|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: September 27, 2010

Posts: 950

|

Faux Color Case Hardening refinish for vaquero

Got a Ruger Vaquero with the color case hardening. My understanding is it's cosmetic and not actual case hardening. Well evidently it's a weak finish or I was too aggressive scrubbing a spot of surface rust off and it's now missing on part of the frame.

Aside from sending it off to Turnbull for the real thing, are there other options for putting the finish back on? |

|

|

|

|

#2 |

|

Senior Member

Join Date: September 8, 2007

Location: Mississippi

Posts: 16,190

|

It's just an acid wash. I don't know of any way to replicate it but somebody might.

|

|

|

|

|

#3 |

|

Senior Member

Join Date: March 1, 2000

Location: Boise, ID

Posts: 8,518

|

You could try applying cold blue in a pattern matching the surrounding area.

__________________

Runs off at the mouth about anything 1911 related on this site and half the time is flat out wrong. |

|

|

|

|

#4 |

|

Staff

Join Date: September 25, 2008

Location: CONUS

Posts: 18,477

|

__________________

NRA Life Member / Certified Instructor NRA Chief RSO / CMP RSO 1911 Certified Armorer Jeepaholic |

|

|

|

|

#5 |

|

Senior Member

Join Date: September 27, 2010

Posts: 950

|

Perfect. Thanks!

|

|

|

|

|

#6 |

|

Senior Member

Join Date: January 14, 2018

Location: Colorado

Posts: 385

|

I’ve used the gels from SteelFX on a couple of projects with good results.

https://steelfxpatinas.com/product-c...ening-patinas/ Takes some experimenting with before trying a touch up job. |

|

|

|

|

#7 |

|

Staff

Join Date: November 2, 1998

Location: Colorado

Posts: 21,848

|

Finish is a hot acid bath

__________________

Vigilantibus et non dormientibus jura subveniunt. Molon Labe! |

|

|

|

|

#8 |

|

Senior Member

Join Date: July 10, 2012

Location: Memphis, Tennessee

Posts: 2,989

|

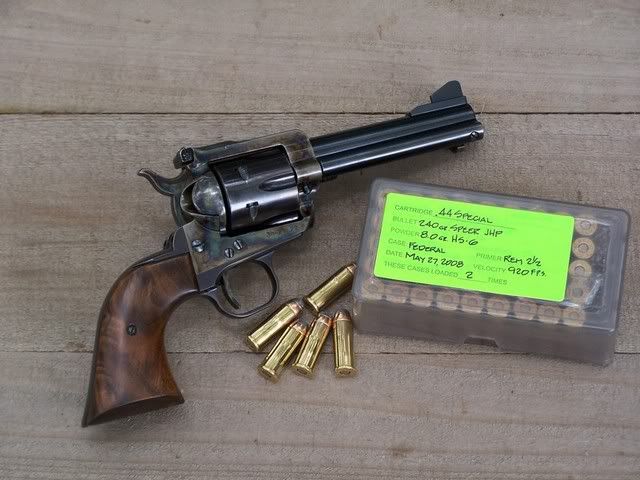

Color case finish....

__________________

Time spent at the reloading bench is an investment in contentment. |

|

|

|

|

#9 |

|

Senior Member

Join Date: April 13, 2013

Location: N. Georgia

Posts: 1,150

|

My understanding is that real color case hardening

tends to fade away depending on how much it is exposed to the weathering elements or sunshine. The looks have always been purely cosmetic although the increased durability of the steel remains. |

|

|

|

|

#10 |

|

Senior Member

Join Date: September 8, 2007

Location: Mississippi

Posts: 16,190

|

Acid wash fades too. The reason for case hardening is Colt frames were made from wrought iron up until 1900 or shortly before. They weren't warranted for smokeless until 1900. They case hardened them for added strength. The colors are a result of the process used. The hardening itself is only a few thousandths thick.

|

|

|

|

|

#11 | |

|

Staff

Join Date: September 25, 2008

Location: CONUS

Posts: 18,477

|

Quote:

The fake "case color" finishes used today are strictly done for the appearance. Since the metal is fully heat treated, there's no need or reason to case harden the surface.

__________________

NRA Life Member / Certified Instructor NRA Chief RSO / CMP RSO 1911 Certified Armorer Jeepaholic |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: November 13, 2006

Posts: 8,289

|

I'm not a metallurgist,but the rough idea is about higher levels of carbon in the iron/steel.

The low carbon parts were packed in leather chips and/or bone meal in an iron box..Various salts ,cyanide,etc might be part of a proprietary recipe. The loaded box would be baked at roughly red heat for a prescribed time,then quenched in agitated water. Its sort of like smoking the bark into a beef brisket. The carbon would cook into the surface of the workpiece,increasing the capacity to harden in quench. The colors were a by product and they gave a visual indicator of quality. |

|

|

|

|

#13 |

|

Senior Member

Join Date: July 14, 2008

Location: South Carolina

Posts: 2,918

|

Looks good Bob, I always did enjoy the looks of case color on a six-gun. Be sure to post some before and after pics if you decide to do any work. I would love to see how it turns out.

