|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Junior Member

Join Date: March 3, 2012

Posts: 6

|

9mm 125 gn. hard cast bullet seating depth and load data

I am new into reloading and have gone to the local gun shows here in Dallas and purchased several thousand cast bullets for reloading all of my various calibers.

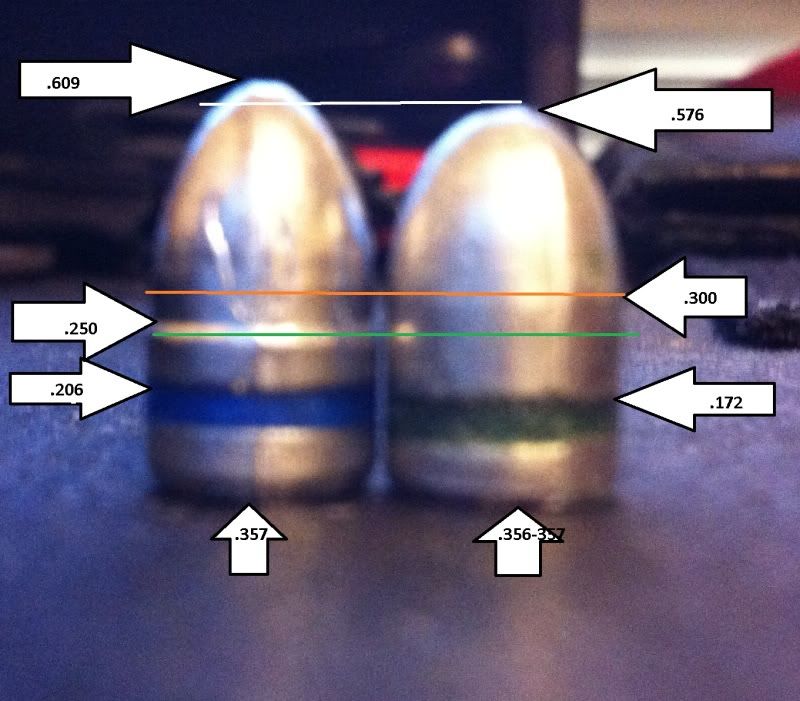

When purchasing these bullets I have noted that there is not really any load data available on OAL or suggested loads from the locally cast bullet manufacturers. when i have asked them they always refer me to my reloading manuals. The problem I have is that several of these manuals state the load and the weight of the bullet but never discuss the length of the bullet and where on the bearing surface to seat the bullet to. It does provide OAL for a given weight of bullet but it doesn't seem to take into account the length of the bullet.The bullet load data I can understand for a powder charge but different bullet dimensions "height" I would think would change the OAL dimensions. My concern is that while I can make sure they will chamber in my guns fine I don't want to compress powder charges by seating to deep and or too little creating explosive headspace in the round. Am I over thinking this? what should I use as a OAL when bullets are obviously different heights? If anyone else is using bullets with the same demisions what is the load data for them using unique or titegroup powders? I am using a Lee Precision 4 hole turret press with the auto disk powder measure and the adjustable charge bar and 2x auto index risers for clearance on the Lee safety prime. The dies I have chosen are the Lee 4 die Deluxe pistol 4 die set with the factory crimp die . I have removed the decapping pin from the sizing die because I do this in a separate step before cleaning the cases. I have bullets from 2 manufacturers in Dallas.   1. Southwest ammunition supply in Mesquite that have the bullets under the trade name Ruckers bullets. Dimensions are 124-125.gn .605 Height and .357 dia the bearing surface is .250 until the Ogive. the top of the lube groove is approx.173 from the base. 2. Bullets from southwest casting inc. in the Dallas area. The bullet dimensions 124-125.gn .356-357dia .575 height .236 of bearing surface until the Ogive. the top of the lube groove is .162 from the base of the bullet.  The case dimensions after sizing and de-priming are .750 case length .598 internal case depth .373 external top of case width .354 internal width of case at top and .386 base of case before rim. Powder charge and head-space inside of case. There is .192 inch of space if the base of bullet is to top of powder using a 5.1-5.2 .gn charge of Alliant Unique powder.  I also have an issue when seating the bullets there is a slight bulge in the case where the base of the bullet is seated. I have tried flaring the case more in the powder through expanding dies but with the bullets being.356-.357 witdth and the inside dia of the case being .350-.353 after decaping and full length sizing with my Lee dies extra flaring just adds to the waves at the mouth even with the factory crimp die. how do you set this up to not happen? Do I need to use a RCBS expanding die instead? I seems doing that would ruin the whole reason for the Lee dies. [IMG]  [/IMG] [/IMG]

