|

|

|

#1 |

|

Member

Join Date: August 3, 2009

Posts: 78

|

pots??

im going to start casting soon and have a question. do you have to use a cast iron pan or pot to melt the lead in or can it be a steel pot? around here a cast iron pan is $25 and that seems like alot to me.. can you use the steel pots with the coatings or not??? thanks

dale |

|

|

|

|

#2 |

|

Senior Member

Join Date: December 23, 2008

Location: Southern Illinois

Posts: 1,527

|

Just stay away from aluminum....like the aluminum turkey fryer pots. These may work for a awhile, but you run the risk of pot failure. Are you going to be smelting WWs in this pot or casting out of it? I smelt my WWs in a large cast iron pot. Pans are too shallow and your run the risk of splashing lead where you don't want it. You also need to be able to stir and flux it well, and this may be difficult with a pan. Any homemade pot made of steel should work, as far as I know, as long as the steel isn't to thin. Cabelas sells a cast iron pot and turkey burner combo deal. It is kinda pricey, but it pays for itself pretty quick, and is everything you need except for the propane. As far as a casting pot, I use a Lee Pro 20 pound bottom pour pot. It is cheap and it works, but will have the occassional drip...which can be fixed quite easily. Good luck!

__________________

~~IllinoisCoyoteHunter~~ ~NRA LIFE MEMBER~ ~NRA CERTIFIED INSTRUCTOR~ |

|

|

|

|

#3 |

|

Staff

Join Date: November 28, 2005

Location: Montana

Posts: 9,443

|

I bought a 5 quart dutch oven from Harbor Freight for $20. It holds more than enough lead.

You may find it at the Home Depot, otherwise you'll have to buy it online: The Bayou Classic burner. It's an inexpensive, yet sturdy burner. The only drawback is the volume control valve is pretty touchy. Otherwise, it's been good for me.

__________________

If it were up to me, the word "got" would be deleted from the English language. Posting and YOU: http://www.albinoblacksheep.com/flash/posting

|

|

|

|

|

#4 |

|

Senior Member

Join Date: April 30, 2007

Posts: 176

|

Cast Iron pot from HF and a turkey deep fryer from craigslist.

|

|

|

|

|

#5 |

|

Senior Member

Join Date: August 1, 2007

Location: Tabor City , NC.

Posts: 1,969

|

my first pot was a paul revire stainless 2 qt. , the handle was busted ,best part was $1.00 at yrd sale.

i made a couple out of 6" pipe & 1/4 plate ,left the plate as is & makes a great mold warmer. went to a small lee bottom pour but some molds still want the ladle

__________________

GP100man

|

|

|

|

|

#6 |

|

Member

Join Date: August 3, 2009

Posts: 78

|

thanks guys! i will be casting out of a pot for now. a bottom pooring one is still alittle to much for me to pay for. i have a turkey fryer, all i need is a pot( well pots, one for smelting the lead in, and the other for casting.) thanks again guys!

