|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 | ||

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

PSA PA-10 chamber out of spec

Good day all . This is a continuation of a thread I started in the reloading section of this forum . see here for thread https://thefiringline.com/forums/sho...d.php?t=602454

Here is a review I just left on there website that sums up where I am now . Quote:

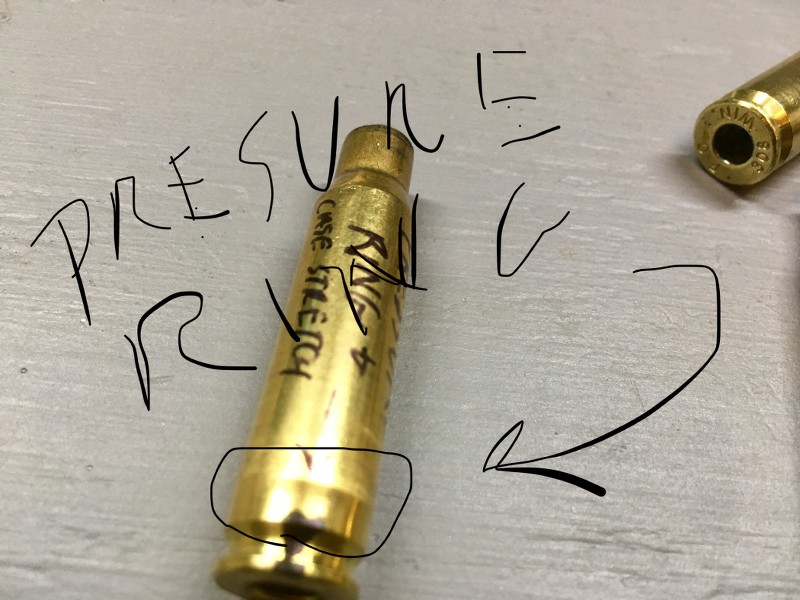

TOOL MARKS ON SPENT CASES  These are the actual cases I sent them . Turns out they never took them out of the bags I sent them in . How do I know , I had stapled them closed when attaching the notes that explained what cases were in the bags . They were still stapled shut when the upper came back .  I'm not even sure what to do next ??? I have to assume they think there part is done seeing how they sent me back my upper . I have no intensions on shooting it so now what ? I can only think that it passed there field gauge and they think that's OK . I was just reading about a guy that had his bolt face cut to deep leaving to much of the case unsupported ( completely different manufacture and rifle type ) . I'm wondering if that's what is causing the stretching/bloating of the web area of the cases . What is the depth your bolt face should be from the front of the bolt lugs ? Since they sent the cases back , tomorrow I'm going to buy a dremel tool and cut that case open to see if it really is about to have case head separation . I just sent this to PSA in response Quote:

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; July 12, 2019 at 03:56 AM. |

||

|

|

|

|

#2 |

|

Staff

Join Date: March 11, 2006

Location: Upper US

Posts: 28,843

|

I'd say the most likely explanation is a communications failure at the factory. Seems pretty obvious that if nothing was opened and looked at, no paperwork added my first thought would be someone at the factory made a mistake and put your stuff in the "done, send out" pile instead of the "to be done" pile.

I mean, it could be they are maliciously ignoring you, and not standing behind their product or it could just be simple human error in the shipping dept. I'd give them a chance to do the right thing, before passing final judgement.

__________________

All else being equal (and it almost never is) bigger bullets tend to work better. |

|

|

|

|

#3 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

You had me thinking that might be it until I remembered I zip tied the BCG in to the receiver and it was returned with out the zip tie . Somebody had to have cut that off so at minimum they took the upper out of the box and gave it a look see . If so all the cases and notes could not have been missed .

but you almost had me thinking it was a simple mistake . but you almost had me thinking it was a simple mistake .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#4 |

|

Senior Member

Join Date: May 22, 2007

Location: Arizona

Posts: 5,299

|

That blows. Have you called anyone at PSA?

|

|

|

|

|

#5 |

|

Senior Member

Join Date: March 2, 2014

Posts: 11,789

|

Does the same thing happen no matter what kind of ammo you use--and what was the ammo used? You should be able to easily see chatter in the chamber walls by shining a flashlight into it. Do you have a case gauge you can check the over-all stretch on? Some stretch is normal--but what is really at issue is if there is something causing an over-pressure situation. I occasionally get that in some cases, but usually when pushing re-used brass in hot loads that have weakened the web/body join over time. I've also noticed that when pushed that far--very often the head will also expand, often to the point that it can't be resized back into compliant dimensions. Did the primers show any unusual flattening/cratering etc? Lastly--are you sure you got ALL of the packing grease out of the barrel/chamber before use? it's remarkable how hard that stuff can be to get all of it out at times. Just a few "shots in the dark."

