|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#26 |

|

Senior Member

Join Date: October 21, 2007

Location: Between CA and NM

Posts: 858

|

Back in the '70s, the only reason to worry about case lube was if you were shooting above 60ksi or shooting a bolt with rear locking lugs. A standard bolt action was not a concern, unless loading really hot.

Progressive press: if you want to load to benchrest standards, a progressive is of no help. If you simply trim as needed and load for a normal rifle, then you drop all the silly case prep and load with two dies. Never found a clean primer pocket was more accurate in any of my standard rifles than a decap-and-recap process. Test your various case prep steps and see if they actually are doing you any good...shooting a lot is better for developing small groups than all the time spent on case prep. |

|

|

|

|

#27 | ||

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Quote:

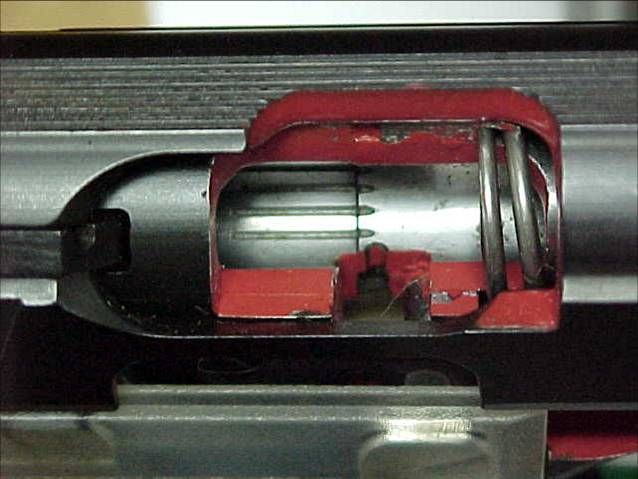

Do you even need to clean guns in utopia?, are headspace gages needed?, do you even need to full length resize?, does steel case ammunition function flawlessly? In my dystopian existence guns get dirty, and they get dirtier the more they are shot, ammunition is not a perfect fit, magazines are still the most common cause of malfunctions in AR’s and after sixty years they still have not got that straightened out. In dystopia, what eventually causes all semi automatic weapons to jam is breech friction. In fact, the greatest problem, going back to the beginnings of automatic weapon mechanisms, is how to get the mechanism to work in spite of case/chamber friction. At some point the frictional forces between case and chamber are such that the case cannot be extracted. Lubricated cases will help keep the chamber clean for a while as oils/sizing lube will solvate the dirt, thus extending the time till a good thorough mechanical cleaning is required. But here in dystopia, nothing goes forever without a good cleaning. The Ordnance Department kept trying to reduce breech friction in its 20mm antiaircraft guns, I found these reports: “Case extraction tests in two, 20mm M24A1 tubes, with fluted chambers”, 16 May 1956, another report was “Test of teflon coated (lubricated) 20mm automatic guns” 24 May 1956. The Ordnance department was trying to increase the reliability of feed and extraction, reduce the number of jams, and to increase the cyclic rate, something that is highly desirable when shooting at an aircraft about to torpedo your ship. Besides chamber fluting, they teflon coated, oil dipped teflon coated, and ceresin wax coated ammunition. In the end, they had to go to multiple barrel weapons to get enough lead on target. I am reminded of modern mechanisms that functioned better, even when supposedly clean, with lubricated cases. At least twice I have been at the range and the shooter next to me has had failures to extract in their Walther P22. http://en.wikipedia.org/wiki/Walther_P22 These P22’s were out of the box, looked clean, and yet they were leaving a fired rimfire case in the chamber. Over the prognostications of the more “learned” folks there, I showed that dribbling a drop or two of oil on the rounds,rolling them around in my hand, then loading these in the magazine, that the pistol would function flawlessly. Just dripping some oil over the stack in the magazine made the pistol function. The shooters were happy because they did not have to drive home to get a cleaning kit. I do the same with steel cased ammunition and AR15's. A drop of oil, roll the cases around, load and shoot. This helps reduce the stickness between steel cases and the chamber walls improving extraction. I got tired of hard 9mm case sizing on my Dillion. I use a carbide die but forcing range pickup cases into the die was hard. So I lubed the cases, sizing was smooth and easy, and I left the lube on the loaded rounds. It is my opinion that my pistols run smoother and ejection is more even. As long as I keep dirt off the rounds every thing is just fine. As I have shown, lubricating 308 and 30-06 cases for Garands/M1a’s extends case life. I see no need to lubricate cases for bolt rifles unless you are fireforming them and don’t want a case head separation. Even then, I would fire a light load because I have concerns about action peening. This is something I did for my 35 Whelen and 300 H&H cases. Coated them in paste wax and shot them so they would slide to the bolt face without any stretching in the sidewalls. I have shown modern mechanisms, that is post WW2, which require case lubrication in one form or another. The G3 type actions were all developed in the 50’s same as the AR actions, which I assume is considered “modern”. What Col Chin said about the need for lubrication in high power delayed blowbacks is as true in the 1950’s, as it was in the 1890’s, and will be in the 2090’s. Until such time that case less ammunition replaces cased, this will always be true.  Is a P7 modern enough?  What about MP-5's?   Now to go back to what you said : Quote:

Unfortunately, I am in a different place, and sometimes a little lube helps.