|

|

|

|

|

#2 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,060

|

Patmetz,

Welcome to the forum. Seating Depth = case length + bullet length - COL COL = case length + bullet length - Seating Depth Look up a load for a known cast bullet, such as are in the Lyman Handbook, use the first formula to determine the seating depth for that load as Lyman had it. Then measure the length of the bullet you want to use and use the second formula with the Lyman seating depth to get a COL for use with your bullet. Use SAAMI standard case length in both instances rather than a real case length just to keep it standardized and avoid variation. Nick

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#3 | ||

|

Senior Member

Join Date: May 19, 2011

Location: Eastern IA

Posts: 428

|

Welcome! I've gotta say, for someone new to reloading you seem to have a real grasp on things. You're completely right that the length of the bullet has a direct effect on seating depth and charge weight, and that finding data for a specific bullet can be difficult. This is why you always want to start with a "starting" charge and work your way up. I use a bullet similar to the second one you posted and found 5.2 gr of Unique to be too hot at 1.120" OAL, if that helps you at all. I run 4.7 gr and get 1120 FPS out of a 4.7" barrel.

Quote:

Quote:

|

||

|

|

|

|

#4 |

|

Senior Member

Join Date: March 16, 2010

Posts: 733

|

9mm bullets should actually be .355" diameter. Though, lots of people use .357" and usualy its fine, my rugers run fine with .357" bullets, but my kel-tec PF9 doesn't, many wont allow the gun to go into battery.

As for the buldge, even my .355" bullets cause that in my 9mm reloads... I don't know what the explanation is, but it has never caused me a problem. I guess thick brass and .357" diameter bullets would make it even more visible... |

|

|

|

|

#5 |

|

Senior Member

Join Date: April 23, 2008

Location: Medina, Ohio

Posts: 273

|

Welcome - and very good start, good reasoning to understand the details.

Bulge is normal. You have sized the case down, then only expanded the neck part way to accept the bullet. The base of the bullet extends into the un-expanded part of the sized case causing the bulge, and that helps prevent bullet set-back when chambering. OAL is driven by two things - will they fit in the mag and will they fully chamber in your gun. I start with the bullet seated long and then keep seating deeper until the round will drop into the chamber without any help, and I can turn it w/o resistance. Now I know it's not stuck in the rifling and the rim is even with the barrel hood. If the dummy round will fit and feed through the magazine, I go to a starting load of the powder I chose and load a few. Work the load up from there.

__________________

God Bless America US Army, NRA Endowment TSRA Life, SASS |

|

|

|

|

#6 |

|

Senior Member

Join Date: July 26, 2011

Location: USA

Posts: 1,730

|

Your loaded rounds should drop into the chamber, and fall out with the correct COL.

The bulge at the base of the bullet is normal. The factory crimp die, it can size the bullet smaller. Buy a standard taper crimp die. Take the bell out + a tiny bit more. With a bullet of .357" diameter, you might have to seat the bullet extra deep for the ogive to enter the chamber fully. The bulge at the base of the bullet is normal. The factory crimp die, it can size the bullet smaller. Buy a standard taper crimp die. Take the bell out + a tiny bit more. With a bullet of .357" diameter, you might have to seat the bullet extra deep for the ogive to enter the chamber fully.

|

|

|

|

|

#7 |

|

Senior Member

Join Date: March 31, 2011

Location: central Wisconsin

Posts: 440

|

I use some of those same lead bullets.The first one I believe is concidered a type of bore rider(the front part just slides down the bore)and the back half does the sealing and grabing of the rifling,it is done to aid accuracy, I think.The second is a standard RN,and is shorter. Usually the manuals will list coal for the second or "standard" RN so you can figure you will have to reduce charges a bit from published charges due to the deeper seating of the longer bullet.

Scimma= by 4.7" barrel I assme your talking Beretta? If so, do your barrels slug at .357 like mine? I have to use .38 bullets or the few 9mm's that are sized to .358 to end my leading and tighten up groups.

__________________

sent via telegram |

|

|

|

|

#8 |

|

Senior Member

Join Date: June 12, 2010

Posts: 479

|

Welcome to reloading!

