|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Search | Today's Posts | Mark Forums Read |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: November 22, 2006

Posts: 819

|

Lee Dies & Berry's Bullets

Is it just me or has anyone else noticed lately that the combination of Lee dies and Berry's bullets seem to be a recipe for bullet setback? There are several active threads right now where people are seeing this, it's been mentioned here more and more as of late, and in just the last year I've personally encountered the problem as well. It became enough of a problem for me in 45 ACP that I switched to a U sizing die so that I could continue to use Berry's at the indoor range.

So my question is why does it seem this combination is becoming a more common source of problems? Is it the Lee expander die design, are Berry's bullets a little undersized, or is it just coincidence? Maybe I'm wrong entirely, but it just seems like this is becoming somewhat common.

|

|

|

|

|

#2 |

|

Senior Member

Join Date: August 20, 2002

Posts: 2,108

|

I've noticed no problems with 45acp,40,9mm using Berry and Lee dies I especially watch for set back in 40. I seat and crimp using two operations.

|

|

|

|

|

#3 | |

|

Senior Member

Join Date: May 22, 2010

Location: North East WI

Posts: 418

|

Quote:

|

|

|

|

|

|

#4 | |

|

Senior Member

Join Date: November 22, 2006

Posts: 819

|

Quote:

There are active threads here and here describing similar problems, and here's my thread from last spring describing my own experience. Just seems strange that this keeps occurring in this particular combination.

|

|

|

|

|

|

#5 |

|

Senior Member

Join Date: December 1, 2002

Posts: 2,832

|

Given a proper crimp, I've never experienced such set-back no matter what dies I used.

|

|

|

|

|

#6 |

|

Senior Member

Join Date: May 13, 2006

Location: WA, the left armpit of the USA

Posts: 1,323

|

I have had not even a hint of a problem using Berry bullets to load .32 acp, .32 HRM, .380 acp, 9mm luger, .38 spcl, .358 mag, .40 SW, .44 mag, and .45 acp. You might want to take a look at your die seating.

__________________

"If the enemy is in range, so are you." - Infantry Journal

|

|

|

|

|

#7 |

|

Senior Member

Join Date: April 4, 1999

Location: New Mexico

Posts: 1,889

|

No problem here.

Jerry

__________________

Ecclesiastes 12:13 ¶Let us hear the conclusion of the whole matter: Fear God, and keep his commandments: for this is the whole duty of man. 14 For God shall bring every work into judgment, with every secret thing, whether it be good, or whether it be evil. |

|

|

|

|

#8 |

|

Senior Member

Join Date: June 8, 2004

Posts: 289

|

Many thousands of .38, 9mm, and .45 acp- zero setback problems.

Chuck |

|

|

|

|

#9 |

|

Senior Member

Join Date: September 15, 2007

Location: NC

Posts: 753

|

I use several different berry's bullet in my 9mm and load them with Lee dies have zero problems. A couple thing could be causing problems,resizing die not set up properly cut incorrectly or oversized expander plug.

You could also be flaring the case to much or have the taper crimp die applying to much taper crimp which will buckle the case and release the tension on the bullet or you could not be applying enough taper. The sole purpose of the taper crimp die is not to crimp anything at all but to remove the flair and provide reliably feeding. If you take a FL resized case with no flair applied and run it up into your taper crimp die the outside case mouth dia. should be no more than .002 inches smaller from the original case mouth dia. I segregate all my 9mm brass by headstamp,you will find that not very many headstamps are identical in either length or thickness. Lengths and thickness can vary by several thousands. All this will play a part in how much flair is removed and taper is applied to the mouth of the case,depending on what case you use to set up the die with. I went out to the reloading shack and measured a few random 9mm case I resized with my Lee dies the other night. Inside neck dia. measure .752 that give me .004 neck tension of the Berry's bullets I'm currently shooting. This is about the amount taper I put in the case mouth notice the light ring on the plated bullet,much more than that is resizing the bullet. Just some random thought may not help you at all.

