|

|

|

#1 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

pillar bed question

Am I foolish to think that eliminating all contact between the action and the stock of my rifle is "good", if I have good contact between the stock and the recoil lug?

I have reason to ask this... I've read up on the subject of pill bedding, glass (or epoxy) bedding, and the typical combo style bed job and it gets pretty foggy after 3 months of googleing... Last edited by bow shot; February 26, 2010 at 12:27 PM. |

|

|

|

|

#2 |

|

Member

Join Date: February 13, 2010

Location: wisconsin

Posts: 31

|

I think the goal of pillar bedding is to have a flat surface to mount your action to, to make everything more consistent. I think when they glass bed you put a little pressure on your barrel, but so it doesn't move.

I am no expert, and this info could be false but that was my interpretation of the things I have read. |

|

|

|

|

#3 |

|

Senior Member

Join Date: February 13, 2006

Location: Washington state

Posts: 15,248

|

You definitely want full contact between the action and the stock, but not necessarily between the stock and the barrel. Pillar bedding just keeps people from crushing the stock when they put action screws in (no, it's not OK if your knuckles turn white).

__________________

Never try to educate someone who resists knowledge at all costs. But what do I know? Summit Arms Services |

|

|

|

|

#4 |

|

Senior Member

Join Date: November 19, 2009

Location: Deary, Ideeeeeeho

Posts: 531

|

Some and proper contact is important.

Contact between the action screws and the stock is not desirable. If you glass bed the action, drill out the glass enough to relieve the screws. Contact between the front of the recoil lig and the stock is also something to avoid. As said, piller bedding is to prevent crushing the stock when the action screw are tightened. Personnaly I like all my hunting rifles to have the barrel totally free floating. Some rifles do group better with some amount of barrel to stock pressure, but this leads to the potential of shots being "off target" due to changes in stock pressure form hot/cold - wet/dry conditions, or because the rifle is held or rested differently. For consistant hunting groups, a fully floated barrel wins hands down in almost every case. Keep em coming! Crusty Deary Ol'Coot |

|

|

|

|

#5 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

this is what I'm thinking...

Is there any reason to have contact between the stock and the action at all if the recoil lug is indeed making contact? Seems to me its only an opportunity to introduce bending influence to the action if the action screws aren't torqued to some "perfect" degree.

I've been reading on this stuff till my eyes bleed, and I'm starting to develop my own opinion... which may be absolutely stupid, so I'm looking to the hombres for wisdom. Last edited by bow shot; February 26, 2010 at 12:27 PM. |

|

|

|

|

#6 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

gonna re-post

Just changed the thread title, and moved the picture to the top. I changed to a more appropriate title. 'Trying to get some visibility from the wise grey-headed ones...

Last edited by bow shot; February 26, 2010 at 12:28 PM. Reason: clear out confusion |

|

|

|

|

#7 |

|

Senior Member

Join Date: November 19, 2009

Location: Deary, Ideeeeeeho

Posts: 531

|

The only problem with the action touching the stock, with the exception of those issues listed above, would be if your putting the action in a bind.