I used to use the "stepped, more pointed" 9mm RN lead bullet (like the left bullet in the OP picture above) but now use more rounded and shorter RN bullet (like the right bullet in the OP picture above). Why? The stepped bullet with shorter bearing surface (part of the bullet that rides the rifling) has an inherent limit to how short the bullet can be loaded. For some newer semi-auto pistols that require shorter OAL to feed/chamber more reliably, seating a stepped bullet deeper will push the shoulder below the case neck. The newer cast bullet shape with longer bearing surface and smoother transition to the shoulder allows shorter OAL yet more reliable feeding/chambering. The longer bearing surface/larger bullet base also helps to seal the bullet with the barrel better to produce more consistent chamber pressure and reduce gas cutting/leading which translates to improved accuracy. Check this resource out for more in-depth information on cause of leading and prevention - http://www.lasc.us/Fryxell_Book_Chapter_7_Leading.htm patmetz, determining proper bullet diameter and OAL is crucial when shooting lead bullet to reduce/prevent leading and obtain accuracy. I also use Lee Classic Turret press with Pro Auto Disk powder measure and would suggest the following steps for a new pistol/bullet: 1. Determine the groove diameter of the barrel by slugging the barrel 2. Use lead bullet diameter sized .001" larger than the groove diameter of the barrel. 3. Determine the Max/Ideal OAL by using your pistol/barrel/magazine. 4. Using the Ideal OAL, conduct a full powder workup from start-to-max load data to determine accurate loads that reliably cycle the slide. 1. Determine the groove diameter of the barrel by slugging the barrel. Determining the groove diameter of the barrel should be done BEFORE purchasing lead bullets as the diameter of the bullets should be .001" larger than the groove diameter of the barrel.  Groove diameter is measured groove-to-groove of the rifling and often determined by slugging the barrel - http://www.youtube.com/watch?v=CR_WiL8Dkgw Groove diameter is measured groove-to-groove of the rifling and often determined by slugging the barrel - http://www.youtube.com/watch?v=CR_WiL8Dkgw2. Use lead bullet diameter sized .001" larger than the groove diameter of the barrel. Typical 9mm groove diameter is .355" but many factory barrels are oversized (.356"-.357"+) and will require larger sized lead bullets. If your barrel is .355", then use .356" sized lead bullets. If your barrel is .356", then use .357" sized lead bullets, and so on. 3. Determine the Max/Ideal OAL by using your pistol/barrel/magazine. You do not need to use the OAL listed on published load data as often test barrel fixtures (and not real pistols) are used to measure chamber pressures. Using published OALs WILL NOT ensure reliable feeding/chambering of finished rounds in your pistols. Determining OAL should not be a guessing game and I use the following process for semi-auto loads whenever I use a new bullet: a) Make sure resized cases drop freely into the barrel chamber. If not, adjust the resizing die to ensure the cases are resized full-length and fall in freely into the chamber. b) Determine Max OAL - Make a dummy round (no powder/primer) and perform the barrel drop test with the barrel out of the pistol starting with the SAAMI max OAL until the dummy round falls into the chamber freely with a "plonk" and spin without hitting the start of rifling. To determine the amount of taper crimp to return the flare back to flat, I usually add .020" to the diameter of the bullet (So for 9mm .355" diameter bullet, .375" taper crimp and for .356" bullet, .376" taper crimp). Note: Some headstamp case walls are thicker and you may need to use even less taper crimp by .001" (so for .355" bullet, .375"-.376" taper crimp and for .356" bullet, .376"-.377" taper crimp). c) Next determine Ideal OAL - Load the Max OAL dummy round in the magazine and manually release the slide without riding the slide with your hand. Incrementally decrease the OAL until dummy round reliably feed/chamber. Depending on the pistol/barrel used, Ideal OAL that will work reliably will vary. If you are reloading for multiple pistols, use the Ideal OAL that will work reliably in all the pistols. 9mm cases headspace on the case neck edge/mouth and length of leade/start of rifling will determine the OAL of finished round and may vary barrel to barrel. Since case wall thickness will vary depending on headstamp (usually around .010"), adding .020" to the diameter of the bullet will either add flat taper crimp or slightly negative taper crimp shown below. Note: Drawing not to scale As to bulging of case and the "Coke bottle look" of finished rounds, this is normal for reloaded ammunition, especially when using larger diameter lead bullets. 9mm is a tapered case (the base of the case is larger than the case neck) and when the spent case is resized, the diameter of the case neck is reduced. When a bullet is seated, the neck tension of the case neck against the bullet will show as bulge at the base of the bullet. The bulge will be more prominent when using larger diameter lead bullets. 4. Using the Ideal OAL, conduct a full powder workup from start-to-max load data to determine accurate loads that reliably cycle the slide. Once you determined the OAL that works well for your pistol/barrel/magazine, next you want to conduct a full powder workup. Why? Conducting a full powder workup will allow you to determine the precise powder charges (for the OAL you are using) that will start to reliably cycle the slide of your pistol. Once you have reliable slide cycling/spent case extraction, then you can focus on the accuracy trends of your shot groups to determine the most accurate powder charge loads (either target, full-power or both). If I am using shorter OAL that seats the bullet base deeper in the case neck, I will often reduce the published start/max powder charges by .2-.3 gr. I will load 10 rounds of .1-.2 gr incremental charges and range test 3 shot groups at 7-10-15 yards. Typically, most powders will produce more accurate shot groups as the powder charges approach high-max load data. Faster burning powders like W231/HP-38 will often produce accurate shot groups even at mid-to-high range load data and I reserve these powder charges for lower velocity target loads. I have outlined my load development of similar bullet nose shaped 125 gr RN and SWC bullets using Promo/W231/HP-38 powders on this thread - http://www.thehighroad.org/showthrea...23#post8004823 Last edited by BDS-THR; March 3, 2012 at 10:59 PM. |