__________________

If I'm not shooting, I'm reloading. Last edited by Slamfire; August 5, 2013 at 01:46 PM. |

||

|

|

|

|

#28 | |

|

Senior Member

Join Date: December 21, 2010

Location: Minnesota

Posts: 288

|

Quote:

Unless there's a motorized trim/chamfer/deburr die on the market, or the trimming can be done before resizing in a progressive, I'm stuck with at least one pass through my single stage press prior to tossing the brass into the case feeder of my progressive press.

__________________

The most feared gun control law proposal: Require buyers to register all gun purchases with their wives

|

|

|

|

|

|

#29 |

|

Senior Member

Join Date: October 21, 2007

Location: Between CA and NM

Posts: 858

|

Here is my world:

Barrels shoot great for up to 1000 rounds in pistols and several hundred rounds of rifle. Of course, the breech and feed ramp areas need brushing occasionally, but not nearly as often as some people seem to think. Now, for a rifle shooting in the 60ksi range, the barrel needs to be cleaned more frequently due to copper fouling or if you are shooting too fast and heating up the barrel quite a bit. For pistols, I tend to shoot until accuracy drops off or I feel like cleaning. It is amazing how many shots it takes to get a clean barrel shooting well again (5-30, depending on the gun, and how long they will hold their accuracy with occasional checks to be sure there is no lead build up). Ask most Olympic shooters how often they clean the barrel of their pistol or rifle and they'll just look at you odd. Clean a barrel that is shooting great? Clean as you feel necessary, but do not imply that it is required for everyone. |

|

|

|

|

#30 | ||

|

Senior Member

Join Date: December 24, 2008

Location: Loveland, CO

Posts: 1,476

|

Quote:

You do realize that faster doesn't always mean better, right? I was only offering a different perspective that works very well for me. I wasn't trying to get anyone to follow my process. And I use 3 steps on the progressive with powder, seat and crimp (if necessary). And from the original post: Quote:

__________________

NRA Benefactor Life member |

||

|

|

|

|

#31 | ||||||||||

|

Staff

Join Date: February 12, 2001

Location: DFW Area

Posts: 24,989

|

Quote:

"If lubricating cases really does improve function in a modern firearm, then there is something wrong with the gun or the ammunition or both."I'm not claiming that things don't go wrong, in fact, to the contrary I'm saying that if you need to lubricate the cases to improve function in a modern firearm--SOMETHING HAS GONE WRONG. The solution is to find what's gone wrong and fix it. Not to apply a bandaid--unless, of course, there is no other option under the circumstances. Quote:

Quote:

Quote:

Quote:

Quote:

Quote:

Quote:

As I said in my last post I can accept that case life in semi-automatics is probably extended by lubricating cases. But I'm still not willing to go so far as to agree that it's a practice that should be recommended... Quote:

Quote:

Sure, sometimes things don't work. But when a modern firearm stops working, it's not because the cases aren't properly lubricated. It's because there's an underlying problem that needs to be addressed. Modern firearms are made to function with unlubricated ammunition, or (in rare cases--only one that I know of) the ammunition comes from the factory already properly "lubricated". There's a very simple method--and really it's the only logical way--for you to defend your position. Find at least one modern manufacturer of semi-automatic firearms who provides official material stating that their firearms need lubricated chambers in order to function as intended. Until you can do that, what you're effectively trying to do is argue that although manufacturers know how to make their firearms work properly, they are, for some reason, withholding that information from their customers. Clearly that's a nonsensical premise.

__________________

Do you know about the TEXAS State Rifle Association?

|

||||||||||

|

|

|

|

#32 |

|

Senior Member

Join Date: September 15, 2007

Posts: 1,707

|

Wow. So much new information.

I remember when I started out handloading the Lyman manual I read, from cover to cover several times, stated that one needs to remove case lube, as to leave it in place will increase bolt thrust to potentially unsafe levels. So I have meticulously removed case lube. |

|

|

|

|

#33 |

|

Senior Member

Join Date: April 25, 2010

Location: Arkansas

Posts: 3,309

|

I haven't read all the very long replies.

My technique is to use Dillion spray lube. Reload. Then wipe every round with an old towel. Works for me. |

|

|

|

|

#34 | |

|

Staff

Join Date: February 12, 2001

Location: DFW Area

Posts: 24,989

|

Quote:

Unless you are using something more exotic than a typical petroleum lube, it's unlikely that small amounts of case lubricant left in place after the reloading process are going to cause any major issues. That's a separate issue from the one he and I are discussing.