I personaly like to bed the action BEFORE floating the barrel, as the action is given a bit more support during the glassing process. You can loosen the front and rear action screws, one at a time and watch how the action does or does not move. If it moves, is it because of upward barrel pressure? For example the front of the action raising out of the action posssibly because of a lot of barrel pressure. Or maybe with the front screw tight, the rear tang raising because there is pressure or a twist between the stock and the action. Watch and see how this situation plays out. If I saw the front of the action lifting because of barrel pressure, I would glass the action, making sure the action screws - front & rear - were tight during the cure time. Then I would float the barrel and after that again see what happened with pressure/twist in the barrel. A person can always add a bit more glass, if needed, to get things solid. I like to drill the screw holes - in the stock - out as far as possible, without showing on the outside, then fill the holes with glass during the bedding process. After that, as I mentioned before, relieve the screws by running a drill slightly larger then the screw through the cured glass. This will give you a "piller bed" with glass. I also like to remove a lot of wood in the recoil lug area, taking care to allow enough wood to remain so as to assure proper positioning of the barreled action during the process. Properly mixed and cured, Acraglas is VERY!!!!!! strong! I cannot say enough about prep before mixing the glass. Pay me now or pay me later, it not properly done ahead of time, you will wish you had not even started, that is unless you really want an action forever stuck in your stock. Use the release agent as directed, then put a dolip of grease in the action screw holes and coat the action screws with a light coat of grease - ON TOP - of the release agent. Before mixing, take some electrial tape and tape the front and bottom of the recoil lug to prevent contact in these areas after glassing is finished. REmove all parts from the action that could possibly come in contact with the glass. The glass can and most likely will get where you don't want it unless prevented, WHICH CAN CAUSE GREAT!!!!!!!!!!!!!!!! problems. Modeling clay can be used to fill voids where glass is not wanted. BE aware that once the glassing process is finished, the stock and action will not want to come apart. THEY WILL BE TIGHT!! Once the action is cleaned up, tape gone, clay removed, excess glass removed, they will fit snugly but not excessively tight. I like to have a stack of double toliet paper squares already torn off the roll and ready to go before the glassing begins, as the glas WILL get places you don't want it, and needs to very quickly be cleaned off the stock etc. As I said, pay me now or pay me later, don't mix the glass untill EVERYTHING is ready! Read and heed all directions. And personaly, I have liked the results of the liquid Acraglas better then the jell. Harder to handle maybe, but does a better job. Keep em coming! Crusty Deary Ol'Coot |

|

|

|

|

#8 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

understood

Thanks kindly for the detail, Crusty!

|

|

|

|

|

#9 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

and..

...I see I wasn't real clear in the original post.

I'm asking if it would be "good" to leave total a total void under the action (ie., "air") except for where it contacts the pillars, and where the recoil lug contacts the stock. |

|

|

|

|

#10 |

|

Senior Member

Join Date: November 19, 2009

Location: Deary, Ideeeeeeho

Posts: 531

|

Unless your "pillers" had some sort of flat on them for a flat bottomed action or round cradle for something like a Remington action, the action would not be stable without additional contact .

There should be good and full contact in the area of the recoil lug, except for front and bottom of the recoil lug. For many actions, it would be very hard or impossible to have "full length" glassed contact between the action and the stock. In many cases there is not room between the magizine box and the stock for much if any "bedding." However, bed around and below the front recoil lug and below the rear tang, taking care to prevent springing the action when the screw are tightened. See my last post. The goal is for stability and consistancy in contact between the action and the stock, provided by proper contact. I can see no real advantage in attempting to minimize this contact and in fact a number of the manufactures go to great lengths to produce a stock including a full length of the action - aluminum bedding area - to maximize this contact and stability. If the quality of the stock is doubtfull, meaning subject to great amounts of movement as the weather changes, the answer would be a laminated stock or possibly a quality synthic stock. Thinner and more lams are better and more stable then less and thicker lams. I have, in 40 years or so, never had a factory stick give this type of problem, ***** ONCE ***** the action was bedded as indicated above AND the barrel was floated. I have however, seen great shifts of impact before floating, simply because of changing the point at which the stock was rested during firing or because of the attachment of a stock mounted bi-pod. If however, you are going the direction of a high end bench rest setup, we are talking about a totally different breed of cats. What I have tried to outline is done to produce consistancy of shot placement in a hunting or varmit class rifle. Keep em coming! Crusty Deary Ol'Coot |

|

|

|

|

#11 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

that's what I thought...

the pillars in the VLP are flat topped, and the botton of the action has a radius, so it seemed pretty flimsy to me.