|

|

|

|

#9 | |

|

Senior Member

Join Date: May 19, 2011

Location: Eastern IA

Posts: 428

|

Quote:

|

|

|

|

|

|

#10 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,060

|

Patmetz,

The reason for the bulge is the sizing method. As mentioned earlier, the case is formed by the factory with a slight taper from .3910" starting 0.2" from the breech end down to .3800" at the mouth, with a tolerance of +0.000"/-0.007" for either end of it. That taper pulls the sides away from the bullet base in a factory loaded round. A carbide sizing die is just a ring at the mouth of the die that has to be narrow enough to size the case mouth to grip the bullet. It then applies that same OD all the way down the case to the start of the head. No taper. Moreover, owing to the tolerances, it has to be able to size enough to get the thinnest in-spec brass to still grip the bullet, so it over-resizes the average case, making it straight to the head at an OD narrower than the factory ever even made even the mouth of the case, if they made it thick or average. So sticking the bullet into that extra skinny straight case does, indeed, cause a bulge to show. If the bulge bothers you, you can get a steel resizing die that is not straight and that has the same taper as the factory form. It will still be made for worst case thin brass, so you might still get a slight bulge with it, just not as much. Also, you will have to lubricate your cases same as a rifle case to resize them in a steel die. I've never heard of lack of that taper causing a feed problem or any other issue. It's mainly just a carryover from the original design that keeps the case head the right diameter. Your sizing die doesn't change the head fit, so it still centers rounds to the same degree in the chamber. The only functional advantage to resizing to keep the taper that I can think of is the case will be worked a little less at each resizing, theoretically extending it's life. But 9 mm brass is so inexpensive and easily picked up at ranges for free that I don't know a single soul who uses a steel die with them. They just load, shoot, then toss or recycle it when mouth splits start to occur, assuming they don't lose it to the range gods first. On crimps, if you looked at the taper crimp in BDS-THR's middle illustration, that is helpful to prevent setback during feeding, but unless you headspace on the bullet, as the third from left barrel in my illustration that 243winxb posted shows, you have to be careful not to crimp it below minimum case mouth OD spec, which is 0.373". As long as you don't taper crimp below that diameter, headspacing on the case mouth can still work when needed.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle Last edited by Unclenick; March 4, 2012 at 11:24 AM. Reason: typo fix |

|

|

|

|

#11 |

|

Junior Member

Join Date: March 3, 2012

Posts: 6

|

RE: Information

Wow,

I really appreciate all of the information, most of the loading manuals kind off glass over this type of information on cast bullets. I have been using the barrel of the pistol to see if the round chambers ok. I will follow the advice and back the charge down to 4.7 .gr unique and that will give me more room for seating. I also bought a pound of tite group if the Unique takes up too much case space to seat the bullet properly. I will also make up some more dummy rounds to make sure feeding will not be an issue. I have been researching the hell out of this, that way I don't waste a lot of money making trash or hurting myself. I will work up some rounds go to the range and if I still have fingers publish results tonight. Thanks Pat |

|

|

|

|

#12 |

|

Junior Member

Join Date: March 3, 2012

Posts: 6

|

Question

I was following the instructions for head-spacing and noticed in my barrel it is only .600 deep so some of the case is exposed above the rim and the rifling starts around .800 deep. Factory ammo does this also. I assume just run with the case length to factory specs right? my cases size out to .749 and the factory ammo is sizing out to .750.

