|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#26 | |

|

Member

Join Date: November 24, 2009

Location: Missouri

Posts: 44

|

Quote:

Glad you showed up to set things straight. Forget I have a Mechanical Engineering degree, with specialties in hydrodynamic and aerodynamic studies, as well as Fluid Dynamics, forget that this is my 16th patent, forget that we've already shot many rounds to confirm this design. While I'm at it, I guess I should halt the testing, going on right now with a major ammunition manufacturer (that the President of the company himself is conducting), and I should call the other two companies that have contacted me, and tell them to "forget it". Guess I gotta tell my researcher with a PhD at the University of Missouri that he doesn't know what he's talking about as well. Oh, I should also ring up Ted Nugent and tell him he wasted his time too. This ain't my first rodeo "chief"... I find it fascinating that you can look at ONE PHOTO, and in an instant, without waiting for any independent test data to come in, that you can determine the total outcome of this concept. I'm really impressed! Must be cool to be so omniscience... More power to you... |

|

|

|

|

|

#27 |

|

Senior Member

Join Date: October 24, 2009

Posts: 280

|

They1, slow yer roll!

If you have the education you claim, you should not be so defensive. Remember where you posted your info(on the internet) some folks have more understanding of what you are doing than others. I cannot tell you who understands and who doesn't, but, your reaction on this forum was a bit overkill! Relax, time and testing will tell. I don't claim to be one who knows all about what you say, but your defensive attitude doesn't help your point! Sometimes it is not easy to hear negitive comments about your ideas, but hell this is the internet, take it with a grain of salt! Perhaps those folks are right, perhaps they are wrong. Keep working on it!

__________________

When seconds count, why is help minutes away? |

|

|

|

|

#28 | |

|

Member

Join Date: November 24, 2009

Location: Missouri

Posts: 44

|

Quote:

It isn't just about my projects...it relates to many issues. When it comes to my work however, anyone who knows me knows that no one is more critical of any project than I am. And if any project fails anywhere in it's development, I'm the first one to shut it down, either until I work out the problem, or for good. I try to keep an open mind, gather as much reasonable information I can, and then make a decision. It's a failing on my part that I assume that same standard in other folks. |

|

|

|

|

|

#29 |

|

Senior Member

Join Date: March 17, 2008

Location: Indiana

Posts: 2,857

|

So because you have an engineering degree you are magically able to prevent liquid under pressure from taking the path of least resistance (through some magic holes you drilled that only allow air to pass)?

Sure. From the only photo you have posted that expansion sure looks minimal and uneven. Why do you suppose that would be? If you generate some test data that shows an improvement, then I will be less critical. The only thing you have presented so far shows a significantly poorer performance compared to the unmodified projectile. Have fun tinkering, but don't be surprised when people question your allmighty engineering. Particularly when the only resuts you have obviously contradict what you are saying.

__________________

"A human being is primarily a bag for putting food into; the other functions and faculties may be more godlike, but in point of time they come afterwards." -George Orwell |

|

|

|

|

#30 |

|

Staff

Join Date: March 20, 1999

Location: Somewhere in the woods of Northern Virginia

Posts: 16,947

|

Note to all - let's keep this thread on a non-personal level.

They1, you posted your invention specifically asking for feedback. Please accept any and all feedback without taking it too personally. As in most projects, some feedback will be useful, and some won't be. Take the good stuff, and ignore the less-than-good. All other members, please remember where we are and refrain from personal comments. Voice your opinions, as vehemently as you wish, but keep the comments focused only on the topic at hand. |

|

|

|

|

#31 |

|

Senior Member

Join Date: May 20, 2001

Location: Oshkosh wi.

Posts: 3,055

|

I don't know if my comments will be CONstructive, or DEStructive. But here goes.

A hollow point bullet pushing through the air has an immense pneumatic pressure built up inside the hollow cavity. Caused by ram air. Bleeding that pressure off will diminish it's performance. Once it enters a body, that pressure will increase expansion because the flesh will try to pack into the cavity. Bleeding that air off will REDUCE expansion. Besides, I bet they WHISTLE as they go downrange!  I'm sure it has been tried before, I'm surprised you got a patent, they must have had a slow day at the patent office.

