|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#26 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

What it comes down to is: You can probably get away with light cartridges with out a problem. High pressure rounds would probably need some looking into. More than "Hey, I have heat sink and a welder". I am working at a shop right now that deals in tons (Yes, tons) of 4140 series pre-heat material every year, and both cast steel and iron. All three can go crazy when you weld on them.

I will admit, I have done plenty of things with guns that the books say "Don't ever do this....". That is because I really take everything into account before experimenting. I don't see that on this thread. |

|

|

|

|

#27 | |

|

Senior Member

Join Date: August 1, 2010

Location: Tampa Bay

Posts: 4,556

|

I have much to learn still about welding techniques as applies to the specific application at hand.

But, I do believe this is true.. Quote:

Depending on what you're doing, full-penetration (strength) welding may not be necessary- and thus less heat is generated. I can run a short MIG bead, and then pick up the part an inch from where I just welded and quench (if needed) before that area even gets too hot to hold. The HAZ using these methods is extremely small.

__________________

Remington 700/Savage Rebarreling /Action Blueprinting 07 FFL /Mosin-Nagant Custom Shop/Bent Bolts Genuine Cerakote Applicator www.biggorillagunworks.com |

|

|

|

|

|

#28 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

You are welding junk steel on Russian rifles, just like on Mausers. Do you frequently weld on the barrels of these guns, which are high carbon steel? Do you weld on springs? Do you frequently weld on Russian and Mauser bolt lugs? Would you buy a chromemolly barrel that was normalized and not heat treated at all? Over the years I have seen really stupid stuff done to guns with welding, and even worse with brazing. The defense is usually, "Hey, this was made from good steel back then." It probably was good steel before they got a hold of it.

|

|

|

|

|

#29 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,061

|

Bob Day used to build up 1911 link lugs for fitting by gas welding using a magazine spring as the filler so he'd get a surface that would last. I wouldn't have tried it. When I was building 1911's, I always had a guy who was a good TIG welder with aerospace certs who was in our pistol league do that when it was needed to salvage a barrel. I watched him weld two pieces of Studebaker fender steel together as part of a car restoration, and get a seam nearly perfectly flush on that thin steel. No, it's not 4140, but in terms of localizing the heat, it's not anything I can imagine any MIG welder I've seen producing, though most of the MIG welding I've been around was done on aluminum, so it probably doesn't count.

Gunplumber, I think you and I got off track back there. Your concern seems to be the surface hardness and finishing issues and unpredictability therewith. My point with the flow-through coolant was to preserve a layer of steel in original hardness on the inside of the bore and chamber and leave managing the outside up to the welder and his skills. I had in mind Hatcher's photo of a 30-06 barrel he turned down until it was only 0.0625" thick (Hatcher's Notebook pp. 201-202) over the chamber and reported it withstood three regular rounds, and then was blown out by a blue pill rated at 70,000 CUP (he says "pounds", but they still believed copper crushers were giving them real psi back then, so it was probably closer to 110-120 kpsi (see error curve for 30-06 p. 43, Brownell et al.)). If you can preserve that much thickness at the core, or more, then you at least have a pressure vessel you know is not brittle and can contain normal rifle peak pressures. It might look like a misguided attempt at color case-hardening on the outside, but the inside would have integrity. I have eleven issued patents related to applied thermodynamics and the second half of my career was built in the area of heat transfer, so I can guarantee what I suggested will preserve that core layer without needing to do an experiment. All that is required is that the steel be homogeneous and at least 5/32" thick from the bottom of the trough of the melt to the core. I am not a welder, though, so I don't think that even if I wanted to try it, I could do a valid experiment whose result would compare well with what a skilled welder's work would produce. My TIG guy is long gone, alas. But also, I'm not sure what the experiment would demonstrate? I could show the original temper survived at the core, as I predicted, by sectioning the work and getting a lab at the University to provide a radial hardness profile, and to do one on the material before stress-relieving and one after to show changes out beyond the preserved core. I do have a large knife oven that would handle the stress-relieving. But some expense would be involved in getting the lab to make the measurements that I don't care to undertake given that I can show in a finite element analysis exactly what result to expect at the core. Again, what happens to the outside is not within my purview, beyond being able say I am confident the metal can be welded with the fluid running through it with enough power, and that it may subsequently be stress-relieved. If it looks like it ran naked through a blackberry patch afterward, that's another matter.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#30 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

