|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: June 20, 2007

Location: Rainbow City, Alabama

Posts: 7,167

|

Is brass consistent across product lines for a given headstamp?

The mainstream ammo manufacturers frequently have many product lines. For example, in rifle ammo from Federal you have the basic blue-box, Federal Premium, and Federal Fusion. From Hornady, you have American Whitetail, Full Boar, Superformance, etc.

Does anyone know if each manufacturer uses the same basic brass for all their product lines or if each product line has it's own brass spec (which may or may not have the same interior volume)? The only one I've heard about for sure that is different is Hornady's LeverEvolution brass which is trimmed a tad short. |

|

|

|

|

#2 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

As most reloaders have made it very clear to me they believe it is volume that counts. The length of the volume means nothing, the diameter of the volume means nothing and then there is that thing with the powder column not being in the center, none of that matters; the only thing that matters is volume. I am the fan of eliminating a lot of problems. F. Guffey |

|

|

|

|

|

#3 |

|

Senior Member

Join Date: December 10, 2005

Location: Central , OR

Posts: 1,888

|

The ammo manufactures have no pity for reloaders.

I was sorting some 9x19 Blazer brass and noticed three different case head types. It seems that CCI, Speer and F-C are the same brass in 9x19 for some ammunition. For 9x19 and 45 acp I sort by head stamp and then as I resize the cases I have three bins, the easy to size goes in the scrap bin the brass that is hard to size and the stuff that is somewhere in the middle are separated and reloaded. |

|

|

|

|

#4 |

|

Senior Member

Join Date: June 11, 2016

Location: SE Wisconsin

Posts: 1,524

|

Sorting just 9mm I have found this;

RP have found 4 distinct different headstamps FC have found 4 distinct different headstamps Win have found 3 distinct. 4 if you want to add WWC |

|

|

|

|

#5 |

|

Senior Member

Join Date: April 4, 2011

Location: LA (Greater Los Angeles Area)

Posts: 2,598

|

Yes, generally consistent

Yes, generally consistent. But that is not always a good thing. For example Federal and Remington are made from softer "low brass", while Lake City milspec brass is made from cartridge brass.

"Cartridge brass (C260) 70 30 — ≤ 0.07[29] Good cold working properties. Used for ammunition cases, plumbing, and hardware." "Low brass 80 20 Light golden color, very ductile; used for flexible metal hoses and metal bellows." https://en.wikipedia.org/wiki/Brass I will sometimes load FC and Rem for general purpose, like leave-at-the-range, but never for anything serious, hot, or max loads. To further complicate this, The parent company for Federal Cartridge (Vista Outdoor) operates the Lake City Army Ammo plant on a contract basis. But LC brass is always cartridge brass. Federal branded brass and ammo is always "Low Brass". Vista Outdoor also owns: Alliant powders, Bushnell's scopes, Weaver Optics, RCBS, Speer bullets, CCI Primers and everyone's favorite aluminum cased ammo: Blazer https://vistaoutdoor.com/brands/ My practical solution is to acquire and use LC (or Starline) brass, and conversely, do not acquire FC rifle brass. For straight-walled pistol cartridges I do not think there is much (or any) any benefit or risk, to using one over the others. If you are not loading military cartridges, you will have to use what you can get. Finally, if you are loading for an auto loader like an FAL, M60, etc., you will REALLY appreciate that milspec brass is thicker, and can stand-up to hot-loads and being extracted and flung 30+ feet, bouncing off your upper receiver. Yes you will see wear in extractor grooves at the rim head, that I never see on my Savage bolt rifle empties.

__________________

............ |

|

|

|

|

#6 |

|

Senior Member

Join Date: October 21, 2010

Posts: 1,025

|

I have FC 9mm brass with 3 different headstamps, all from American Eagle factory ammo. FWIW, all 3 have different average case volumes after resizing in the same die.

|

|

|

|

|

#7 |

|

Senior Member

Join Date: October 16, 2014

Location: Iowa

Posts: 1,634

|

If you pay attention while sorting you will notice that there are numerous variations as noted by kmw1954. I would have to assume there are some small variations between these. I would guess there are numerous plants making the brass each with there own machinery and it's all probably very close but possible to make distinctions if you were to examine them close enough

|

|

|

|

|

#8 |

|

Senior Member

Join Date: June 11, 2016

Location: SE Wisconsin

Posts: 1,524

|

I did this one night out of boredom. These three manufacture are the most common and what I have tons of so I dumped a container and started the examination. Each brand has at 2 with distinctly different head stamps which I also do sort and separate.

I do not do this to try and gain an advantage in accuracy but I do, do it to try and gain some consistency when I run it thru my progressive press. This way I try to maintain a consistent feel of the shell case and the press. So if something feels out of whack I can halt and check. |

|

|

|

|

#9 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

The main reason headstamp appearance across a given make of cases is each bunting die that stamps the case head is slightly different. They wear out. Some companies change brass lot numbers when any part of the case forming process is adjusted or replaced, others don't.

