|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

Powders That Accelerate Barrel Wear?

I have come across reference to that statement but have not seen anyone list the powders that do.

We also have a lot of new powders from the VV line to R17 (not the standard R series powders but all of its own) and are the other R powders diffferent as well? Ergo, 4350 is a slower though standard rifle powder and R17 is close to the burn rate though a lot different characteristic due to its makeup. Rather than vague slow vs fast etc, can anyone shed light on this using specific power mfg and type (i.e H4350 vs Reloader 17). Winchester Ball powder (double base) vs single base And how much a percents difference to the point is it an issue. If there is some reality based experience out there that allows you to maximize barrel life with more or less mid to a bit sub mid level loads or does just doing that (mid level say) make more difference than a powder type? Last edited by RC20; April 20, 2014 at 01:16 PM. |

|

|

|

|

#2 |

|

Senior Member

Join Date: August 3, 1999

Location: Houston, Texas

Posts: 2,991

|

It is a very interesting topic of which I am a student. Please take the following as my summary based upon what I have read and experienced.

Ball powders tend to be harder on barrels than other shapes. It is due to the ball powders burning at high temps and getting blown down the barrel vs. extrduded/flake/rolled powders jamming up in the case and not going down range. Higher nitroglycerin content, hotter burn, worse for barrel Double based powders are harder than single based powders due to higher nitro. These are just observations and concepts. I use them but others may disagree.

__________________

10mm and 357sig, the best things to come along since the 38 super! |

|

|

|

|

#3 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

Well said, definitely always learning.

|

|

|

|

|

#4 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

Powder doesn't matter nearly as much as HOW a barrel is shot.

With a low pressure round, below 45k PSI, no one I've ever come across has noted any difference in barrel life between flake, ball, and stick powders. With a high pressure round, 55k and above, accuracy can be degraded extremely quickly the more "overbore" the cartridge. For example the 6.5x284 is a "barrel burner" compared to the 6.5x55 Swede, even though the 6.5x284 only has 9 grains of case capacity on the Swede, it is the extra pressure that kills barrels. Now in theory ball powders are the worst because of a "sandblasting" effect on the bore as unburnt and burning powder is slammed into the barrel steel at high pressure. In reality this is such a minor consideration that no one has ever been able to accuractly quantify it. For a while Winchester was advertising longer barrel life from their ball powders because peak temperature was less than some comparable stick powders. However I think that Winchester has backed off of that claim. For what it is worth, I'll continue to use both ball and stick powders for rifle loading. For pistol it doesn't seem to matter as the pressures aren't high enough to cause noticeable barrel wear (although there are some pistol shooters who just plain shoot enough to wear out a barrel!). Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#5 | |

|

Senior Member

Join Date: March 8, 2013

Location: Ohio

Posts: 1,820

|

I have always been under the impression that barrel wear was increased by friction as far as the Lands and grooves go, Fatigue leading to structural failure is a whole other thing IMO. The higher the friction, the higher the wear. Two things that come to mind that increase friction and that is higher velocity and the Coefficient of Kinetic Friction. Depending on he barrel material and the bullet material the Coefficient will change. Also the kinetic Friction will increase with velocity.

If there is any truth to this statement: Quote:

Here is an interesting read. Be sure to check out page 12 as well...http://www.google.com/url?sa=t&rct=j...WatProyYIcNDNg

__________________

If you ever have to use a firearm, you don't get to pick the scenario! |

|

|

|

|

|

#6 |

|

Senior Member

Join Date: January 2, 2009

Location: Northern Virginia

Posts: 922

|

I believe that heat at the mouth of the chamber is the biggest culprit to barrel wear and not friction of the bullet causing wear in rifling. Of course, loading to stay away from constantly shooting super hot loads might also cause even more heat at the chamber mouth and accelerate the barrel wear and further reduce barrel life.

My statement is based on extensive measurements using my .308 Savage 10 FP that was one of the first Law Enforcement models that Savage sold. Apparently, in those days, Savage built rifles with deep chambers. My newer Savages have much shorter factory chambers. I always loaded my early Savage towards the middle to middle-high end of the loading tables with everything from 150 grain to 190 grain bullets. I used about 8 different powders and a large variety of bullets trying to find the best combination. I was the rifle that I learned to reload with and, because it had such a deep chamber depth from the factory, I wound up loading way more rounds than I have with any other rifle that I load for. I found it had three node ranges with some bullet type and the OALs were 0.030 to 0.040 apart from around SAAMI recommended OAL to really long. I was able to shoot lots of rounds through the original barrel and after about 6000 - 6100 rounds, the accuracy started to drop off from an overall average just over 0.5 inches at 100 yards. For the first 6000 rounds, the top 25 loads average under 0.44 inches at 100 yards. Loss of accuracy happened very quickly. The last 200 round averages were closer to 0.7 inches for the better performing loads so I got the barrel replaced by Savage. After 6300 rounds on the old Savage barrel, a bore scope showed that the rifling on the old barrel still looked like it was deep and clean so rifling wear wasn't the reason for the loss in accuracy. But the chamber measured 0.090 longer than it was when new. The chamber was eventually so deep that there was no way the bullets could be seated long enough to be within 0.020 of the rifling and still have enough bullet in the neck to keep neck tension consistent. Loading for maximum length that would keep the bullet still in the neck wound up with a longer and longer jump to the rifling and that, I think, led to the eventual drop in accuracy. The new Savage barrel is slightly more accurate than the old barrel was when new and the chamber is much shorter so I didn't have to shoot so many rounds to find the all the nodes - there is only one node range before the bullet is lodged in the rifling. In fact, when the replacement barrel was new, some factory ammo had to be seated 0.015 deeper in order to keep the bullets from jamming into the rifling when the bolt closed. After over 600 rounds through the new barrel, the chamber has already grown 0.010 inches in depth. |

