|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Member

Join Date: January 11, 2010

Location: Seattle, WA

Posts: 45

|

How do you measure Lands and rifleing

Been reloading for about 3 years now, but mostly .223 for an AR and pistol stuff. I got a new 300 win mag model 700cdl and now Im more interested in fine tuning my loads. To tell you the truth Im not 100 percent sure exactly what the lands are? Ive read to loosely seat a bullet chamber it and let the rifleing seat in down, then jst back it out .1" and see if it fits in your box, but I cant really feel it seating. Help or suggestions would be greatly appreaciated. Thank in advance.

__________________

Trust me...I do this all the time

|

|

|

|

|

#2 |

|

Senior Member

Join Date: January 23, 2006

Location: GA

Posts: 1,862

|

|

|

|

|

|

#3 |

|

Member

Join Date: January 11, 2010

Location: Seattle, WA

Posts: 45

|

Oh wow. Thats nice!

__________________

Trust me...I do this all the time

|

|

|

|

|

#4 |

|

Senior Member

Join Date: November 12, 2008

Location: Fort Worth, TEXAS

Posts: 909

|

The link you have been provided with is to a good product. Remember one thing when using the OAL guage though... the case that is drilled and tapped for the OAL guage will probably have a different length to the datum line when compared to a case that has been fireformed in your rifle. You musn't forget to take this into consideration when calculating your final OAL.

For instance... my fireformed 270 cases are about .005" longer (to the datum line) than the Hornady drilled and tapped case. Therefore, I must add and additional .005" to the COL when seating bullets with fireformed cases. |

|

|

|

|

#5 |

|

Member

Join Date: January 11, 2010

Location: Seattle, WA

Posts: 45

|

Thanks Tex, I would like to think that I would of checked that, but...Ive suprised myself before

__________________

Trust me...I do this all the time

|

|

|

|

|

#6 |

|

Member

Join Date: January 6, 2010

Location: Houston

Posts: 70

|

Everybody has their favorite and this is mine. It is the C.O.L E-Z Check tool ($25.00 4 years ago) from R-P Products 318-424-7867 r_reeves61#bellsouth.net shown here with the Hornady (formerly Stoney Point) OAL gauge

It is a stainless rod with a brass tip that you can take off for caliber under 257  and 2 lockable collets. Instructions are to insert the rod down to the bolt face (make sure the bolt is cocked so the firing pin is retracted) and lock the outside collet  insert the bullet to the lands with the Hornady tool, a pencil or a dowel to hold it there  reinsert the rod down to the bullet tip and lock the inside collet  and measure between the collets  it is foolproof which helps me out and will work for all your guns (except possibly the 204 or 17. It takes away the headspace you have to allow for with the Hornady modified cases and gives you 2 hard smooth surfaces to measure between unlike the marked cleaning rod method where you are guessing at the measuring points on the edges of the tapes on the rod. The only variable left is how hard you push the bullet into the lands and how far it goes into the land, but that is the main variable with any method of measuring.

__________________

Guns have 2 enemies, rust and politicians |

|

|

|

|

#7 |

|

Senior Member

Join Date: October 13, 2009

Location: nw wyoming

Posts: 1,061

|

You can easily make one yourself for nothing in 5 minutes.

Take a FL sized case and with a Dremal or hacksaw cut 4 slices from the mouth down to the base of the shoulder. This gives you 4 fingers to hold your bullet. Use a chainsaw file or something like it to clean all the burs off and squeeze the "fingers" together for a little tension. Put in whatever bullet your using (leave it long) and chamber it to full battery. Carefully extract it and measure the length. I usually do this 2 or 3 times to make sure the measurement is the same. I would post I picture but I've never tried posting them before. I could have made 2 in the time it took me to type this.

|

|

|

|

|

#8 |

|

Member

Join Date: June 30, 2007

Posts: 85

|

Wouldn't it be easier to do a cerasafe cast of the chamber/throat?

Last edited by frogsaw; January 11, 2010 at 09:24 PM. |

|

|

|

|

#9 |

|

Member

Join Date: January 11, 2010

Location: Seattle, WA

Posts: 45

|

Thanks woods. The pics really help, hope you already had them and didnt do all that work for me

I think Ill order some of the good stuff, but until it gets here I wont be able to resist trying what RELOADER does. I think Ill order some of the good stuff, but until it gets here I wont be able to resist trying what RELOADER does.