|

|

|

|

|

#10 |

|

Senior Member

Join Date: May 22, 2007

Location: Arizona

Posts: 5,295

|

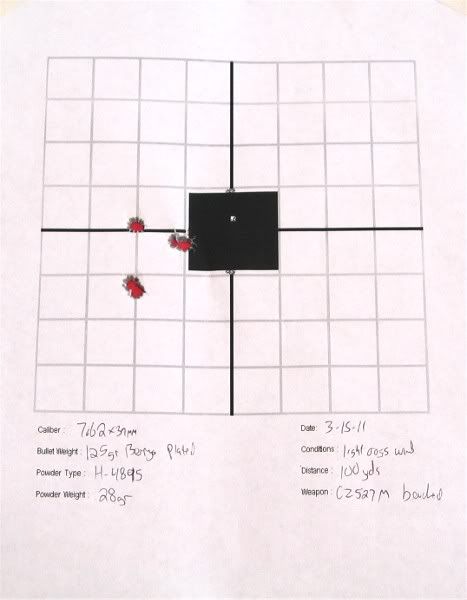

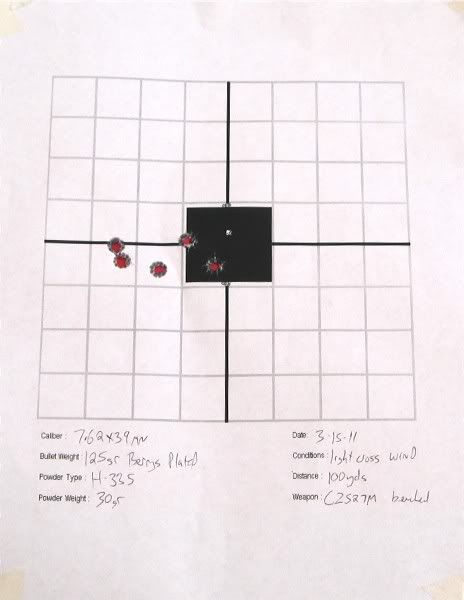

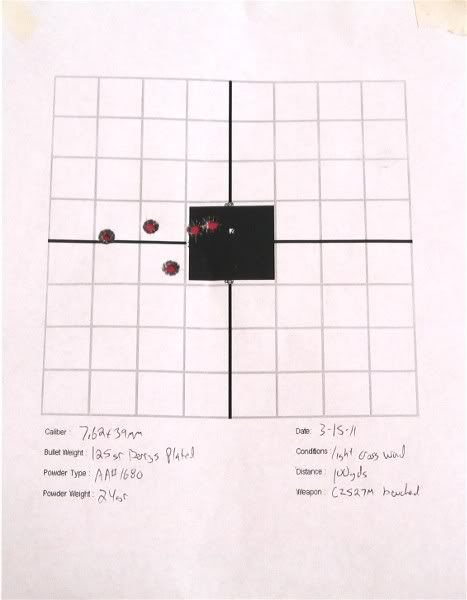

Never had any set back issues with Berrys', and I run Lee dies only. I just started testing thier brand new 125 grain .311 rifle bullet in my 7.62x39mm dies, no issues, and my CZ 527M seems to like them quite a bit.

|

|

|

|

|

#11 |

|

Senior Member

Join Date: November 28, 2007

Posts: 302

|

I have ran a boatload of 9mm through my lee dies using berry bullets and have never had a problem of any type. I would measure the bullets with a micrometer to determine their size. I would also mike the expander to see if it is about .002 smaller than the bullet. I have had brass that did not want to hold

the bullet firmly due to thin case walls. Don't over crimp with the FCD die if you are using one as you can crush the bullet to a smaller diameter. Seat and crimp in separate operations if you can. You may want to separate brass by headstamp if you are using mixed lots of brass to see if this is a condition of a brand of brass. Don't cycle the same round through your pistol continuously and some bullet profiles tend to seat back more than others you may want to have the feed ramp polished. Some guns drag the empty case into the next round during ejection and while this may not affect round nose bullets it may shove back flat nosed or hollow points. You can call Lee to see if they have any suggestions. |

|

|

|

|

#12 |

|

Member

Join Date: September 4, 2010

Location: Woodstock, GA

Posts: 88

|

I have reloaded 20,000+ rounds of 9mm and .45 ACP using Lee dies, Hornady dies, and Redding dies...with no problems. About 4 months ago, I started reloading .40 S&W using Hornady dies. I loaded 10 rounds in my first batch. When I inspected those 10 rounds, I was able to push the bullets into the case, between 1/8 and 1/4 inch, on 6 of the rounds. There is no doubt I would have had serious bullet setback if I had fired those rounds.

