|

|

|

#1 |

|

Senior Member

Join Date: January 3, 2012

Location: Justin Texas

Posts: 313

|

Lake City Brass

I just called Hodgdon to get load data for CFE 223 using 65 grain bullets in .223, there was no data for that size bullet on their website. I was told to use their data for 63 grain bullets which is on their website.

The guy asked me what brass I was using and I told him Lake City. He then told me to reduce the starting and max loads by 10%. I asked him if that were true also if I were to use 63 grain bullets. He said yes. I have heard before that Lake City brass has less capacity because the walls are thicker. I have also heard that the powder capacity of Lake City brass is pretty much the same as other brands so you do not have to reduce your loads.does anyone have the real skinny?

__________________

Assistant Secretary - U.S. Dry Bean Council |

|

|

|

|

#2 |

|

Senior Member

Join Date: February 13, 2002

Location: Canada

Posts: 12,453

|

It's one of those things that causes regular arguements on the assorted forums. I don't think it matters considering the number of places selling the stuff with no hazard warning.

Telling you to reduce by 10% is the standard for any milsurp brass. Lake City .223/5.56 supposedly isn't thicker if the head stamp isn't NATO. Personally, I'd just reduce and forget about it. |

|

|

|

|

#3 |

|

Senior Member

Join Date: January 3, 2012

Location: Justin Texas

Posts: 313

|

I feel the same as you about spelling and grammar. It is a pain to read a post when there is no capitalization and punctuation. I understand a few misspelled words now and then because sometimes people just fat finger and some people just can't spell.

__________________

Assistant Secretary - U.S. Dry Bean Council |

|

|

|

|

#4 |

|

Senior Member

Join Date: January 3, 2012

Location: Justin Texas

Posts: 313

|

It does have the NATO headstamp.

__________________

Assistant Secretary - U.S. Dry Bean Council |

|

|

|

|

#5 |

|

Senior Member

Join Date: April 4, 2011

Location: LA (Greater Los Angeles Area)

Posts: 2,722

|

5.56 / 223 all brands including LC are about the same.

7.62 / 308 DO vary and require attention.

__________________

............ |

|

|

|

|

#6 |

|

Senior Member

Join Date: January 3, 2012

Location: Justin Texas

Posts: 313

|

That's what I've been reading. I've been loading with Lake City for a little over a year using other powder, haven't reduced the load and haven't noticed any pressure signs. I always stay at least a grain under the stated max for all of my loads.

__________________

Assistant Secretary - U.S. Dry Bean Council |

|

|

|

|

#7 |

|

Senior Member

Join Date: December 23, 2005

Location: Minnesota

Posts: 2,968

|

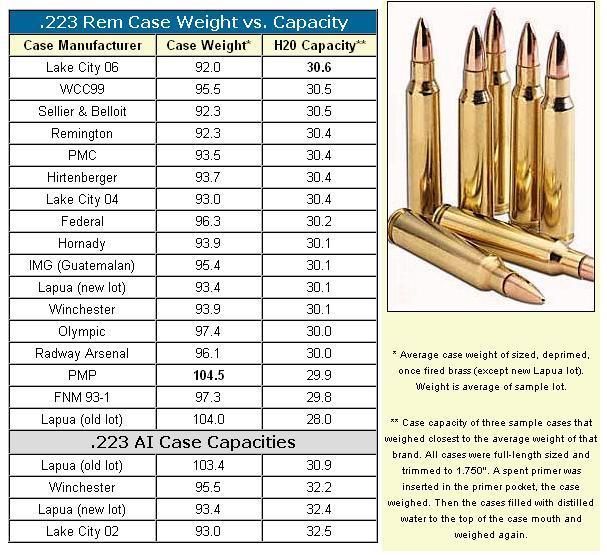

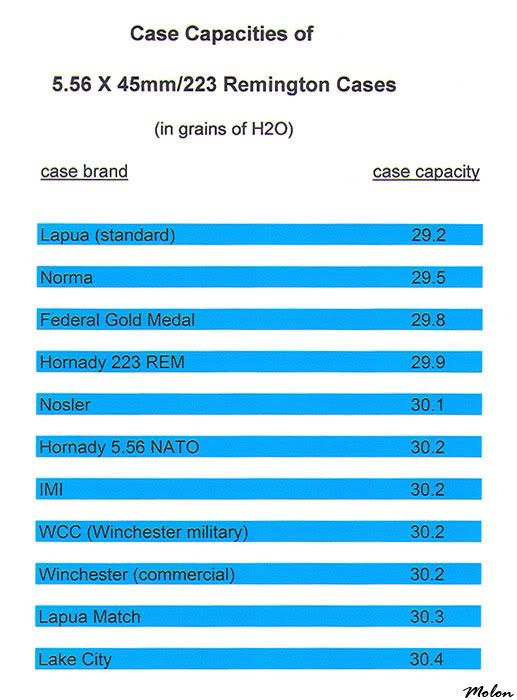

LC brass has one of the highest case capacities available.

From Sierra. The conventional wisdom to reduce loads with military brass is familiar to most reloaders and is generally good advice. The rationale here is that the military cases tend to be somewhat thicker and heavier than their civilian counterparts, which in turn reduces capacity and raises pressures. This additional pressure normally requires a one or two grain reduction from the loads shown in most manuals or other data developed with commercial cases. While this is most often the situation with both 308 Winchester and 30-06 cases, it is less true with the 223 brass. We have found that military cases often have significantly more capacity than several brands of commercial brass. Again, take the time to do a side-by-side comparison of the cases you are working with and adjust your load as needed. There may be no need for such a reduction with the 223. Know your components and keep them segregated accordingly.

|

|

|

|

|

#8 |

|

Senior Member

Join Date: January 3, 2012

Location: Justin Texas

Posts: 313

|

Well, I ain't gonna reduce no loads.

__________________

Assistant Secretary - U.S. Dry Bean Council |

|

|

|

|

#9 |

|

Senior Member

Join Date: February 6, 2014

Posts: 526

|

just to throw in my 2 cents, when I work up a load for military brass, just treat it as normal, start at the base load and work up, watching for pressure signs. I have never run into a problem.

|

|

|

|

| Thread Tools | Search this Thread |

|

|