

What are your thoughts on the press, and where would be the best place to keep watching for it to come in stock. Thanks |

|

|

|

|

#2 |

|

Senior Member

Join Date: November 6, 2001

Posts: 1,125

|

Great press. The floating die does contribute to rounds with less bullet runout without hassle. Graf & Son's has them in stock now. Prices for this press is high but I think worth it. Seldom see sales and like you said they are often out of stock. Graf's for one has them in stock now. Buy a pack of Forster die lock rings as some of your die lock rings may not fit the slot or not correctly fit the slot. They usually have a pack of 10 lock rings and they are worth it.

http://www.grafs.com/retail/catalog/...productId/4863 |

|

|

|

|

#3 |

|

Senior Member

Join Date: September 15, 2007

Posts: 1,707

|

Back in the late 80s or early 90s I bought one. It is a nicely made press. However, I found that I achieved better rifle ammo with better concentricity and uniformity of seating depths when I used a Rock Chucker.

I sold it to a friend who berated me for not telling him about the concentricity issues. It ended that friendship. In fairness though, I always figured it might have had something to do with the dies, like maybe the expander ball pulling the necks to one side or something. Recently I bought a RCBS Summit and it has loaded excellent ammo, but then my techniques have also changed as well as the dies I am using. The two features I didn't like was the way the die was held by the lock ring and the jaws of the shell holder opening and closing like that. I thought the shell holder was cool when I bought the press, but became frustrated by that feature after a time. I also found it aggravating to set the shoulder bump on a given die set as one had to remove the die, unscrew the lock ring screw, make minute adjustments and reinsert it in the press. If I used the grub screw in the press to hold the lock ring in place, it would introduce another variable in uniform shoulder setback. In all I was disappointed. These were my experiences, yours may be nothing short of stellar. |

|

|

|

|

#4 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,068

|

Stubbicatt,

That's 180° from my experience with this press. I'm guessing something was out of whack with your copy—sprung rods or bad casting or something—if it produced high runout ammo for your ex-friend, as well. I understand the U.S. Army Marksmanship Unit has 20 of these presses that they use for their special loads. Their experience is like my own with this press: I've been able to get more concentric ammo out of it than I can get from any of my fixed O-presses. Die setup is quick if you just don't tighten the lock ring for more than light friction until you find the right position. Forster makes an adapter that lets you use standard shell holders if you want to, say for using the Redding Competition Shell holders, but then you lose the self-centering of the universal holder design. But the die has room to move enough to make up for that, so it's the user's choice. As a bonus, the press has the only primer seater made that I am aware of that fixes primer seating depth at a nominal level. It is a little slow to set up, but when you have it set, it produces ideal seating for minimizing slamfires in floating firing pin gas-operated military weapons.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#5 |

|

Senior Member

Join Date: April 16, 2009

Location: North Dakota

Posts: 111

|

Been using mine for over 30 years, no problems, love it.

|

|

|

|

|

#6 |

|

Senior Member

Join Date: November 13, 2004

Location: PacWest

Posts: 455

|

I bought one, it's worth the money. I'd just backorder and wait.

I bought one, it's worth the money. I'd just backorder and wait.

I wouldn't want a Coax as my only press. I use a Harrell's 4 station turret and a Redding T7 more. The Harrell's because it's handy for next to the computer say and decapping and sizing smaller cases while doing something else and loading at the range or motel room. The T7 because I can leave Redding Instant Indicators and such setup for ready reference. I'd hate to be bumping shoulders in a CoAx and swapping dies to measure. Same with seating depth. I like the Redding Micrometer adjusting seating and crimping dies for easy adjustment from the top for everything but especially in the CoAx and in progressive presses. I think the Coax does the things it does well better than any other press including little things like controlling spent primers. It's a little different and may need extra care and expensive dies to show any advantage. I like the spring loaded shell holder mostly but do have multiple sizes for different rims and the adapter for standard shell holders to use with Redding Competition shell holders - within a narrow range those help bumping shoulders. Probably for the hobbyist who wants to fiddle rather than an easy way to buy points. There is no easy way to buy points. I'd buy a T7 before a CoAx but a CoAx supplements nicely. Capitalism works and most all the competition will make good loads. |

|

|

|

|

#7 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

I hear that a lot, might have been, had something to do with and to do with something. When I wonder I figure it out. F. Guffey |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: November 6, 2001

