|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Member

Join Date: January 12, 2017

Posts: 26

|

new memebr and new to reloading, need help

Been reading tfl for awhile now, just recently decided to join. Ive been interested in reloading for a while not only to save money so I can shoot more but because I think it seems like a fun hobby and this past Christmas finally got a press (rcbs supreme kit) , been buying all the accessories and dies and just about have my bench built so I can start using it but I have a lot of questions. I have the nosler reloading manual as well as the lee modern reloading manual and a couple of the caliber specific manuals from cabelas, so I’ve been reading them, watching videos and soaking up as much information as I can from here and other websites . I plan on reloading for 9mm and 44 magnum to begin and than go from there.

As for the questions I have is it ok to use any of the major brand name brass and right caliber primers for the loads? for example my lee book doesn’t even list specific primers or brass while my nosler book shows Winchester cases and Remington 1 ½ primers, so would it be ok to use cci or Winchester primers? Or maybe starline brass? Also what about the bullets, in my nosler book it lists for one of the 9mm loads the sporting handgun pistol 124 grain, would it be acceptable to use the berrys 124 grain hp as a substitute for that or no? I’m sure I will have a ton more questions but that’s it for now, any help would be appreciated and can’t wait to get advice from all of you , thanks! |

|

|

|

|

#2 |

|

Senior Member

Join Date: November 3, 2016

Location: Outside of New Orleans, LA.

Posts: 313

|

I am new, too, so won't go into a lot of info as there are so many people here who've forgotten more than I know! I also have An RCBS single-stage "RockChucker" press and like it a lot. Functional and easy to use but it's been slow (which is OK...) as I am taking a lot of time and being careful so as to learn the proper methods so when I ramp things up I'll be doing the CORRECT things.

You didn't mention what powder(s) you're using. This HODGDON site has a table where you put in the information and it will compute all the data using Hodgdon and Winchester powders. Great tool at http://www.hodgdon.com/ . Now wait for the smarter/experienced guys to show up. Good luck. |

|

|

|

|

#3 |

|

Member

Join Date: December 1, 2016

Posts: 33

|

To my new experience with Lee modern reloading manual and Hornady V10 manual. And a buddy of mine. A 124 gr bullet is a 124 gr bullet regardless of the brand. Lee recommends staying away from federal primers. I use cci and winchester. Personally I like cci. (They make a nice.22 mini mag bullet) I tip I can recommend is start low work higher to your liking. If you're looking to save money find the best "low" load for cost. Also, cross reference your recipes

and! If you find a load that works with a cci primer. It may not work for a different companies primer. Just read that in the latest Hornady manual Sent from my iPhone using Tapatalk |

|

|

|

|

#4 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,743

|

Welcome to the forum.

In general, the answer to your first question is yes, but some exceptions exist: Don't swap magnum primers for standard primers without starting your load workup over again. Usually it makes little difference, but there are instances in which it can raise pressure enough to start seeing pressure signs, so you always start over. Magnum primers are designed to make more gas than standard in most instances. A single exception is Winchester large pistol primers (WLP primers) which are designed to work as both standard and magnum (they separate the two functions in the their small pistol primers) reflecting that large primer substitutions between standard and magnum frequently have less effect on performance than the small primer substitutions do. 9 mm has some unique problems. There are some funny stepped cases out there now with significantly reduced internal capacities, and they are not substitutable, requiring their own load workup, as they potentially can raise pressure dramatically. These cases are heavier, so you may identify them that way, but visual inspection is the only final answer as you cannot count on a thickened case to be made of the same density alloy as your standard brass. (Search the forum for other threads with photos of some of these cases) I am not aware of any problems with substituting any brand of .44 Magnum brass. Starline has always provided exceptionally consistent handgun brass. I would highly recommend them for both .44 Magnum and 9 mm Luger (parabellum). Their new venture into bottleneck rifle brass in .308 is not proving more consistent than other brands, but the process is new to them and I expect they will get better over time. To your second question, plated bullets like Berry's are typically softer than cup and core jacketed bullets. It is best to look at them as sort of half way between lead and jacketed bullets and figure they will use loads that are roughly half way between the two types. IIRC, Berry's recommends using jacketed bullet data up to the middle of the available load range in most manuals. Splitting the difference between lead and jacketed data often puts you there, so when in doubt, I would go that route, but use lead bullet starting loads in your workup to be safe. There are harder plated jacket technologies, like the Speer Gold Dot and Hornady AMP jackets that don't necessarily require avoiding jacketed bullet loads. But most bullets sold as "plated" are not that harder jacket plating, so don't assume it without information from the bullet maker themselves to the contrary. It is good advice to always check three sources of load data and use the lowest starting load among them to work up towards the highest target data. Pressure workups can be done in increments of 2% of maximum, which doesn't take that long to do. You really only need one round at each load level to examine for pressure signs, but you should do what SAAMI does and handle the gun so the powder falls and stays over the primer for the shot. This produces higher pressure than when the powder is forward in the case and should be your test standard. Have fun and stay safe! Nick

