|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: September 6, 2013

Location: JAX, FL

Posts: 377

|

help, cast bullets for odd number land barrels

concerning revolvers with odd number lands/grooves, short of taking a slug to a machinist, or sending the slug off to one of the custom bullet manufactures to be measured, how can I match bullet to barrel?

or should I forget the barrel diameter, and just go with the correct diameter bullets that just passes through the cylinder throats. the problem with this is what if I have undersized throats? or if I have generous/large throats, should I be pushing softer or harder lead? I must admit I have become a bit frustrated finding the right combination of bullet size, hardness, load, and powder which will not lead. Both guns have been fire lapped to remove thread choke and roll mark constrictions. At any rate this is what I have done and what I think I have fingered out. Guns are: Ruger Speed-Six, 4" .357, throats via pin gauges: .358 (.3578") snug but will still just pass with coaxing. S&W J frame, 2" snub .357, throats via pin gauges: .358" (.3578") pass easily but the .359 pin gauge is a definite no go. I am not yet a caster so I am trying to use what I have on hand. I currently have: SNS .358" (.3584-.3586") 158 gr, RNFP, Hi-Tek coated, 16-17 BNH. Unknown source 158 gr, SWC, measuring .3577", finger nail dent hardness. the SNS bullets will not pass thru the cylinders on either pistol. Duh! While the SWC's fall through all cylinders on both revolvers. I swaged a SWC .3577" into the muzzle of each gun and poked a bore light into the breach looking for light seepage: S&W no seepage, but no visible scuff or contacts marks on one groove. Ruger Speed Six has light seepage all around. I swaged one of the SNS coated bullets into the Speed-Six and had no light seepage, but two of five grooves did not show any contact marks. Here are my conclusions: 1. Lack of scuff marks on bullets while no light seepage is probably slightly out of round bullets and isn't critical. 2. Ruger Speed-Six has undersized cylinder throats. Options are to find a gun smith to measure and ream cylinder throats to .001" over bore size, or ream myself attempting to match the size of the SNS coated bullets. 3. S&W is ready to shoot the SWC's as is (using Ben's Red lube). With properly sized (hand honed) Lee bullet die the SNS bullets can probably be used. Magnum loads soon become brutal in that little S&W I so will be loading either 38 spl, or 38 spl powered 357. Powder "on hand" options are Unique, Titegroup, and Blue Dot. Which is best for finger nail dent hardness bullets? FYI finger nail dent details. pressing without motion on flat nose = barely discernable. with rocking motion a more obvious dent. on the edge an obvious dent. By comparison they are definitely harder than 11 BHN fire lapping bullets. thoughts, corrections, and recommendations??? added by Oley; OK I think I must have something wrong with my thought process concerning the Ruger Speed-Six. Or so me thinks. I just remembered I had failed to try passing the barrel swagged bullet back through the cylinder throats. Surprise, it passes through all six cylinders without resistance. So that has to mean my cylinder throats must be equal to or very slightly larger than the barrel grooves. So now all I need to do for fit is lap out a sizing die to allow the bullet to pass through the cylinder throats with light pencil eraser pressure. Right? Last edited by oley55; February 19, 2015 at 03:51 PM. |

|

|

|

|

#2 |

|

Senior Member

Join Date: September 12, 2002

Location: Twin Cities, MN

Posts: 5,313

|

Just a note on Titegroup, I tried it a while back and gave up on it too soon.

I was loading powder puff .357 148 grain wadcutters and got a LOT of smoke. I’ve been told since (and I believe it) that moving up the charge would have reduce the amount of smoke and odor I was getting. I’ll probably give it another try in the future. |

|

|

|

|

#3 |

|

Senior Member

Join Date: February 7, 2009

Location: Southern Oregon!

Posts: 2,891

|

I have a lot of experience with micrometers so this may or may not help. I have fairly accurately measured odd number rifling, by slowly turning the slug in the micrometer. I have a pretty good "feel" so I can tell when the drag of the tips against the slug are giving a correct measurement. Some will use a known shim stock thickness (say .005") to wrap around the slug, then measure and subtract twice the thickness of the shim stock (measurement minus shim stock on both sides of the slug equals slug diameter. Say a slug with a .003" shim wrapped around it measures .363". Subtract .006" and you have the slug size, .357".)

I have never liked "finger tight", about", "snug" or "finger scratch" (your fingers or mine? newly clipped or 12 days old? 25 year old fingers or 68 year old fingers? After 2 cups of coffee or three beers?) as measurements as they really mean nothing and it's easy to figger out/measure items in real measurements... Use micrometers to measure slugs/bullets. Use pin gauges or expanding ball gauges to measure cylinder throats. Make very sure you need to ream throats before you start removing an metal from your gun. Scuff marks come under the "WTH does that mean" heading. Don't rely on forum info for your gun's dimensions, measure them.