__________________

The more people I meet, the more I love my dog They're going to get their butts kicked over there this election. How come people can't spell and use words correctly? |

|

|

|

|

#32 |

|

Senior Member

Join Date: April 1, 2005

Location: Gilpin county, CO

Posts: 261

|

I don't have an opinion on this particular adjustment to the hollowpoint design. But I would note a couple of things:

1) The stated purpose of this bullet is to reduce what you might call "over expansion". The characteristic that the OP saw was that the petals of a JHP arc backwards. They go from pointing forwards, to pointing 90 degrees from travel axis, to pointing backwards. You can regularly see this in bullets recovered from ballistic gel. The idea behind the JHP-with-hole is that the petals would ideally stop at the 90 degree point. Since the 90 degree point is point at which the diameter is greatest, the assumption would be that the wound channel would be maximized by this method. If the petals fold over backward early in penetration, then the bullet can pretty easily return to near-caliber-size, thereby diminishing wound channel size. It seems that the porting falls under the category of "controlled expansion". 2) I doubt liquid would flow through the porting in the same was as air. While they're both fluids, the surface tension and viscosity of water probably makes the port radically less available for water than air. Not to mention, now you have target clogging it up. 3) The OP is currently making one assumption that I question: that the diameter of the recovered bullet is indicative of the entire wound channel size. What I mean is this: bullet penetration happens over a timeline (duh). Looking at the end result does not indicate what the bullet's expansion was at any other point in the timeline. It only tells you how big it was when it stopped, at the end of the timeline. Let's suppose that, with a regular JHP, expansion begins at 20ms after penetration, diameter peaks at 30ms, and then diminishes (through backfolding) over the last 20ms before the bullet comes to rest at 50ms. This would give a greater wound channel size over the course of penetration than a modified round that begins expansion 30ms in, peaks at 35ms, and then only carries that bullet size for 15ms--regardless of the actual ending diameter of the projectile. The JHP would also give larger wound channels than a modified round that starts expansion at 20ms, but doesn't finish expansion until just before it stops. I don't care to speculate on the actual expansion timeline for this bullet, but I do suggest that it be investigated. High speed footage would easily answer the question. |

|

|

|

|

#33 |

|

Senior Member

Join Date: June 21, 2009

Location: West Central Missouri

Posts: 2,592

|

I wonder how this bullet will compare to the ones that have a filled cavity? (American Rifleman had an article on them a few months ago.) If this pans out, I also wonder how it will affect sales of the above bullets. (I can not remember the names or companies that produced the newer type of bullets.

As far as penetration performance, I thought the testing the OP indicated he was undertaking also measured penetration performance and not just terminal performance? i.e., what the bullet looks like after it has come to a complete stop. (Do they measure the "wound" channel?) To my un-engineering background mind, I would think the holes in the bullet would relieve pressure on the petals after penetration. The fluid passes through bullet cavity, relieving pressure on the petals, allowing them to stay open and causing more damage (a wider would channel) for a longer period of time. But again, in my ignorance, I thought you wanted a bullet to fragment, somewhere along the wound channel, to cause more channels and more damage. I also look forward to hearing more about these bullets and wish the OP much success. Please remember, he is from the Show ME state.

__________________

Inside Every Bright Idea Is The 50% Probability Of A Disaster Waiting To Happen. |

|

|

|

|

#34 |

|

Senior Member

Join Date: November 8, 2007

Posts: 2,001

|

A few thoughts:

1. I don't think that the fluid in the cavity will be simply "water" at the speed that this bullet is going when it initially hits flesh. The water in the flesh will be heated by the energy of the impact. If the pressure in the cavity is vented to a lower pressure region under the "petal" of the folded-out nose section, then I would expect the hot water to flash to steam at some point as it "flows" from the front of the cavity through the hole. So, the fluid dymanics should get quite complicated to predict. And, THE FLUID DYMANICS COULD CHANGE A LOT WITH DIFFERENT IMPACT MEDIA that has different volatility. For something like this, shooting wax might not give you the same results as shooting a water-based medium. A paper slurry or a ham would probably give more realistic performance measures.