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: October 21, 2010

Posts: 1,025

|

Quote:

FC 9mm LUGER FC .9mm LUGER. .FC. 9mm LUGER |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: February 13, 2002

Location: Canada

Posts: 12,453

|

"...ammo manufactures have no pity..." It's more that they don't care what reloaders want, say, do or think.

Sorting brass is busy work. It makes no difference of any kind. Even when loading match grade ammo. Vista Outdoor's is just the holding company. They don't actually run any of the company's they own. Milspec brass is not intended to be reused. It gets sold for scrap value when fired.

__________________

Spelling and grammar count! |

|

|

|

|

#12 | |

|

Senior Member

Join Date: September 12, 2002

Location: Twin Cities, MN

Posts: 5,313

|

Quote:

Plus it brought out some interesting information I sure didn't know. Thanks. |

|

|

|

|

|

#13 | |

|

Senior Member

Join Date: June 8, 2016

Location: Cleveland, Ohio Suburbs

Posts: 1,750

|

Quote:

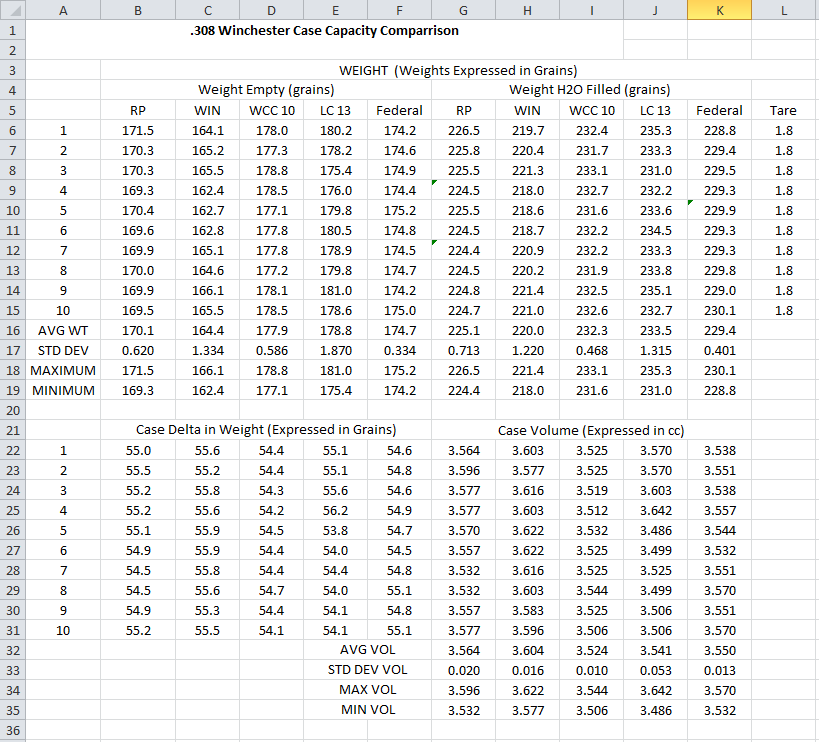

Like many I sort by head stamps when I load simply because based on my own observations it helps to get uniformity in the loading process. I also like to try and load brass which demonstrates the lowest standard deviation over cases selected at random from a given lot. Just as an example here is what I came up with on some 308 Winchester cases where each case was full length sized and all cases were trimmed to equal length of 2.005".  I think if we look at the final case volumes expressed in cc the apparent winner would have been the WCC 10 GI Brass. Only because it has the lowest standard deviation. The real question becomes how much does it matter? Commercial Winchester brass had the highest case volume at about 3.604cc where the LC 13 brass had the lowest volume at about 3.541cc. The difference being 0.063cc between highest and lowest volume. How much will that really matter if everything else in a loading process is equal? Will other components outweigh that like powder lot or type and manufacturer of primer? I just want my loads to be as uniform as possible and assume that should help translate into tighter groups. Ron |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: June 20, 2007

Location: Rainbow City, Alabama

Posts: 7,167

|

Reloadron, thanks for those tables. For my purposes, I'm looking at 30-06, .35 Whelen, .260 Rem, and 7mm-08. To my knowledge, I don't have any Win brass and I know I don't have any LC brass so that excludes the extremes at both ends. I have lots of Hornady (from multiple product lines), Federal (again, multiple product lines), and some Remington.

|

|

|

|

|

#15 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

When comparing case volume across several, if the case outside dimensions across all are not equal, the volume inside won't be valid for comparison.

Only way I know of to make all cases outside dimensions the same is to put them in a full length sizing die. Then fill them with water. Tedious? Yes. Precise and meaningful? Yes. Cases with a 2% weight spread are good enough for 99.99% of us and test sub MOA-through 1000 yards. Case volume uniformity is not on my list of needs for best accuracy. Last edited by Bart B.; July 11, 2019 at 04:43 PM. |

|

|

|

|

#16 | |

|

Senior Member

Join Date: June 8, 2016

Location: Cleveland, Ohio Suburbs

Posts: 1,750

|

Bart B.

