|

|

|

#1 |

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

Have Time To Cast

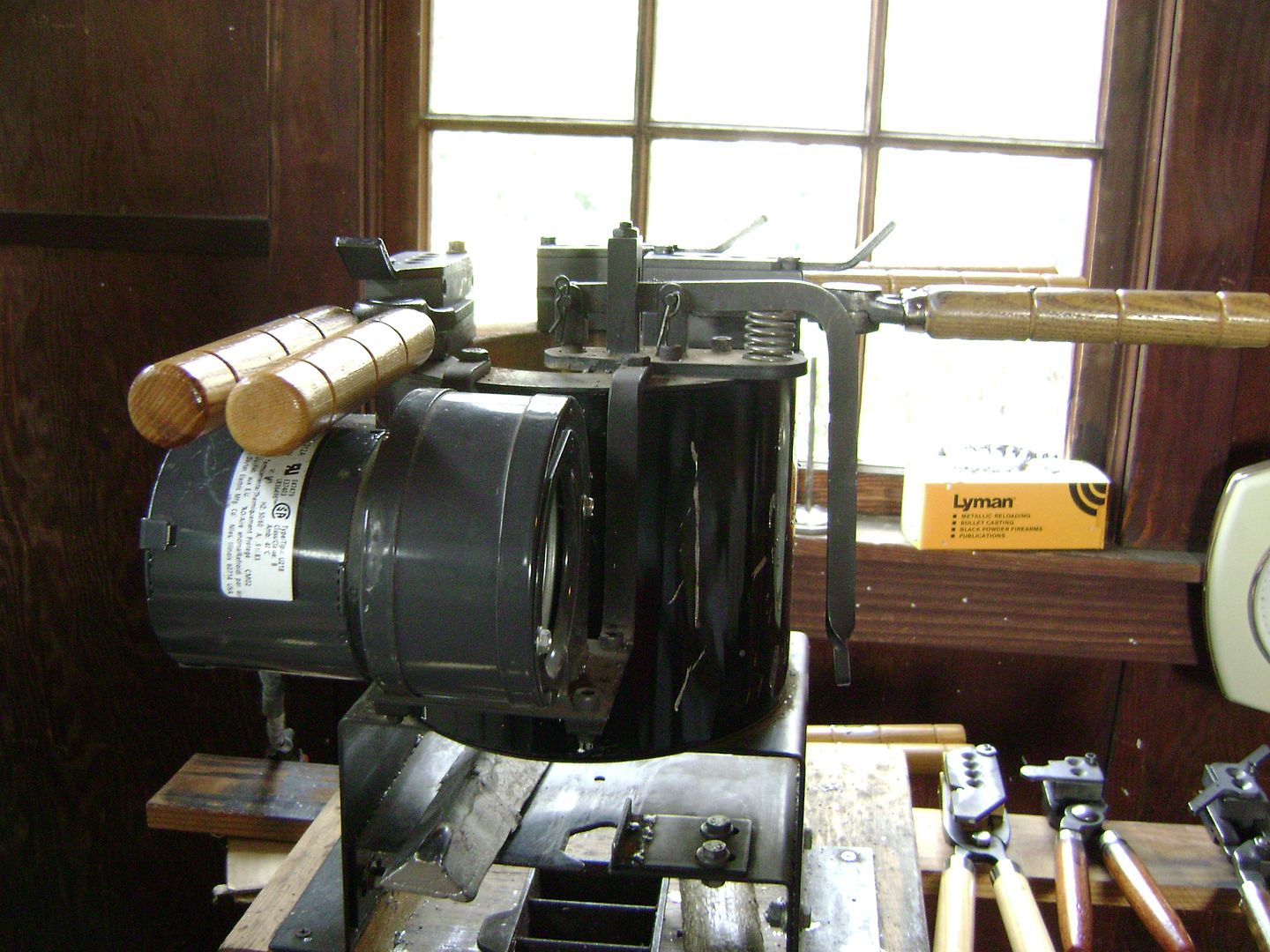

One thing I hear much is: I have no time to cast. At times I can relate. Monday evening found a need for 1000 Lyman 429421 bullets to leave here this week, pretty simple stuff. Well my part time boss called Monday evening also. He needed someone to run an air hammer. The place I was going I’d hammered before so I knew it could be several days’ work. This means I’ll have to cast after work.