|

|

|

|

#7 | |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

Quote:

However with something that gets fired very rapidly, such as a machine gun, powder temperature matters more than a match rifle, in terms of barrel wear. To illustrate why it is so hard to quantify that, If you max out a 200 degree difference between ball and stick powder, then you are at a 1/16th difference in temperature, so you could in theory fire 106 rounds with ball powder for the same heat transfer that 100 rounds of stick powder would put into the barrel. Considering that barrel changes are mandated every 200 rounds for rapid fire, or every minute, the 200 degree difference is negligeable and the manuals don't specify any difference in barrel changes based on powder used in the ammo. However, as the barrel heats up the chamber heat will change the burn characteristics of the powder, so this 6% difference isn't a fixed difference. As folks who have noted, single base powders generally have better temperature stability than double base powders (IMR 4064 is better than Re15 in a 308 Win for example), so even this gap will narrow as the steel heats up. Sorry for the "back of envelope" calculations, but it frames the issue of powder heat and barrel wear. Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 18, 2011

Location: SE VA.

Posts: 216

|

I agree with all of the previous posters on this topic. The only thing I can add is that from my experience RL17 has been easier on my Savage rifles than IMR4350. Once I started using RL17 the throats of my rifles did not wear as rapidly. I check my two rifles about every 200-300 rounds. I started to notice that there was less measurable throat wear after shooting RL17 than IMR4350. I know this isn't the most scientific analysis but are my observations. .243 tend to wear fairly rapidly so they are good candidates for these type of observations.

|

|

|

|

|

#9 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

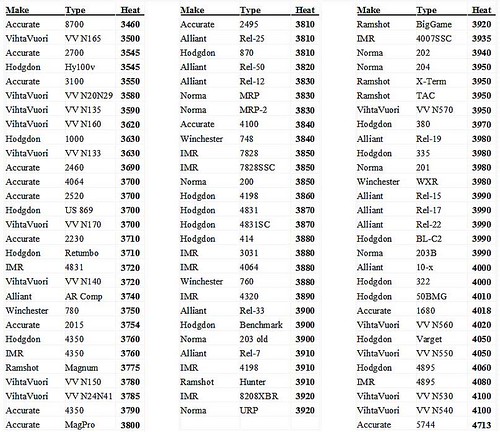

Here's a list of powder heat indices used by QuickLoad to compute pressures. These numbers were cranked into a barrel life spreadsheet to calculate approximate barrel life for different bore diameters and powder charge types and weights. For a given cartridge and pressure level in the same barrel, powders with higher heat numbers gave less barrel life.

Comparing the head index for IMR powders 4064 to 4895, that explains why competitive shooters got more barrel life using 4064 than 4895 in their .308 Win and .30-06 cartridges. And why IMR4350 was the favorite for 30 caliber magnum's barrel life as well as excellent accuracy for long range competition. Last edited by Bart B.; April 21, 2014 at 02:42 PM. |

|

|

|

|

#10 | |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

Quote:

Which was my point to begin with, the reason why you can't make a judgement on which powders are "harder on barrels" than others is that there are more factors involved than just powder type. I apologize if I wasn't clearer on that point before. Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

kerrect, what cartridges did you use in your comparisons betwen INR4350 and RL17 for erosion?

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 18, 2011

Location: SE VA.

Posts: 216

|

My comparison was with .243 using Nosler 80gr ballistic tip. I loaded to try and achieve the same velocities with each powder and I came pretty close. I have no way to measure pressure but have a chrono and came within 100fps. which made me happy. This was just one of those "I wonder what if" sort of things. Careful but by no means scientific.

|

|

|

|

|

#13 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

I just remembered to get back to this.

Thank you all for the contributions, interesting and unsettling as the powders I use of the most part (H4831 and R17) are in the higher end of the heat index. More specifically 52 gr of H4831, IMR 4350 and 50.5 of R17 in 30-06 using 175 gr Sierra match. |

|

|

|

|

#14 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

RC20,

I wouldn't worry. It isn't just heat. It is heat AND pressure AND barrel temp AND carbon buildup AND nitrile surface contamination AND heat checking AND mechanical wear AND primer residues AND bullet friction AND a whole lot of other stuff too. Heck, when you take a look at IMR4895 and H4895 you see they have a high heat number compared to IMR4064. The heat at which the powder burns doesn't matter so much as the total heat from the charge weight as spread out over the pressure curve. A few extra milliseconds of burn time is a pretty insignificant source of heat compared to the resulting pressure that is pushing the bullet down the bore. Hope this helps put things in perspective. Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#15 |

|

Senior Member

Join Date: May 18, 2011

Location: SE VA.