I did a lot of research on thefiringline and other loading blogs on loose bullets and bullet setback. My belief, in this case, is that the cause of the loose bullets was a defective sizing die. I measured the inside diameter of the Hornady sizing die and it measured at .415. I called Hornady customer service, and they stated that .415 was within their manufacturing tolerance for .40 S&W sizing die. I found that I could resize a spent case using the Hornady sizing die, take it off the press, and without expanding it, I could insert a bullet and push it into the "resized" case. No amount of crimping would prevent a loose bullet. After further research, I became aware of the EGW undersize reloading dies. http://egw-guns.com/store/index.php?...products_id=40 I bought the EGW .40 S&W die and loaded 10 rounds. All were good...no loose bullets. To make a long story short, I have loaded 1000+ rounds of .40 S&W using the EGW sizing die with no problems. As I stated earlier, the Hornady die measured at .415. The EGW measured at .405...huge difference. There is no doubt in my mind that the cause of the loose bullets was a defective sizing die. My recommendation to the OP is to measure the Lee sizing die, call Lee customer service and see what they say regarding manufacturing tolerance. Anybody else using the EGW undersize reloading dies? |

|

|

|

|

#13 |

|

Senior Member

Join Date: September 8, 2005

Posts: 123

|

Loaded quite a few 10mm, 165g Berry's bullets over the last few years with Lee dies without issue.

__________________

Without weapons, it's just another airline!

|

|

|

|

|

#14 |

|

Senior Member

Join Date: June 7, 2010

Location: St. George, UT

Posts: 122

|

RES45 That is what I would consider the perfect crimp on our bullet. When I take a tech call on a question like this I just have the loader do the math. Where is the number off? Measure the bullet, measure a sized brass, then measure the brass after the expander has been used. Remember that the brass will have a springback affect after it has been sized. I've never used a set of Lee dies, so I can't comment on them.

|

|

|

|

|

#15 |

|

Senior Member

Join Date: July 28, 2007

Location: Ohio

Posts: 11,755

|

I use these Berry's plated bullets:

.32 -- 71gr Pl-RN .380 -- 100gr Pl-RN-FP 9mm -- 124gr Pl-RN 9mm -- 124gr Pl-FP .38 Spl -- 158gr Pl-FP .40 -- 180gr Pl-FP .45 -- 200gr Pl-SWC .45 -- 200gr Pl-FP .30 Carbine, 110gr Pl-RN I've used more than 10,000 of these bullets. All my handgun dies outside of .357 Magnum are Lee dies. (I use jacketed bullets in .357 Magnum) The only problems I have with case mouth tension and bullet setback are when coupled with R-P brass, and the nickel R-P seems to be worse than the brass R-P. Some calibers are worse than others. .38 Special and .45 give me no trouble... .380 and 10mm give me grief. I won't even consider using R-P in .40 S&W. R-P in 9mm works fine. Nosler jacketed bullets give me much more trouble with case mouth tension and setback than any Berry's plated slug ever has. In the end, the trouble is with R-P brass and not anyone's bullet. Definitely not Berry's bullets. When you flare case mouths, run 6 pieces of R-P then run one piece of CBC/Magtech or older Federal or Winchester. You will easily feel the thinness of the R-P brass. You feel it when glaring, you can easily feel it when seating bullets and crimping. This goes for all calibers with R-P brass. Berry's is not the weak link. I'm sure on this one.

__________________

Attention Brass rats and other reloaders: I really need .327 Federal Magnum brass, no lot size too small. Tell me what caliber you need and I'll see what I have to swap. PM me and we'll discuss. |

|

|

|

| Thread Tools | Search this Thread |

|

|