Posts: 1,125

|

I agree with ClarkEMyers in that I wouldn't want the Co-Ax to be my only press. I have a RCBS RockChucker and also a RCBS Big Max press. The Co-Ax does 90% of all the tasks. I use the other presses for bullet sizing, primer pocket crimp removal with the RCBS swaging tool, and I seat in the Co-Ax and crimp some bullets in the RCBS. Having the Co-Ax and another standard press is very handy.

|

|

|

|

|

#9 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

I am fortunate, I have been sorting cases, thousands of cases that I did not fire and or size. What ever I was doing must have annoyed my wife because she ask "What are you doing?" That always leaves me to ask "Why do you ask?"

Anyhow I was rolling cases, I was looking for necks that turned like a cam or cases that hopped because they were bent, I was listening for that waa, waa etc. sound made when something is not rolling smoothly, nothing. The man that gave me the cases threw in the press also, a Rock Chucker. When I start sizing it gets real noisy around here, all of my presses are hollering "pick me, pick me!"  . . Self centering and floating, I have used equipment that had air float when centering, when sizing cases with a press I will have to settle for the shell holder centering before it gets into a bind, I suppose I could put some slick-um on the shell holder deck and beneath the shell holder to reduce friction, if I had that problem. F. Guffey |

|

|

|

|

#10 |

|

Senior Member

Join Date: January 27, 2010

Location: AR

Posts: 1,401

|

Never used one, but I have known people who swear by them. Can't remember any Forster owner ever complaining.

IMHO, I have a number of Forster products on my bench and still own their case trimmer which has given me great service for 40 years. |

|

|

|

|

#11 | |

|

Senior Member

Join Date: September 15, 2007

Posts: 1,707

|

Quote:

Regards, Stubb (still putting my shoes on one at a time).

|

|

|

|

|

|

#12 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

Again, I was sorting cases, not my intention but the wife was annoyed. I was rolling cases across the kitchen table. I was looking for cases that went in three different directions at the same time, I was listening for the wobble sound made by rolling something that was bent. The assortment of cases was a 50 year accumulation of a smith, builder, collector, shooter and friend. He also gave me his press, all he had was a Rock Chucker. before that, I do not know. Before I assumed what I read on the Internet then repeated what I read as reloading gospel I spent a small amount of time "figuring it out". I found the yanking and pulling of the neck had to do with reloaders with bad reloading habits. F. Guffey |

|

|

|

|

|

#13 | |

|

Senior Member

Join Date: May 31, 2007

Location: NC

Posts: 2,614

|

Quote:

As to the Co-Ax, I'm very happy with mine. I've been primarily loading .223 for High Power competition. Because it's faster (and good enough), I use a hand primer, rather than the Co-Ax's primer, which is slower. I've started to load for my 7mm-08, though, and have a .260 coming soon. And since volume here is less of an issue, I'm going to start using the Co-Ax's primer for these. From what I've read, it gives a very consistent seating depth. My only issue with the Co-Ax has to do with the shell holder jaws: When switching the jaws to/from the "small" setting, the 2 itty bitty springs that tension the jaws are easily launched if you're not careful. It only took a single careless moment to launch 1 spring already, so I bought a 4-pack of replacement springs "just in case". |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

I have two co-ax presses side by side in the reloading room.