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#5 |

|

Member

Join Date: January 12, 2017

Posts: 26

|

Thanks for all of the info guys , I really appreciate it, and I definitely plan on going with the lowest loads first and like robhic I definitely will be going super slow and taking my time for quite awhile . I will probably use the exact load in my nosler book to start out just to be safe but eventually would like to try some of the cheaper bullets like berrys.

By the way the that load is 124 grain jhp 9mm...sporting handgun pistol bullet, 4.6 grains of unique, Winchester case and it says REM 1 1\2 primer but I'll probably use a cci instead since I didn't see any of the Remingtons last time at cabelas...just to be sure it would be ok to use cci primer right ? |

|

|

|

|

#6 |

|

Senior Member

Join Date: February 7, 2009

Location: Southern Oregon!

Posts: 2,891

|

Welcome to the wonderful, oft frustrating and confusing world of reloading!

For new reloaders I have a couple suggestions; first get a copy of The ABCs of Reloading. It'll show you the "how to", and "why" of reloading and after reading you'll have an idea of the equipment needed. Keep your text handy for reference when you need to remind yourself of a procedure. After you determine what you want to reload for (hunting, target, SD) and before you buy any components (powder, primers, bullets) find a load in your reloading manual. Many fewer headaches and delays that way trying to find data for "mismatched" components. For 9mmI'd suggest a jacketed 124-125 gr. bullet (at this point in time design doesn't matter, just get round nose) over a "medium burn" powder (Power Pistol, Unique, Universal, AA #5, etc.). Go slow, double check everything, and most important, have fun... |

|

|

|

|

#7 |

|

Senior Member

Join Date: January 3, 2017

Posts: 1,583

|

I have loaded for rifle and pistol for over 45 years and when I started loading 9mm I found out that the listed seating depth in the manual is bullet specific. That means the over all length of a loaded cartridge in the Speer manual may not work with Hornady or Sierra bullets. I found this out the hard way. I loaded my ammo and went to the range. After pulling two stuck bullets out of my 9mm I went home to find out what I did wrong. I looked at the book length and measured my loaded rounds to find they were just .002" under the specified length. I pulled my barrel from my CZ and did a "plop" test. It was too long. TheSpeer manual, using Speer bullets called for an OAL of 1.125", an older Hornady book listed an OAL of 1.105" and the Sierra book listed the OAL of 1.050". I tested to see how far I had to seat the bullets for my gun. I found that 1.070" was too long but the Sierra listed length worked. I triple checked the powder charge for the reduced powder space and it was fine.

I pulled the bullets and dumped the powder charges and reloaded the 100 rounds with an OAL of 1.050". The difference in length to ogive in 9mm is obviously enough to require different seating depths for different bullets and barrels. The 9mm is a small case and changes in seating depth can radically change the pressure from a given powder charge. Check your powder charge against your seating depth and watch for over pressure signs which are difficult to spot with pistols. The change in my seating depth effectively shortened the available powder space by .075" and if I had been loading maximum loads could have been enough to raise pressures considerably. Use your barrel to check the loaded ammo for fit and triple check your loads against the seated depth of you bullets. Being safe is always better than being fast or injured. Note: I was using a Hornady bullet that was not listed in my old book. Even the same manufacturer will have different seating depths for different bullets of the same weight. Mine were the 115 grain XTP. My old Hornady manual listed a 115 gr bullet #3554 (which is no longer listed in their catalog). Last edited by ShootistPRS; January 13, 2017 at 04:23 PM. |

|

|

|

|

#8 |

|

Senior Member

Join Date: September 12, 2002

Location: Twin Cities, MN

Posts: 5,384

|

ShootistPRS--one of the best explanations of over all length considerations I've read.