So I'll heed the wisom and continue with the conventional bedding job. Here's to better groups! Is there a way to add pillars and epoxy to a shooter and fix his problems too? LOL!! Yes I'm a believer that the position of the bags makes a difference in the group. My beloved 6.5x55 must have the front bag directly under the barrel/action joint, and I have to be directly behind it, with the tip of my thumb steering from the rear swivel stud. The Savage VLP .204 likes the front bag a little forward, but I'm not solid on the rest of the form for that gun yet. It goes a little poo-poo when I use the bipod. Coot, do you know of a good way to experiment with bipod mounting? Does anyone have success with mounting alternate studs for the 'pod? Last edited by bow shot; February 27, 2010 at 08:50 AM. Reason: spelling and grammar |

|

|

|

|

#12 |

|

Senior Member

Join Date: November 19, 2009

Location: Deary, Ideeeeeeho

Posts: 531

|

Morn'in Bowshot.

I have thought about putting a second sling stud on the forend for bi-pod mounting, as I don't like the mounting of a sling to the bi-pod. Doesn't seem very secure to me!!!!!!!!! As to the "piller bedding for shooters", it a very simple process. NOT pain free, but simple. The shooter simple, STOPS! EVERYTHING!!!!!!!!!!!!!!!! Coffee, NO! Smok'in, NO!!!!!!!!!, drink'in no NO!!!!!!!!, breath'in - only in moderation. Best to stop everything. Most folk get real steady after awhile if they follow these recommendations. AND, no cheat'in! Back to the bi-pod thing ---- oldest son had a heavy barrel 6mm that shot quite well. We went after rock chucks and he was over shooting. So, Jeff took some rested shots at a rock bluff out aways, rifle rested on a sling stud mounted bi-pod - and sure enough the rifle was hitting waaaaaaaay high. Later, I bedded and floated that rifle and that was the end of the forarm pressure induced changes in point of impact. Have a good day an, Keep em coming! Crusty Deary Ol'Coot |

|

|

|

|

#13 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

thank you!

Thanks for the post 'Coot! I'm learnin' !!

|

|

|

|

|

#14 |

|

Senior Member

Join Date: November 19, 2009

Location: Deary, Ideeeeeeho

Posts: 531

|

Yep, we are all, at least most of us, still learn'in and are just indifferent stages in the process.

I just bought a new to me #1-s in 45/70 with the goal of casting my own bullets for hunting. I have cast for years, but mostly for handguns, so this will be a learning experience. I have owned a number of the single shot RUGERs and loved the RUGER #1, probably since I saw the first advertisement. Now bedding and floating a two piece stock is a bit different, but it can be done with good results, so that will be coming up along with the casting of what I hope to be bullets worthy of hunting, putting a piece of ebony on the forend, installing a new (read thick an soft) butt pad and glassing the butt stock to the action. All in good time. The components, dies, bullet mold etc. are on the way, so should be a fun summer doing tests with a cast bullet rifle. Keep em coming! Crusty Deary Ol'Coot |

|

|

|

|

#15 |

|

Senior Member

Join Date: October 21, 2009

Location: Black Hills of S. Dakota

Posts: 195

|

Bedding:

The purpose for bedding a barreled action to a stock is to provide a tension free register that is inert to changes in ambient weather. (temperature, humidity, etc)

