|

|

|

#1 |

|

Member

Join Date: November 29, 2016

Location: Long island ny

Posts: 67

|

Trying to size 7.62x51

I am pretty new to reloading.

Only been doing it for six months So I can definitely be a dufos At times. I have reloaded full sized and neck sized 308 brass for my savage. No issues. Some of the brass I bought new , some I resized after firing etc. So, I buy 500 rounds of 7.62x51 (WMA 2015) clean it nice (tumbled)Brass and adjust my full length die 1/4 to 3/8 turn after hitting case holder Lube up a case , size it, then put it in Wilson headspace gauge and to high. Will guess I need a little more of a turn Give it another 1/4 turn. Try again Case is still to high. Slide a new razor blade over head space gauge and it hits. Well after taking die apart and cleaning it, And three full turns of sizing die. I wanted to crush neck. Nothing Didn't crush it and still is up to max on headspace gauge. Anyone know what's going on. ? Tried it with 5 different cases. |

|

|

|

|

#2 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

It doesn't matter what the Wilson headspace gauge says as long as the brass fits in your chamber. So test it out in your chamber.

But, excessive brass spring back could be a sign you need to anneal your WMA 2015 headstamp brass. So a anneal five cases that didn't size right before, and see if that fixes the problem. Jimro |

|

|

|

|

#3 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,742

|

If you've never done annealing before, the slow but simple way is to hold the casehead between thumb and index finger, rolling the thing back while you hold the neck and shoulder in a candle flame. When the case head starts to get too warm to hold onto, wipe the soot off against a damp towel or drop it into water and wipe the soot off later. Either way, you have a case you can try resizing again.

Turning the die down further and further is just stressing your press needlessly. Once you reach the point there is no crack of light between the die and the shell holder with the press ram fully extended, the die isn't letting the case in any further. That would require grinding the die mouth back shorter. Or, there is one other thing you can do: You can remove the decapping pin from your die and try board member F. Guffey's trick of slipping an automotive feeler gauge under the case head in the shell holder so it elevates the case by that amount. If you put in, say, a 0.005" feeler gauge, that's how much shorter the die will make the case on the next pass.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#4 |

|

Member

Join Date: November 29, 2016

Location: Long island ny

Posts: 67

|

Great ideas

I'll try the feeler gauge first Then annealing. Hope I don't have to anneal 500 cases. Also, the cases I have been working with Resizing to death I'm going to throw out But the headspace gauge says Up to max but they chamber fine in my 308 Go figure. |

|

|

|

|

#5 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,742

|

The headspace gauge is designed to tell you if the cartridge passes for loading in a chamber at the small end of the tolerance range. Most guns don't have a chamber with minimum headspace, but rather are between minimum and maximum, so most guns are fine with a slightly longer case than the gauge passes. If you want to maximize the life of your cases, you want to measure the length of the case as fired in your chamber, and only run it into the die as far as necessary to come out a thousandth shorter for target shooting and two or three thousandths shorter for reliable fast feeding from a magazine.

