|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Member

Join Date: November 16, 2014

Location: North Carolina

Posts: 25

|

Making guns in the garage

This is what I like to do in my spare time:

__________________

https://www.youtube.com/watch?v=0joaQpLzVjs |

|

|

|

|

#2 |

|

Member

Join Date: November 16, 2014

Location: North Carolina

Posts: 25

|

This one is in .40, I have used it in USPSA limited and IDPA ESP  USPSA open division gun in 9mm Major These are a few years old. They both run.

__________________

https://www.youtube.com/watch?v=0joaQpLzVjs |

|

|

|

|

#3 |

|

Senior Member

Join Date: January 24, 2011

Location: Monroe,NC

Posts: 669

|

I'm impressed, I assume your not self taught.

__________________

The man that die's with the most stuff win's! |

|

|

|

|

#4 |

|

Staff

Join Date: November 2, 1998

Location: Colorado

Posts: 21,855

|

I'm very impressed.

Why not back plate when your milling out the channel for the op-rod spring and its guide? I'd worry about the mill pushing it over.

__________________

Vigilantibus et non dormientibus jura subveniunt. Molon Labe! |

|

|

|

|

#5 |

|

Senior Member

Join Date: September 5, 2010

Location: McMurdo Sound Texas

Posts: 4,322

|

Very impressive. How long does it take you to make one?

__________________

Cave illos in guns et backhoes |

|

|

|

|

#6 | |||

|

Member

Join Date: November 16, 2014

Location: North Carolina

Posts: 25

|

Quote:

Quote:

Quote:

__________________

https://www.youtube.com/watch?v=0joaQpLzVjs |

|||

|

|

|

|

#7 |

|

Member

Join Date: November 16, 2014

Location: North Carolina

Posts: 25

|

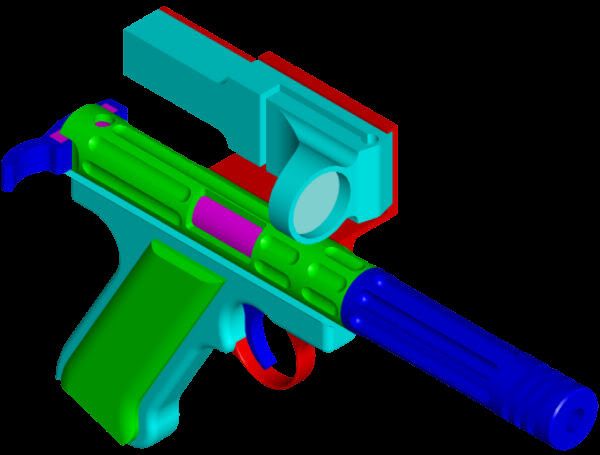

New top end for my old MKII I made almost two years ago

Stainless receiver, aluminum barrel (Steel liner) I built this for steel challenge and ruger rimfire matches

__________________

https://www.youtube.com/watch?v=0joaQpLzVjs |

|

|

|

|

#8 |

|

Senior Member

Join Date: April 3, 2011

Location: to close to other houses

Posts: 1,176

|

Wow. That ruger is impressive.

__________________

One day, Men in tall hats will thump their chests and proclaim..."oh, what a great sea of mud we lived in"--The unalterable fate of billy creek  .... .... "Smoke.....it's what's for dinner" |

|

|

|

|

#9 |

|

Senior Member

Join Date: January 18, 2013

Location: Virginia

Posts: 283

|

That's a great piece of craftsmanship there!

|

|

|

|

|

#10 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

When I was a little kid, we made firecracker guns with a hacksaw and a drill in the garage.

Now we are old retired men, we make gun parts on our mills and lathes in the garage.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#11 |

|

Member

Join Date: November 16, 2014

Location: North Carolina

Posts: 25

|

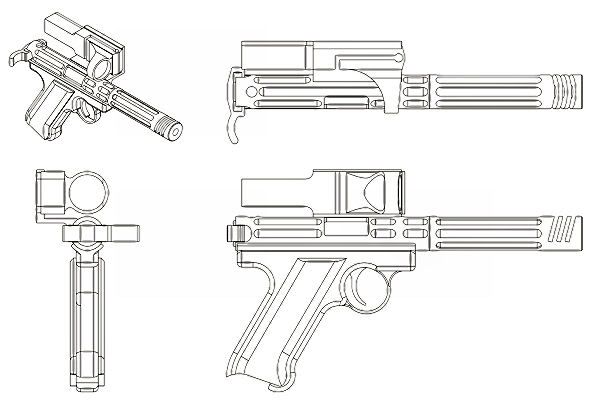

My youngest daughter is right handed, left eye dominant. The sideways C-More does not work for her at all. I made this for her.