2. With regard to putting something in the cavity that allows expansion without plugging, Hornady has done that. I think it is the same polymer that they use in their "FTX" flex-tip "Leverevolution" ammo, but has a flat-nosed configuration. They call it "Critical Defense" ammunition. It is intended to shoot through clothing without plugging, then expand inside flesh. But, I don't see it available in .45 caliber, so Qball45 may still want to switch away from HPs in his carry ammo for the winter. (But, I would choose wide FPs instead of RNs for personal defense against guys in heavy coats.) 3. They1, please realize that there are plenty of people on this forum that have multiple engineering degrees. We like to SPECULATE about physical processes and TINKER with our gear and components to make our ammo better. But, most of us have found that we really can't predict the effects of these changes from "first principles" of physics and chemistry. There are just too many variables and their interactions are just too complex. Most of our standard predictive processes are based on correlations of data from physical tests. When we tinker, what we really need to do is try things and get good empirical data to guide our efforts. Often, those data confound us because they are not what we expected from our book-educated speculations. And, sometimes our tests give us the results that we expect for reasons that we misunderstand, and we don't find out that we have mislead ourselves until we try the new thing in different circumstances. That kind of education you do NOT get from books - - you get it from experience in trying things out and then dealing with the results. There are a lot of people on this forum who have that kind of experience, too. Some from working with laboratory equipment in the firearms industry and some from other professions. The combination is what keeps me here, because I think it is the best mix available today on the Net. So, if you want to tap the wealth of knowledge on this forum, I suggest that you NOT try to use "credentials" like college degrees and numbers of patents to "trump" a commentor's perspective. That will just cause us to roll out eyes and let this thread die (or at least the part of the thread that will help you). A discussion that sticks to theory and observations can be conducted without getting personal. And, if others do start getting personal, taking the high road and staying out of the egotistical mud will further your cause more than an in-kind response. Good luck with your development efforts. I am kind of skeptical, but am keeping an open mind. It will be intereting to me no matter how it works-out, so please keep us informed. SL1 |

|

|

|

|

#35 | |||

|

Member

Join Date: November 24, 2009

Location: Missouri

Posts: 44

|

Quote:

In the case of an HC bullet, note that the diameter of the ports are only 1/32 (Test round being .38+P 135 gr)(Note that calibration for other calibers, and velocities will be necessary). While there will be some air exchange wile in flight, our calculations show that value to be around 0.02%. Not enough to worry about. Increasing port diameter, and that percentage goes up accordingly. Quote:

Although I have had some guys suggets I design the ports so it would...they thought it would be 'neat'! Quote:

There were some patents, as I recall, 4 German and two French (1914, 1922, 1927, ect.) who actually cut notably large channels laterally down the axis of the bullet, in order to affect the bullets flight pattern, specifically, to cause the bullet to "tumble". Others have designed "fins" to stabilize/ and impart additional rotation. yet another series worked on a hole through the entire bullet, with a "base plate" being necessary to fire the round, then seperating in flight. Last edited by Mal H; November 25, 2009 at 10:09 AM. Reason: Added quotes for ease of reading |

|||

|

|

|

|

#36 |

|

Senior Member

Join Date: July 28, 2007

Location: Ohio

Posts: 11,756

|

I have a leg-up on some of the detractors here... simply because I don't have to try and "guess" if some other person has the knowledge, diligence and attitude to see a project through. The only thing I have to figure out here is what --I-- know, and when it comes to this, I know less than squat!

I'm taking the high road. I have no reason nor evidence to believe the OP has lied about any part of the operation thus far. Given what I've read, I wouldn't bet a nickel against him. What I've seen here is pure American spirit. Build a better mousetrap. I say more power to ya. And I don't think you've over-reacted whatsoever. What I'd like to see is a thread that stays a little productive, so that maybe the OP will drop in and post some updates through the process. Speaking of that, bullet performance and technology has never been a big interest of mine... but learning about ammo companies and one man's interaction with them from the top down is something I would find absolutely interesting. I wish you luck and YEAH, it'd be pretty slick if 2-5 years from now if this idea finds it's way to fame and fortune and commercial success, I'd like to be able to think back and say, "HEY, I remember when that guy came to the forum and discussed this before it was a retail product!"

