|

|

|

#26 |

|

Junior Member

Join Date: January 11, 2014

Location: Helena, MT and La Pine, OR

Posts: 6

|

It kinda looks like this turned into a bit of a pissing match

~ I had started shooting the 8x57 in the mid 60's after my dad bought a old FN intermediate length sniper rifle for about 8 bucks thru the mail. Sure miss those days. We turned the steps out of the barrel, reworked the bolt, d/t the receiver and I built a stock for it. It is one of the most accurate rifles I've ever shot. About that time I met Parker Ackley through my dad's Stockmaking shop. As I got to know him I asked why he never did anything with the 8x57 case and he said "I never thought much about it. Most people wanted to make the 8mm-06 so I just improved that case instead." He did encourage me to experiment with it and it 1972 I rechambered mine to the AI version. Since then I have taken it from 6mm up through .375 and they do outperform those made on the 7x57 case. As I stated earlier in the posts I called this family the "Ackley Super Improved" series. ~ I had started shooting the 8x57 in the mid 60's after my dad bought a old FN intermediate length sniper rifle for about 8 bucks thru the mail. Sure miss those days. We turned the steps out of the barrel, reworked the bolt, d/t the receiver and I built a stock for it. It is one of the most accurate rifles I've ever shot. About that time I met Parker Ackley through my dad's Stockmaking shop. As I got to know him I asked why he never did anything with the 8x57 case and he said "I never thought much about it. Most people wanted to make the 8mm-06 so I just improved that case instead." He did encourage me to experiment with it and it 1972 I rechambered mine to the AI version. Since then I have taken it from 6mm up through .375 and they do outperform those made on the 7x57 case. As I stated earlier in the posts I called this family the "Ackley Super Improved" series.There are so many versions of the 98 Mausers and not all the magazine lengths are the same, most of my full length 98 Mausers have a magazine length that is long enough to seat 06 length rounds without having to seat bullets to deeply so I use the full length 06 cases for them when wildcatting but the intermediate length Mausers are fun to work with and the 8x57 case is a great to work with. My 338x57 ASI is spitting out the 210 gr Noslers at 2790-2850 with H-4895, Alliant Re 16 and 17 as well as IMR LVR and Alliant Pro 2000. The 35x57 ASI will out do my 35 Whelen hands down with 225 gr bullets. I've never shot any heavier weight bullets in the 35 as I don't think there is enough case capacity to really warrant using them but I'm planning on taking both the 8mm ASI and the 35 ASI to Alaska the fall on a moose and black bear hunt...hope to find a bou with a death wish as well. Anyway, you can't go wrong with the 8x 57 case! I hope you don't mind the ramblings of an old gun nut! Last edited by archeratlrg; February 3, 2017 at 01:18 AM. |

|

|

|

|

#27 |

|

Junior Member

Join Date: February 1, 2017

Posts: 4

|

I thought of this years ago when I read Ackley's books. When the time came I had the time and money to do so, I want to pursue all manner of 8mm endeavors since infind the bore expansion ratio to be more favorable than 30 cal. I dod know an elderly club member who had an 8mm improved, but it was not as aggressive as Ackley, if memory serves it was based on the RCBS method.

Sent from my SM-G920V using Tapatalk |

|

|

|

|

#28 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

With and or without the books there was a lot going on; Norma was giving chamber reamers to gunsmiths for consideration? Norma developed the 308 Norma Mag to boost case sales. Rifles chambered for the 30/06 Springfield were candidates. I have an A4 barrel that was removed from an A4 rifle after the scope mounts were removed, the rifle SR# indicated it was an A4. I am surrounded on two sides by those that put them back together.