dale |

|

|

|

|

#7 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

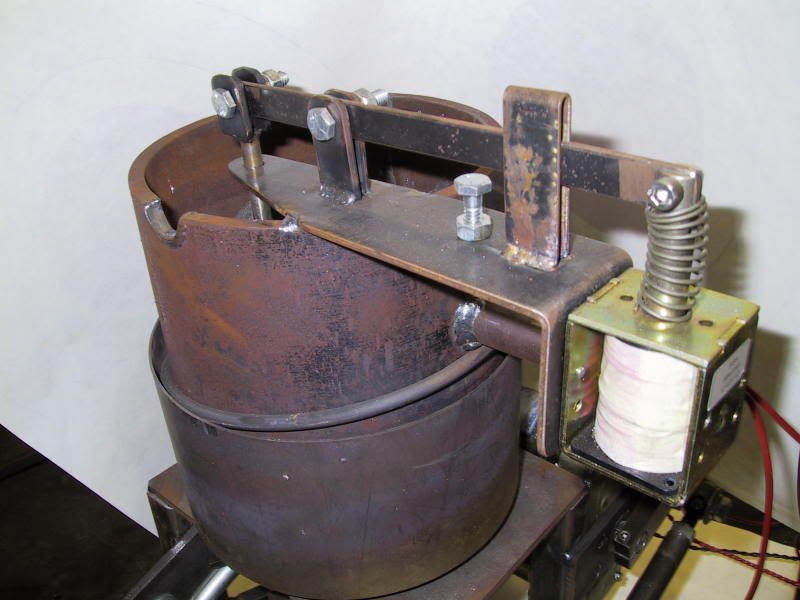

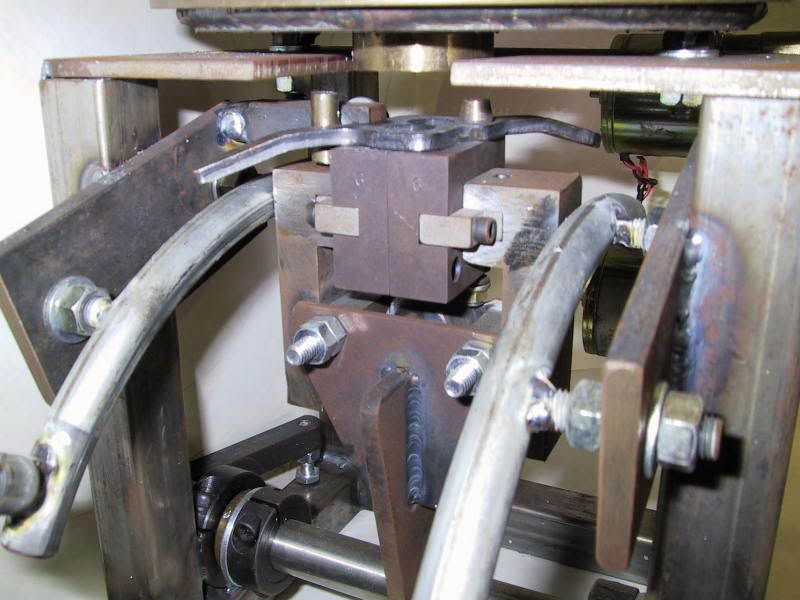

I made a melting pot out of 7" 3/8 wall pipe then wrapped a 3500watt oven element around the pipe. I had the pipe and the element only cost $9 at Sears, so it’s cheap enough and it will take 60#’s of lead from room temp to casting temp in under 30 min. I later added the bottom pour when I built my automatic casting machine.

|

|

|

|

|

#8 |

|

Senior Member

Join Date: October 28, 2006

Location: South Central Michigan...near

Posts: 6,501

|

Wow!!! jmorris, you are my hero! Very clever, very inventive.

|

|

|

|

|

#9 |

|

Senior Member

Join Date: December 23, 2008

Location: Southern Illinois

Posts: 1,527

|

Do you have a video of this beauty working? I would love to see it in action!

__________________

~~IllinoisCoyoteHunter~~ ~NRA LIFE MEMBER~ ~NRA CERTIFIED INSTRUCTOR~ |

|

|

|

|

#10 |

|

Senior Member

Join Date: May 20, 2001

Location: Oshkosh wi.

Posts: 3,055

|

Here's a couple of mine.

The big one is a lee 20# pro 20. The little one is the small 6 pound melter, but it does have a thermostat.  Here's a mold guide I made for the lee pro-20. The one supplied by lee couldn't be made to work by me. Not saying someone else couldn't get along with it.  Another view, I modified lee's guide by cutting the "ear" off and screwing the ¼" oak strips to it. There's a chunk of 3/16 alum. angle used in there too. The guide allows the sprue plate openings to be accurately positioned directly under the stream of lead coming from the bottom of the pot. So you get this, a nice straight sprue puddle;  That's a lee 90342 mold, it casts a .429-250-SWC.

__________________

The more people I meet, the more I love my dog They're going to get their butts kicked over there this election. How come people can't spell and use words correctly? |

|

|

|

|

|