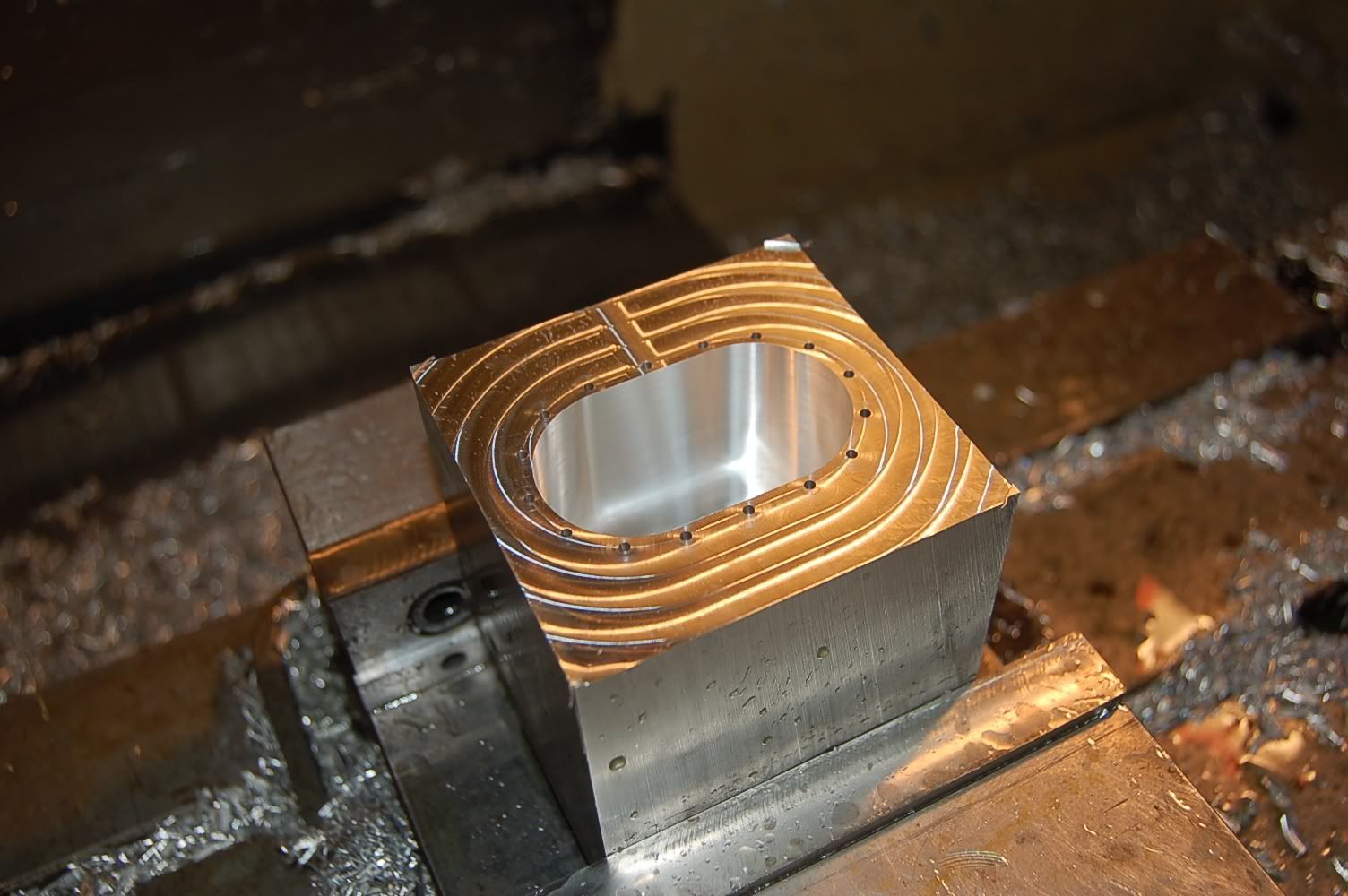

The resin should have the following traits: High shore hardness Minimal shrinkage High compression strength High shear strength High resistance to acids and alkalies Bedding a portion of the barrel or floating it completely is an often debated topic. I've bedded close to a thousand rifles in the 13 years I've been at this trade (career). Some actions respond well to a bedded barrel, others don't require it. As a general rule, I do not bed the barrels as it can greatly complicate things. Barrel swaps require bedding all over again for instance. Here's what bedding won't do: It can't polish the proverbial "[color=#FF0000]█[/color][color=#FF0000]█[/color][color=#FF0000]█[/color][color=#FF0000]█[/color]". A gun that sucks is only going to suck slightly less with a properly bedded action. A great rifle can become exceptional. It's a minimal gain but it's viable when done properly. Here's an example of what mine look like: With care and attention to detail these results are attainable by anyone. Good luck. C