Posts: 216

|

I assumed there were more factors than powder causing barrel wear. The only reason I started measuring was that I had read that .243 were "hard on barrels". I got curious about how hard. In the end there is very little I can reasonably, do. This is a hobby. I will shoot the loads, I like and I will continue to experiment with knew loads. Thanks, this has been real interesting. I am always impressed with the knowledge of fellow contributors.

|

|

|

|

|

#16 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Those heat indices need the same pressure to be meaningful. A powder with a higher heat index at lower pressure may well give more barrel life than a load with higher pressure with powder that's got lower heat numbers.

Competitive shooters using the .243 Win got half the barrel life as those using the .308 Win; 1500 vs. 3000 rounds. |

|

|

|

|

#17 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

thank you. As korreckt noted, its an intersting subject and responses and info.

I have to manage my Mil Surplus collection as someday most of it gets sold. Long term plan is to get a dedicated 30-06 shooter to do most of it and then if I need to replace that barrel its not a collector value issue. |

|

|

|

|

#18 |

|

Senior Member

Join Date: January 16, 2010

Location: Minnesota

Posts: 3,577

|

Non Scientific here- I use RL-15 in my 308 and 6MMBR. Due to the lack of RL-15 latley I have been forced to try other powders. Last week I tried RL-17 in the BR with 107 Serria's. I found powder charge had to be boosted almost 2 grains higher then Varget and RL-15 to get accuracy I was used to. I think as others have posted- Your shooting habbits are more imortant than the powder in the long run. My 308 has well over 3500 rounds down it and will still take a golf ball 9 out of 10 times at 300 yards. I have no way to measure chamber wear, I can say after 3500 plus rounds I still set my bullet to same length as when new with no drop in accuracy. I shoot 5 rounds and let cool always before next 5 rounds.

I know some say this or that caliber is a barrel burner, but makes you wonder. My 243 has about 3000 rounds and is still going strong as can be. My 6 br had over 4000 rounds down it before I replaced the barrel. And I did not replace it due to accuracy issues.

__________________

NRA Certified RSO NwCP- Performance Isn't Optional |

|

|

|

|

#19 |

|

Senior Member

Join Date: December 10, 2012

Posts: 6,165

|

FFFG will really accelerate your barrel wear.

|

|

|

|

|

#20 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

I can help you there.

Steven Mathews makes a TE (throat erosion) MW gauge. While eit may not be right for you gun, if you take a measurement and log it, you will see the progression of wear. Some also do it using a bullet depth seater and log those results. I have the gauge so I keep an eye on things with that but so far I have spread the shooting out between rifles so its not been a factor. |

|

|

|

|

#21 |

|

Senior Member

Join Date: September 15, 2007

Posts: 1,707

|

This is an interesting academic discussion, and for that part of me where frugality reigns supreme, of acute interest.

After reading this and reflecting a moment, I shrugged my shoulders and remembered that barrels are wear items, and will need to be replaced from time to time. Not unlike pistons and rings in antique motorcycles. I will have to admit to an internal struggle between frugality and practicality, but I must keep in mind that the best approach I know of is to do my best to keep the carbon ring out of the throat, clean the bore as necessary, and shoot the things until it is time to replace the barrel. I use bore brushes, as they clean the bore more effectively than plain solvents. These cause wear. Some say they will degrade accuracy by eroding the crown of the muzzle. I use RL17 in my 6.5x47 Lapua because it offers good accuracy and velocity. It is supposed to be a barrel burner. I have used VV N540 as it is a super great powder, but I can't find any right now...  Also a barrel burner. Also a barrel burner.The bore will wear out. The throat will be eroded, this is the nature of things. One thing nobody has factored in here, or maybe it is implicit in the initial question, but I remember reading that shoulder angle has a lot to do with the wear in the throat area of the barrel. Somewhere I saw it opined that the blast of hot gasses will pretty much focus on a point at the center of the diameter of the cartridge where the imaginary lines paralleling the shoulder angle of the case meet. If this angle converges within the case neck of the cartridge, this will reduce the erosion of the throat. This being one of the purported benefits of a steeper shoulder angle. On the other hand, a longer, more tapered, shoulder of a cartridge, combined with a shorter neck, where the focal point of the convergence of the hot gases is outside the case neck, in the leade proper, there you will find greater erosion. When I was a high-power competitor, the common wisdom on the firing line was that the replacement of a barrel was a factor of how much powder was shot through it, an folks opined at that point in time that it wasn't the bore diameter, or the charge weight, but factored in barrel replacement at 16 pounds of powder, of whatever sort, down the bore. |

|

|

|

|

|