I am not willing to give up one of my 03s or 03A3 receivers, I have a Remington rifle/receiver that was before the A3 that is one of the most accurate rifles I own. It went to Golden State and then to Sears. I purchased it from the man that purchased it from Sears with two boxed of R-P ammo. He shot the rifle 3 times. And I have one of the old reamers and a M1917 with the 308 Norma Mag chambers. Picture this; a M1917 barrel with a P14 bolt and receiver and a modified/opened up box. And I have a M1917 barrel with a M1917 bolt and a P14 receiver, stock with a M1917 box. F. Guffey |

|

|

|

|

#29 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I ACTUALLY do know about the "Firing pin pushing it forward" THEORY. It does not happen in a Mauser, Arisaka, or any gun with a good claw extractor. Period. You would have to take the extractor off. I had an empty 6.5x50 case that was fired in a 6.5x55 (That ain't .015) and it stretched about .200 with a new shoulder and almost no neck. That was not the first, and probaly not the last one I will see. The firing pin knocking the cartridge forward goes back to the early days of rimmed cases mostly. Not all, but most have an area milled out at the edge of the chamber to push the extractor out of the way when the cartridge is in the barrel. We are not talking about rimmed cases here.

Last edited by Gunplummer; February 4, 2017 at 01:28 PM. |

|

|

|

|

#30 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

I've always wondered about how push round feed actions like the Rem700 and Savage 10/110 manage snap that extractor over the rim of the case. Clearly SOMETHING stopped the case from going forward, so it makes me wonder how much further the firing pin could make the case go forward if the extractor couldn't push it any further forward and had to snap over the rim.

Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#31 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

F. Guffey |

|

|

|

|

|

#32 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

F. Guffey,

My response there was a little "tongue in cheek" as the ejector button and extractor can put the cartridge hard into the chamber so shoulder touches shoulder, but still leave a small gap between the case head and the bolt face because tolerance stack or a deliberate "bump size" that pushed the shoulder a thousandths or two back. My point was really to say that the firing pin can't push the brass any further forward with some action designs, because the brass is already as far forward as it is going to get. The brass can and does stretch backwards of course. Whether a controlled round feed or push round feed action is "more accurate" because of this is probably something I'd like to avoid, suffice to say that either is accurate enough for my purposes. Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#33 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

A man build 4 magnificent rifles, he made the reamer etc. He called and said he had 5 case head separations out of the first 10 rounds fired. I told him I could have told him that would happen before he left the shop, I told him I could have fixed the problem before he left the shop and I told him I could have met him at the range and fixed the problem long enough for him to fire forms his cases. I also told him I could have formed his cases to fit before he fired them. Back when reloaders were claiming you will blow up your gun if your fire it with too much head space, I chambered a round with .127" clearance between the shoulder of the chamber and shoulder of the case. Again, the shoulder of the case did not move. F. Guffey |

|

|

|

|

|

#34 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

My experience with excess headspace is pretty similar to the gentleman you mention.

I made a measuring error on a 30-06 chamber once, left 0.1" of excess clearance on a long chambered barrel. The rounds stretched and cracked, as it was a Mauser action I was building on. The extractor held the brass firm enough that the firing pin did a fine job igniting the primer every time. Odds are if I'd been using a Rem700 action the rounds wouldn't have gone off as the ejector and extractor would have pushed the cartridge too far into the chamber for the extractor to snap over the rim. But, I pulled the barrel, cut back the shoulder and face, then torqued it back on. All was well after that. Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#35 |

|

Junior member

Join Date: December 23, 2016

Posts: 30

|

Guffey

Of course the shoulder moves. Measure it according to SAAMI and you will find the location is different.... Why do you keep playing word games? |

|

|

|

|

#36 |

|

Senior Member

Join Date: November 13, 2006

Posts: 8,289

|

ireload, while I understand your point,actually,usually it is not the shoulder that moves.

First,the brass is thinner at the neck,shoulder,and forward part of the case. Thinner,it expands before the thicker part of the case does The firing pin strike does drive the case forward during ignition,as far as it mechanically can go. Yes,an extractor CAN limit the travel...but,IMO,I would like tighter control over head clearance than the extractor provides. As designed,the shoulder of a rimless bottleneck cartridge is the "anvil"that limits forward motion of the case against the shoulder area of the chamber. So,lets look at this picture: The shoulder is against chamber steel.Its not moving. The case head is forward,clear of the bolt face by whatever the head clearance is. As pressure rises,the thin,forward part of the case expands(obturates) ,tight to the chamber. So,really what happens is the shoulder stays still,the CASE HEAD moves,stretching back to the bolt face. There are ways,as simple as using a rim or belt ,to limit the forward travel of the cartridge,and in those instances,yes,shoulders may be blown forward. A long seated bullet,jammed into the rifling can serve to keep the case head on the bolt face.Then you can blow a shoulder forward.Necking up,over bore dia,then backdown can create a small step,a shoulder of sorts,as a headspace feature,and then,yes,you can blow a shoulder forward. Last edited by HiBC; February 10, 2017 at 06:03 AM. |

