|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: April 4, 2011

Location: LA (Greater Los Angeles Area)

Posts: 2,598

|

Resizing LC 7.62 to 7mm-08 Annealing first mandatory?

I recently acquired a Savage Axis II in 7mm-08. I have a good supply of machine gun fired LC 7.62 on hand. I am able to size these to 308 using lithium grease as case lube. I bought 7mm-08 dies.

Question is: Can I size to 7mm-08 in one step, trim, champher, and load? Or, should I size in 2 steps to 308, then 7mm-08? Or should I anneall before sizing? I have sized to 308 w/o annealling first with no issues.

__________________

............ |

|

|

|

|

#2 |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

Marco: I am not into the steps to convert it, but once fired cases are not going to need to be annealed and your working them won't cause that kind of issue.

I ran a 30-06 case into the 270 dies a while back, very interesting and while all wrong, it was just fine.

__________________

Science and Facts are True whether you believe it or not |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 13, 2012

Location: Maine

Posts: 158

|

I've sized some of my 308s down to 7mm-08 and had an issue with the case mouth being to thick so you may need to turn them down.

|

|

|

|

|

#4 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

And then I measure the length of the cases 'to be sized' from the shoulder/datum to the case head. I do that because my shell holders have a deck height of .125" and a minimum length/full length sized case protrudes from my dies .125" from the die. Annealing; many years ago I made tools for annealing, the tools I made are easy and simple to use and fast. I would talk about my annealer but it would take forever to convince someone the it works. F. Guffey |

|

|

|

|

|

#5 | |

|

Senior Member

Join Date: October 28, 2006

Location: South Central Michigan...near

Posts: 6,501

|

Quote:

|

|

|

|

|

|

#6 |

|

Senior Member

Join Date: April 4, 2011

Location: LA (Greater Los Angeles Area)

Posts: 2,598

|

RC20, 3006 to 270 is the exact same thing I am contemplating. I am just necking down (that is what we call it in Cali too

) to .284. ) to .284.What was "all wrong"? That sounds right to me.

__________________

............ |

|

|

|

|

#7 |

|

Senior Member

Join Date: June 23, 2013

Location: Central Taxylvania..

Posts: 3,609

|

I've necked 308 and 7.62 down to 7mm-08.

My first reaction to wanting to neck 7.62 to 7mm-08 is don't do it. The 7.62 has less case volume than 308. Consequently your powder charge, will be lower than a standard 7mm-08 case. That or your pressures are gonna be kinda high. If you like RL16, you won't be able to get a full load of powder to physically fit in the case.

__________________

When our own government declares itself as "tyrannical", where does that leave us??!! "Januarary 6th insurrection". Funny, I didn't see a single piece of rope... |

|

|

|

|

#8 |

|

Senior Member

Join Date: April 4, 2011

Location: LA (Greater Los Angeles Area)

Posts: 2,598

|

I have used mil-spec 7.62 and commercial 308. I keep them separate, and load them as different items. So, that aspect, lower case volume, does carry to 7mm-08 too. I am not going for maximum loads (yet). I am not convinced that lower case volume will have a material effect on max velocity. Rather, I think it will mean using slightly less powder.

__________________

............ |

|

|

|

|

#9 |

|

Senior Member

Join Date: June 8, 2016

Location: Cleveland, Ohio Suburbs

Posts: 1,750

|

I have taken once fired 7.62mm. likely in a machine gun, Lake City brass just using RCBS case lube, and run it through my 7mm-08 dies and it worked out just fine. Using 7mm-08 load data and starting low I never had a problem. Yes, when resizing the brass you are necking down so the brass needs to go somewhere making for a slightly thicker case neck but it was never close to an issue.