Soooooooo came home Tuesday, turned the pot on, filled it with sprues & set the moulds on top. Next, let the dogs out, fix the fire & pour a large glass of water. Once the lead was up to temp it’s only a few rounds with the moulds & they were also hot. For this session we did the three mould rotation, two 429421 moulds & on 358156, all 4 cavity. Two short sessions, one Tuesday evening & one this evening did the trick with 1300ea. 44s & 700ea. 38s. The moulds  The pot  Sprue & dump box  Results

|

|

|

|

|

#2 |

|

Senior Member

Join Date: August 1, 2007

Location: Tabor City , NC.

Posts: 1,969

|

Nice set up Creeker !!!

Is that a Waage 40# pot ???& a very nice landing pad ya got built for those 4 bangers !! Bullets(they don`t likey boolits over here) look nice also !!!clean sharp , can`t tell for sure but maybe a hint of frosting ?? & how do you stand on the 429421 round lube grooves vs. square lube grooves in hand guns ??? Your set up sure looks motivating  PS : don`t post of the air hammer anymore ,my back & elbows hurt frm just reading the post

__________________

GP100man

|

|

|

|

|

#3 | ||

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

Quote:

Round vs square lube groove. Probably start a war but I'll say this: The only "for sure" thing I know is I've owned & cast the Lyman 358429 in both the round & square versions. I see no difference in either as to accuracy or leading. Quote:

BTW: That hammer was really hydraulic & attached to a 305 Cat.

|

||

|

|

|

|

#4 |

|

Senior Member

Join Date: February 28, 2008

Location: Michigan

Posts: 2,619

|

How nice it is to see "real" bullet moulds, not aluminum wannabees.

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 22, 2007

Location: Arizona

Posts: 5,297

|

Jag, my Lee "wannabes" cast pretty darn good - neener!

Very nice setup, sir! I have to say, for me a productive hour in front of the pot is 200, not 1000!   But I'm using two cavity and a single cavity, too. But I'm using two cavity and a single cavity, too.I feel pretty dumb - I never thought of a sprue box, great idea, gonna do that next time. |

|

|

|

|

#6 |

|

Senior Member

Join Date: January 14, 2011

Location: on the north side of DFW

Posts: 970

|

Dang... now I'm ashamed of most of my molds.

Guess I'll keep using them, though... can't often justify the cost of "real" molds...

__________________

I always felt that if I got to the point where I thought it was time to bury my firearms, it was actually time to pick them up.. |

|

|

|

|

#7 |

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

Now guys you don't have to have a big set up to cast. I normally cast at least 50 pounds at a time. But if one is casting for their own use a 2 cavity mould will work fine. I have a couple of the 2 cavity Lee moulds. They cast fine but with those I like to use only one mould cause I don't like to whack the sprue cutter. Still you can turn out several bullets.