|

|

|

|

#37 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Reminds me of Coach Vince Lombardi when he took over the Green Bay Packers. He made it clear they were going to start over with basic fundamentals; he started with Gentlemen, this is a boot ball and before he could move on Paul Horning raised his hand and said; "slower coach"

F. Guffey And I am thinking two of the players in the room included Captain Who and Joe Don. F. Guffey |

|

|

|

|

#38 | ||

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

I agree with everything you have said down to :

Quote:

Quote:

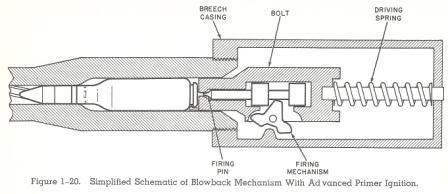

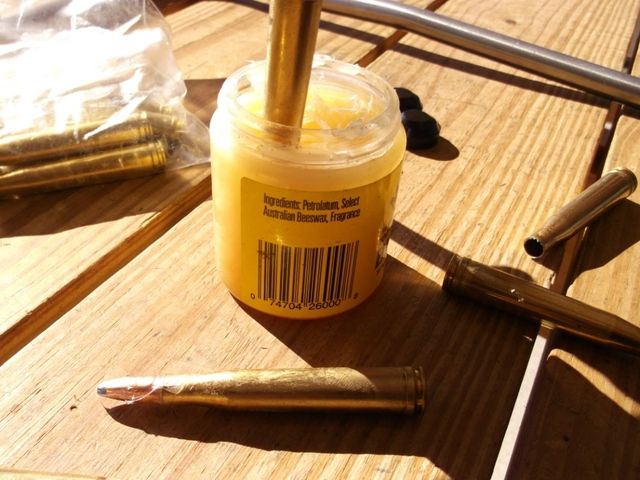

Now what if the case was lubricated? Army Ordnance Magazine, March-April 1933 Automatic Firearms, Mechanical Principles used in the various types, by J. S. Hatcher. Chief Smalls Arms Division Washington DC. Retarded Blow-back Mechanism There is one queer thing, however, that is common to almost all blow-back and retarded blow-back guns, and that is that there is a tendency to rupture the cartridges unless they are lubricated. This is because the moment the explosion occurs the thin front end of the cartridge case swells up from the internal pressure and tightly grips the walls of the chamber. Cartridge cases are made with a strong solid brass head a thick wall near the rear end, but the wall tapers in thickness until the front end is quiet thin so that it will expand under pressure of the explosion and seal the chamber against the escape of gas to the rear. When the gun is fired the thin front section expands as intended and tightly grips the walls of the chamber, while the thick rear portion does not expand enough to produce serious friction. The same pressure that operates to expand the walls of the case laterally, also pushes back with the force of fifty thousand pounds to the square inch on the head of the cartridge, and the whole cartridge being made of elastic brass stretches to the rear and , in effect, give the breech block a sharp blow with starts it backward. The front end of the cartridge being tightly held by the friction against the walls of the chamber, and the rear end being free to move back in this manner under the internal pressure, either one of two things will happen. In the first case, the breech block and the head of the cartridge may continue to move back, tearing the cartridge in two and leaving the front end tightly stuck in the chamber; or, if the breech block is sufficiently retarded so that it does not allow a very violent backward motion, the result may simply be that the breech block moves back a short distance and the jerk of the extractor on the cartridge case stops it, and the gun will not operate. However this difficultly can be overcome entirely by lubricating the cartridges in some way. In the Schwarzlose machine gun there is a little pump installed in the mechanism which squirts a single drop of oil into the chamber each time the breech block goes back. In the Thompson Auto-rifle there are oil-soaked pads in the magazine which contains the cartridges. In the Pedersen semiautomatic rifle the lubrication is taken care of by coating the cartridges with a light film of wax. Blish Principle….There is no doubt that this mechanism can be made to operate as described, provided the cartridge are lubricated, …. That this type of mechanism actually opens while there is still considerable pressure in the