I had to find this info out the hard way before the interwebs and stuff. I thought the overall length for all .45 ACP ammo would be the same regardless of bullet type. Obviously, incredibly, WRONG. Luckily .45 ACP is maybe the most forgiving pistol cartridge around and I was using very light loads. |

|

|

|

|

#9 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,743

|

Here's an old illustration of mine for why two bullets might have the same distance off the lands, but different COL's.

Here are couple for the terminology:   In pistol cartridges the bullet seating depth controls the amount of space in the case under the bullet. This often matters more to pressure in a small capacity cartridge case than distance off the lands does. To use this to find your seating setting, take a known load's bullet and determine its seating depth as: Seating Depth = Case Length + Bullet Length - COL Then measure the length of your same-weight and same-construction-type bullet and rearrange the above formula to calculate what COL you should use. Ignore anyone who tries to tell you the construction type does not matter (see this article). COL = Case Length + Your Bullet Length - Seating Depth found for original bullet length This will give you a COL that should function with the same powder, case and primer combination as long as it plunk tests into your chamber properly. If you don't know the length of the original bullet load, but the bullet is specified, the length data at the JBM site is a useful resource.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#10 |

|

Member

Join Date: January 12, 2017

Posts: 26

|

Thanks for all the info guys , definately a lot to take in and I have a lot more reading and learning to do, only reason I decided to start with 9mm Is because I thought that would probably be the easiest thing to start reloading but looks like I maybe wrong . I'm probably going to try to follow the load exactly in my nosler book but I definately will be taking the barrel out of my cz75 and doing the plop test.

|

|

|

|

|

#11 |

|

Senior Member

Join Date: September 12, 2002

Location: Twin Cities, MN

Posts: 5,384

|

Wow Unclenick. Really, really nice illustrations.

|

|

|

|

|

#12 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

Unclenick should be a technical/instruction writer if he's not already.

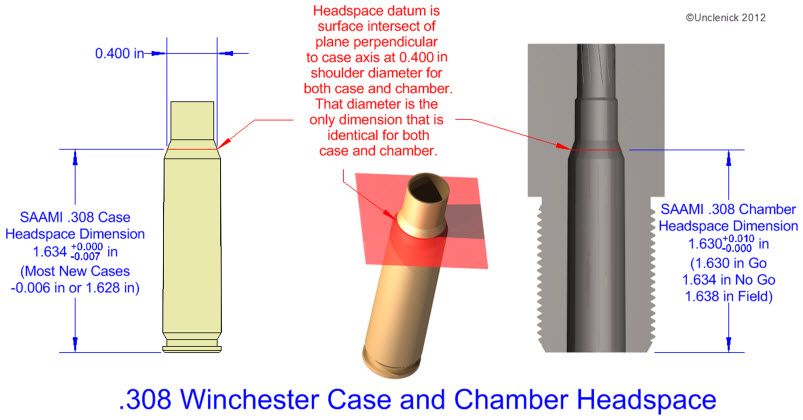

Instructions that DON'T read like stereo instructions in Korean ALWAYS help! When sizing 'Bottle Neck' cases, own a Head Space 'Go/NoGo' gauge at the very least. This will give you a VERY good idea if your cases are properly 'Head Spaced', As well as letting you know when to trim the case, And it's a 'Last Word' gauge to let you know your LOADED rounds came out right, no bulged shoulders, etc. http://www.lewilson.com/casegage.html A case gauge will help you produce rounds that will fit in every firearm of that particular caliber, It will keep a 'Newbie' out of trouble, It will help you set up dies in a snap, When you get a little experience it will help you fit YOUR particular chamber without screwing up. Tells you when you didn't size enough, tells you when you crunched the brass too much, tells you when you need to trim, tells you no mistakes were made during the loading process. Handy gadget to have. ---- A good quality caliper is a must. I like dial, no dead batteries, but that is your choice. ---- Now, 'Head Space' is used as a generic term here. Headspace is actually in the firearm chamber... What you are bending on the brass is called 'Datum Line' point.  You are trying to push the shoulder/Datum Line back to a point the brass will fit the Head Space in the firearm chamber. Once you get that shoulder pushed back to an acceptable point, THEN you worry about the neck length... The deal with the case gauge, it gives you an acceptable 'Datum Line' reference so you can measure your cases and see if they will fit your headspace. |

|

|

|

|

#13 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,334

|

Component Listing:

