|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#26 |

|

Senior Member

Join Date: October 23, 2005

Location: US

Posts: 3,652

|

Can I say it also depends on the brass. I get 5 firings max out of federal brass with very warm (but not over book max) loads in .270. After that I pitch em as primer pockets are opening up. Some pieces have loose primer pockets after 3 or 4 firings.

No hard bolt lift. Can shoot 3 firings with neck sizing. I’m at the max for that gun I think, but I’m not in dangerous territory. I have .223 going on the 10th firing with no issue. Some 8x57 into the 6th or 7th firing with no issue, and I load 8mm above most anemic book listed max. .223 is mixed brass (I’ve had to toss a few, most are good) and 8x57 is PRVI.

__________________

Support the NRA-ILA Auction, ends 03/09/2018 https://thefiringline.com/forums/sho...d.php?t=593946 |

|

|

|

|

#27 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

I've got 20+ loads per 308 Federal case with listed max loads; 47 on one before I ran out of powder. Primer pockets still tight.

Depending on the powder lot chemistry, bullet release force, bullet and bore/groove diameters plus pressure measuring methods, a given book max load can be well over maximum pressure specs when all those variables add up. People developing book loads don't use our stuff and we don't use their stuff. All book maximum listed loads for a given powder are not developed with the same stuff and don't have the same charge weights. Asked a Dupont rep about their IMR rifle powders charge weight spreads to produce a given pressure. He said about 4% for commercial canister lots but bulk lots used at Lake City army ammo plant about 8%. Last edited by Bart B.; July 31, 2019 at 11:22 AM. |

|

|

|

|

#28 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

Before the Internet: Case head expansion with factory ammo was .00025". Today that means nothing but back before the Internet a reloader could determine if his loads were close to factory loads. I have fired cases loaded once that had .010" case head expansion. Forget the primer pocket, the flash hole and the thickness of the case head from the cup above the web to the case head. When the case head was crushed and the case body was locked to the chamber the case was well on its way to suffering case head separation. F. Guffey |

|

|

|

|

|

#29 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

Agreed on 20 x for 30-06 and 308 cases.

I use mostly RP, they do well, good quality and my take is they are as good as Lapua. I do the off maligned minimum shoulder bump back. You are welcome to disagree of course. My once fired RP is in better condition that the bulk Lapua I get and I have yet to duplicate the Lapua dents even dropping cases.

__________________

Science and Facts are True whether you believe it or not Last edited by RC20; August 1, 2019 at 11:56 AM. |

|

|

|

|

#30 |

|

Senior Member

Join Date: September 2, 2010

Location: Plainview , Long Island NY

Posts: 3,863

|

I haven't had problems with any brands , maybe because I loading light loads . Remington brass I found were on the thin side and being I'm loading light the thicker brass using IMR 4064 filled the case to the bottom of the necks 40.8 grains . Cases are FC , ADI and HSM .

|

|

|

|

|

#31 |

|

Senior Member

Join Date: March 23, 2017

Location: Northwest Indiana

Posts: 831

|

cw308, yes I'm trimming to same length. When you say "chamber fired clean case then size down..." are you referring to trimming it down? I do use the RCBS Trim Pro-2 Manual Case Trimmer. I clean after a range trip (few days after or before range trip). Yes, the bolt at times does feel a bit rough, not for every round though when I get a rounds through the barrel. To be honest don't count.

|

|

|

|

|

#32 |

|

Senior Member

Join Date: March 23, 2017

Location: Northwest Indiana

Posts: 831

|

5whiskey/Bart B., thanks for your reply.

------ F. Guffey, I am guilty of that as well. I don't measure case heads. ------ RC20, is the shoulder bump a necessity? I do read here and online regarding shoulder bump. |

|

|

|

|

#33 |

|

Senior Member

Join Date: October 23, 2005

Location: US

Posts: 3,652

|

The “minimum shoulder bump” RC (and I in most cases) uses allows for ammo that very closely matches chamber dimensions, sizing the case only enough so that there is just enough case head clearance for reliability in chambering while not over sizing the case. Oversizing works the brass more than needed, and theoretically more case head clearance than needed is less accurate. Not “bumping” the shoulder at all will eventually lead to brass that is difficult to chamber.

__________________

Support the NRA-ILA Auction, ends 03/09/2018 https://thefiringline.com/forums/sho...d.php?t=593946 |

|

|

|

|

#34 |

|

Senior Member

Join Date: March 23, 2017

Location: Northwest Indiana

Posts: 831

|

Thanks 5whiskey... will look up a video on shoulder bump. There should be some videos on youtube about this.

|

|

|

|

|

#35 |

|

Senior Member

Join Date: September 2, 2010

Location: Plainview , Long Island NY

Posts: 3,863

|

nino

Sorry the a was missing " chamber a fired clean case " . Its so your not oversizing a case . You can setup your die letting your F/L die bottom on the shellholder , that case is most likely over sized by a few thousands but you will feel the case chambering without resistance . The goal is , is to have that same feel with .001 to .002 headspace . If your neck sizing only , at some point you will have resistance from the case being expanded , slowly F/L size it down until it chambers . |

|

|

|

|

#36 |

|

Senior Member

Join Date: March 23, 2017

Location: Northwest Indiana

Posts: 831

|

When I set the F/L die... I back up the die about one full turn to avoid crimp. Does this somehow take a toll on the brass?

------ So I found this video from the many out there: https://www.youtube.com/watch?v=V2Wt8-VqeAE |

|

|

|

|

#37 |

|

Senior Member

Join Date: December 10, 2014

Posts: 1,965

|

The F/L die doesn't crimp. The seater die crimps.