cartridge case is evident from the fact that the gun does not operate satisfactorily unless the cartridges are lubricated. Mechanisms that used greased cartridges and oilers were extensively used through WW2, but, not in the civilian world. These mechanisms have been out of service for so long, and they were never common in the hands of civilians, that they have been basically forgotten by the shooting community. Only those with an esoteric interest in antique mechanisms and the principles of operation even know about them. The very stupid and ignorant are clueless about them, and the operation of guns in general, and make up stories why they could not work. If the case is lubricated, breaking the friction between case and chamber, than instead of the case mouth fixing the cartridge case in place and causing case stretch, the case slides to the bolt face. The shoulder however, is blown out without stressing the case. This is something World Champion Benchrest shooters do when fireforming to achieve perfect, stress free cases. This mechanism, the cartridge was greased or oiled. This is the Oerlikon mechanism, used by the American’s, British, Germans, and Japanese during WW2. Cases were pregreased in WW2, though after WW2, the US continued to use the gun with oilers. I have a Bullseye bud who stole an Oerlikon from the USAF, in Vietnam, and used it on his river barge. His Oerlikon used an oiler.  I have been greasing my rounds so that when I fired the cases, I don’t have sidewall stretch leading to case head separations. I also have been greasing my bullets, just as our fore fathers did during the days of cupronickel bullet jackets. I am convinced that my barrel cleanup is quicker and I have no detectable fouling.  This is a 300 H&H Magnum, which has a very shallow shoulder. Also, the base to shoulder distance is not controlled as the round headspaces on the rim. The end result of firing these things dry, in a dry chamber, is to stretch the heck out of the cases, leading to case head separations in a short number of firings. I lubricate the heck out of my new cases, fireform to fit the chamber, and then, I only bump the shoulder back a bit. Even greased, they shoot well.

__________________

If I'm not shooting, I'm reloading. |

||

|

|

|

|

#39 |

|

Senior Member

Join Date: November 13, 2006

Posts: 8,289

|

Slamfire,you can do all that.Whatever makes you happy.

I don't,very few people do.(Work with greased rounds in my gun) A guy had a question.I tried to explain it to him. Somebody can always come up with something to argue about. I gave him good information,I really do not care who agrees or not. And,actually.if you read and comprehend what I actually said: [QUOTE/] ireload, while I understand your point,actually,usually it is not the shoulder that moves. [/QUOTE] You will note I said "usually" .I did not say "Always". I would suggest your practice is "unusual" If you wish to read a tech article about it,here you go. http://varmintal.net/a243z.htm Al does address highly polished chambers and greased ammo.He did not seem to embrace the idea. You do,I understand.Whatever makes you happy. Last edited by HiBC; February 10, 2017 at 06:16 AM. |

|

|

|

|

#40 | ||||

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Quote:

Quote:

Al's buddy, James Boatwright says here: Steel Support for the Brass Cartridge Case James A. Boatright http://www.thewellguidedbullet.com/p...tridgeCase.pdf Quote:

__________________

If I'm not shooting, I'm reloading. |

||||

|

|

|

|

#41 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

And then there is the air, I want clean air, I do not want dirt, grit or grime. And then there is the surface of the chamber, I want my chamber to have a mirror finish, logic says 100% is better than 90%, that also goes for my dies. When I clean my dies with a towel on a dowel I do not want to change to a white towel when determining when my dies are clean. 100% contact between my disc rotor and pads does not benefit from cross hatching, same goes for drums; drums do not benefit from course spiral cuts, spiral cuts will cause a strange sound and cut the life expectance to a few days in heavy traffic. I know, slide and glide shooting is cute. I do not find it necessary because I am a case former, I form first then fire. And then there are those that want to reinvent/rediscover, that is good; that brings up the shoulder of the case. I am not going to jump out in the fast lane and reinvent the events that take place between pulling the trigger and the bullet leaving the barrel. I say the shoulder of the case does not move; reloaders have spent their entire life saying the shoulder moves. I could say something like; "think about it", but that does not work, before thinking about it reloaders are already pounding away at the keys on the key board. Rediscover? Has anyone ever marked, painted or scribed the shoulder on a case before starting. I have; I did not have to but when forming cases I was getting artifacts on the formed cases that I did not believe should be there. I have never assumed the shoulder moved, I assumed the shoulder of the case was erased and become something else and the shoulder on the case after forming was a new shoulder. I always make the distinction when sizing and forming I am increasing and or decreasing the length of the case from the shoulder to the case head, I never say "I am moving the shoulder back", and then there is 'bump', bump is a function of the press; it was a function of the press before social media. Back then when a press bumped it bumped twice because bump presses were cam over presses. For years reloaders have claimed the case has head space and they purchased tools that were comparators thinking they were purchasing head space gages. Again, the case does not have head space and every tool is not a head space gage. And then there was Hatcher. When someone builds a rifle and then has problems the first piece of information they omit is the make of the receiver. F. Guffey |

|

|

|

|

|

#42 | |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Guffey has been building old military Mauser actions using belted magnum cartridge cases and he still does not understand why two of his converted actions cracked their bolt lugs. I believe a combination of incompetence and narcissism prevents Guffey from accepting the fact he is at fault, we can tell that he does not understand the problem, and instead, creates a fantasy absolving himself from his failures. Rightfully he is afraid of bolt thrust for the rifles he builds, but since Guffey is so incompetent that he does not know he is incompetent, he does not realize that the problem is the combinations he creates by combining inappropriate actions, cartridges, and pressures. In short, Guffey is a quack gunsmith.

Reloading 303 british for no4 enfield https://thefiringline.com/forums/sho...ghlight=mauser Quote:

In Europe, at least, all firearms have to go through a proof house before sale. Proof Houses do more than simply fire 30% over cartridges, they gage the weapon, check the function of its features, and if it fails in any regard, it cannot be sold. Here in the US, all buyer can do is go by reputation and ask questions before using a Gunsmith. If the gunsmith cannot do even a first order analysis of why certain actions are inappropriate for belted magnum conversions, walk away.  Doctors were unregulated in this country for a very long time, till the general public got tired of medical quackery and instituted educational and licensing requirements to limit the damage caused by medical quacks. However, in this country, there are no educational, training requirements for an individual to call himself/herself a "gunsmith". Any fool can call himself a gunsmith . The only way to regulate quack gunsmiths is after the fact, after the Kaboom . Gunsmiths, incompetent or not are considered manufacturers, they are expected to have more than just a working knowledge of materials, structures, and product liability applies to them, just as in any other manufacturing profession. With every rifle Guffey builds, Guffey should provide the buyer a printed card. One side should have the phone number of the nearest emergency room and the other side a good liability attorney. Guffey is responsible for building safe products, and every customer of his should know that if the belted magnum Mauser conversion they buy from him kabooms in front of their face, that they have the option to sue Guffey for everything he has, and everything he will every have. This will have the positive effect of getting Guffey out of the business, and with his computer gone, the web will be improved for the better.