Unlcnick may correct me, but I believe those are listed components are so that the consistency of the cartridge you build is close to the ones they use. Its the issue as you get close to maximum some components may get there sooner than others. So if they list the combo they used, then yours should be close to the same pressure and not go over so far as to damage you or the gun. Realistically if you start at the low end it makes no difference what components you use and you work up carefully anyway to anywhere near max. I will strongly recommend of if not both of two reloading manuals for different reasons than others choice. Those are Sierra and Hornady. Both have the widest bullet types of any mfg and they also list the most powder choices. I have no problem using their data starting low and working up using the same type and style bullet from another mfg (that's me, but I think its a fair statement) Powder wise their choices and lots of them all shoot decently, so if you are powder limited due to availability, you should be able to find one that will at least shoot if not the dead accurate one that is the best. Lymans used to have a lot of good shooting background, now its gone and their breadth and width is not nearly as wide. I have one but mostly because of the pressure listings and as cross ref. I don't think its the bible it used to be. The caliber specific books are good as they give you something to start with if that powder is not listed. It may not be the great choice for best accuracy but also will shoot at least ok. Bullet manuals list the ones that shoot best as they want best results and more returns. |

|

|

|

|

#14 |

|

Member

Join Date: January 12, 2017

Posts: 26

|

Rc20 thanks a lot for the info , I definately plan on getting more manuals to read through ,

Jeep hammer I appreciate the illustration and suggestion on the case gauge, didn't even know they existed but I'm definately going to get one because that's one thing i am worried about Also quick question to everyone I read that you need to do an initial cleaning on your die set, what would you suggest to use ? |

|

|

|

|

#15 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

Use common penetrating oil.

All the initial cleaning is for is removing any anti-rust or cutting lube left in the die, that lube isn't for resizing brass and may contain chips from the machining process. When you are done loading, clean & lube. Short intervals between loading sessions something like WD-40 works OK, For longer storage you probably want something that prevents rust longer. The best rust preventative I've found so far is Caseys/Burchwood BARRICADE. If you live with humidity, this stuff isn't cheap, but it works very good. |

|

|

|

|

#16 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

No such thing as 'Too Much Reference Material'

The home town reloading shop has booklets (free!) from the powder companies. They carry WARNINGS & RECALLS that are current, Along with the latest load data & new powders, new uses for old powders. (And you can't beat FREE!) Don't just check ONE source when starting with new powder! MISSPRINTS ABOUND! Check two or three sources and if one source looks high, it probably is a misprint. I just ran into that with 'TightGroup' for 9mm, published data was a full grain too high, and a full gain of TiteGroup is A LOT in a small case! Also, if you look at footnotes, magnum primers are usually footnoted when they are supposed to be used... The load booklets & full size load books have the footnotes, while a lot of the 'internet quick references' don't have the footnotes. |

|

|

|

|

#17 |

|

Senior Member

Join Date: September 28, 2008

Posts: 646

|

Outstanding posts, Uncle Nick, and not for just a newbie, either. I've found one of the best things I've added to my reloading equipment is Hornady's straight O.A.L. gage, along with the bullet comparator insert set. I've also gotten the modified cases I need for the bolt rifles I reload for. The gage, comparator insert set and mod. cases take any guesswork out of the "distance off lands" you show in your diagrams. Very nice, easy to understand, and thanks a bunch for those pics.

Just as a side-note, I'm testing loads for my .223 bolt rifle, and using 60 grain bullet offerings exclusively throughout my loadings at this time; the Hornady soft point, hollow point and VMAX, and the Nosler Ball-tip Varmint. Each of those bullets have a different C.O.A.L., and once again, I find that Hornady set I've mentioned to be absolutely helpful in determining a safe and accurate load in my .223. I know there's easier, more economical ways to determine the "distance off lands" as you show, but the O.A.L. set is what I use whenever a C.O.A.L. question comes into play for me for any of my rifles. This is a great thread for any and all of us reloading folks. Keep up the sharing. robhic, I, too, have a Rock Chucker (II) that I've been using for over 30 years (same one). Slow's certainly o.k., too, kind of a built-in safety factor/check during the reloading process. For my reloading needs, slow and methodical works quite well for me. REVOLVERfan, this IS a fun and rewarding hobby, and it looks like you're absolutely serious and wanting to learn to do it right, right from the start. Kudos to you. I know my comments were geared toward the rifle, but I do load for a Ruger NM Blackhawk and a Marlin M94, both in .41 rem. mag. I've come up with a load that works safe, and well, in both pieces. Because of the magazine use in the Marlin, I just full-length resize, make sure my trim length is right on, load the case with the bullet, and crimp well on the cannelure (I use the Hornady book pretty much exclusively with this load using their 210 grn. XTP). No problems at all, and I'm happy with the performance in both guns. That's the cool thing about reloading; you did it yourself, safely, and slowly as robhic mentioned...me too. I live in the West, so my Ruger and Marlin are my cowboy, same cal., same ammo, guns. Fun, and legal to hunt big game with, too! |