Should be a pretty simple matter to ask them did they test the gun with firing to verify whether or not somethings wrong; and that you want them to assure you that they tested and verify that the upper assembly measures and functions within SAAMI compliance.

__________________

"Everyone speaks gun."--Robert O'Neill I am NOT an expert--I do not have any formal experience or certification in firearms use or testing; use any information I post at your own risk! Last edited by stagpanther; July 12, 2019 at 04:59 AM. |

|

|

|

|

#6 | |||||

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

Quote:

Quote:

Quote:

I did look at the first several cases fired pretty close and noticed the tool marks right away nd the primers looked fine but the bloating of the web is harder to see at a glance just after firing and did not notice it till later . Quote:

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|||||

|

|

|

|

#7 |

|

Senior Member

Join Date: March 2, 2014

Posts: 11,789

|

I would relax. I've dealt with PSA before on warranty issues before--the biggest problem is that usually it's nearly impossible to get an actual technician on the line. It's actually better that you used factory ammo--many manufacturers will question backing up their products if you use handloads (which is almost all I use). I was wondering if they may have sent you a new upper and you don't know it, too. PSA is also known to be pretty slow in responding at times. Anyway--you are perfectly right to be hesitant to use the upper any further IMO without some positive information from PSA that they have either corrected the problem or will replace it. Otherwise ask for a refund if you want to abandon it altogether. Each 1000 views of this thread and others is probably far more costly to them than making you happy would be my guess.

It's a pretty sad commentary--but in my experience I run a rate of about 30 to 40% of defects or damage of some kind on almost everything I order related to the firearms industry.

__________________

"Everyone speaks gun."--Robert O'Neill I am NOT an expert--I do not have any formal experience or certification in firearms use or testing; use any information I post at your own risk! Last edited by stagpanther; July 12, 2019 at 04:17 PM. |

|

|

|

|

#8 |

|

Senior Member

Join Date: March 2, 2014

Posts: 11,789

|

I just had to return the fancy 15" anodized red rail for my new mystery build this morning--the barrel nut was hopelessly locked into the rail as shipped. Made in China, of course. A high percentage of my fails/defects/damage are made in China.

__________________

"Everyone speaks gun."--Robert O'Neill I am NOT an expert--I do not have any formal experience or certification in firearms use or testing; use any information I post at your own risk! |

|

|

|

|

#9 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Just received this from Gary at PSA

Quote:

I'm thankful they got back to me so quick . I just sent the email last night . Well it appears I was right about the first barrel being out of spec . Glad I only used factory ammo , I knew the question would come up . I sent a response stating the new barrel also fails the same headspace gauge used in the previous barrel and asked 3 specific questions 1) Do you recommend I fire the upper in it's current condition ? 2) should I take it to a local gunsmith and have the actual headspace measured then have those findings notarized and sent back to you ? 3) Do you want it back , are you confident the chamber is with in SAAMI specs ? I could do all that but would require I strip the bolt and remove the barrel to do it right . Might be able to do it with out removing the barrel but it would be easier if the barrel was off .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; July 12, 2019 at 02:55 PM. |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

UPDATE

My NOGO gauge

BCG with .004 piece of feeler gauge in the bolt face  Even with that .004 shim in between the gauge head and bolt face . The bolt still fully closed on the gauge . I think it's pretty official the chamber is way out of spec . I mean maybe worse then the other .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#11 |

|

Senior Member

Join Date: March 2, 2014

Posts: 11,789

|

Don't feel bad--I just got back from shooting and my $700 Nikon FX1000 scope is starting to have black paint flake off the inside of the main tube and fleck onto the glass. Grrrrrrr.