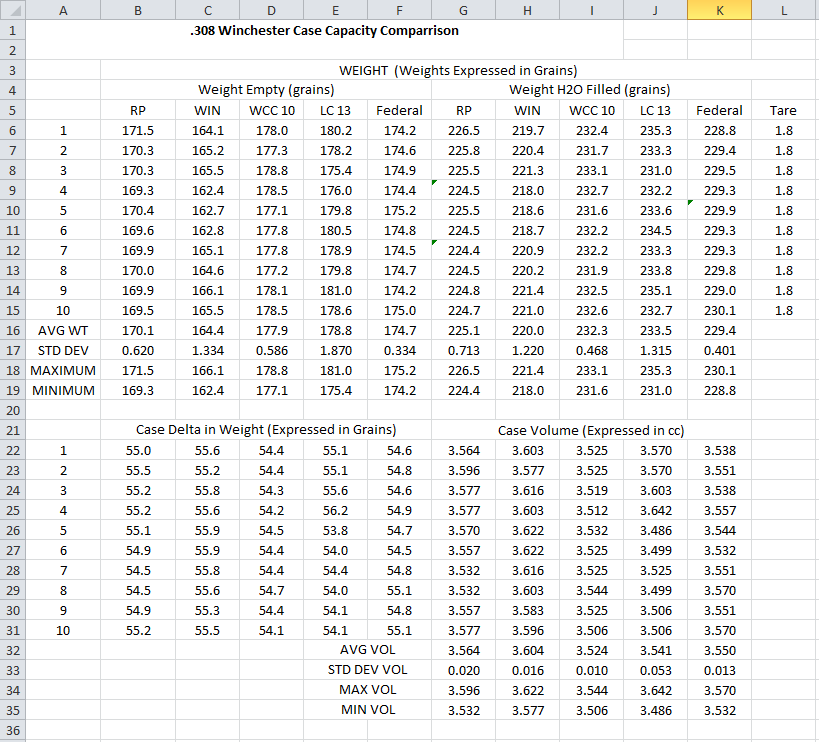

As to the case capacity you can decide for yourself.  The comparison was between Remington, Winchester, 2010 Winchester 7.62mm 308, Lake City 2013 7.62mm and Federal. While I have not loaded and fired this brass yet looking at case actual difference volume I really don't know what the pressure difference would be considering the small delta in case volume. The 7mm-08 Remington I loaded from GI brass was fired in an M1 Garand using both 150 and 168 Sierra Match King bullets IMR 4064 and IMR 4895. The rifle functioned just fine. That's about all I can say, it worked fine for me just using a single step. You may want to measure case neck thickness before and after as I don't have the numbers but I recall it was not enough to concern me when I did it. Ron |

|

|

|

|

#10 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Yes. It has changed. The differences used to be greater. I have about 500 Winchester bulk cases from 15 years ago that average 156 grains weight. I was told Winchester's 1992 Palma brass weighed 150 grains. I've got old Remington that averages 163 grains. I think the proliferation of interest in self-loaders has caused the designers to beef the head areas up a bit.

MC, Think of the neck-down exercise as an excuse to invest in outside neck turning tools so you get really concentric neck walls. That is, if you need to. The SAAMI standard lets you have a neck diameter of 0.3150" over a seated bullet. That's 15.5 thousandths neck wall over an exactly 0.2840" bullet. The thickening from the neck size reduction will only be about 0.001" at most. So if you start with cases around 0.014" wall thickness, which is pretty typical, you may not need to do anything with it.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#11 |

|

Senior Member

Join Date: April 4, 2011

Location: LA (Greater Los Angeles Area)

Posts: 2,598

|

Thanks Unklenick, and other responders. I will certainly be measuring the neck thicknesses. I have 100 running in a tumbler now, before I try the resizing.

If it turns out they are thick, I would see that as a reason to buy Starline 7mm-08 brass. Trimming these 7.62 is a enough of a chore on a Wilson trimmer. They tend to be crazy long after sizing.

__________________

............ |

|

|

|

|

#12 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

^^^An excellent illustration of the fact neck growth occurs during resizing, not shooting.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#13 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

F. Guffey |

|

|

|

|

|

#14 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

F. Guffey |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: March 20, 2011

Location: Willamina, OR

Posts: 1,908

|

Be sure to inspect for head separations on those 7.62 cases. M60's tend to cram the brass so hard into the chamber that the shoulder sets back then the case stretches on firing.

I wouldn't worry about commercial .308 but military cases should be checked. Tony |

|

|

|

|

#16 |

|

Senior Member

Join Date: May 27, 2018

Posts: 302

|

If this brass is not seeing any use and you want to convert I say go for it but take a small sample size first to make sure there is no wasted efforts.