The barrel is 3.75 long from the mouth to the part where the bullet sets. the entire barrel is 4.3 inch, it is a Ruger P89DC. I guess with all of the measurements and information some simple math with some fit testing I should be all set. I am using this invaluable info to start on 9mm. I have a couple thousand 45 and .40 rounds and several hundred .38 .357.44 mag. I also hope that this will seed the internet for other newbies like myself. I am an engineer and the lack of data just drives me crazy. I want to get this down "pat" no pun intended before I start loading .223 and 7.62x39 till then i am buying steel ammo for the ruski gun. |

|

|

|

|

#13 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,060

|

Take a look at my illustration put up by 243WinXB in post #6. Many semi-auto barrels have that extension or hood you see on the right side (that one is a 1911 barrel) that leaves the extractor groove of the case exposed and that determines where the breechface is when the gun is loaded. The tip of that barrel extension is what you measure the chamber length from. The SAAMI spec for 9 mm Luger chamber length to the case mouth is 0.754"-0.776".

Lots of variables in firearms. I suggest you download SAAMI's older free versions of their info here: Centerfire Handgun Centerfire Rifle Rimfire Shotgun Their test standards and specifications are explained as well.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle Last edited by Unclenick; March 4, 2012 at 12:25 PM. |

|

|

|

|

#14 | |||

|

Senior Member

Join Date: June 12, 2010

Posts: 479

|

Quote:

Quote:

I usually don't recommend faster burning powders like Titegroup to new reloaders. I usually recommend more moderately fast burning W231/HP-38 (same exact powder but HP-38 costs less) which is coated flattened small ball powder that particularly meters well in Auto Disk with less than .1 gr variance. Unique is a bit slower burning than W231/HP-38, but due to larger powder flake size, meters with .2+ gr variance in my Pro Auto Disk. Adding to your information resource, here's a powder burn rate chart - http://www.hodgdon.com/burn-rate.html I typically use faster burning powders than W231/HP-38 to develop lower velocity/lower recoil target/match loads that are clean burning and slower than W231/HP-38 for full-power loads. Slower burning powders tend to develop optimal accuracy at high-near max range load data while some faster burning powders will develop acceptable/optimal accuracy at mid-to-high range load data. For me, W231/HP-38 sits right at the transition junction of pistol powder burn rate to produce accurate target/match loads in 9mm, 40S&W, 45ACP. You'll hear differing opinions of virtues of different powders from different reloaders using different pistols/barrels with different loads. I suggest you try a pound of different powders and see for yourself, starting with W231/HP-38.  Quote:

I can reload .223 cheaper than case prices for my AR that is more accurate than factory/mil spec ammo. My AR ejects brass more gently than AK and you can modify/"train" your AR to be kinder to the brass - http://www.ar15.com/archive/topic.ht...&f=14&t=225953 Although this website is geared towards long-range (1000 yards) precision shooting of .308/.30-06 cartridges, I have gleaned a lot of useful reloading information (start with Basics, Primers, Cartridges, Reloading categories) - http://riflemansjournal.blogspot.com...les-index.html Last edited by BDS-THR; March 4, 2012 at 04:23 PM. |

|||

|

|

|

|

#15 |

|

Senior Member

Join Date: June 12, 2010

Posts: 479

|

To help with powder selection, I posted this in another thread with information from here - http://www.reloadbench.com/gloss/powders.html