|

|

|

|

#18 |

|

Member

Join Date: January 12, 2017

Posts: 26

|

Appreciate the info reinert , definately excited to get started, my bench is almost complete so I'm sure I'll have a ton more questions

|

|

|

|

|

#19 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

I'm happiest when 'Fiddling' with something.

It's the process rather than the end result for me. If you aren't a 'Tinker' then reloading is just going to frustrate the crap out of you! Hand fitting never bothers me and when something fits PERFECTLY it's real satisfaction for me, don't know about others... Getting that brass into a condition so it will accept sizing, Then getting the press set up to the Nth degree so I make nearly perfect brass is where the charge is for me. Sometimes I think I still shoot as much as I do just so I can take on the challenge of getting the brass just 'So' again... About anyone can prime, charge, install a bullet once the brass is done, it's getting the brass into a consistant product that can be a real challenge! If it's not reloading, it's gun smithing, or electronics, or something else that drives most people crazy... So, anyone know what's wrong with us?

|

|

|

|

|

#20 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,334

|

On the slow note.

I shoot anywhere from 50 to 150 rounds a session. Colder or bad weather shorter but even last week when pretty miserable I shot 60. I am still using my Rock Chucker I got 35 years ago. I am not inclined to mess with a turret or progressive press. I like the one step at a time and frankly I don't think I would get as good results trying to do it in bulk (how good they are may be arguable of course!) At some point if I can figure out how to fit it in I want to deploy the Rock Chucker my brother gave me (oddly also about 30 years old!) On the other hand you always have the wrong die in it anyway so it probably does/t help anyting except take up more space.......,. One tool I dearly love is the RCBS universal (note the univeal) hand primer. It has sliding spring loaded lips, no adaptor, primes Large Pistol or Large rifle. I have two butg they have an adapor with them to load small as well. The entry thing is a bit flimsy, I broke mine, taped it up and did fine but RCBS sent me the parts to fix it 3 years ago - still holding up so I have not done so. A tool I think is now indispensable is a good electronic scale. Hornady and Lyman make good ones that are not auto chargers. I have a Lyman now (Hornady backup). It has a built in trickler that's a bit of a pain but work pretty well (high scales are an issue to get a trickler to work with) That said you don't have to jump into it, use the beam scale for a while. I know a lot of older loaders swear by them, I am pretty much of a conservative stick in the mud but I love them, better than slice bread. The one caveat is you have to pay attention to when they start to drift off the pan weight and zero it again. As long as you do that they are good to 1.10th of a grain and that's far more accurate than is needed for rifle loads ( pistol and even more so 9mm or smaller it starts to become a factor) |

|

|

|

|

#21 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,334

|

Unclenick:

Thank you for the bullet link. I learned more from that one short article than anything anyone has ever written (that I have seen) in 40 years of doing this. ps: the 40 years was not continuous but I always read the reloading stuff I came across. |

|

|

|

|

#22 |

|

Senior Member

Join Date: December 23, 2011

Posts: 153

|

You may want to look into a bullet puller too.

|

|

|

|

|

#23 |

|

Senior Member

Join Date: August 22, 2007

Location: Illinois - down state

Posts: 2,514

|

Go for it . . . carefully.

There is indeed a lot to learn.