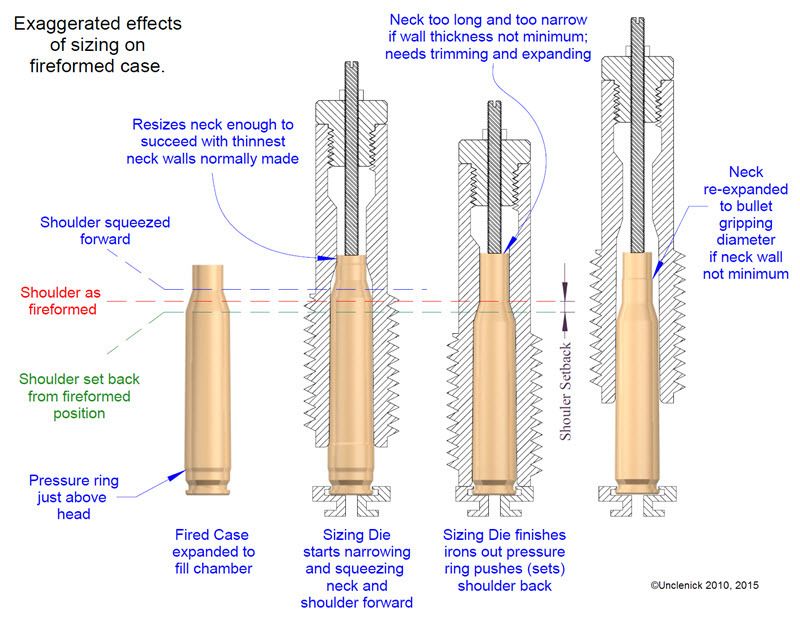

You can buy an adapter for your caliper with inserts for comparing case. You can, however, just buy a fat spacer from your hardware store whose hole lands over about the middle of the case shoulder. Set it on the case shoulder to use it. It's a little slow going, juggling the case, caliper, and spacer, but that's OK just to get a die set up or to sample a few cases. Basically, first measure a fired case and zero the caliper on it. Then you can check your resized cases to see if they are shortened adequately for your chamber. Below is an example of measuring a .308 Winchester case this way. The caliper is a 12", so it's a little bigger looking than the usual 6", but both work.  Below is an illustration showing what happens to brass during resizing.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#6 |

|

Senior Member

Join Date: February 13, 2002

Location: Canada

Posts: 12,453

|

You check the case lengths?

It is highly unlikely annealing is required. Annealing is only done when cases get work hardened after repeated sizing and firing. It is not a part of the regular reloading process. "...they chamber fine in my 308..." Like Jimro says, that is what matters. That Wilson thing(it is not a headspace gauge. Cartridges do not have headspace.) is only making things complicated for you. |

|

|

|

|

#7 |

|

Member

Join Date: November 29, 2016

Location: Long island ny

Posts: 67

|

Let me restate

The 7.62 brass that I resized several times Will chamber in my 308, even though they Are flush with top of headspace gauge. 7.62 brass that I put through the full length die with normal die setup Are slightly above gauge. Gauge with no shell in it , reads 2.015 With shell 2.025. Can not chamber in ,308. All the 7.62 I fired in my 7.62 rifle Fit perfect in gauge, as does all 308 Ammo. I don't have my 7.62 rifle here to check Because I had to send the piece of junk back for repair. I'm an idiot for not buying a Remington or ruger like I was considering But that's another story. Tried annealing, tried putting .006 gauge under case holder. No difference. Is this Lee full length sizer The problem ? Although a resized and resized the brass I was experimenting with all day , will chamber in ,308 chucked it all. To over worked. I thought 7.62 was same dimensions as 308 except for thickness of case. Don't understand. Need to buy rcbs die |

|

|

|

|

#8 |

|

Senior Member

Join Date: July 9, 2007

Location: Fort Pierce, Florida

Posts: 381

|

WMA -- Winchesters newer ammo plant

WMA 15 would have been fired in a machine gun machine guns have an oversized chamber for reliable feeding, and then some guns have a lot of wear in the chamber resulting in a case that is extremely difficult to size correctly, shoulder way to long and or diameter of case is too big around Your problems sound typical of others trying to size machine gun brass some say a small base die does the trick, others sized what they could and trashed the ones that would not size If it was me I would keep trying Next time spend the extra and get the cases marked LR ( long Range ) they would have been fired in a rifle, and are much easier to work with |

|

|

|

|

#9 |

|

Member

Join Date: November 29, 2016

Location: Long island ny

Posts: 67

|

Firewrench044.

Think your right on The brass was fired through a machine gun I think I'm going to buy another full length sizing die, just for the hell of it. Narrow base. I'm going to wait until I get my 7.62 back So I can chamber the resized brass in that chamber vs the 308. |

|

|

|

|

#10 |

|

Senior Member

Join Date: February 7, 2012

Posts: 299

|

Put a piece of 220 wet or dri sandpaper on a flat surface and using a figure 8 motion, sand a few thou off the top of your shellholder.