Alliant Bullseye Bullseye is a double base powder and perhaps the most popular handgun powder in the U.S. It has proven extremely accurate in a wide range of standard velocity handgun cartridges and will offer maximum and extremely uniform ballistics. It is probably the powder most used to load pistol and revolver cartridges. It is ideal for the tiny 25 ACP as well as the 45 ACP. It is perhaps most often used for target loadings for the 38 Special. Alliant Red Dot This double base propellant was designed as a shotshell powder and may well be the most popular of its type. It is also a popular selection for many handgun and cast bullet rifle loads. It takes its name from the color coded granulations mixed into the propellant. Alliant Promo America's number one economy-priced 12 gauge target powder. Promo has the same burn speed as Red Dot, but is more dense, thus requiring a smaller bushing to obtain the same charge weight. Available only in 8 lb. containers. Hodgdon Clays Clays is a shotshell powder that has specific handgun applications. This extra clean burning propellant is perfect for 7/8, 1 and 1 1/8 oz. loads. Trap, skeet, and sporting clays' shooters will love it. Clays also performs well in many handgun applications. These include .38 Special and .45 ACP. IMR 700X This propellant was originally intended for application in shotshells. However it has practical use in many handgun cartridge applications. It is popular as a target load powder in many handgun cartridges. Hodgdon Titegroup As the name implies, this new spherical propellant was designed for accuracy. Because of the unique design, this powder provides flawless ignition with all types of primers including the lead-free versions. Unlike pistol powders of the past, powder position in large cases (45 Colt, 357 Magnum and others) has virtually no effect on velocity and performance. TITEGROUP has it all, low charge weight, clean burning, mild muzzle report and superb, uniform ballistics. Alliant Green Dot Smokeless shotshell powder. It delivers precise burn rates for uniformly tight patterns and lower recoil. Versatile for target and field. Slightly slower burning than Red Dot this double base powder incorporates a small amount of green colored granulations, hence its name. It is popular for applications similar to Red Dot. Winchester WST Winchester Super Target is a shotshell powder by design and generally replaces the now discontinued 452AA. It is also used by many handgun target shooters. Accurate No. 2 A fast burning, low density ball propellant developed for use in .38 Special loads. Excellent for target loads in almost all handgun cartridges, especially where low pressure and clean burning are desirable. Its low charge weights help the hand loader stretch his shooting dollar. Ramshot Zip Zip is a double based, modified (flattened) spherical powder that performs extremely well in small to medium sized handgun cases. Clean, fast burning and consistent with a wide range of cartridges, Zip is a great choice for target and competitive shooters. Zip's versatility and ability to perform at low charge weights also makes this powder the choice of high volume, cost conscious reloaders. Ideal Calibers: 9mm, .38 Special, .40 S&W, .45 ACP IMR SR-7625 This is a single base powder intended for shotshell and handgun loads. It is also used in many lead bullet rifle loads. This is the fastest burning propellant in the canister grade SR series. The SR nomenclature of this and other IMR propellants using the same letters stands for Small Rifle; a confusing name for seldom used powders. Hodgdon HP38 (now same as Winchester 231) This double base spherical powder is manufactured by Olin and sold under the Hodgdon name. It will nearly duplicate the performance of Winchester 231 and it is extremely fast burning. The name was derived from Handgun Propellant ideal for the 38 Special. Hodgdon suggests it is a perfect candidate not only for the 38 Special but also for the 9mm Luger and the 45 ACP. It is suitable for use in almost all handgun cartridges and is an economical powder to use. HP38 is a spherical powder that is great for low velocity and mid-range target loads in the .38 Special, .44 Special, and 45 ACP. Winchester 231 (Now same as Hodgdon HP38) 231 is a ball pistol powder ideally suited to the 38 special, 45 Auto, and 9mm standard loads. Consistency, clean burning, low flash, and a broad range of applications make this powder a choice for any pistol cartridge reloader. It is highly favored for its well known accuracy potential. Alliant Unique Most versatile shotgun/handgun powder made. Great for 12, 16, 20 and 28 gauge loads. Use with most hulls, primers and wads. It is also a fine choice for cast bullets in many rifle cartridges. It has long been considered the very best selection for the 45 Colt cartridge. It is a good choice for the handgunner wanting slightly higher velocities in a wide range of calibers. It works in the small 25 ACP as well as the 44 Remington Magnum. Universal Handles the broadest spectrum of cartridges for both pistol and shotgun. From the 25 ACP to the 44 magnum, UNIVERSAL provides outstanding performance. In shotgun, it produces excellent loads in 28 ga. 3/4 oz., 20 ga. 7/8 oz., 16 ga. 1 oz., and even 12 ga. 1 1/4 oz. As with all the "CLAYS" series powders, clean burning and uniformity are part of its attributes. Alliant Power Pistol Designed for high performance in semi-automatic pistols and is the powder of choice for 9mm, .40 S&W and .357 SIG. Alliant Herco Heavy shotshell and handgun powder including 10, 12, 16, 20 and 28 gauge target loads. The ultimate in 12 gauge, 1-1/4 oz. upland game loads. A relatively slow burning shotshell and magnum handgun cartridge propellant, Herco is a double base type with coarse granulations. Its use is mostly for heavy or magnum type loadings. Winchester WSF Winchester Super Field is another Winchester shotshell powders having applications in handgun cartridges, especially for competition loads. Accurate No. 5 Use of this fast burning double base spherical handgun cartridge propellant starts with the 32 H&R Magnum. It has also been used for the 9mm Luger, 357 Magnum, 38 Super Auto, 40 S&W (with superb accuracy), 10mm Auto, 44 Remington Magnum and 45 ACP with outstanding results. No. 5 is Accurate's most popular handgun propellant. Hodgdon HS6 Nomenclature is short for Hodgdon Shotshell type number 6. It is basically a shotshell powder that has handgun and cast bullet applications. HS-6 is a fine spherical propellant that has wide application in pistol and shotshell. In pistol, 9mm, 38 Super, 40 S&W and 10mm Auto are some of the cartridges where HS-6 provides top performance. In shotshell HS-6 yields excellent heavy field loadings in 10 ga., 12 ga., 20 ga., and even the efficient and effective 28 ga. HS-6 is truly an outstanding spherical propellant. HS-6 is identical to Winchester's discontinued 540. |