__________________

Do you know about the TEXAS State Rifle Association?

|

|

|

|

|

|

#35 |

|

Member

Join Date: October 4, 2012

Posts: 81

|

Can anyone give me some advice on de-lubing in the following scenario: I use liquid-lanolin + alcohol to lube .308 for progressive case-prep (after tumbling in fine ground walnut shell with car polish + mineral spirits).

Thanks! .. |

|

|

|

|

#36 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

If one makes some tests with different amounts, type and application methods of lube on decapped and cleaned cases when full length sizing them measuring shoulder set back spread, they may well be surprised. That spread will also vary with the amount of spring the press has. And keeping the case all the way up in the die for a long period of time will usually set its shoulder back a bit more; very slowly depending on press spring pulling it back down and lubricity of the lube on the die and case surfaces.

One comment on setting fired case shoulders back ".002" gives .002" headspace" ain't quite kosher. For bottleneck cases headspacing on their shoulders, chamber headspace is the distance from the bolt face to the chamber shoulder reference point; case headspace is the distance from the case head to the case shoulder reference point. The distance from the bolt face to a chambered round's head is most commonly called head clearance. A fired bottleneck case's headspace will be about .001" or more less than chamber headspace. So, setting a fired case shoulder back .002" ends up with about .003" head clearance; a good but maximum number to work with for most instances with bottleneck cases. Best thing I've used to clean case lube off cases is to wash them in laquer thinner then lay them out in the sun to dry. Have also used shush tubes made from terrycloth towels with laquer thinner sprayed on their inside then dumping in a bunch of cases and raising each end of the closed shush tube back and forth to wipe the case lube off of them. |

|

|

|

|

#37 | |

|

Senior Member

Join Date: October 28, 2007

Location: Upper Indiana

Posts: 609

|

Quote:

I use white gas, AKA Coleman Fuel, NAPTHA, as here in No. In. Amish country we can buy it at the pump for $4.00 a gal. But I realize not many have that option.

__________________

U.S. Army Veteran NRA Certified Range Officer |

|

|

|

|

|

#38 |

|

Senior Member

Join Date: October 12, 2010

Posts: 403

|

I use a Hornady LnL AP Progressive press to reload .223.

I load in 2 steps. Step 1) Station #1 decapping. I use a .223 sizing die with the expander ball but the die backed off nearly a complete turn so that it doesn't push. The shoulder of the case back any. Station #3 Dillon RT-1200 Rotary trimmer. The trimmer die is setup to push the shoulder back to the proper location and trim the cases to the proper length. My cases go into the case feeder approximately 200 at a time lubed with Dillon case lube/ they are sprayed in a shallow roasting pan. Once the brass makes its first pass in the progressive it is now decapped, sized, and trimmed. It now gets wet tumbled which removes all of the lube and brass shavings from trimming and the SS pins knock down the slight burr remaining from the trimming step allowing the brass to be ready to reload if using boattail designed bullets. |

|

|

|

|

#39 | |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Quote:

What I am saying is the simple static analysis of pressure times head area can’t be counted on to predict actual forces in dynamic conditions. One result of dynamic analysis is the actual force normally applied (chamber not especially smooth; no lubrication) to a bolt face is lower than the static calculation predicts by about 50%. When you add in super low friction, only then does it approach the static number. So the doubling of force is not doubling the static number, but rather is eliminating the halving of it that is normally seen. Dynamic analysis has to include such factors as the reaction force due to inertial masses and friction and anything else that’s being moved in the actual firing event. It has to allow for how conditions change during the time it takes things to happen. Probably the most familiar example is that .30 caliber rifle bullet pull, such as in a .308 Winchester, is typically about 60 lbs. A static analysis says about 800 psi should produce enough force to unseat the bullet during firing. But making actual measurements of the dynamic case, H. P. White Labs found they could detect no bullet movement until pressure reached about 10,000 psi. The point is, dynamic and static analysis or measurement can give significantly different results, especially if the time frame is short. Wait long enough and conditions will equilibrate toward the static case, and, eventually, the 800 psi will get the bullet moving. Just not soon enough for the firing event time frame. The actual numbers for the bolt face thrust come from Varmint Al’s non-linear FEA of a .243 Winchester case operated at 55,000 psi. Al is a former Lawrence Livermore National Labs senior structural engineer, and the software he used was developed at LLNL and is high end. I did enough FEA work for my patents in vaccine and blood transport equipment to know you can mess it up if you do it incorrectly. But I did work on a couple of projects that included contributions by engineers at Oak Ridge National Labs and found the national lab engineers generally tend to be from the sharper end of the tack box. Al's got meshing fine enough to easily pass the eyeball test for adequate resolution, and his results converged (or he'd have no results), so I’m confident Al did it right. The reason for the dynamic case bolt thrust approaching the static case when friction is reduced seems to have mostly to do with the modulus of elasticity of the brass. The modulus of 70:30 brass is 16 Mpsi. STANAG 17 drawings (the only case hardness spec I have) show 7.62 NATO brass cases in the head area and forward about three quarters of an inch having a Rockwell 15T scale hardness of 89, which corresponds to a tensile strength of about 83 Kpsi. With cartridge brass that strong, the yield is about 64 Kpsi. Dividing the yield by the modulus gives 0.004, meaning 70:30 brass at that hardness would stretch elastically about 0.4% before reaching its yield, or 0.004 inches per inch of stretching length. Hold that thought. When pressure builds enough to stick brass case to the chamber wall, the brass expands first where wall thickness is thinnest, rolling back from the shoulder toward the thicker parts of the wall. Sticking also happens in that order over a finite length of time, with adequate deformation against the chamber surface for sticking happening first where the brass is thinnest, toward the shoulder end. Without lubrication the sticking pressure is reached before the case head stretches. Stretching of the brass then happens only over a very short distance, stretching and starting to form the pressure ring right at the first firing. The amount of stretch that short length experiences, percentage-wise, is high, with the end result that the case head doesn't move appreciably until the yield strength of the brass is exceeded. Only then does it start settling the bolt against the lugs and building force against it. But when you add lubrication to the case, the chamber sticking pressure requirement gets higher, and only the thinner portion of the case wall arrives at its higher sticking pressure before stretching commences. This means the overall length of brass over which the stretching is spread is greater than without lubrication simply because a shorter portion of the case below the shoulder is stuck. As a result, it takes less force to achieve a given total number of thousandths of an inch of stretch, so the head moves back earlier in the firing event and absorbs less force. This also means the stretch in a lubricated case is spread over enough additional length that, in a chamber that's not too loose, the head may make it to the bolt breech face before the brass reaches its yield point, thereby eliminating the most significant pressure ring thinning. This is exactly what Varmint Al's FEA's of the .243 Win show: The lower the coefficient of friction between the case and the chamber, the further forward along the case between the head and the should the sticking friction anchoring moves, letting longer portions of the brass participate in the stretch. I’ll include some further information when I finish putting an answer together to your post on bolt lug design in the bullet case bonding thread. This year’s obligations have kept me from spending as much time online as I used to do, but I’ll get to it. Suffice it to say here that because the gun steel is not being operated in its true elastic region, the slow plastic displacement that results in a Field Reject gauge telling you your headspace has grown excessively, will happen very slightly over twice as fast if you allow twice as much bolt thrust by approaching zero friction. That's why I don't recommend the ultra low friction lubes. But just using petroleum-based lubricants won't get friction down that far. Probably of more interest to you in this context is a result Al got from some physical experiments with friction between brass and stainless barrel steel. He found that when the steel surface was smooth and mirror polished (Flitz was used), a light oil coating no longer reduced friction between the two metals very much. The polishing already brings friction close to what the oil can do. (I think he was using 3 in 1 oil.) You can check his web site. That experiment suggests a smooth and highly polished chamber could give you pretty much the same result you get from lubricating now, but without the extra step. I just know I've had to clean oil out of the bedding in my match Garand enough times that I don't want to introduce extra oil on purpose if there's a workaround. I got one of Greg Tannel's through-bore lubrication devices and a pump and chlorinated cutting fluid awhile back. I've been stabilizing my lathe with some stand reinforcement and additional vibration isolation from the motor, and am about ready to try this out on one of the Criterion Garand barrels I got last year, in lieu of the usual pull-through reamer I use to chamber these guns. I hope to get a finish similar to the one on the pre-cut portion of the Criterion chamber, then to polish it mirror smooth and see how the brass behaves vis-à-vis Al’s calculation. When I have brass that's been through several load cycles in this chamber, I'll section some and post photos so you can see how it's doing.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

|

#40 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

I've loaded .308 Win ammo using new Federal nickel plated cases with IMR4064 powder charges more than 10% below max and had the fired cases come out with shorter case headspace (head to shoulder datum length) than what they were before firing. 1.629" new, 1.625" fired. Proof to me the firing pin drove the case hard enough into the chamber shoulder to set the shoulder back a few thousandths before the round fired.

But the chamber pressure was only enough to press the front part of the case body hard against the chamber wall holding it there and the the back part didn't stretch back enough to push the case head against the bolt face. The primer had pushed out a few thousandths from being flush with the case head. Go figure...... |

|

|

|

|

#41 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Sound like overall low pressure from the primer description. Surprising from just a 10% reduction. It would have been interesting to measure the Pressure peak value.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

|