Exactly. You are not a welder. One of the posts (Not going back through) roughly stated that the poster was not sure if the lug actually did anything at all. Really? What, as long as you can still cut the chamber with a reamer, the rest of the barrel is someone else's problem. I re-cut chrome lined chambers with reamers made from 0-1 T/S. There are carbide reamers out there. That is not the point.

|

|

|

|

|

#31 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,061

|

Again, we just don't seem to be discussing the same thing. I thought the concern was whether or not the thing would be safe to fire in the end, not whether or not it is possible to cut a chamber into unevenly hard steel. Whether or not it is safe to fire has two parts. One is containing pressure in the barrel, the other is holding the gun closed via the lug on the barrel. What I described doing only addresses the first part of the equation. It forces a layer of steel around the bore and chamber with unchanged properties to be preserved and that is thick enough to contain pressure. Just that part of the equation. Nothing else. Not the strength of the lug attachment. I am not seeking to impact the welding of that attachment one way or another, nor offering advice on how to best weld that attachment. I am just addressing managing the heat from welding as it nears the bore.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#32 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

I have images of (3) Mosin Nagants my brother TIG welded for me after I fixtured them.

http://thefiringline.com/forums/atta...1&d=1419581917 http://thefiringline.com/forums/atta...1&d=1419581918 http://i757.photobucket.com/albums/x...ntDSCF0024.jpg http://thefiringline.com/forums/atta...1&d=1273379196

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#33 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

Yep. I actually played around doing the same thing once, but was aware of the steel's qualities and heat treatment. Sold it at a show years ago. Somewhere there is a 30-40/scoped/welded Russian out there. Welded in a receiver bridge and put a Remington bolt handle behind the bridge. Check the area around the weld. When I did mine, it retained the case around the weld (Scratch check) almost up to the weld. Russian receivers are mild steel like Mausers. If you grind off the case, the steel underneath will not get hard unless you add carbon to it. It does not work that way with barrels(4140).

|

|

|

|

|

#34 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

This one's not a "I have a heat sink and a welder" but no knowlege of welding project. Not a lot to this one, not even close to this little 30,000,000,000 BTU hydrogen/NG, stainless/Inconel burner, for example. That was much more complicated and tested by several methods including x-ray before being put into service.

|

|

|

|

|

#35 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I fail to see what that has to do with welding rifle barrels.

|

|

|

|

|

#36 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

An understanding of what it takes to make a good weld that does't harm parent materials. Seems like a tangent has spun off of the thread. The simple fact is that "factory" TC barrels are welded and you don't have to have recieved a check from TC to make as good or better weld than they acheive.

|

|

|

|

|

#37 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

Yup. Not learning anything here. I'm done.

|

|

|

|

|

#38 | |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

Sure you did, on the last page you didn't know that TC welded the lugs onto their barrels. You thought they machined them from a single billet then drilled and rifled them.

Quote:

|

|

|

|

|

|

#39 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

I have a TIG welder, but I forget how to turn it on.

But I have a butane torch, and I could still solder a barrel to break action front end.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#40 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Clark, that's a nice TIG machine.

|

|

|

|

|

#41 |

|

Senior Member

Join Date: March 26, 2005

Location: Osborn, Missouri

Posts: 2,697

|

jmorris,

Very nice machine work and interesting thread. I can't comment on the welding as I do not claim to be a welder. I have welded but not on guns, when it comes to that I farm that work out. Thanks for posting this thread. Best Regards Bob Hunter |

|

|

|

|

#42 | |

|

Senior Member

Join Date: August 1, 2010

Location: Tampa Bay

Posts: 4,556

|

Quote:

I luv my Lincoln...15 years old and still tickin....