|

|

|

|

#16 |

|

Senior Member

Join Date: November 16, 2010

Location: Arkansas

Posts: 996

|

Yeah, Unclenick's plunk test picture is nice and really gets around. To bad my 9mm barrel don't have a hood.

__________________

NRA life member When the going gets tough, I just open another beer. |

|

|

|

|

#17 |

|

Senior Member

Join Date: December 17, 2005

Location: Swamp dweller

Posts: 6,187

|

Post # 6 has it covered. No need to add any more to the confusion thats posted here already.

__________________

NRA Life Member, NRA Chief Range Safety Officer, NRA Certified Pistol Instructor,, USPSA & Steel Challange NROI Range Officer, ICORE Range Officer, ,MAG 40 Graduate As you are, I once was, As I am, You will be. |

|

|

|

|

#18 |

|

Senior Member

Join Date: October 21, 2007

Location: Between CA and NM

Posts: 858

|

COL is determined by the bullet ogive, the barrel's chamber, the feed ramp, and the magazine lips. Since there all pertain to your specific bullet and gun, then my COL may not be best in your gun.

Sorry, but you will simply have to read your manuals and learn how to determine the best COL for your gun(s). Some guns like 1.125-1.135 and some can only be loaded short at about 1.080-1.095. In my 1911s and 2011s, I tend to find a COL of 1.160-1.170 is best. For 115gn L-SWCs, I have found a COL of 1.025" to be best. Do you see the trend? It all depends on what you have and there is NO universal COL that is best for all guns. Also, note that the COL in the manuals is either the COL they used with their equipment or it is the minimum SAAMI COL or it is (and this gets very confusing for some) the maximum under SAAMI guidelines for industry testing. In no case, is this COL a recommendation for the handloader, other then being the minimum COL that the data can be applied to without pressure testing. |

|

|

|

|

#19 |

|

Junior Member

Join Date: March 3, 2012

Posts: 6

|

Range report

Loaded the ammo using Unique 4.7 Grain 1.120 OAL Crimped using Lee factory Crimp die by seating Die to shell holder then loading piece of re-sized brass and adjusting top to be flush + 1/2 tun further.

Rounds seem to fit in the gun fine as in the diagrams, loaded in the magazine fine, would ploink, rotate and drop out with no problem. Loaded 150 rounds up and went to range. I have all of my fingers but only had 1 FTF, but had a larger issues. 1. the gun would cycle and run through several rounds but when magazine finished not all rounds would throw slide back to lock when magazine was emptied. tried a factory load and gun did this just fine. 2. Had old magazine with me and a weak spring forgot to throw this thing away. The new testing mag was left on my desk from load testing. Had 2 instances within 100 rounds that the gun just jammed the #@$#@$ up. Rounds were jammed in sideways in the magazine causing a on range magazine operation to extract them, the rounds that were jammed were trashed and when the range officer saw the bulges in the brass since I gained his interest while having to rebuild my mag on the line, he expressed some real concern and blamed that on my jam, I did explain the bulge was from oversized lead rounds and I felt the jam was most likely due to an extremely weak spring in the mag, needless to say he kind of stayed clear of me the rest of the session that I was there.  . .Anyway is the load too light to get the gun to not throw the slide back and the end of a mag but it would cycle during the rest of the mag load? My theory by using just a couple of factory loads and they threw the slide back seem to add some credence to this. Accuracy was so so, but I was focused on how the gun was feeling rather than trying to win an award. I had also brought an recently purchased AMD-65 with me to test fire and had nothing but problems with this old thing too, luckily I also brought my trusty Taurus model 44SS 44 mag and finished the night with her.

|

|

|

|

|

#20 |

|

Senior Member

Join Date: March 16, 2010

Posts: 733

|

my first thought was light loads too. Though, I have always be told that lead bullets need less powder due to being easier to push down the barrel, and 4.7gr of unique with a 125gr bullet wouldn't exactly be a light load, depending on who's data you are going by.