I would grab 5-10 cases as practice. You will not be able to really ensure your sizing die is set up properly for your chamber until you have some fire formed brass to use as a baseline for set up. With this in mind know that your first time closing the bolt on your freshly formed brass could be difficult if not impossible without some trial and error. This is why a small sampling is in order. Here is a idea of how I might tackle assuming no 7mm08 cases were available for my use: 1. Set up the new 7mm08 die in your press and have the piston all the way up with the shell holder installed. Screw the die in until contact to the shell holder ( standard die setup ) and then give it a 1/4 turn and lock it in place. grab 10 cases you plan on converting and make sure they are cleaned and lubed. 2. Have your 7mm08 rifle ready and take 1st piece of brass and size it. You hopefully will feel more resistance then normal resizing and a very slight "cam over" at the very bottom of the handle. Inspect....make sure shoulder isn't crushed and neck is sized properly. Trim, chamf/deburr to SAMMI spec. Check the inside of the necks for any signs of unusual brass growth but if you take your time the Chamfering will smooth it out enough without neck turning. 3. Take the newly formed case and see if it chambers in your rifle. If the bolt is tough to close the shoulder may not be in the right spot. Unlock your die and give it another 1/4 turn down. Use the same case you just formed ( normaly I wouldn't want to over work the brass but this is your guinea pig case and it is expendable ) and lube/size it again. If you have a headspace gauge this will help see how much your bumping but it can be done without it. Check to see if it requires more trim etc and rechamber it. Repeat this process until your bolt closes on the case with little or no difficulty. I am a fan of no difficultly when necking up/down cause you want a smidge of room for the reformed cases to form to your chamber like a factory load would. Too little or tight and you might damage something ...but too small and you could hurt yourself. 4. Now that you have the die set up take the rest of your test cases and size them. Trim/Chamf etc. Now find a moderate load of the bullet/powder combo you plan on firing. Your not trying to find your actual load at this point...your still checking your work. Load it to manual specs ( whichever bullet/manual you have etc) and just note the expected velocity for your charge. Now of course it wont match exactly but your going for a reference. If you have a chrony great but if not you will at least see how the cases perform. Fire! Be wary and see how bolt lift is etc. Check for pressure after each shot regardless. Once they are all fired, back to the bench to prep them again. 5. Go through your normal routine for brass prep. When you get to the resizing part this is where you can now make the final adjustment to your sizing die. As with before you can back the die off a bit and redo the shoulder bump test or you can leave it as is now that you know your brass worked and resize all your remaining or you can go the extra mile and reaccomplish the sizing to get the shoulder bumped to the sweet spot on your rifle ( some would say 0.002 back from a fire formed case) and once you have it set THEN go wild with sizing the cases to 7mm08. Seems like a lot of work but its not too bad. The most time consuming is actually the fire forming of your brass after necking down. If the test rounds were not horrible with your moderate load in terms of grouping up then you can begin load development with the expectation that the groups will tighten up as you have the brass formed to the chamber and by the 2nd firing in the new rifle it should perform without a hitch. *** These are my opinions and suggestions and should not be taken as law etc. Please exercise caution and if anyone sees I missed something CHIME IN!!!! I want OP to be safe in the endeavor which is possible. *** |

|

|

|

|

#17 |

|

Senior Member

Join Date: February 13, 2002

Location: Canada

Posts: 12,453

|

"...a reason to buy Starline 7mm-08 brass..." Best one is that fiddling with LC brass is a nuisance in the first place. So is necking down .30-06 to make .270 Win. Different thing if there wasn't a boat load of, easy to find, relatively inexpensive, commercial 7mm-08 and .270 brass.

"...likely in a machine gun..." Pretty much the only place 7.62NATO is used any more. Other than the odd PBI DM.

__________________

Spelling and grammar count! |

|

|

|

|

#18 |

|

Senior Member

Join Date: June 23, 2013

Location: Central Taxylvania..

Posts: 3,609

|

Yeah, cause the USMC wouldn't use LC brass when the armory makes rounds for their M40 sniper rifles...