__________________

"Everyone speaks gun."--Robert O'Neill I am NOT an expert--I do not have any formal experience or certification in firearms use or testing; use any information I post at your own risk! |

|

|

|

|

#12 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|

#13 | |

|

Senior Member

Join Date: March 2, 2014

Posts: 11,789

|

Quote:

__________________

"Everyone speaks gun."--Robert O'Neill I am NOT an expert--I do not have any formal experience or certification in firearms use or testing; use any information I post at your own risk! |

|

|

|

|

|

#14 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|

#15 |

|

Senior Member

Join Date: March 2, 2014

Posts: 11,789

|

I'm a bit confused here--are you saying the returned upper still has issues after PSA did their work and sent their report? .004 is definitely a bit much for a brand new autoloader though not radically out of range of a fairly common .003. If it were me I'd probably would take a shot or two to see what happens based on PSA's "all clear" report.

__________________

"Everyone speaks gun."--Robert O'Neill I am NOT an expert--I do not have any formal experience or certification in firearms use or testing; use any information I post at your own risk! Last edited by stagpanther; July 13, 2019 at 01:45 AM. |

|

|

|

|

#16 | |

|

Senior Member

Join Date: September 28, 2013

Posts: 3,827

|

Quote:

-TL Sent from my SM-G930T using Tapatalk |

|

|

|

|

|

#17 |

|

Staff

Join Date: March 11, 2006

Location: Upper US

Posts: 28,843

|

right now, I'd say you need another "opinion".

Consider this for a moment, they replaced the barrel, and the new one failed YOUR headspace check. Might it not be time to see if someone has the same result with their test tools?? I see several possibilities, in no particular order. #1) Your replacement barrel is out of spec. #2) Your NoGo gauge is out of spec. #3) Your bolt is out of spec #4) a combination of 1,2,3, or maybe something else... is there any chance of testing that same upper using a different bolt and/or carrier assy?? OR with a different NoGO gauge?? Any chance of checking a different rifle (with known good headspace) with your gauge?? I'd say the odds of you getting two bad barrels, in a row are pretty high, but that doesn't mean impossible. However it does lead me to wonder if, perhaps, it might be something else giving a "Fail" result. realizing, of course that AR10s are not identical to M16s, I believe they do use the same principles. When I was a Small Arms Repairman (MOS45B20) the process in the shop, if we got an M16A1 that failed NoGo, was to replace the BOLT until we found one that would pass with the installed barrel. If we went through all the bolts in shop stock without finding one that would pass, THEN we would replace the barrel, and try again, with the same bolts. Always seemed to work. One (at least) of the new bolts would always pass with a new barrel. Aside from the headspace, your original barrel that left tool marks on the brass should have been fixed (polished or replaced). Now you have another barrel and it fails your test. What do you do?? PSA said its ok and they shot it 20 times. I would take it to a smith you trust to know what they are doing (or someone else who knows what they are doing, there are a lot of skilled experienced people who aren't doing it as a business, some of them are on this forum) and have them check the headspace with their gauges, not yours. If they don't deadline the weapon, then I'd shoot it, with FACTORY ammo (and taking precautions to protect my precious self, at first, anyway), and see what the brass looks like. Do remember that no matter what the fired brass is like (including ruined) if the rifle functions properly and reliably, the maker has met their minimum moral requirement. We expect to be able to reload our brass, and most designs do leave us brass that is reloadable (at least once) the makers are under no obligation (other than self imposed) to make their guns so fired brass can be reloaded. I'm not trying to defend PSA in any way, but they said its fixed, so go shoot it, and prove them wrong, if they are. But do CYA in case they are wrong.

__________________

All else being equal (and it almost never is) bigger bullets tend to work better. |

|

|

|

|

#18 | ||||||

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

Quote:

Quote:

Quote:

Quote:

Quote:

I'm very much looking forward to getting that field gauge on Sunday .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

||||||

|

|

|

|

#19 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|

#20 | |

|

Senior Member

Join Date: March 2, 2014

Posts: 11,789

|

Quote:

__________________

"Everyone speaks gun."--Robert O'Neill I am NOT an expert--I do not have any formal experience or certification in firearms use or testing; use any information I post at your own risk! Last edited by stagpanther; July 13, 2019 at 07:18 AM. |

|

|

|

|

|

#21 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

No it’s there bolt , sorry I thought there bolts only fit there barrels , thats what I meant by proprietary and I only have the one . Didn’t know you could use there bolts in any AR 10 style barrel .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#22 |

|

Senior Member

Join Date: February 13, 2002

Location: Canada

Posts: 12,453

|

"...have not look at the chamber visually..." That'd be the first thing to do. Any tool marks would be visible to the eye.