__________________

My Anchor is holding fast! I've learned how to stand on my own two knees... Last edited by mikld; February 19, 2015 at 02:00 PM. |

|

|

|

|

#4 | |

|

Senior Member

Join Date: September 6, 2013

Location: JAX, FL

Posts: 377

|

Mlkd,

can't say how many times I tried to accurately measure those odd grooves. I know I wore out a couple swagged slugs in the process. perhaps if I were using a larger caliper with larger pads it could bridge (catch) the edge of the opposing ridge better, but still some wagging going on. on the use of a shim material, I do not follow. If I wrap a shim around an uneven surface won't I still be measuring the low and high surfaces? I have tried using a feeler gauges as a shim by sliding it into the groove but it was too cumbersome, and too I was wagging it again (eye balling) a flat gauge on a cylindrical object up against the ridge trying to match the height. reference: Quote:

just saying.... just saying....and to be certain I am a loooong way from removing metal. I been chasing this dog for months and ain't caught him yet. |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: April 8, 2000

Posts: 2,101

|

Oley,

I'm not going to say your sweating the small stuff a little too much as everyone wants something different out of their experience. Me however, I hunt with my revolvers which means I DO want the best accuracy I can get out of them, but I have not slugged but one of them and that was my 45 Colt and I only did that one due to all of the horror stories I head about Ruger's. Guess what, it was right on the money at .452". The bore was nice and smooth with no tight spots. Now then, I also have two GP-100's, a couple of 38 SPL's, and a few other .357 barrels for my Contender. I haven't slugged any of them and I get some darned good groups from them all using a variety bullets of various alloy. But I don't use anything harder than a 14BHN in any of them no matter what. I have run plain based 11 BHN bullets up into the 1350fps range out of all of them with no problems that I can contribute to their .358" size. I use both a Lyman and Lee sizers on them and get the same results. With my 41 though I did have a fellow measure everything for me, and it came out at .410" just like it should have. But I wanted to make SURE and CERTAIN since the first time I ran cast through it, it took me a week to get all of the remnants out from only firing 5 rounds. Then not long ago I ran some REAL soft alloy through it using a top end load. One of those I knew better but had to see for myself things. Well I saw alright. It looked like this after 4 shots, I know that looks terrible, but it cleaned up in about 10 minutes to nothing left to see. As a side note to that though. I recently shot the same alloy using the same loads only with a different lube on 25 of them and 25 of them powder coated, I had nothing but powder residue after any of them. I loaded them in 5 round groups starting with the minimum load and worked up to max in .5gr increments. I checked after the first, third, and fifth shot on each increment of each batch, and cleaned in between to bare bore. Nothing what so ever accumulated through the whole test. To be honest, I would load up some of your bullets using the Unique and go have fun and see what they will do.

__________________

LAter, Mike / TX |

|

|

|

|

#6 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Oley,

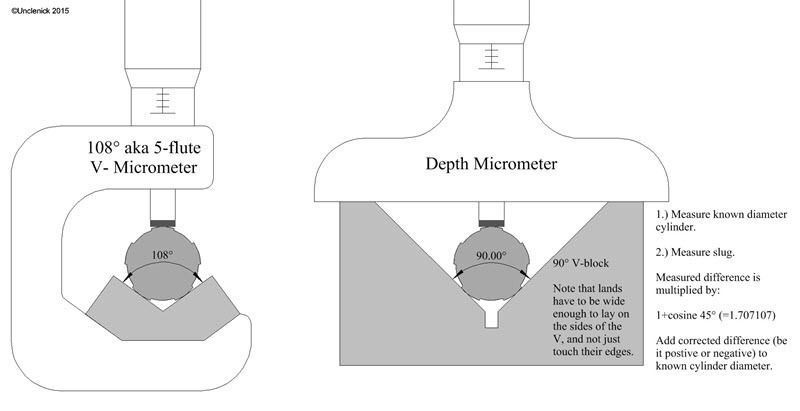

There are several methods available to you. Toolmakers have the problem of having to be able to measure the diameters of 3-flute and 5-flute end mills and taps and reamers, so special V-mic's are made for the purpose, with 60° V-anvils for the 3-flute tools and 108° V-anvils for th 5-flute tools. This is not a high volume tool, though, so the good ones are in the $500 range pretty often. I did find some for under $120, but they have no Vernier scale, so you have to be good with your eye to split thousandths on them. If, like my K-38, you have lands and grooves of near equal width, then you may be able to get away with using a common V-block and a depth micrometer, which combination should cost you about half what V-mic does if you don't already have them. The main thing is that the groove impression on a lands at the bottom be in good contact with the sides of the V. If the groove impressions are narrow (unlikely) you could miss and park a corner on the V-block. I use this method and have never had that happen, though. In the drawing below, the V-mic is on the left and the V-block method is on the right. You put in a rod or cylinder of known diameter, like a hardened and ground dowel pin or a drill shank or anything else you can measure accurately with a standard micrometer. Take the difference between that reference measurement and your slug's measurement and multiply it by the multiplier factor and then add it to the reference cylinder diameter. That will be your slug diameter. The formula I gave assumes you V-block is exactly 90°. You can check this by measuring a second reference cylinder of known diameter and dividing the difference in those diameters by the difference reading you get on the depth mic, and this will give you a multiplier customized to your tools.  A third method that will get you very close is to chuck the slug in a drill press and turn the spindle by hand as a dial indicator drags over its surface to fine the average height of the groove impressions measured. Then use a micrometer to measure the slug from land to groove impression and add that height result to this measurement. (You will do best to take the diameter measurement first and write it down, as the drill chuck may partly deform the slug.) NIck

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#7 |

|

Senior Member

Join Date: September 6, 2013

Location: JAX, FL

Posts: 377

|

Uncle Nick,

many thanks, you obviously put a good bit of time into this and it is much appreciated. I suspect these diagrams will be helpful to many others. now I know how to articulate what is needed, and will be on the lookout for a deal on the right tool/s. Last edited by oley55; February 21, 2015 at 10:02 AM. |

|

|

|

|

|