|

|

|

|

|

#8 |

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

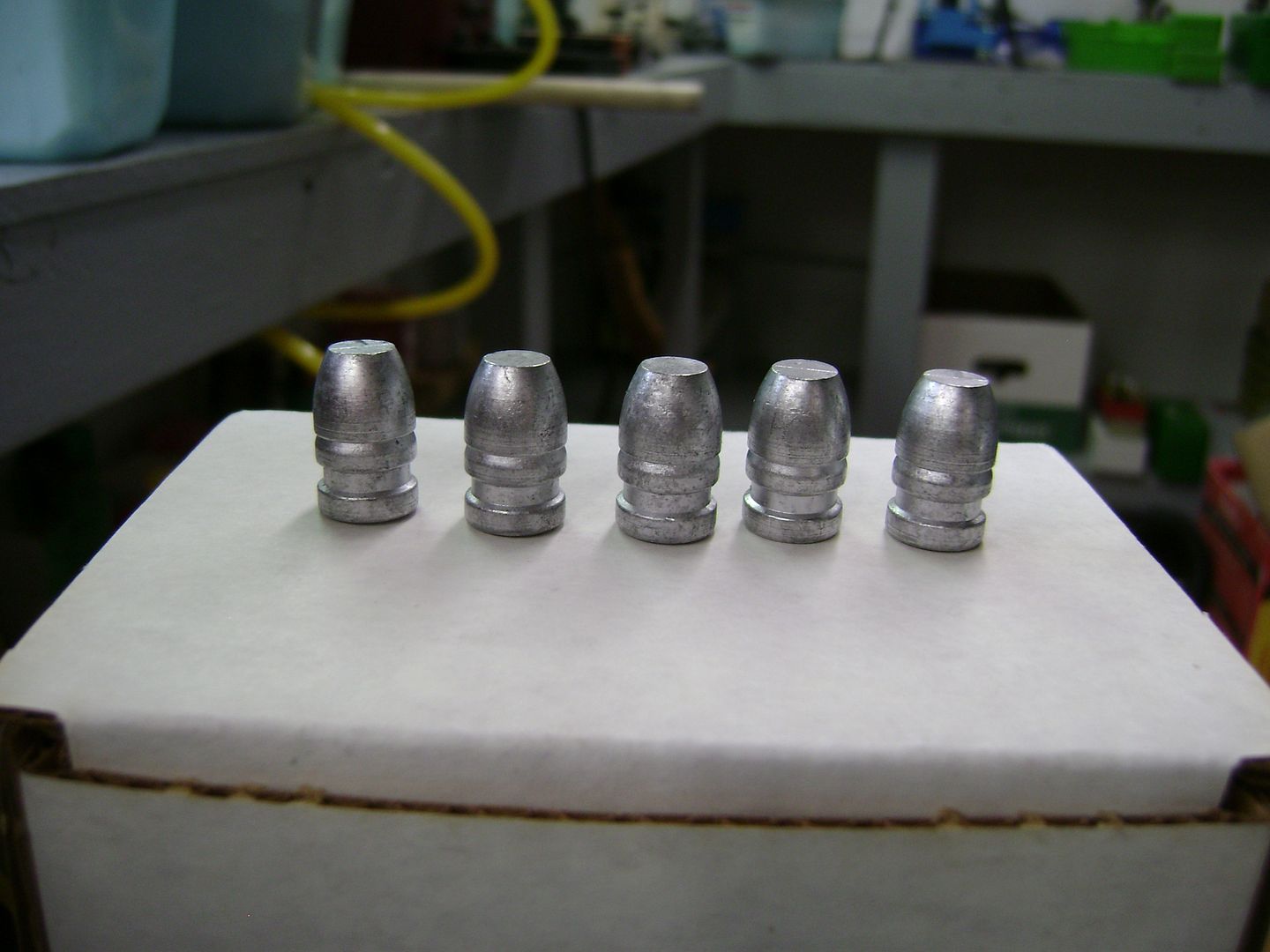

Sized & lubed several of these today

.431 Diameter & LBT Blue

|

|

|

|

|

#9 |

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

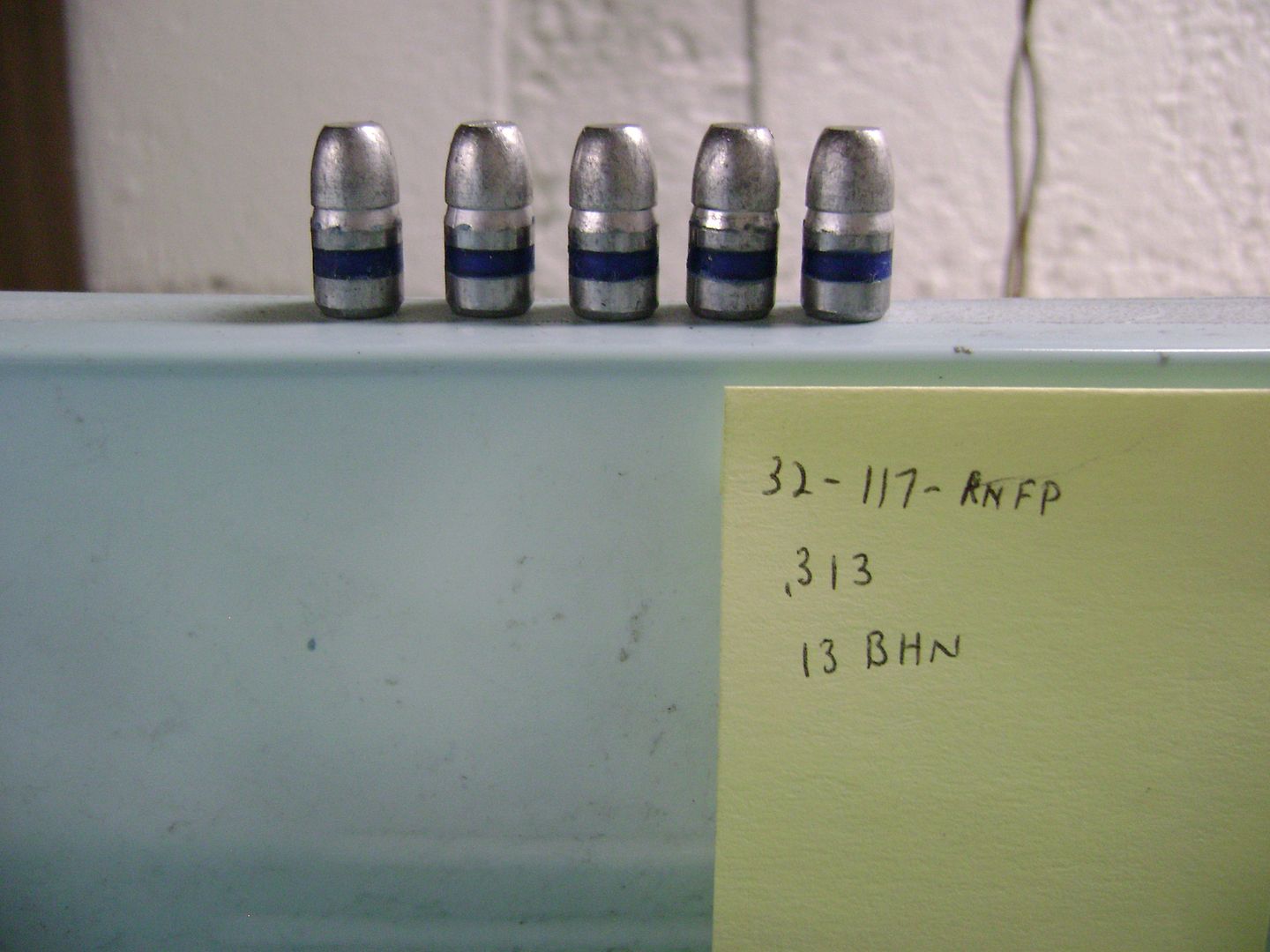

Here's a few 32s from a couple weeks ago

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: October 28, 2006

Location: South Central Michigan...near

Posts: 6,501

|

Quote:

|

|

|

|

|

|

#11 |

|

Senior Member

Join Date: January 16, 2010

Location: If you have to ask...

Posts: 2,860

|

If you can afford a wife and kids you can afford real molds. If you cannot afford real molds, get rid of the wife and kids.-dahermit

You're a wise man, my friend! Being single isn't so bad with fine rifles, quality moulds and a good dog to keep me entertained.

__________________

Life Member NRA, TSRA Smokeless powder is a passing fad! -Steve Garbe I hate rude behavior in a man. I won't tolerate it. -Woodrow F. Call Lonesome Dove My favorite recipes start out with a handful of used wheelweights. |

|

|

|

|

#12 |

|

Senior Member

Join Date: February 5, 2011

Posts: 282

|

I don't mean to hijack the thread but what would be the point of using several moulds in a rotation. Is there some kind of advantage other than getting different bullet types. Wouldn't it be faster to use one mould at a time. Then switch after x number of bullets?