When I started I read a couple of reloading books and then for my first loads I simply followed the formulas and the instructions that came with my dies. Worked pretty well. I was a year into reloading before I learned about primers that came in different "numbers" like the Remington primers. For the most part, other than standard or magnum, small or large and rifle or pistol, a primer is a primer is a primer. And most primer manufacturers treat it that way too. I'm thinking Remington is the only one with different numbered primers. Anyway the main thing is to stay safe. If the formula calls for a #2 primer then use that. The formulas I follow don't call for a specific # primer. 44 mag was my first reloading and I was so careful and nervous that I put the gun in a handgun vice and pulled the trigger with a lanyard for my first reloads. Beware of minimum loads and lee powder dippers. The combination of those two things gave me some very dangerous squibs. Not a good thing. Live well, be safe Prof Young |

|

|

|

|

#24 |

|

Senior Member

Join Date: January 3, 2017

Posts: 1,583

|

RevolverFan,

As far as using different components go, you can usually get away with starting loads and work your loads up to an accuracy that is under the maximum loads. There are at least two manuals that you should have; 1. the manual from the bullet manufacturer for the bullets you use and 2. the manual from the powder manufacturer of the powder that you use I have an ever-growing number of manuals to grab the information for my reloading. I follow the information in them with a bit of caution because the powder I am using may not be listed in the bullet manufacturers manual so I check for any trend differences in powders listed in both manuals. This information will give you information about why the differences exist - a pistol bullet seated deeper leaves less space for the powder so pressures can be higher in the case with the bullet seated deeper. You can decide to start your load a bit lighter and know that you are likely to hit maximum pressures with less powder too. You should keep records of every load - not ust the ones that work well because ten years from now you may wonder how a different powder will work in your gun forgetting that you tried it in the past and it flopped.  I keep my reload records on my computers and print them out for the three ring binder for each gun. I have load data that goes back to 1968. |

|

|

|

|

#25 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,743

|

There is a difference between how load manuals use SAAMI pressure information and how manufacturers use it, with the manuals erring on the safe side of the line. The common SAAMI pressure limit is called the Maximum Average Pressure (MAP) and for a manufacturer is an average peak pressure value for ten shots using pressure guns calibrated by firing reference loads (to see to it that their technician running their equipment is getting a matching pressure). They have other, higher pressure numbers that, based on statistics, allows for a second random ten shot sample to have a different average and the have a limit for how much higher it can be, and another for a ten shot sample taken when the lot has aged a certain amount, and a limit for the extreme spread of the ten rounds fired in the MAP. Those other pressures are numbers most handloaders are not even aware of, and they wouldn't really help a lot if they were because most handloaders don't have pressure guns and reference ammunition.

So load manuals from the bullet and powder companies don't work the way manufacturers do. Hodgdon explains this in their print manual. It says they treat the SAAMI MAP as an absolute limit rather than an average. For this reason, if one powder is producing more peak pressure variation from shot-to-shot in their tests than another does, they will stop increasing the load at a lower pressure than they will for a very consistent load. This is to ensure the probability of a load exceeding the MAP is minimized. Indeed, Hodgdon even states that if you select a powder from their load data that has a maximum pressure given that is highest (closest to the MAP value), you know that powder exhibited the least shot-to-shot peak pressure variation in their testing. I don't know the manual author's exact criteria, but would guess they limit the maximum peak pressure to a couple of their test load's standard deviations below the MAP. The reason for this apparent abundance of caution is simple: despite quality control efforts there is some burn rate and bulk density and moisture and solvent content variation among powders by the time they are actually loaded, and they can't control anything beyond the condition when it leaves the factory. So they feel a need to allow something for normal variations between when the data is published and when the powder is actually used. There is some good information about the effect of moisture and solvent content on burning rates in the Norma manual, which I find more completely informative than most others because of that information. I recommend it just for reading the information that precedes its load data. A nod to board member Mete for conveying the heads up on this manual as a good resource. RC20, Glad you got to read the article. Jone's article on primers is also good if you haven't read it. But apropos of the bullet difference article, the Norma manual I just mentioned states on page 148: "Careful laboratory testing by M. L. McPherson & Bill Falin demonstrated a 32.4% pressure variation in peak pressure, in otherwise identical 270 Winchester loads, using various 150-grain bullets." Below is an old illustration of the headspace datum plane I did, just to throw in another way of looking at it and to emphasize that the datum (singular form of data) is a reference measurement (can be a plane or a point or any other definable reference) and is the only dimension that both the cartridge and chamber have in common. Since the datum is a reference dimension it has no tolerance, but rather is a basic measurement value. All tolerances are figured either with respect to that value or to one another while not moving or changing that value. The term "datum" is also used in refiguring machine tools. You pick the datum point or plane from which all else is figured, including right angles and tolerances (I've done a little scraping in my time.)  Notice in the above that the tolerance for headspace is 0.002" larger than the Field Reject gauge value commonly produced. I don't know why, other than they have to allow for the gauges to be off a little, too, and I've had some inexpensive ones that were off by that much.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

|