I have one of those "one book/one caliber" booklets, in the alliant powder section it shows 125gr lead with unique with a max load of 6 gr at 1165FPS.... On another page it shows an RCBS 124gr lead RN with unique powder with loads ranging from 5.1gr@1102fps to 5.5gr@1022fps, it shows a speer 125gr lead round nose going from 4.1gr@911fps to 4.5gr@1007fps..... my hornady #8 manual shows unique at 4.0-5.0 grains. Judging by all that, I would say you are probably safe to go up a bit. 5-5.3 or so is what I would try.... do it at your own risk though....  I have also read that an overcharge is less dangerous with lead bullets, so you have that on your side I have also read that an overcharge is less dangerous with lead bullets, so you have that on your side

|

|

|

|

|

#21 |

|

Senior Member

Join Date: December 26, 2004

Location: Louisville KY

Posts: 13,806

|

The Lee FCD is a must with my cast loads, otherwise the occasional cattywampus bullet seat will bulge the case on one side and jam my CZ up like you described.

Honestly, you're severely over-thinking the process. Start with a minimum charge, seat the bullet just to the point it passes the 'clink' test in your barrel, then reduce that OAL figure a bit more for wiggle room. Make sure they fit in the magazine...done. At the range, if they don't reliably cycle the slide, up the charge a bit more until they do. Check for accuracy/keyholing issues. I'd skip Titegroup for cast. Stick with something like Unique or Universal that fills the case a bit more. |

|

|

|

|

#22 |

|

Junior Member

Join Date: March 3, 2012

Posts: 6

|

2nd Range Report

Went today with a brand spanking new magpul magazine and what do ya know?

As suspected the gun would lock back perfectly after emptying the mag. With the other load information The loads do feel awful weak compared to factory loads. but every now and again a strong one comes out mid magazine. I did have 2 FTF rounds and just chucked them. Question about crimping now. On the crimp there is about 1/16th of an inch where you can see where the FCD really bit into the brass at the bell to taper it back in. Is it better to flare less and have a hard time seating or crimp more and have this wear on the brass at the mouth? I am thinking of adding a bit more powder next session and seeing how they feel. Maybe going to 4.9 or 5.0 grain. I had loaded some of these previously with 5.2 and they worked but I was not paying attention to accuracy or much anything besides making sure I still had fingers as those were my first loads. I got the data from the reloaders reference access database from the cast boolits forums. |

|

|

|

|

#23 | |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,060

|

Quote:

You also want to be sure you have enough crimp that the bullet isn't being pushed deeper into the case on feeding. For lubricated lead bullets it's a good idea to run the taper crimp just enough to bite a thousandth or two into the lead to prevent that. Some case brands don't get a good grip on the bullet and these can be dangerous without that. Jacketed bullets are held onto a lot harder and rarely need a crimp beyond ironing the expander flare out.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

|

#24 |

|

Member

Join Date: October 28, 2012

Posts: 21

|

OAL of 9mm Luger

Sammi sez:

min OAL = 1.00 inches max OAL = 1.169 There is neat stuff on the sammi site. The test methods are pretty dry but the standard drawings are cool. Here's a link to the 9mm Luger. http://www.saami.org/PubResources/CC...Luger%20+P.pdf |

|

|

|

|

#25 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,060

|

Welcome to the forum.

Though this thread has been sleeping for awhile it is maybe not quite a zombie thread yet. Keep in mind the SAAMI specs are used by manufacturers to be sure their ammunition will fit and feed from magazines by different makers. It is not uncommon for handloaders to find something a little outside SAAMI specs that work in their particular gun. That's OK because their ammo isn't going in anyone else's gun. Just as long as they worked the load up with their funny length, it's just fine.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

| Tags |

| cast bullets , load data , oal , reloading 9mm , seating depth |

|

|