Tapatalk ya |

|

|

|

|

#13 | |

|

Senior Member

Join Date: May 20, 2001

Location: Oshkosh wi.

Posts: 3,055

|

Quote:

__________________

The more people I meet, the more I love my dog They're going to get their butts kicked over there this election. How come people can't spell and use words correctly? |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: December 19, 2008

Location: milton, wv

Posts: 3,640

|

Thas what I do also Snuffy..

__________________

Desert Eagle Alliance Group Launcher Extraordinaire ______ ----Get Busy Live'n.....Or....Get Busy Die'n......Red -------They call me Dr. Bob,,,, I have a PhD in S&W |

|

|

|

|

#15 |

|

Senior Member

Join Date: February 28, 2008

Location: Michigan

Posts: 2,619

|

It is the best way rotating moulds as the 44's and 45 moulds can get very hot.

|

|

|

|

|

#16 |

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

The rotation of moulds is to help with cooling. Instead of waiting to dump a mould you simply grab another. I can run 3 or 4 moulds if they are 44s or 45s. In this case I ran two 44 Lyman moulds & one 38 Lyman. Once the 44s became too hot I would dump/fill a 44, dump/fill a 38, dump/fill the other 44, dump/fill the 38, then back to the first 44 & over & over. It's simply a matter of doing what needs done.

|

|

|

|

|

#17 |

|

Senior Member

Join Date: April 16, 2011

Location: Georgia

Posts: 1,599

|

I do the same. Big boolits heat a mold up quickly.

|

|

|

|

|

#18 | |

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

Quote:

|

|

|

|

|

|

#19 |

|

Senior Member

Join Date: January 16, 2010

Location: If you have to ask...

Posts: 2,860

|

Big boolits heat a mold up quickly. -shootniron

I recently used 2 new Lee 6-bangers in the same session. The 32 mould took forever to get up to production temp with a fast cadence and when I changed over to a big 350 gr 45 mould it was a huge cadence adjustment. It's the mass of the moulds vs the mass of the pour. Small caliber moulds mean less molten lead and more mould to heat up. Obverse is true for bigger moulds.

__________________

Life Member NRA, TSRA Smokeless powder is a passing fad! -Steve Garbe I hate rude behavior in a man. I won't tolerate it. -Woodrow F. Call Lonesome Dove My favorite recipes start out with a handful of used wheelweights. |

|

|

|

|

#20 |

|

Senior Member

Join Date: August 7, 2000

Location: Floating down the James River in VA

Posts: 2,599

|

I run the Lees pretty hot, but cool them off by resting them on a water soaked cotton sock between casts. (Tip from one of Lee's manuals,IIRC)

Periodic cooling in that manner keeps me just at the fringe of frosty bullets, where I get nice fill out, and allows me to cast rather quickly. I'm doing my casting sessions lately as well. Did 240gr .430 LSWC-GCs and .309 FP-GCs last night, and new wheelweight smelting/ingot making over the weekend. Next up are 200gr .430 RNFPs. Handgun and rifle casting with w/w alloy is so much easier than pure lead casting of huge shotgun slugs, buckshot, and muzzleloader minies and ball. |

|

|

|

|

#21 |

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

Used only two moulds today but went well.

The Lyman 429421  Made several

|

|

|

|

|

#22 |

|

Senior Member

Join Date: February 5, 2011

Posts: 282

|

How long did you spend casting? I'm trying to get a bullets/hour comparison going, I only have a 2cavity lee right now my 6cavity is with lee, they are repairing it.

Tapatalk ya |

|

|

|

|

#23 |

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

You ask: How long did you spend casting?