Not to mention there is still probably several million rounds left over from M14s along with Nato allies and their FALs and other rifles.

__________________

When our own government declares itself as "tyrannical", where does that leave us??!! "Januarary 6th insurrection". Funny, I didn't see a single piece of rope... |

|

|

|

|

#19 |

|

Senior Member

Join Date: April 4, 2011

Location: LA (Greater Los Angeles Area)

Posts: 2,598

|

7mm-08 brass is NOT inexpensive. I ordered 50 Starline for $24 @ Midway. That is 2.5 times as much as cleaned and primer pocket swaged LC. Also twice as much as Top Brass fully processed LC 7.62. I have 1000 untouched LC sitting idle.

LE Wilson sells a neck reamer that fits their trimmer for $30. Out of stock today.

__________________

............ |

|

|

|

|

#20 | |

|

Senior Member

Join Date: April 10, 2008

Location: Alaska

Posts: 7,014

|

Quote:

Ergo, all wrong (for what I was after).

__________________

Science and Facts are True whether you believe it or not |

|

|

|

|

|

#21 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

the 30/06 case is .041" shorter than the 270 w case. And then there is that part about necking up and or down. If a reloader necks the 30/06 case down to 270 what happens to the neck of the case. Golly  guys in California call it necking up. In one response we have one member that had the neck get thicker and another member thinks it gets thinner. That leads me to believe the neck gets thicker and or thinner when necked up and or down. guys in California call it necking up. In one response we have one member that had the neck get thicker and another member thinks it gets thinner. That leads me to believe the neck gets thicker and or thinner when necked up and or down. Who measures? F. Guffey |

|

|

|

|

|

#22 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

I have purchased thousands of 30/06 from Kentucky and Ohio that were pull down meaning the cases have never been fired. The only purpose I had for the cases was to form cases that could be formed from 30/06 cases. Building failure into formed cases: Anything that has been fired twice should be annealed, I have gotten away from failures with once fired cases. Testing cases for forming: I have formed 35 Whelen cases from 30/06 cases without splitting the necks, I have also formed 338/06 cases from 30/06 cases with success but I have always used unfired cases. When forming/necking up: I have had cases shorten .045" from the end of the neck to the case head when forming and after firing. F. Guffey |

|

|

|

|

|

#23 |

|

Senior Member

Join Date: June 23, 2013

Location: Central Taxylvania..

Posts: 3,609

|

Marco,

If your necking down 30-06 cases to 284 to make 270, your doing something wrong! Lol. Your making 280 Rem brass, and you gotta watch that because the datum is further forward on 280 Rem.

__________________

When our own government declares itself as "tyrannical", where does that leave us??!! "Januarary 6th insurrection". Funny, I didn't see a single piece of rope... |

|

|

|

|

#24 |

|

Senior Member

Join Date: April 4, 2011

Location: LA (Greater Los Angeles Area)

Posts: 2,598

|

No I am not doing that. Read the title.

__________________

............ |

|

|

|

|

#25 | |

|

Staff

Join Date: March 11, 2006

Location: Upper US

Posts: 28,832

|

Quote:

Now, I understand the desire for economy. And, it seems you are clear with the extra work needed to convert military brass, including crimped primer pockets, and overthick neck when sized down to smaller calibers. And that the generally "heavier" construction of the GI cases means load data needs to be developed FOR THEM, not just use what the book lists with commercial cases. Going from .30 down to 7mm should not need annealing. Might need case neck turning (outside) OR inside neck reaming, depending on when you find the need, and where you are in the loading process if/when the need arises. (and, of course trimming for length..) One thing to watch out for, machineguns are noted for having "generous" chambers, and fired brass can be quite a bit out of spec. (its fired, no one cares now...) They can be far enough out that brass springback after sizing can still leave them out of spec. IF that's the case, you might need a small base sizer die, just to get them to chamber in a bolt action! Not saying it will be the case, only that it might be... Good Luck.

__________________

All else being equal (and it almost never is) bigger bullets tend to work better. |

|

|

|

|

| Tags |

| 7.62 , 7mm-08 , sizing |

|

|