__________________

Attention Brass rats and other reloaders: I really need .327 Federal Magnum brass, no lot size too small. Tell me what caliber you need and I'll see what I have to swap. PM me and we'll discuss. |

|

|

|

|

#37 |

|

Junior member

Join Date: November 28, 2001

Location: West Tennessee

Posts: 4,300

|

How do the holes affect downrange performance? Does it affect the bullet's flight? How does it affect accuracy at 50-100yds? How does it affect velocity?

|

|

|

|

|

#38 | |

|

Senior Member

Join Date: August 6, 2009

Location: Albuquerque

Posts: 2,832

|

I agree that the viscosity and surface tension difference makes the a large pressure loss through the holes once entering tissue unlikely. But if liquid gets jetted out to the side that's not necessarily a bad thing, you instantly have a very destructive water jet coming out of the sides, cutting up tissue as it passes through it.

As for Quote:

__________________

I used to love being able to hit hard at 1000 yards. As I get older I find hitting a mini ram at 200 yards with the 22 oddly more satisfying. |

|

|

|

|

|

#39 | ||||

|

Member

Join Date: November 24, 2009

Location: Missouri

Posts: 44

|

Quote:

Please remember; this is a brand new technology and approach to HP design. It's a new "tool" in the box. Much has yet to be explored to see any and all possible benefits this new design brings to the table. Having said that, please keep in mind my original mind-set on validating the concept; My ultimate goal was to make a Hollow-Point bullet, operate and function as originally designed, except do so over a wider range of conditions. Everything else, is secondary. ___ Quote:

(Ever notice how well you can hear the slightest noise underwater, yet cannot tell what direction it's coming from?(just a note...)) ___ Quote:

Quote:

Yes, High-Speed video would be very useful...let alone cool! As it stands, I doubt that will be something I initiate. That'll probably be best served by the end licensee. they'll have the high-end expertise, budget and talent to do the complete R&D spread. Last edited by Mal H; November 25, 2009 at 10:13 AM. Reason: Added quotes for ease of reading |

||||

|

|

|

|

#40 |

|

Senior Member

Join Date: June 21, 2009

Location: West Central Missouri

Posts: 2,592

|

I was thinking about this a little more and I wonder if the air pressure (pneumatic pressure) is bled off through the ports, would it affect stability in flight?

What does it do to velocity? The ports would bleed off some air pressure, thus decreasing resistance. Does it affect stability? Again, my understanding is it would actually help stabilize the bullet while in flight. (Sort of like a golf balls dimples.) What sort of ranges would be best? I would think as a self-defense round, it would be used between 25 and 50 yards? I look forward to your answers and I hope I am not being a pain in the butt asking them. Although I could not do the book learning to become an engineer (Because most of them use language I am not familiar with) I do enjoy talking to people who are engineers and can explain things in words I do understand.

__________________

Inside Every Bright Idea Is The 50% Probability Of A Disaster Waiting To Happen. |

|

|

|

|

#41 |

|

Staff

Join Date: March 20, 1999

Location: Somewhere in the woods of Northern Virginia

Posts: 16,947

|

They1 - here's a post writing tip for including quotes from other members' posts:

http://www.thefiringline.com/forums/...d.php?t=323215 |

|

|

|

|

#42 | |||||

|

Member

Join Date: November 24, 2009

Location: Missouri

Posts: 44

|

Quote:

Any time there is a medium to overcome (i.e. a filled medium cavity), it's yet another process to be reacted with. In this case, look at the base bullet-to-contact scenario staging: 1.Bullet contacts target. 2. Bullet begins penetration. 3. Bullet begins filling cavity with tissue. 4. Bullet begins pressurizing cavity with tissue, while at the same time, pressurizing air trapped in cavity. 5. Pressurization reaches "critical mass". 6. Bullet begins expansion process. (2.) Simple is always better. With either air, or a filled cavity medium, those fundemental processes are unchanged. The HC design however, limits the effects of stages 4 and 5. ___ Quote:

However, I did find it interesting that in one of our tests, we hit a ballistic medium that was almost twice the density of standard ballistic gel, and the HC version opened (the example in the photo) and the stock round opened and folded back almost to the shank. ___ Quote:

HC only 'lives' for that first 20m/s. ___ Quote:

___ Quote:

::Cue up the Banjo!