"...close on a NO-GO gauge. This means the chamber is out of spec..." No, it doesn't. While you should not use any pressure when checking head space, head space is the issue. Bad head space is not an indicator of an out of spec chamber. And bits of feeler gauge does NOT make a head space gauge. "...there bolts...there barrels..." What? Their bolts? (The word 'there' is directional. 'Their' is a possessive pronoun.) Bolts are fitted for head space to the rifle. Makes no difference who made it. Or who made the barrel. You can put anybody's barrel on a PSA rifle and use the PSA bolt. Just like you can put a Douglas barrel on a Rem M700 and use the factory bolt.

__________________

Spelling and grammar count! |

|

|

|

|

#23 |

|

Senior Member

Join Date: March 2, 2014

Posts: 11,789

|

Well this is a stumper! I asked before if you had a case gauge and measure your cases for expansion. Forget about all the go no go stuff and just fire cartridge an then measure before and after stretch--a bit of stretch is natural but if you really have .004 on top of a closed no-go gauge you're probably up there around .008 +/- headspace. Get some budget Federal cartridges (probably made with military grade LC brass) and test fire em and see what happens. If you're that worried put a bag on the rifle and a string on the trigger so you can fire at a distance.

__________________

"Everyone speaks gun."--Robert O'Neill I am NOT an expert--I do not have any formal experience or certification in firearms use or testing; use any information I post at your own risk! |

|

|

|

|

#24 | |

|

Staff

Join Date: March 11, 2006

Location: Upper US

Posts: 28,843

|

Quote:

If I remember correctly (and that's NOT a given anymore  ) with the gauges we used, for the M16A1 the carrier should be flush with the rear of the upper, when closed on the GO gauge and stick out a bit on the NoGo gauge. And stick out more on the Field gauge. ) with the gauges we used, for the M16A1 the carrier should be flush with the rear of the upper, when closed on the GO gauge and stick out a bit on the NoGo gauge. And stick out more on the Field gauge. Again, if I remember right, a rifle that failed NOGO was to be repaired, but could be put back in service without repair under certain conditions (like active combat nearby, etc) A rifle that failed the FIELD gage was immediately deadlined until repaired. If possible, see if you can get a copy (or download) of TM 1005-249-34, I'm pretty sure the standards are in there. Get the TM not the FM. The M16 TM is worth a look, if you have any AR class rifles, or an interest in history. I don't know what standards PSA is working to, they aren't building M16s for the govt, so it could be about anything. SAAMI standards are worth mention, but remember that SAAMI standards are VOLUNTARY US industry standards, and no one is under any compulsion to use them. I don't know what you ought to do, if the maker says its ok, and you know its not, how much are you willing to spend to get them to "see the light"?? Testing by an independent recognized authority and providing those results to PSA, proving they are wrong might get some action. A letter on a lawyer's letterhead might also be useful. If they won't recognize your valid claim, then I guess filing in court is the final option. I hope it doesn't come to that, but if PSA is ...unreasonable, what else is there? For what its worth, I've never had any PSA stuff, can't state anything about them from personal first hand knowledge, but the guys in the "Tactical" shop near me consider PSA to be bargain basement stuff, barely worth owning, and a PITA to deal with when (not if) their stuff isn't right. Good luck!

__________________

All else being equal (and it almost never is) bigger bullets tend to work better. |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: March 2, 2014

Posts: 11,789

|

I've bought TONS of PSA stuff--everything from parts to uppers--and never had a out-of-compliance issue; though have had some fitment issues--but they make no secret of that; especially in the PA10 platform and parts. That's why this thing is so intriguing to me. I think what the field gauge amounts to is "can get by, but not for long."

__________________

"Everyone speaks gun."--Robert O'Neill I am NOT an expert--I do not have any formal experience or certification in firearms use or testing; use any information I post at your own risk! |

|

|

|

|

|