__________________

LongRifles, Inc. "More than a business, This is a lifestyle." www.longriflesinc.com |

|

|

|

|

#16 | |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

My shpeal on bedding Mausers:

Quote:

|

|

|

|

|

|

#17 |

|

Junior Member

Join Date: February 25, 2010

Posts: 3

|

Before everyone scatters after answering bow shot's questions, I need help on bedding also. Just to make sure I have everything straight, let me give you my impression on bedding since I have one to do soon.

Assume we are talking about a simple cylindrical action (think 700 Rem or 110 Sav) which has been glass bedded into a wooden stock with the barrel free floated. My conception is that when finished: 1. The barrel is free floated. 2. The recoil lug is not in contact with the stock except for the rear face of the lug. The rear face will be, in effect, in full contact with the stock because glass has filled any small voids which may have previously existed between the rear face and the wood. 3. If there is a magazine, it will be isolated from the stock. (Okay, so the magazine spring may or may not be resting on the bottom of the magazine well.) 4.The entire trigger mechanism is isolated from the stock. 5. As part of the bedding, the two action screw holes were enlarged and filled with glass and the properly coated action screws inserted to draw the action down into the soft glass bedding during the cure. After cure the screw holes were drilled out slightly oversize to form what might be called a "glass pillar." The purpose of this was to avoid contact between the action screw shanks and the glass. The only contact between the action screws and the stock is achieved by the clamping action of the screw heads against the bottom face of the "glass pillars." (Had a true metal post been desired it would have been inserted during the bedding process. The same "no contact between screw shank and post" would have held true.) 6. The action body (talking abut anything not already covered above) is now snugly resting in its new glass bed. That is, through full contact with the glass bedding it is in full contact with the stock from the mid waterline of the cylindrical body down, and from just behind the recoil lug aft so as to include the rear action screw "glass pillar." Please correct any error in the above concept. Question: to what inch-pounds should the front and rear action screws be torqued? UPDATE: This request was made without my seeing the immediately preceeding post by Clark which introduces the bit about not bedding the sides of the receiver. Clark, does this procedure apply only to the Mauser or should I heed this technique as well? Thank you. John Seymour, a man up on Lookout Mountain in extreme NW Georgia Last edited by Manupon; February 28, 2010 at 02:35 AM. |

|

|

|

|

#18 |

|

Senior Member

Join Date: November 19, 2009

Location: Deary, Ideeeeeeho

Posts: 531

|

Really REALLY nice work Longrifles, INC.!!!!!!!!!!!!!!!!!

Sounds to me like you have covered most of it Manupon. Keep em coming! Crusty Deary Ol'Coot |

|

|

|

|

#19 |

|

Senior Member

Join Date: October 21, 2009

Location: Black Hills of S. Dakota

Posts: 195

|

a few more

__________________

LongRifles, Inc. "More than a business, This is a lifestyle." www.longriflesinc.com |

|

|

|

|

#20 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

on that Savage...

...there is very little area to bed (normal style action, with blind box magazine):

1) Most of the bedding area is in the vicintity of the recoil lug 2) there is a tiny amount of area to bed at the rear action screw (which is the forward screw of the trigger guard). 3) There is no action screw at the tang So the question is this: Im reading that the tang area should be floated.. but I don't understand the function of doing that, since there is so little bedding area left! What don't I get?? |

|

|

|

|

#21 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

and here's a very nice tutorial...

... go to the battenfiled technologies site, and download the "Bedrock Instructions"

http://www.battenfeldtechnologies.co...structions.pdf Lots of pictures, some of the "why"s come to light as you go...which is nice for a bloke like me. Last edited by bow shot; March 1, 2010 at 10:07 AM. Reason: boo boos. |

|

|

|

|

#22 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

great info..

