|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: June 30, 2012

Location: Anaheim, CA

Posts: 139

|

Heat treating and tempering a hammer

(I mentioned in a previous post about repair work I did on one of my revolvers and wanted to give the question I had its own thread.)

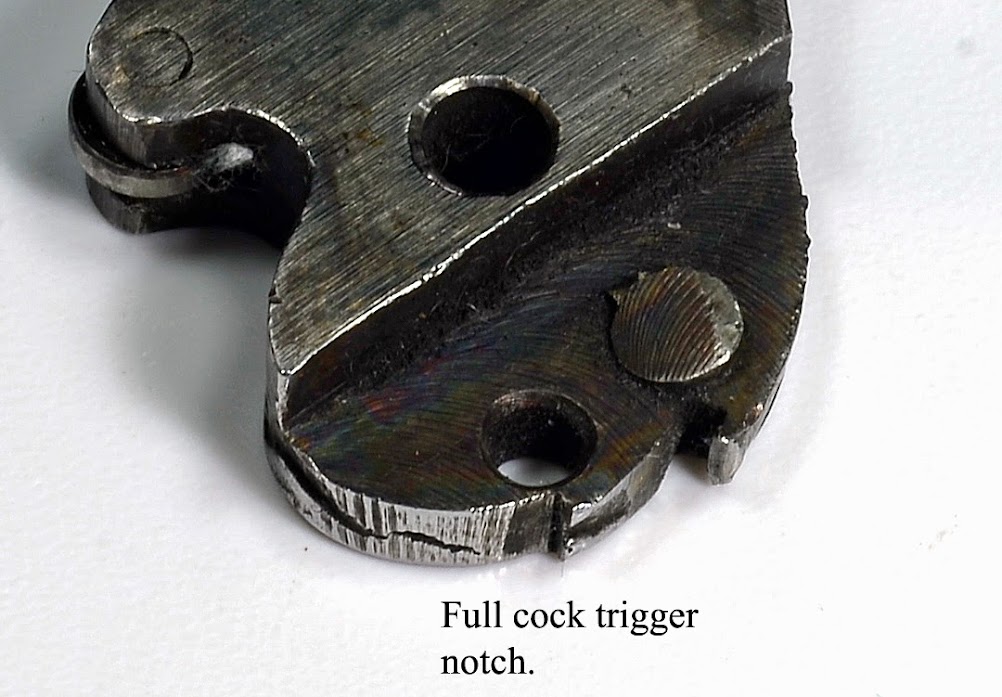

I have milled the full cock notch square to repair damage to my 1949 Colt pocket pistol hammer. James K commented that I should use Casenit to harden the hammer notch to lessen new wear on the repaired area. (see pictures below of the work done and the area of concern.) I have a few questions about the hardening process: 1: Do I heat treat only the notch area or the whole hammer? 2: How long do I need to keep the metal “cherry red”? 3: After heat treating, can I use my molten pot of lead to temper the metal? 4: How long do I need to temper the metal and at what temperature? Thanks for any help! This forum is a wealth of information and knowledge. I learn something new all the time here!

|

|

|

|

|

#2 |

|

Senior Member

Join Date: May 31, 2013

Location: East Texas

Posts: 1,705

|

I've used the casenit for things like this and had good results. I just heated to a cherry red, and buried the part in the can of casenit until it cools pretty good. I then pulled out the part and quickly burned off the casenit that was stuck to the part by just waving the flame over the part until it was gone. I don't know if this would be considered the proper method, but it has always worked for me.

|

|

|

|

|

#3 |

|

Senior Member

Join Date: August 30, 2010

Posts: 1,635

|

I've not used casinite and I don't think you can buy it anymore.

I have case hardened and heat treated BP gun parts by packing them in a metal box with leather scraps and heating them over a propane burner for an hour letting it glow, and then quenching. Then I polished the piece and re-heated watching the colors change until I got a straw color and then quenching again. The lead pot idea has been suggested to me and lets you more accurately control the quench temperature. Here is a great book on heat treating alloys and temps: http://www.secowarwick.com/assets/Do...EBook.2011.pdf Steve |

|

|

|

|

#4 |

|

Senior Member

Join Date: June 30, 2012

Location: Anaheim, CA

Posts: 139

|

Thanks for the comments.

I'm not really set up for full on heat treating. More quick and nasty in the garage type heat treating for small parts. Interesting link about heat treating, but way over my head. I don't know if I should re-treat the whole hammer if all I did was cleanup one surface or can I heat treat just the area I worked on? Will I get the results I want by heating till it is red, rapid cooling in water and tempering by letting the part sit in the molten lead pot for a five, ten, fifteen minutes?? Is this overkill? I figure other than tempering, this should take all of five minutes, but I may be wrong! I've researched the internet with mixed results, meaning it is hard to get a consistent answer. |

|

|

|

|

|