I think the are the best press for me for that application. Right now I am on a month long hunting trip with two RCBS parnter presses mounted in my vehicle, and really old big clunky reloading presses in the homes of fellow hunters I am staying with. A few years ago I made a numbers of parts to improve the co-ax, espeically a stronger shell holder jaw housing that captures the springs. I sold a couple dozen. Since then I gave the drawings to a young man that is currenly making them with CNC and selling them. Since then I ran into an old retired machinst on a gun forum that did the same thing I did 10 years before I did it. My guess is that if the Chinese start make that press, they will only charge half as much, but will not improve the shell holder jaw housing, but instead add more problems.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#15 |

|

Member

Join Date: June 9, 2011

Posts: 33

|

First and foremost. Tis a poor carpenter that blames his tools.

Everyone will find what works for them. What works for your application? Forster at one time was only making presses once a quarter in lots of 500. Now they are on a much more frequent basis. There are places to look..www.gunstop.com is a good place to check for decent pricing. Graf's is another. I know a few people that have more that one Coax Press. Where as others have a host of presses. Rock Chuckers, Ultra Mag's, T 7, and a smattering of others, too. The ability of the Coax to have the die self center is one potential benefit. The key thing is using the right Die Lock rings with the press. Some just are not compatible. You get what you pay for ...... When it comes to single stage presses pick your poison #1 Co-Ax or Rock Chucker Supreme For turret presses....there is only one choice.....Redding T-7! For heavy duty case forming...Ultra Mag Harrell's presses are nice but they are niche presses.... |

|

|

|

|

#16 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

I got an RCBS Rockchucker kit ~ 1998 and lived with that press until I ponied up and got a new co-ax in Jan 2007 for $214.

Within a couple months I was in love and making all kinds of parts for it. I felt like I had wasted 9 years of my life with a rock chucker. Then someone gave me a Dillon 550B set up for 9mm and 223. I never used it. I am sure there are lots of guys who love the rockchucker and love the 550B, but have no use for the co-ax. It depends on preferences and the kind of reloading you do. I reload ~ 65 different cartridges and fire ~ 200 rounds per year. The last round I fired killed a deer.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#17 |

|

Senior Member

Join Date: October 11, 2007

Location: Texas

Posts: 152

|

Used a Rock Chucker for two decades and now it belongs to my son. I now have a CoAx, Big Boss II, and a RL550B on my bench.