Clark, I'm happy to say that I've actually alreay read every link you've posted except for the "z-hat" one... and I STILL don't know what to do!!! LOL!!

Just kidding... Actually I feel very well armed at this point. I just need time and $. I think I might just be the guy that beds the sides of the lug. Depends on how tough (stupid?) I feel that day... |

|

|

|

|

#23 |

|

Senior Member

Join Date: October 14, 2009

Posts: 141

|

Bow Shot,

Put some electrician's tape on the sides and front of the recoil lug and trim with a razor blade. That will prevent that area from being bedded. Long Rifles, Again, beautiful bedding jobs! I disagree with you that anyone can do it because it obviously takes a lot of practice. One thing though: I notice that you have some cut slots on each side of the action screws. What is this for? - Ivan. |

|

|

|

|

#24 |

|

Senior Member

Join Date: March 26, 2009

Posts: 263

|

ok..

...but I don't understand why we don't want the sides of the lug contacting the bed.

I see that if ALL sides of the lug are bedded, that suction and friction might make it nigh to impossible to get the action out one the beddng cures. but there will be plenty of void (air) in front of the lug, right? I don't understand that part (not letting the sides of the lug contact the bedding).. |

|

|

|

|

#25 |

|

Senior Member

Join Date: October 21, 2009

Location: Black Hills of S. Dakota

Posts: 195

|

The "slots" were the old way in which I finished the pillars.

The story: Years ago I worked for another company. The philosophy there was that pillars should not actually contact the receiver. It was thought a layer of bedding material should be sandwiched between the pillar and the receiver. The logic behind came from one of the owners who happened to be a fully certified metallurgist. He reasoned that two dissimilar metals create a small electric charge when in the presence of moisture. This would create corrosion. Well, you do what your told so for a long time we whittled the little ears out of the pillars. I've since done away with the idea as I've built enough rifles (approaching close to 500 now) to know it's not hurting anything. So, I've modified my pillar design slightly and now leave them as they are. The "secret" to this stuff is nothing more than taking the time to evaluate the process and establish a procedure that makes good common sense. Fancy tools and equipment sure make it easier but if a guy just thinks it through a bit the results aren't hard to replicate. The forums and "how to's" are good but it's all stuff that has been around a long, long time. It's easy to get stuck in the "crab bucket" mentality. Experiment to improve the process. Materials become a small part of the equation. Just about any epoxy resin will work for this stuff. Some certainly work better than others but the place to focus your effort is in how you apply it. It's been often said "rookies" focus on equipment where's "veterans" pay attention to procedure. There's a lot of truth to that in a number of ways. As for points of contact for the recoil lug. Again, years ago it was a cardinal rule that it should basically take a hydraulic press to install and remove a barreled action from a bedded stock. People wanted them tight so they had no chance of moving around. The problem is the material won't tolerate it for very long. The hardest epoxy I've ever seen is Devcon Titanium. I use it on my tactical rifles. It's rated on the rockwell C scale and not the shore hardness scale (traditionally used for rubbers/plastics). Be that as it may it will still suffer from the effects of abrasion. Folks have finally realized this after watching the recoil lug shave bedding material on the sides and below as the gun is assembled. So, they tape the lug now in front and in the rear to help minimize this. A GREAT addition to this is choosing the right lug to begin with. I manufacture all my own lugs in house and they are different from what I see offered. the sides are drafted slightly and (most importantly) they are fully finish machined with a radius in all the corners so that they don't chew their way through the bedding as they are installed. Little things can make big differences. Hope this helped. Cheers, C

__________________

LongRifles, Inc. "More than a business, This is a lifestyle." www.longriflesinc.com Last edited by LongRifles, Inc.; March 2, 2010 at 09:11 AM. |

|

|

|

|

|