__________________

https://www.youtube.com/watch?v=0joaQpLzVjs |

|

|

|

|

#12 |

|

Senior Member

Join Date: March 26, 2005

Location: Osborn, Missouri

Posts: 2,697

|

Very impressive work, I would say you learned your machining skills very well.

I always wanted to take some machining classes, never had the time, so all my machining is self taught. Best Regards Bob Hunter www.huntercustoms.com |

|

|

|

|

#13 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

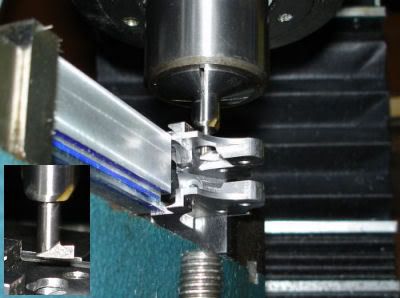

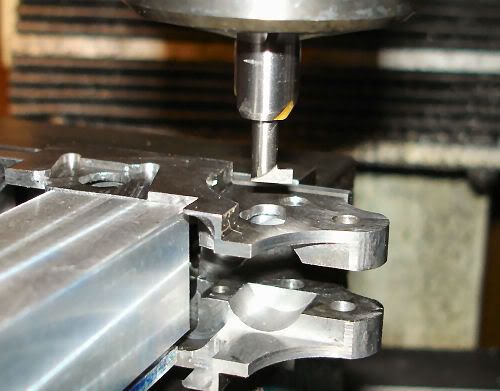

I noticed something in Clark's photo of the indexing head, that he did correctly, and should be pointed out. Always leave the quill or spindle up, and use the knee to raise the part when milling. I've seen many bring the quill down to meet the part, and an extended quill will cause chatter. Always, keep everything tight and drawn up as close as possible. Use the quill for drilling and tapping only, unless you have to reach inside a cavity, and if so, take lighter cuts. Always lock the quill when milling.

On lathes, you want to do the same thing, especially when parting. |

|

|

|

|

#14 |

|

Member

Join Date: November 16, 2014

Location: North Carolina

Posts: 25

|

This was for my oldest daughter:

The barrel looks like a bull, but it weighs next to nothing. All aluminum with a Redman liner

__________________

https://www.youtube.com/watch?v=0joaQpLzVjs |

|

|

|

|

#15 |

|

Senior Member

Join Date: October 24, 2008

Location: Naples, Fl

Posts: 5,440

|

OFS!

Which, of course, stands for...

Out Friggin Standing!

__________________

Seek truth. Relax. Take a breath. |

|

|

|

|

#16 |

|

Member

Join Date: March 23, 2010

Location: Central Idaho

Posts: 95

|

Very, very nice work!

|

|

|

|

|

#17 |

|

Member

Join Date: November 16, 2014

Location: North Carolina

Posts: 25

|

AKs, cuz they are easy

Bending an AMD65 receiver flat on a homemade jig    This is what it looked like when I first built it.  I was never quite happy with it so I made a new brake (Pined & welded), fabricated a new stock and added the magpul grip and AFG. This thing blows a giant fireball. I still have not duracoated the new bits  A Romy G built on a pre-bent blank. I parkerized the receiver, not too dark but it came out even.

__________________

https://www.youtube.com/watch?v=0joaQpLzVjs |

|

|

|

|

#18 |

|

Staff

Join Date: November 2, 1998

Location: Colorado

Posts: 21,855

|

Can you share the

Homemade metal bending jig plans please?

__________________

Vigilantibus et non dormientibus jura subveniunt. Molon Labe! |

|

|

|

|

#19 |

|

Senior Member

Join Date: August 1, 2010

Location: Tampa Bay

Posts: 4,556

|

Thanks for sharing!

I'm self-teaching machining...just added a LMS Hi-Torque Mini-Mill and a lathe to start learning the basics. Rigged on an inexpensive DRO to start playing around, thinking about milling me and the boys some lowers from 80%'ers to get started. Then, Mach 3 and CNC conversion...so much to learn in "spare time"of which I have zero... Now, that's some motivation, with those pics.