__________________

Trust me...I do this all the time

|

|

|

|

|

#10 |

|

Senior Member

Join Date: October 13, 2009

Location: nw wyoming

Posts: 1,061

|

Its actually very easy and you can use them forever

|

|

|

|

|

#11 | |

|

Senior Member

Join Date: November 12, 2008

Location: Fort Worth, TEXAS

Posts: 909

|

Quote:

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: November 12, 2008

Location: Fort Worth, TEXAS

Posts: 909

|

Hey Woods,

Welcome to the forum! No to be argumentative, but I think your method of finding the OAL might be flawed. I cannot disagree that your method gets you "close enough", but I see a few drawbacks to it. 1) You must make sure that the rod is cut perfectly square on the end (obviously), otherwise your results will be skewed when the rod tip hits the bullets tip. Just for grins, lets say yours is .003" out of square. 2) Say that you determine the "to the lands" measurement in your particular rifle using your method is, just to make things easy, is 3.000". If you set that bullet to the lands every time your method can be sucessful because it takes the cases shoulder to chamber fit out of the equation. Picture the case head resting on the bolt face, and the bullet's ogive resting on the lands. It makes absolutely no difference where the case's shoulder is in this particular situation because you are making contact on the case head and bullet ogive, not the shoulder. Lets pretend that while the case head and bullet ogive are making contact with the rifle, the shoulder is .005" away from making contact with the corresponding part of the chamber. Now say you want to seat your bullet to be .010" off the lands. This is where your method can become problematic because now the cases shoulder can come into play. The shoulder can now move up in the chamber .005" (moving the bullet further up into the lands too) for a final measurement of .005" off the lands even though the COL is at 2.90". Add the variation from paragraph 1 (.003") plus the variation in paragraph 2 (.005") for a total of .008". To me, that .008" can be substantial, especially if you are wanting to be only .010" off the lands. I hope I explained that clearly. It is difficult for me to explain it via writing. As I said before, your method is definitely "close enough" for most folks, but the Hornady guage will let you get the get the COL measurement perfect, pending you remember to account for the datum line difference between the Hornady case and whatever case you are using. A set of Hornady's cartridge headspace guages allow you to measure the distance to the datum line using the case head as a reference point. I own a set of these guages along with Hornady OAL guage. These are priceless tools for the reloaders bench, and both can be had for around $50 total.  Next time I feel industrious, I will try to see what size of threads Hornady uses to tap their cases. It would be much easier if I could just tap the cases that are already fireformed to my particular chamber and use them. It would not surprise me one bit if it is some crazy type of thread pitch that I cannot match. I think Hornady is fetching 4 or 5 bucks per case!!! Last edited by Tex S; January 12, 2010 at 12:47 AM. |

|

|

|

|

#13 |

|

Member

Join Date: January 6, 2010

Location: Houston

Posts: 70

|

Hey Tex

Don't mind a bit, it's not arguing, it's discussing.  The tip is commercially made and I can find no cant to it  As far as the shoulder fit, I always partial full length resize and know exactly where the shoulder is. On new cases when figuring the DTL (distance to the lands) I allow for the head space (or head clearance on belted cases) even though on new cases I am seldom loading for any other purpose than stretching the cases so that I can have little to no bullet movement toward the lands when firing on the subsequent loadings. I too have the Stoney Point OAL tool (now Hornady) and tap my fired cases with a 5/16x36 tpi tap and that is what I use for holding the bullet into the lands. It works very well also as long as you realize the problem with the headspace on the modified cases or tap your own. I use whatever bullet I take the measurements on to set the seating die and take comparator measurements on that bullet when seated to the OAL measurement I get with the R-P tool. I will check the seating as I am seating and the biggest problem with consistant seating depth is the consistancy of the ID of the neck and the finish inside the neck. Also the bullets themselves will vary a little in bearing length. Personally I either seat >.020" of the lands or seat into the lands. When I get in between those measurements flyers start happening.

__________________

Guns have 2 enemies, rust and politicians |

|

|

|

|

#14 |

|

Senior Member

Join Date: November 12, 2008

Location: Fort Worth, TEXAS

Posts: 909

|

Sounds like you've got a good bead on it Woods! May I ask what you have scribbled on your cases with a sharpie?

Oh, thanks for that tap info too! |

|

|

|

|

#15 |

|

Junior Member

Join Date: January 12, 2010

Posts: 2

|

Thanks Woods, I believe I know you from somewhere else, a different name perhaps. You don't have to take the tip off, just turn the rod over and go the other direction. It will work in a 20 cal but that is the smallest.