Discounting the weight of the bucket that's 'bout 1200 bullets. Once the alloy & moulds were ready to go, casting the bullets would have taken appox. 90 to 100 minutes using that set up or 12 to 14 bullets per minute. |

|

|

|

|

#24 |

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

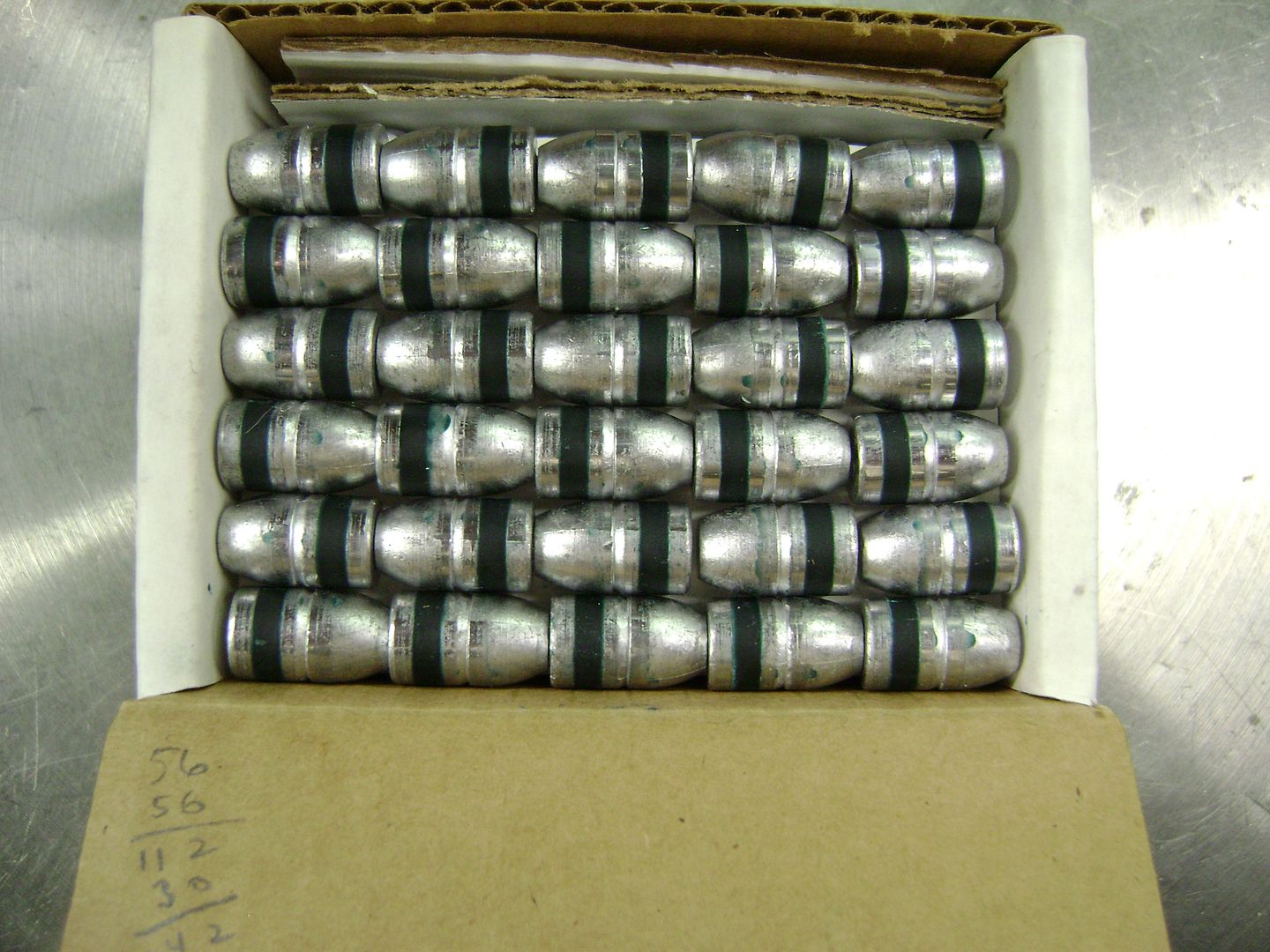

The 44 pounds of 44s are sized & lubed with LBT Blue

|

|

|

|

|

#25 |

|

Senior Member

Join Date: March 22, 2002

Location: In The Hardwoods

Posts: 1,188

|

south.texas.dead.I

Cast these yesterday, 90 minutes.

|

|

|

|

|

|