This will allow your case to go a little farther into your die. I use my surface grinder, but the sandpaper will work, just slow. Over the years, I have had to modify a few shell holders this way. Solved the problem. If you are shooting semi auto, you need .002-.003 of head clearance, try your sized cases in your rifle to be sure the bolt closes easily. Last edited by 1100 tac; December 12, 2016 at 07:37 PM. |

|

|

|

|

#11 |

|

Senior Member

Join Date: July 9, 2007

Location: Fort Pierce, Florida

Posts: 381

|

When you use these cases be prepared for a

case separation (head of the case tares off ) leaving most of the case in the chamber I would not hurt to get a broken case extractor they are not expensive Sounds like these cases have been stretched pretty good with cases like that, that's how they will probably fail |

|

|

|

|

#12 |

|

Member

Join Date: November 29, 2016

Location: Long island ny

Posts: 67

|

I appreciate everyone's help / suggestions

Today. All the reloading I have done so far has been a real pleasure, until today. All the brass I was working with today Is in the garbage. Overworked to death. All the 308 brass I previously loaded fits in the gauge correctly. All the 7.62x51 brass I fired in my rifle chambered for 7.62, fits perfectly in the gauge. All the 7.62 factory ammo I have Which has not been fired, fits in the gauge perfect.. Looks like I bought $65 worth Of NATO 7.62 brass that I just can't Size. Maybe , because it was fired in some sloppy Machine gun as stated above ? Or maybe my die just can't handle this out of spec Brass ? Now, I have to buy another die to find out if Its my die or definitely the brass. This has been a very frustrating day. |

|

|

|

|

#13 |

|

Senior Member

Join Date: October 1, 2013

Posts: 689

|

No way that its your die. Its the brass no questions about it. If you want to use the brass get yourself a .308 small base sizing die. That will work but as mentioned I'd watch that brass for case head seperation.

|

|

|

|

|

#14 | |

|

Senior Member

Join Date: December 10, 2014

Posts: 1,967

|

Quote:

They sometimes ream the die too deep and it will not properly size the case. 7.65 Argentine FL die is the same. The 7.5x54 FL die is too small (0.006" to 0.008") and way overworks the brass. Get another brand FL die and you should be good to go. As far as I know, there are a few other caliber of Lee FL dies in the same category. If you are not using Lee dies, then as UncleNick suggested use Mr. Guffey's tried and proven feeler gauge method. Last edited by Dufus; December 13, 2016 at 12:29 AM. |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: April 4, 2011

Location: LA (Greater Los Angeles Area)

Posts: 2,722

|

I found a few useful tips for sizing 7.62x51. Pretty much all LC is fired in machine guns, as those are the only military firearms currently in service in 7.62x51. It is only the initial sizing that is difficult.

1. I use Lucas White Lithium grease as case lube, from Home Depot. Works incredibly well. I clean the cases before and after. 2. I take the expander assembly out of the die for the first pass at sizing. And then size again, this time in a small base die, with the expander. 3. Trimming is necessary as I get a wide range of sized lengths.

__________________

............ |

|

|

|

|

#16 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 7,135

|

Quote:

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|

#17 |

|

Senior Member

Join Date: February 7, 2012

Posts: 299

|

Also, some folks run their 7.62 MG cases through a .30-06 die before going to the .308 die, pre-sizes so to speak. Of course, not all of us happen to have a .30-06 die laying around, but they say it really helps with MG cases.

|

|

|

|

|

#18 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

Bytesniffer,

I buy a lot of once fired 7.62x51 brass, and the first step in processing is to anneal using a propane plumbers torch. It doesn't take much time at all, and if you don't even need to drop them in water, just a steel bucket. You don't have to heat the neck until it's red, just until you get a little color change just below the shoulder. You should be able to do all 500 in about two hours at a reasonable pace. Military surplus brass is good stuff, it just takes a little more love on the first prep. BTW, love your handle, makes me think you use wireshark a lot  Jimro |

|

|

|

|

#19 |

|

Junior member

Join Date: February 2, 2010

Posts: 6,846

|

"And three full turns of sizing die. I wanted to crush neck. Nothing "

How do you manage to crank the sizing die down THREE FULL TURNS after an initial "1/4-3/8 after contact"? A: I'm pretty sure that would break MY press. B: If your press has that much flex, you need a different press. C: If the case holder is contacting the die at "break over" while sizing a case, lowering the sizing die more won't help. |

|

|

|

|

#20 |

|

Member

Join Date: November 29, 2016

Location: Long island ny

Posts: 67

|

Let just say again thanks for all the info from everyone.