Last edited by Al Norris; November 26, 2009 at 11:44 AM. Reason: added qoutes for readability |

|||||

|

|

|

|

#43 | |

|

Senior Member

Join Date: June 19, 2009

Location: Loadbenchville, Bolt 02770

Posts: 544

|

Quote:

I think Uncle Buck made a good point, as well...The possibility of better retained velocity. Even though the vast majority of shots from a Handgun are inside of 50 yards, better retained velocity is, well, better retained velocity...more FPS on impact. And given the possibility of a bullet that expands more reliably... that's 2 +'s. |

|

|

|

|

|

#44 |

|

Member

Join Date: November 24, 2009

Location: Missouri

Posts: 44

|

Thanks for the quote help MAL H.

Now I'm more confused than ever...  Old dog...new trick. I'll try to figure it out, no guarantees though... "A man's gotta know his limitations." -Clint Eastwood |

|

|

|

|

#45 |

|

Member

Join Date: November 24, 2009

Location: Missouri

Posts: 44

|

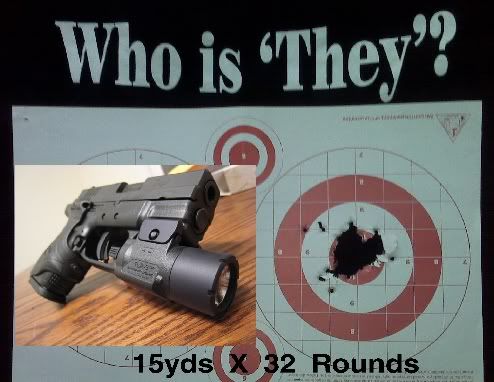

To address the in-flight/stability questions:

We've not done any long range rifle or pistol flight tests as yet, but nothing in our calculations has suggested rounds will be adverely effected by this design. We're currently working up some test rounds to confirm this. However, the following photo shows good accuracy, and no tendency to tumble:  *Note the "zingers". you can tell when the guys on either side of me were firing at the same time...

|

|

|

|

|

#46 |

|

Senior Member

Join Date: November 19, 2002

Location: Mississippi

Posts: 963

|

They1,

Would not the laminar flow being greater, create a vacuum and deplete the cavity of most of its pressure and produce more drag?? OR Is that the Key to this whole thing?? |

|

|

|

|

#47 | |

|

Member

Join Date: November 24, 2009

Location: Missouri

Posts: 44

|

Quote:

|

|

|

|

|

|

#48 |

|

Senior Member

Join Date: March 17, 2007

Location: Western NY

Posts: 925

|

I still struggle with the concept..

They1 - I wish you luck, but I belive that hydraulic pressure created with standard HP's allows them to work properly if the bullet is designed properly. By this, I refer to Federal hydrashok and HST, Golden Sabres, rangers, etc. They all work as designed and I struggle what adding these little holes will do to improve performance. Hopefully, this works out for you, but honestly, how can the following be beat???

__________________

See Ya! |

|

|

|

|

#49 | |

|

Member

Join Date: November 24, 2009

Location: Missouri

Posts: 44

|

Quote:

My whole point has been that nothing is perfect. And in the case of bullets, there are conditions that can, and do, lead to failure to open conditions. You can show me gel shots all day...but in the field, it can be a different story. Frankly, I have yet to ever be attacked by a gel block, but if I do, I'll let you know. I got shot with a Federal Hydrashok .357. The bullet passed through my upper thigh, grazed the bone, and exited the same size. I found the bullet the next day, and could have reloaded it without issue. It wasn't plugged, it just didn't open...good for me, bad for the bullet. The reasons for these failures are many, but the two widely-held, are loss of energy before bullet-crack can be initiated, and plugging. Loss of energy typically come from loss of velocity before contact with the target, or, more commonly, loss of energy after contact, while the bullet exchanges the air (gas), for the tissue medium. My whole point is this; You and I both want the same thing. You want a bullet that goes bang every time, and you want a bullet that opens every time. Porting the cavity is NOT the "magic bullet", again, nothing is perfect. But it does allow a bullet to operate more effeciently, over a wider array of conditions. If one small, inexpensive change to an HP bullet, can make the difference of a round opening or not...then why wouldn't you want it? |

|

|

|

|

|

#50 | |

|

Senior Member

Join Date: March 17, 2007

Location: Western NY

Posts: 925

|

Well, since you brought it up...

Quote:

__________________

See Ya! |

|

|

|

|

|

|