|

|

|||||||

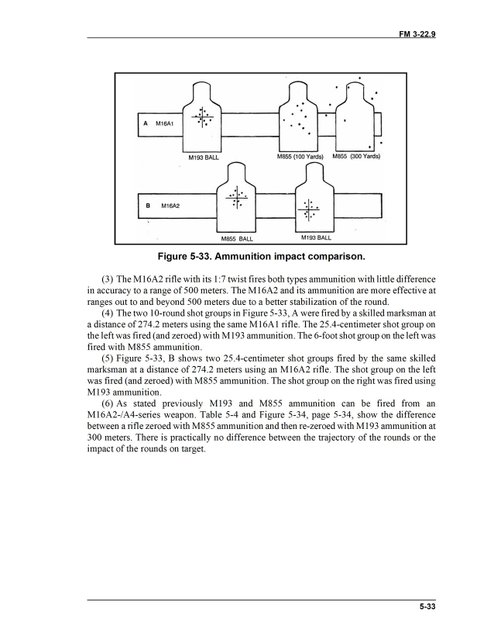

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: August 7, 2009

Location: Not saying b/c I dont want any of you crazy people to rob or kill me. Alright it's Tulsa , Oklahoma

Posts: 224

|

Length of bullet vs rate of twist.

I have always been told that a faster twist likes a heavier bullet. A slower twist likes a lighter bullet. Come to find out the reason behind this is the length of the bullet. Why?

|

|

|

|

|

#2 |

|

Senior Member

Join Date: January 16, 2010

Location: If you have to ask...

Posts: 2,860

|

Rule of thumb is that a longer bullet requires a faster twist for stable flight. Production hunting rifles don't have many if any choices so it's often a moot point unless you're building a rifle or replacing a barrel. Understanding this relationship is important with AR's with all the different twist rates and bullets available but it seems to me some folks make too big a fuss over it.

|

|

|

|

|

#3 | |

|

Senior Member

Join Date: May 31, 2007

Location: NC

Posts: 2,614

|

Quote:

A bullet can rotate 2 ways - along its longitudinal axis (i.e spinning as it does while in flight) and/or along its transverse axis through its center of gravity (i.e. yaw). Each of these rotations is associated with its own gyroscopic force, so for max stability, you want the longitudinal one as high as possible, relative to the transverse one. So, here's the rub: Each gyroscopic force is directly proportional to the moment of inertia and spin rate along that axis, and because of its long length, a bullet has a relatively high moment of inertia through its transverse axis. If the longitudinal gyroscopic force is to dominate, then, it can't do it through its small moment of inertia, and must do it through its spin. The longer the bullet, the greater the spin needs to be for the longitudinal gyroscopic force to dominate. |

|

|

|

|

|

#4 |

|

Member

Join Date: March 15, 2009

Location: Gloucester, MA

Posts: 47

|

Mrborland - that's a great explanation. It cleared up a lot for me.

|

|

|

|

|

#5 |

|

Senior Member

Join Date: January 16, 2010

Location: If you have to ask...

Posts: 2,860

|

Wow! Someone told me that once, MrBorland. Then I made them dumb it down for me.

Great explanation. I'm betting you're a math teacher, MrB. Great explanation. I'm betting you're a math teacher, MrB.

|

|

|

|

|

#6 |

|

Senior Member

Join Date: June 16, 2008

Location: Wyoming

Posts: 11,060

|

It's not just length, its diameter in relation to length. Meaning both.

The Formula is: 150 /(Length / diameter) X Caliber Take a 30 cal bullet that measures 1.279 in length and you get: 150 / (1.279/.30) X .30 = 10.56 or 1 turn in 10.5 inches 150 is a constant for a lead core jacketed bullets, meaning the weight in relationship of cal & length. Some will tell you velocity comes in, and it does, but velocity changes form the muzzle to the target. If you use the standard Greenhill Formula shown above, you'll be pretty dern close. If you error, you want to error on the side of faster twist, because a faster will stabilize a lighter bullet better then a slow twist will stabilize a lighter bullet. Examine the chart below.

|

|

|

|

|

#7 | ||

|

Senior Member

Join Date: May 31, 2007

Location: NC

Posts: 2,614

|

Quote:

Quote:

Kraigwy makes a good point, though, and it's worth clarifying: Within a particular caliber, spin increases as bullet length does. Go to a larger caliber while holding bullet length constant, however, and the bullet doesn't have to spin as fast. This is borne out in the Greenhill equation, and, AFAIK, it's because increasing the diameter (i.e. caliber) increases longitudinal moment of inertia, so the bullet can achieve the same needed gyroscopic force with less spin. |

||

|

|

|

|

#8 |

|

Senior Member

Join Date: March 13, 2005

Location: Pennsylvania

Posts: 1,772

|

Interesting and useful thread and a great explanation. I'm having a .270 rebarreled to .25-06 and when I was aksed what bullet weight I planned to use I advised 120gr, so they automatically entered a 1:9 twist into the work order.

I used the calculation offered herein after measuring my planned bullet and the final calculation was 8.82 - how close can you get? Of interest is the barrel manufacturer did not consider the length of the bullet, just the weight. When I get time, I'll play around with different weights and lengths to see how disparate they are relative to the twist. |

|

|

|

|

|