I approached this issue again from a fresh perspective. I used a new piece of 7.62 brass, never sized etc. Measured 2.026 Tried to chamber not even close. Trimmed to 2.001 Tried to chamber no go. Put brass in Wilson gauge and measured it 2.0225 Adjusted die 1/4 turn after hitting shell holder and slightly more for slack. Sized brass Measured brass now 2.0055 Die definitely sized it. Length increased. Chambers fine, smooth in Rifle. Brass still slightly above Wilson gauge. Measured brass in gauge Reads 2.019 now. Put .006 feeler gauge Between shell holder and brass Resized. Put back into Wilson Gauge and measured 2.017 Two thousands diff. Brass is still not below Max on gauge. I can just feel the case when rubbing Finger over case in Wilson gauge I still don't know why this brass Doesn't drop half way between The high and low marks, like the 308 brass does ? I think I will be able to reload this Brass several times without Any problems ? |

|

|

|

|

#21 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

Problem: you did not measure the length of the case from the shoulder to the case head before you started. I do not know what press you are using, there is a chance the press you are using does not have the ability to overcome the cases ability to resist sizing. There are not many dies I do not have and I always feel like if the press I am using is not tuff enough I have another press that is hollering, "pick me, pick me!". And then there is lube, I use a no name lube for those tuff to size cases, most of the time any ol lubeldo. And not far from you is a member of this forum that is a bench rester, he is not far from exit 45 on the LIE and a little north. F. Guffey Last edited by F. Guffey; December 13, 2016 at 01:20 PM. |

|

|

|

|

|

#22 | |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

Quote:

Jimro |

|

|

|

|

|

#23 |

|

Member

Join Date: November 29, 2016

Location: Long island ny

Posts: 67

|

Metal god

What I said was misleading I was putting the feeler gauge Same place you are placing it. Thanks and it does affect the sizing of the brass. |

|

|

|

|

#24 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Years ago I had a Moderator delete some of my responses regarding the use of the feeler gage, he said it was VooDoo reloading and I was going to get someone killed. I am in no hurry so I waited; as few months later an opportunity came up that would allow him to share his new found method of sizing and troubleshooting. He started out with it is no biggie, and he claimed he had been doing it forever.

When it comes to respect I believe he should earn it. F. Guffey |

|

|

|

|

#25 |

|

Member

Join Date: November 29, 2016

Location: Long island ny

Posts: 67

|

F.guffey,

I am very aware of my limited Experience, this is the reason why I started reloading 308 with a 100 Rounds of new Winchester brass. I had to do nothing to the brass except, run the Brass through my load master progressive Press. Worked like a dream. Love that press. I know some people look down on Lee. I bought hornady 150 grain Btsp interlock bullets to go with the The new brass. To be safe I double checked the 4064 powder with the Lee dipper against My digital scale to make sure the Grains are exact. Triple checked my powder measure To make certain powder amount is Correct. Also I started below the Starting grains and worked up to 43.5 .5 grains above starting load. The ammo fired flawlessly. Now all I have to do is clean Check length and neck size to reload The 308 brass. I have to say that videos , reading Instructions, Lee loading manual and Forums has advanced me to a level In a much shorter time then would have been possible not long ago. Do I have more to learn yep The problem I encountered with the Military brass has enabled to learn Even more. My rifle is chambered for 7.62x51 So I had been buying and firing This ammo. I understand the brass is thicker and less Volume in cc , so powder load will Be lower by several grains. Also, I need to measure my headspace In my rifle in preparation for hand loads That are more tuned to my rifles Chamber. This is an advanced project. |

|

|

|

|

|