The bigger end is there for 27 and larger bores to ensure the bullet tip hits the rod end rather than the rod going down beside the tip. I am the one that makes this tool. It is not really a business but more a hobby. A few clarifications on the post made by TexS. The collets and the rod ends are cut square. In order to find out where the ogive makes contact with the bullet, you must first at least find out what the total length of the loaded cartridge is from case head to bullet tip when that cartridge is loaded to contact the lands. This tool will measure from the bolt face, which is where the loaded cartridge makes contact when chambered. Datum lines and headspace are not of concern when getting this reference point. Next we measure from the bullet tip, when the ogive is making contact with the lands. I will use the rod to seat and unseat the bullet a couple times from the lands to ensure a good contact. with about 5 minutes of learning curve, you can get these two measurements in less than a minute. Now I use the exact same bullet that I got those measurements with and load that bullet in a case to the exact inside measurement of the distance from the two collets. This dummy round if chambered will be exactly contacting the lands. No way around it. Now it is time to find the ogive measurement is so inclined to do so. I have been using this method so long, I don't even make the dummy round. I use that bullet to load my first cartridge in my session. If I want a .010 jump, I will just seat it to jump .010. Then I run that batch through the dies. All of them, due to the dies using the ogive to seat the bullets will have the same jump. Now if you measured all the rounds from bullet tip to base, you will find variations, but the ogives are the same. If good loading practices are employed. Thanks for you time. |

|

|

|

|

#16 |

|

Member

Join Date: January 6, 2010

Location: Houston

Posts: 70

|

There you are Randy! You still working offshore?

You know, I have sold so many of your tools over the last few years that you should cut me in!  For all the rest of you reading this, I have not spoken to Randy since I bought his tool about 4 years ago but know a good product at a decent price when I see one. That is the reason I recommend them. Tex, that is the load info. Keeps an old man from getting confused. For instance it might say "200 AB, RL19 - 57" which tells me that it is a 200 gr Accubond with 57 gr RL19. You need to get the right drill bit too, I think it is an "L"

__________________

Guns have 2 enemies, rust and politicians |

|

|

|

|

#17 |

|

Junior Member

Join Date: January 12, 2010

Posts: 2

|

Onshore, North LA.

You still are one up on me, not sure who you are yet. I have sent several to your area and thanks. Someone from here alerted me when he ordered one via the E-mail you attached in your first post. I had replied before I saw your registration date, so this probably looks like a setup. I hope everyone realizes it isn't. |

|

|

|

|

#18 |

|

Senior Member

Join Date: November 12, 2008

Location: Fort Worth, TEXAS

Posts: 909

|

Its small world!

|

|

|

|

|

#19 | |

|

Member

Join Date: January 6, 2010

Location: Houston

Posts: 70

|

Quote:

Anyone could do a search on any of those forums where I have posted for years and find the same recommendations from me.

__________________

Guns have 2 enemies, rust and politicians |

|

|

|

|

|

#20 |

|

Member

Join Date: January 11, 2010

Location: Seattle, WA

Posts: 45

|

Im a fairly intelligent person, but this is definately one of the most technically challenging and debated parts of reloading. But one has to start somewhere, I always say sometimes its easier to just do something than think about it.

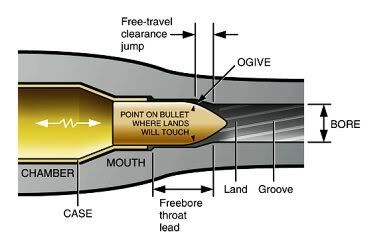

Help me out with 2 definitions though: 1) Lands...The area before the rifleing? 2)Ogive...I know its the tapered part of the bullet, but is there an exact place on the bullet with this name?

__________________

Trust me...I do this all the time

|

|

|

|

|

#21 | ||

|

Member

Join Date: January 6, 2010

Location: Houston

Posts: 70

|

Here is an official glossary of definitions

http://www.saami.org/Glossary/index.cfm For "lands" it is a little confusing although technically correct Quote:

For "ogive" Quote:

So the distance to the lands is from the point on the curve of the bullet to the first point on the raised lands in the barrel that it will hit. This brings up a small minutiae in that the lands are not full caliber, the grooves are, so the point on the curve of the bullet that will hit the lands is not the point where it reaches full diameter, but a little smaller. The Hornady (Stoney Point) comparators have a hole that is typically .011" smaller than caliber so there will be a little discrepancy if you set the seating depth by a comparator.

__________________

Guns have 2 enemies, rust and politicians |

||

|

|

|

|

#22 |

|

Member

Join Date: January 11, 2010

Location: Seattle, WA

Posts: 45

|

Hey thanks, that pic really cleared it up.

__________________

Trust me...I do this all the time

|

|

|

|

|

|