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

|

#43 |

|

Senior Member

Join Date: December 10, 2014

Posts: 1,965

|

I believe that you just broke rule #3.

|

|

|

|

|

#44 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

F. Guffey |

|

|

|

|

|

#45 | |

|

Senior Member

Join Date: November 13, 2006

Posts: 8,289

|

This would be the rule #3 dufus referred to:

Quote:

But I'm not a Moderator. I have had my moments with Mr Guffey! For myself,I prefer to chamber with a good,sharp reamer.I use good practice cutting the chamber with that reamer.Anything less than excellent tool finish is failure. I typically do not polish chambers.Very few people understand how to approach polishing a chamber. If you approach polishing a chamber where the first step is spinning the barrel in the lathe at high rpm and putting something abrasive in the chamber that is cutting lines in the same direction as the tool marks,you may be doing it the way you were taught,but I was trained by a Master mold and die finisher. You cross the marks you re trying to remove. In the simplest form,its called "draw stoning" and the strokes would be in line with the length of the chamber. With all due respect to the 300 H+H,a great venerable cartridge,the case design is based in large part on loading with stick cordite as a propellant. A count of sticks were loaded into basic brass,then the shallow shoulder was formed.Because the shallow shoulder was not a reliable headspace feature,the magnum belt we know and love was added. For reliable cycling in death defying circumstances,generous head clearance was provided from belt to chamber.(In the neighborhood of .006) And so,YES! Stretch rings occur. Reloading case life was hardly the point. If greasing anachronistic case designs is a workaround for a problematic cartridge,well,to each his own. P.O.Ackley took a different approach.The modern reloader has tools and methods to minimize case stretch . As are methods to minimize fouling from cupro-nickel bullets. In the same respect,a number of techniques,lubes,and tricks are used to make Black Powder Cartridge Rifles to perform..very well! But we don't use much deer tallow and bear fat to make a 6.5 Creedmoor shoot these days. I'm not sure how much 1930's Ordnance Dept knowledge regarding blowback and semi-blowback technology applies to locked breech guns. And I really do not understand what any of this has to do with my original answer to Ireaload2's question. Its an irrelevant soap box presentation of a very seldom used pet technique. Slamfire,use it! Enjoy! If it works for you,great! You won't find it in any loading manual,lubed ammo is not recommended,and it just has nothing to do with the mainstream conversation about what happens to a cartridge case when the trigger is pulled. And while I do not deny,a lot of milsurps have been "sporterized" to all manner of rifles,if you will review the custom rifle photos in the vintage "Gun Digests" many very fine gunsmiths made very fine rifles on milsurp actions. Slamfire,your wholesale condemnation of a great period of Firearms Amercana is just insulting to a lot of very fine craftsmen. And on the notion of "regulating " gunsmiths..... Are you suggesting we need more of unelected agency bureaucrats writing regulations with force of law to limit what professional and hobby gunsmiths can do??? What level of firearms ,gunsmithing,engineering,and metallurgical expertise may we DEMAND of these bureaucrats before the may be hired to fill a position? Or would you prefer the ones who ,as we see as "talking heads" on television make cringe worthy ridiculous statements about firearms...as if they were proud of their politically correct ignorance? You,of course,are entitled to your desire for more restrictive firearms regulation...But I am opposed. I favor being able to create a receiver from raw steel as my own needs and creativity see fit. Slamfire,as you have expressed,you ARE aware of a consensus that greasing/lubricating ammo and chambers is ill advised.I understand,you vehemently disagree.Thats OK. I support your FREEDOM. Based on the published advise in loading manuals,magazine articles,etc...What might these "regulators" you suggest write regarding controlling the "potentially dangerous practice of greasing ammunition". Do you think your same regulatory standards should be applied to what YOU do? Last edited by HiBC; February 12, 2017 at 07:12 PM. |

|

|

|

|

|

#46 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

Slamfire,

It's important to talk about sheering lugs off a Mauser bolt. That is a failure of a bolt, which in itself is not a failure of the receiver. In fact, the two front failing is the reason for the third "safety lug" in the first place. As the Mauser action and bolts in the military surplus realm come from a very wide variety of manufacturing sources, with even more manufacturing practices, it is very true that you can get some pretty obvious failures. The other point, is that those failures aren't a design flaw, they are a manufacturing flaw. There is nothing unsafe about a properly manufactured Mauser 98 action and bolt. But if the receiver is soft, even with milspec 8x57 you'll see lug setback and headspace growth as a result. So your warning to get to know your receiver (and bolt) before sporterizing is sound advice. But it shouldn't stop anyone from building on a good quality M98/K98 action. Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

|