__________________

Remington 700/Savage Rebarreling /Action Blueprinting 07 FFL /Mosin-Nagant Custom Shop/Bent Bolts Genuine Cerakote Applicator www.biggorillagunworks.com |

|

|

|

|

|

#43 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

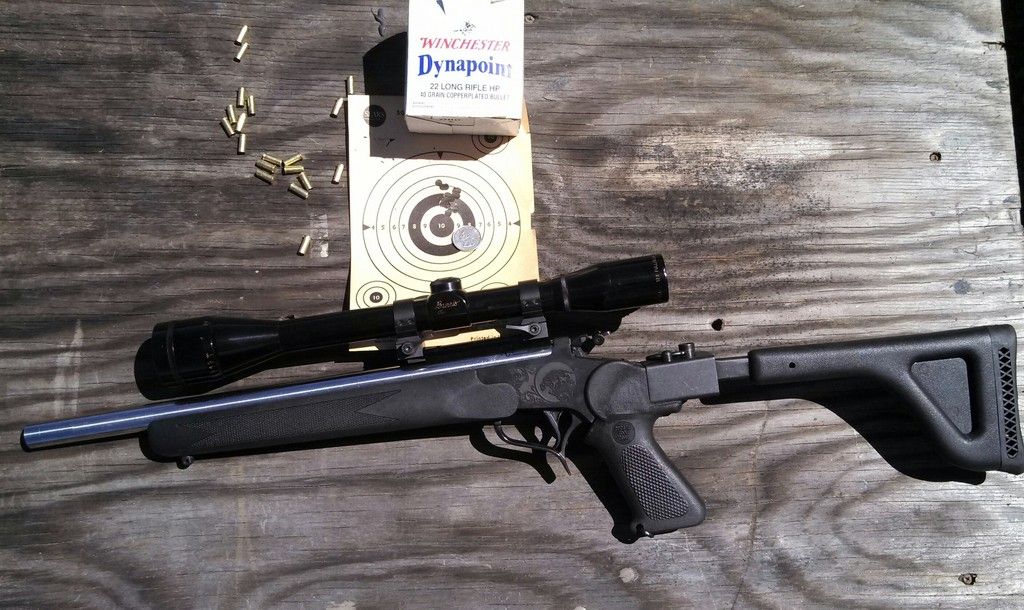

Well I finally had some time to play with this project again and modified a G2 forearm to work with the original frame and mounted it an and optic banged away at some steel until I had it close enough to put a group on paper. Not the best shooting 22 I have or the easiest to bench for groups because of shot to shot movement but the first photo is a 20 shot group at 60 yards (odd distance but just how far it is from the back door to the bullet trap).

For the Kiddo I mounted an aimpoint comp3 I had and even with the suppressor it's shorter than the 510 she has been shooting.

|

|

|

|

|

#44 |

|

Senior Member

Join Date: September 28, 2008

Posts: 10,442

|

Nice work for sure.

Very impressive and far beyond the skills of most folks. But wouldn't it have been much easier to just buy another .22 rifle?

__________________

Walt Kelly, alias Pogo, sez: “Don't take life so serious, son, it ain't nohow permanent.” |

|

|

|

|

#45 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

This is a Remington 510 22 bolt action single shot with cut down butt my brother got for $7 from another teeny bopper in the early 1970s. Then he grew up. I repaired the stock for him.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#46 | |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

Quote:

It will be the exact same "gun" (with a lot better trigger than almost every "kids" .22) and should be good for anything she will ever shoot, in that caliber, IF, she likes it. |

|

|

|

|

|

#47 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

Jmorris,

What looks promising is a very long throat single shot 357 max with boat tail bullet and as long as possible OAL for more powder volume. This could take big game at a few hundred yards.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#48 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

This week I put a green mountain 9" twist barrel on a Win 75 [same action as a Win 69A], so I can shoot 60 gr SSS 22 LR ammo.

I only had to cut a short chamber to get the ammo to fit. http://www.gmriflebarrel.com/rx229-2...-barrel-blank/ https://www.gunpartscorp.com/Products/254460.htm

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

|