__________________

We know exactly where one cow with Mad-cow-disease is located, among the millions and millions of cows in America, but we haven't got a clue where thousands of illegal immigrants and terrorists are

|

|

|

|

|

#14 |

|

Senior Member

Join Date: July 10, 2012

Location: Memphis, Tennessee

Posts: 2,989

|

smee78,

Glad you asked! Before, as a .357 Magnum:  After, as a .44 Special:  Another before:  And after:  I'm pleased with the results. There are several more. Bob Wright

__________________

Time spent at the reloading bench is an investment in contentment. |

|

|

|

|

#15 |

|

Senior Member

Join Date: February 22, 2008

Location: SW Washington state

Posts: 2,018

|

A few Thou?

The depth that case hardening achieves is what is interesting to me. What testing may have been done to determine the depth of hardness?

It's my opinion that it's not a few thousandths. While I know the hardness goes past the colors we often see worn away, how deep does the case hardening go? I would think it's highly variable, thin parts like lock plates perhaps getting a better depth. Given the process, logic dictates depth would be highly limited.

__________________

ricklin Freedom is not free |

|

|

|

|

#16 |

|

Senior Member

Join Date: January 7, 2017

Location: Colorado

Posts: 272

|

There’s a lot of misinformation about color case hardening, it doesn’t fade in sunlight or require exotic materials to do. Bone and wood charcoal with water to quench in is the basic supply’s. Details in how you mix the charcoal, shielding, water temperature, furnace temperature and time has to be controlled for predictable results. I’ve done a fair number as part of my hobby with a lot of experiments in the process. Leather, peach pits, chemicals in the pack or quench water aren’t going to change the results.

Some examples all done with these basic materials,  2015-04-29 001 2015-04-29 001 by Oliver Sudden, on Flickr 2015-04-29 001 2015-04-29 001 by Oliver Sudden, on Flickr 2015-08-20 001 2015-08-20 001 by Oliver Sudden, on Flickr 2015-08-20 001 2015-08-20 001 by Oliver Sudden, on Flickr AA0149F3-4E50-45BB-8CAC-B4D4D9909E96 by Oliver Sudden, on Flickr AA0149F3-4E50-45BB-8CAC-B4D4D9909E96 by Oliver Sudden, on Flickr

|

|

|

|

|

#17 | |

|

Staff

Join Date: March 11, 2006

Location: Upper US

Posts: 28,864

|

Quote:

It was not, and never was the wrought iron we think of today, though the casual use of what today are thought of as precise terms back then can cause some confusion. Everything made by man was "wrought" and since it was made of iron, some folks would say it was wrought of iron, which of course gets shortened to wrought iron, but it was not the wrought iron of ornamental porch railings today. Not even close.

__________________

All else being equal (and it almost never is) bigger bullets tend to work better. |

|

|

|

|

|

#18 | |

|

Senior Member

Join Date: September 8, 2007

Location: Mississippi

Posts: 16,190

|

Quote:

|

|

|

|

|

|

#19 |

|

Senior Member

Join Date: January 7, 2008

Posts: 3,224

|

In resonse to the original post, "Aside from sending it off to Turnbull for the real thing, are there other options for putting the finish back on?", I will offer another, alternative suggestion: Run 10,000 rounds through it and forget about the original finish. By that point, it should begin to develop a nice, genuine, patina.

|

|

|

|

|

#20 |

|

Senior Member

Join Date: February 28, 2008

Location: Michigan

Posts: 2,620

|

Many of the gun makers that use a case harden finish will

give the steel parts a coat of varnish to protect the surface from wear and rust. |

|

|

|

|

#21 | |

|

Senior Member

Join Date: October 11, 2014

Posts: 754

|

Quote:

|

|

|

|

|

|

#22 |

|

Senior Member

Join Date: November 13, 2006

Posts: 8,289

|

I sometimes filled in as a warm body in the heat treat dept in a mfg co where I worked.

Not enough to say I know heat treating. One task I would do was a QC check on case hardening depth. It was not pack color case hardening. I don't recall the process. Gas,maybe, Anyway, we would slice the part with a chop saw then grind and polish the cut surface. The steel that was hard would polish up shiny while the softer core had a dull grey steel look. You could definitely see the boundary of hard case. I did this in the late 1990's. As I recall, the case depth was about .030 to .050 in depth. Roughly 1 mm. Processes and results vary. An automotive rocker arm might be case hardened.There is enough depth that the surface that contacts the valve stem tip can typically be reground to recondition the part. An old Remington Rolling block will case hardened to about 1 mm depth.(or so). Its not necessarily true case hardening is "only a few thousandths deep" Though some processes, such as a quick torch Kasenit job,may only be a few thousandths deep. Some color case jobs are mostly cosmetic but some are a legit deeper case. |

|

|

|

|

#23 |

|

Senior Member

Join Date: January 7, 2017

Location: Colorado

Posts: 272

|

|

|

|

|

|

#24 | |

|

Senior Member

Join Date: October 11, 2014

Posts: 754

|

Quote:

|

|

|

|

|

|

#25 | |

|

Senior Member

Join Date: October 11, 2014

Posts: 754

|

Quote:

|

|

|

|

|

|

|