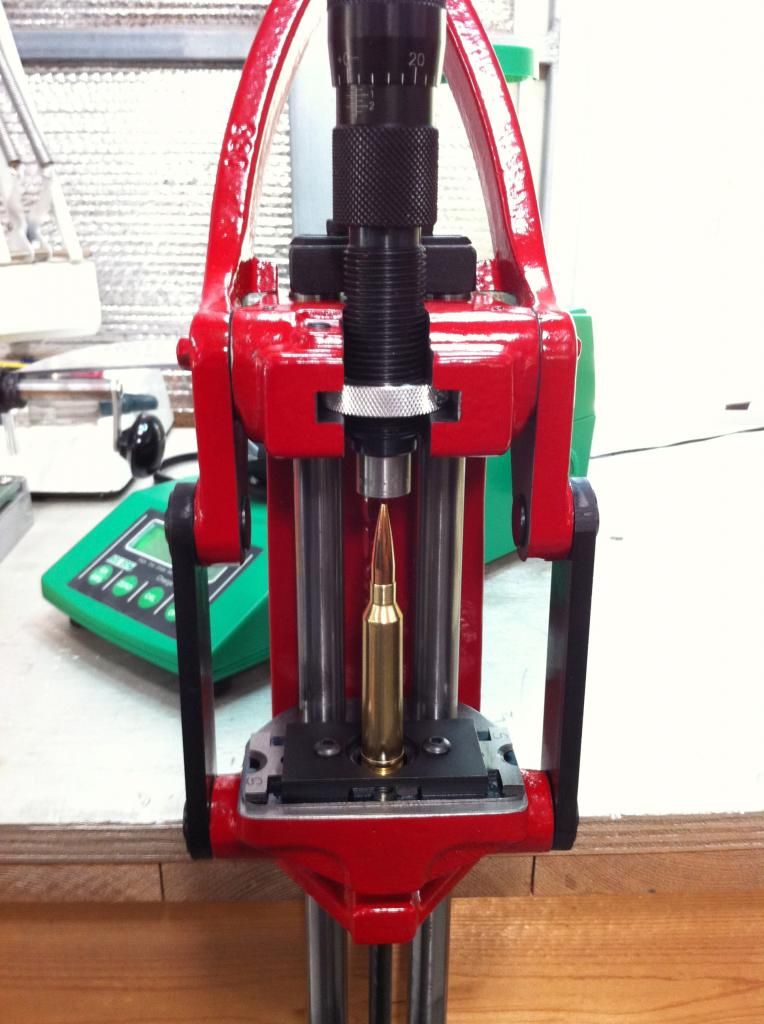

The CoAx makes the most concentric, accurate rifle ammo I have ever made except for custom made bench rest dies (same reamer as chamber) and arbor presses. I use it for at least 80% or my single stage loading chores. I also get slightly better results from Forster over Redding. The Forster is less fussy and finicky to use and they seem to have figured out how to make a seater plug that will accommodate VLD bullets as well as all others. The Rock Chucker and all of them are great but you won’t regret a CoAx and Forster’s precision dies for accurate rifle rounds. I use it for 7mm Rem Mag, 308 Win, 270 Win, 223 Rem, 300 BLK, and 5.56 for my SPR rifle. Get the three die set with FL, Neck sizer, and Precision Mic Seater. Good stuff. The neck die even comes with 3 bushings included. When I talk about “precision” reloading, to me it means: 1) Starting with high quality components. 2) Full length sizing. 3) Trim case, chamfer outside, bevel inside of mouth. 4) Turn necks to uniform thickness. 5) Uniform flash hole (except for Lapua brass). 6) Uniform primer pocket. 7) Hand prime with quality tool and match grade primers. 8) Experiment with seating depth and powder charge for best accuracy. From there after, the cases get cleaned and neck sized only. The 7mm Mag in the picture below shoots 5 shot sub 1/2 MOA groups with Fed Prem brass, Berger 168 VLDH bullets, Fed Match primers, and H1000. My Rem 700 has a Shilen match grade barrel that has the bolt face and lugs trued to the action. It’s a keeper.

Last edited by Woolecox; November 17, 2014 at 10:51 AM. |

|

|

|

|

#18 |

|

Senior Member

Join Date: November 6, 2010

Location: west central Illinois

Posts: 277

|

http://www.forsterproducts.com/catal...?prodid=700682

This thread is good reading for those of us that haven't experienced a high end single stage. Hobie |

|

|

|

|

#19 |

|

Member

Join Date: January 25, 2011

Location: Cleveland, TN

Posts: 74

|

I have been using this press for 40 years and it is still going strong. I have never had a problem with it. When I purchased it the manufacturer was Bonanza.

Bob |

|

|

|

|

#20 |

|

Member

Join Date: November 10, 2014

Location: The WV

Posts: 21

|

For what it's worth .....

I have a Co-Ax & Rock Chucker. I also have 2 small Lee presses that do specific tasks like depriming and bullet pulling. They stay setup up for such.... cause I am lazy about some things. I have found the Co-Ax makes "better" more consistent finished product that my Rock Chucker. Enough that I use it more often for certain things. I have also migrated to Forster Benchrest & Ultra Micro die sets over time. This may have more to do with the finished product that the presses themselves. I also happen to like the Hornady seaters. Wouldn't give up either press, but love the Co-Ax for many reasons. Just a hillbillies 2 cents ....

__________________

** hack spit ** |

|

|

|

|

#21 |

|

Senior Member

Join Date: February 1, 2009

Location: Iowa

Posts: 525

|

I've been using my brown Bonanza CoAx for around 45 years now. Used a blue 550B until it couldn't handle mass quantities of 25-20WCF. Got an LNL AP for that task. I did have to get a Lee Classic Cast and their dies for the big rifle, but I would be purely lusting over a CoAx big enough for the job (50BMG). I've been real happy with my CoAx otherwise.

__________________

"Of all the things I've lost, I miss my mind the most." A. Brilliant |

|

|

|

|

|