__________________

Remington 700/Savage Rebarreling /Action Blueprinting 07 FFL /Mosin-Nagant Custom Shop/Bent Bolts Genuine Cerakote Applicator www.biggorillagunworks.com |

|

|

|

|

#20 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

tobnpr,

DRO's are nice, but I still use a dial indicator and a magnet base for most everything. (I have 1/2" to 3" indicators here). One day, if they'll get the price down for a two or three axis set, then I'll jump on the bandwagon. They're making those new linear readouts, at a good price, but I'm not sure how accurate they are. Has anyone on here tried them? I thought about buying one for depth measurement on the spindle. |

|

|

|

|

#21 |

|

Senior Member

Join Date: August 1, 2010

Location: Tampa Bay

Posts: 4,556

|

I just put two (x,y) of the Igaging DRO's on my LMS mill.

Yeah, ridiculously inexpensive. Accuracy? Well, I'm a total noob to this as I said. But, ten full turns of the leadscrew each axis (@.0625) read exactly .625 on the LCD. They advertise .002, per six inches of travel for this model: http://www.igaging.com/page18.html They have a new line, the Absolute DRO, with an absolute function, better display, and .0015 accuracy per foot. Still, under $100 per axis depending on length. 6" is about $60 on Ebay. The mill had a torsion spring to support the head, I've just replaced it with an air spring so I now have space to add the z axis. I suppose, it depends on the level of precision of the part(s) being machined. Basically, these are the same technology used in calipers, adapted onto longer slides with remote readouts. But, accurate "enough", for me for the time being, at least- and NO MORE backlash compensation! That alone makes it a dream to learn with. Seems to me that even minor errors are bound to occur due to backlash that would end up being no more accurate in the end than using the DRO's. I hesitate to offer an opinion though because I'm so new at this. Hesitating to put a lot of dough into the manual aspects (including a power feed) because I'm giving it some time to figure out whether I'm going to do the CNC conversion which would make these "improvements" moot. There are comprehensive kits designed specifically around these X2 mills that make a turnkey conversion for little more than a grand. I haven't put any DRO's on the lathe yet because it's a bit more challenging to figure out a way to mount them on the cross-slide, and since all cuts are in the same direction I don't see it as a "must-have" just yet. A lot to learn...

__________________

Remington 700/Savage Rebarreling /Action Blueprinting 07 FFL /Mosin-Nagant Custom Shop/Bent Bolts Genuine Cerakote Applicator www.biggorillagunworks.com |

|

|

|

|

#22 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

tobnpr,

You don't really need any on the longitudinal axis of a lathe. When I worked at a machine shop, turning large pump and propeller shafts, most with multiple stepped diameters and 10+ feet long, they only used a tape measure for the lengths layout, since bearing fits are drawn or shimmed up, and nothing was that accurate over the length. The diameters and finish, though, had to be held, along with any threads. So, anything you'll do on a gun, a dial indicator will work. Before several of us were lain off, they had bought a new 10 foot lathe with a two axis DRO, and it was nice. Mills are different, though, and you have to have accuracy in all three axis, so I always just use a mighty-mag with a dial indicator, and if I am running several of the same piece, I set up stops. Long ago, they had some mills with a dial indicator built in, set up like a long dial caliper on the x and y axis, similar to the digital ones you mention, but they were mechanical. Repeatability is the main thing, and the overall accuracy on the full travel. Of course, you should measure the piece after each cut, when getting close to finish size, or I do, as I never really trust indicators nor readouts. |

|

|

|

|

#23 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

This week I did some mill work for the Dumoulin Mauser scope base with a 2" dial indicator and mag base. I also was using the dials on my 1963 Rockwell 21-100 mill. I had a 0.504" on centers hole turn into a 0.521" distance.

When they agree, I am usually within 0.001". So I screwed up. My fault, not the two machines. But my lathe has DRO [the cheapest installed by Machine tools on line before they shipped the lathe.] That has been so convenient... As soon as I finish this carpentry work on the shop, I will buy a new mill with DRO and give a hunting buddy my old mill.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#24 |

|

Member

Join Date: November 16, 2014

Location: North Carolina

Posts: 25

|

When I started out I put one of the cheap "caliper scale" readouts on my mill. It worked but no matter how rigid the scales were mounted there was .002-.003" of backlash in them. When the x axis went toes up I bought a cheap chinese setup with glass scales (X & Y, the Z is magnetic). It is right on time and only cost about $500.

I find them less useful on a lathe. All I have on my lathe is a Trav-a-dial

__________________

https://www.youtube.com/watch?v=0joaQpLzVjs |

|

|

|

|

|