One turn up of the seater die will not harm the brass in any way. |

|

|

|

|

#38 |

|

Senior Member

Join Date: March 23, 2017

Location: Northwest Indiana

Posts: 831

|

Sorry... yes I meant the seater die. I do one full turn on the seater die, not the F/L die.

|

|

|

|

|

#39 | ||

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

I understand length of the chamber from the datum to the bolt face is beyond a reloaders ability to understand. For me? I know what the length of the chamber should be and I know how to determine what the length of the chamber is. The difference is another of those difficult to understand terms called clearance. I have chambers that are short, just right, long and 'too' long; for most this causes problems for reloaders. Not for me; I can sizes cases for short chambers, chambers that are just right, too long and I sometimes form cases for chambers that are tooo long because my cases do not have head space, Quote:

F. Guffey |

||

|

|

|

|

#40 | |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

Quote:

Feel free to keep beating your head against the wall. I believe Einstein once said "Futility is doing the same thing over and over again and expecting a different result"

__________________

Science and Facts are True whether you believe it or not |

|

|

|

|

|

#41 | |

|

Senior Member

Join Date: December 10, 2014

Posts: 1,965

|

Quote:

He did state a real world experience. Think about the landing before you jump off the cliff. |

|

|

|

|

|

#42 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

"By the time the case needs full length sizing it has increased in it's ability to resist sizing."

Easy to understand knowing: * what causes bottleneck case's bullets to be best centered in the bore when fired. * how to get long case life. ...then doing all the right stuff to accomplish those objectives. Last edited by Bart B.; August 23, 2019 at 03:06 PM. |

|

|

|

|

#43 |

|

Senior Member

Join Date: December 29, 2015

Posts: 387

|

If you don't have a set of Hornady headspace comparators, suggest you get them. Some people don't like 'em some do. Utube has some good videos on how to use 'em.

Find one or more of the fired cases that still fits in the chamber and the bolt will close easily, or to your satisfaction. Use the Hornady comparator and measure that case(s), the measurement shown on the caliber & comparator will be what those brass cases headspace measure out to. This should be your "target" for setting your FL sizing die, and then FL size another brass case that does NOT allow easy bolt closure. After FL sizing that case, test it in the rifle and measure it with the comparator tool. It should be very very close (.001-.002) difference to one of the cases that DID fit with easy bolt closure. Then do another case that did not allow easy bolt closure, measure it with the comparator, FL size, measure again, and test fit in the rifle. Each brass case may/may not resize to the exact same measurement, but should be within the difference noted above. |

|

|

|

|

#44 | |

|

Senior Member

Join Date: August 23, 2010

Location: US South

Posts: 857

|

Quote:

Cut one of those cases in half across the diameter top to bottom. See what that ring really looks like inside. Hey >>> and post us a pic.

__________________

Ray |

|

|

|

|

|

#45 |

|

Senior Member

Join Date: September 2, 2010

Location: Plainview , Long Island NY

Posts: 3,863

|

Knowing your chamber length by using a Go Gauge and using shims until your bolt closes with a slight resistance , use that measurement for sizing your cases. My 308 chamber is 1.632 the Go Gauge for 308 is 1.630 , I size my cases to 1.631. You can do the same thing with a clean fired case that doesn't chamber in your rifle , make sure the primer is removed . Back out your sizing die and size your case down until it chambers with a slight resistance , best done with a stripped bolt . That measurement you can size .001 on up

|

|

|

|

|

#46 |

|

Senior Member

Join Date: March 23, 2017

Location: Northwest Indiana

Posts: 831

|

I don't have the Hornady headspace comparators.

------ Will look up a video on the Go Gauge. |

|

|

|

|

#47 |

|

Senior Member

Join Date: March 23, 2017

Location: Northwest Indiana

Posts: 831

|

RaySendero, why didn't I think of that. Will try that. Thanks.

|

|

|

|

|

#48 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,875

|

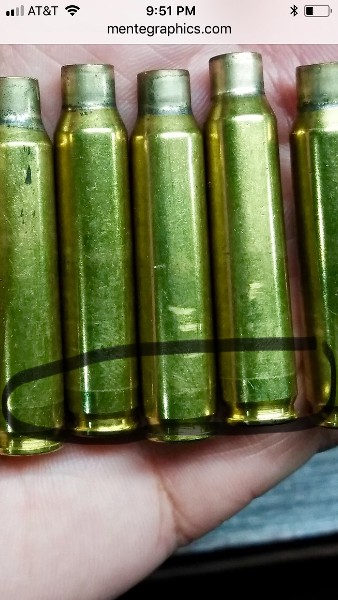

I don't know about you guys but just about all those look like there about to have casehead separation soon ??? Those just look way to crisp and sharp to be from firing and what you sometimes see at the unsupported area of the case .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; August 26, 2019 at 01:37 AM. |

|

|

|

|

#49 |

|

Senior Member

Join Date: March 1, 2009

Posts: 4,232

|

cut one open lengthwise MG

__________________

“How do I get to the next level?” Well, you get to the next level by being the first one on the range and the last one to leave.” – Jerry Miculek |

|

|

|

|

#50 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Those cases look very normal to me. That ridge, usually called the "pressure ring," is where the case body expanded against the chamber but the back 2 tenths inch of the case did not expand.

All my cases with many reloads look that way. Same for everyone getting dozens of reloads per rimless bottleneck case. I've cut a few cases to see all is good inside. Such is life with minimum SAAMI spec chambers and proper dimensioned full length sizing dies set right in the press. Usually, if that fired case pressure ring diameter is sized down more than .0015" by the die, the chamber is too big or the die is too small. The only way to eliminate that pressure ring is to have chamber body diameters exactly the same as new case bodies. Last edited by Bart B.; August 26, 2019 at 07:44 AM. |

|

|

|

|

|