Quote:

Ron |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: April 15, 2018

Location: Baton Rouge - Louisiana

Posts: 407

|

The only thing I'd add to the bottom of this thread is that you're also going to see substantial variances across pistol & rifle brass and it also varies across different calibers. When the rounds were produced is also a factor - i.e. was the round made in a high production demand time as in just before the gulf war is likely to have more variance due to the quantity demanded & produced.

At the end of the day, you will find that there are a few manufacturers that seem to produce cheap crap and their brass is to be avoided for reloading. Reloaders tend to disagree which producers those are. For me, I have photographically documented my dislike and avoidance of all Blazer and all Perfecta brass in .40 S&W. I'm also not a fan of Aguila in .40 S&W. I generally prefer non-military Winchester brass in .40 S&W ( i.e. WMA with crimped primer pockets is a pita and I avoid it ) but I also have sizable stocks of Federal and Remington and would get more GECO brass if it were to be found in larger quantities. I have found that MOA critical rifle reloaders have more and higher standards than the pistol crowd and with good reason. My 2 cents worth - worth every penny - take what you want & leave the rest ;-) |

|

|

|

|

#18 | ||

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

Quote:

Quote:

__________________

Science and Facts are True whether you believe it or not |

||

|

|

|

|

#19 |

|

Senior Member

Join Date: April 4, 2011

Location: LA (Greater Los Angeles Area)

Posts: 2,598

|

Federal and Remington both use Low Brass

Quoting UncleNick (reference link below):

"The issue with Federal brass is that it is "low brass" of 80 parts copper to 20 parts zinc. So is Remington brass, by the way" Post #26 of :Federal Brass worth Keeping? https://thefiringline.com/forums/sho...w+brass&page=2 I remember this because I bought new Remington 308 brass and was disappointed to hear this. However, I have reloaded that Remington brass several times without issue. I do prefer LC because I own auto loaders as well has bolt guns.

__________________

............ |

|

|

|

|

#20 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

I have at least 20 reloads on my Rem 06 brass and no issues.

308 less but a lot and no issues. FC yes, 6 to 8 is the limit even with careful sizing.

__________________

Science and Facts are True whether you believe it or not |

|

|

|

|

#21 |

|

Senior Member

Join Date: September 5, 2006

Location: West virginia

Posts: 653

|

I use hornady brass quite a bit. Oddly the brass they sell for reloading has much better concistency and higher volume than the brass I get from thier loaded hunting ammo. Their loaded match ammo is diffrent yet. Crazy how that works you think it would be consistent from the same manufacturer.

__________________

Kill em all and let God sort em out! USAF |

|

|

|

|

#22 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

Don't get me wrong I'm not disagreeing with you , just trying to figure out how that method of measuring case volume is helpful to the internal ballistics of a specific rifle ? If it's not then does it really matter if that's the most accurate method ?

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|

#23 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Metal god, will a new hard brass case weighing 190 grains expand in a given chamber then spring back to the same outside dimensions as a new soft brass case weighing 150 grains, both having the same peak pressure?

I think all cases of the same shape, metalurgy and weight will have equal volume at the same peak pressure. And a 1 grain spread of weight is good enough. I am not saying your chamber dimensions have no bearing on internal ballistics as long as every case has the exact same external dimensions. The more a given load's case expands to chamber limits, the lower pressure and muzzle velocity is. Same thing with larger barrel groove diameters than bullet diameters. Last edited by Bart B.; July 15, 2019 at 06:59 AM. |

|

|

|

|

#24 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

It may very well be the most accurate way to measure case volume "full stop" but is it the best way to measure case volume when a reloader is trying to get the most consistent reloaded cartridges for a specific rifle ? I believe context and relevance to the application is more important and the reason we as reloaders want the case volume info . Not to just get the simple accurate case volume weight . Looking at it in that context any fire formed case from the rifle in question will have more relevance to the application then any sized case still in the die . At least that's IMHO

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|

#25 |

|

Senior Member

Join Date: March 28, 1999

Location: Tucson, AZ

Posts: 3,802

|

"At the end of the day, you will find that there are a few manufacturers that seem to produce cheap crap and their brass is to be avoided for reloading."

There seems to be a strong grain of truth to that comment. I was gifted 1,100+ rounds of once fired Federal Gold Medal brass in .308 Win. and when I loaded some up to try the primer pockets were so loose that the brass was for all practical purposes, useless. Quite a few years back, the late gun writer either did some tests or had them done testing the brass from Winchester, Remington and Federal. The results were Winchester was the toughest brass, Remington in the middle with Federal in last place. For that reason I've always preferred Winchester brass and Remington as the runner up. I just don't use Federal at all if I can help it. Funny thing as in funny peculiar and not funny ha ha but I've been doing a series of experiments loading 7x57 ammo looking to see just how far I can push it. Without going into details, I have pushed the 150 gr. Nosler Partition to 2910 FPS in both Winchester and Remington brass and the lot of each that i have show the Remington holding up much better than the Winchester. Usually it's always been the other way around. Did Winchester change the metallurgy of their brass or just a not quite up to standard lot of brass? I have noted comments where people say Winchester's quality has gone down hill lately. Could that be the reason? A cheaper quality brass? Paul B.

__________________

COMPROMISE IS NOT AN OPTION! |

|

|

|

|

|