|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: July 4, 2010

Posts: 134

|

Full length sizer problems

hi everyone

I have a old winchester mod 70 that my grandpa had custom made by my winchester back in the early '70s for varmit chambered in .243 win and a heavy target style barrel. the problem i am having is my Lee FL sizer die wont push the shoulder back far enough for it to chamber. when I try to close the bolt with a bullet in it will close but it takes quite a bit of force. the chamber in the rifle is very tight. I guess thats whats needed for match grade accuracy. I shot a box of 20 Rem. cor-loct ammo through it and didnt have this problem. if any you guys can point me in the right direction that would be great! |

|

|

|

|

#2 |

|

Member

Join Date: February 15, 2009

Location: Harlan County,Kentucky

Posts: 81

|

me too!!

I have the exact same problem with a 243 that I have. Its the exact same situation. I would love help also. Mine is a single shot NEF though.

|

|

|

|

|

#3 |

|

Senior Member

Join Date: July 5, 2007

Location: Pacific NW

Posts: 1,310

|

There are a few things that can be going on -

1. Case length is too long and it is contacting leads 2. Bullet is seated out too far and it is contacting leads 3. Resizing die isn't adjusted to take up "slack" in press If your case length is at the recommended "trim to" length and the bullets are seated properly, then the most likely candidate is #3. You should have something like a Wilson-type cartridge headspace gauge to set up the die, to check to see if the resized case is within SAAMI specifications. Another alternative is something like Hornady's bullet comparator / headspace bushings (which can be used with a vernier caliper.) #1 and #2 can create overpressure, so make sure these aren't happening...

__________________

.30-06 Springfield: 100 yrs + and still going strong |

|

|

|

|

#4 |

|

Member

Join Date: January 6, 2010

Location: Houston

Posts: 70

|

If you have a "short shouldered" chamber then the best solution is to take some length off the bottom of the die. I had a problem with a Redding Body Die in 22-250 and took it to a machine shop and had a 1/4" taken off. Now the die can be adjusted down far enough to push the shoulder back.

Some have said to take a little off the top of a shell holder. Most dies and shell holders are hardened so a file will not work. A grinding wheel will but makes a mess and may damage something. If you use a grinding wheel then the shell holder is the best candidate. Much less expensive than a die.

__________________

Guns have 2 enemies, rust and politicians |

|

|

|

|

#5 |

|

Senior Member

Join Date: February 13, 2006

Location: Washington state

Posts: 15,248

|

Since the ammo was fired in the chamber in question, it is not necessary to shorten the die or "bump back" the shoulder. Your problem is one of these:

1- Case too long and running into the end of the chamber. 2- Bullet seated out too far into the rifling (although I have never known a bullet to stop a round from being chambered if it is close) 3- The chamber has a tight neck and the case neck is expanded too far by seating the bullet. I would bet on #1, but check all 3.

__________________

Never try to educate someone who resists knowledge at all costs. But what do I know? Summit Arms Services |

|

|

|

|

#6 |

|

Senior Member

Join Date: July 4, 2010

Posts: 134

|

thanks

I was looking at this again today, the casings have alot of scratches on the shoulder after FL sizing. its not the bullet I know that for sure. I seat them .02 off the lands. I think Im going to get a SAAMI spec FL sizer die. the ram set to where the handle is all the way down it pushes up on the FL sizer die. before i get a new die I will grind down the top of the Lee shell holder and see if that pushes the shoulder back. |

|

|

|

|

#7 |

|

Senior Member

Join Date: June 9, 2010

Location: NEPA

Posts: 909

|

The easy fix for this is to take down your shell holder a little. Lightly sand off 0.001 from the top of the shell holder or do the same thing to the base of the die!

|

|

|

|

|

#8 |

|

Senior Member

Join Date: December 23, 2005

Location: Minnesota

Posts: 2,952

|

I agree that you may need to bump the shoulder back more, but before you go grinding stuff, check a few thinks.

Does the FL sized brass chamber with NO bullet seated? If the brass chambers with no bullet seated then it's in the seating process. How did you set up your seating die? If you did not back the seating die out at least one full turn you may be applying an unwanted crimp, and buckling the case neck just a tad. As already stated, is the brass "Trimmed to length"? Does the once fired brass chamber before FL sizing? Have you taken the Lee die completely apart and cleaned it good? They come with all kinds of crap inside that needs to be cleaned up before use. |

|

|

|

|

#9 | ||

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,885

|

Quote:

Quote:

After initially screwing in the die to the ram top, release the ram back down and screw in the die another 1/8-1/4 turn so the ram has to "cam over." In a press that slightly flexes, this will ensure you fully size to the die's bottom even after that flex. |

||

|

|

|

|

#10 |

|

Member

Join Date: February 15, 2009

Location: Harlan County,Kentucky

Posts: 81

|

.

well i have trimmed my brass to the correct length and it doesnt even work with no bullet seated it looks like it goes in bu then when i try to close the gun it is either hard or wont shut all the way. it has been checked and rechecked. it went in fine the first time when it was factory but not anymore after the resizing.

|

|

|

|

|

#11 |

|

Senior Member

Join Date: June 9, 2010

Location: NEPA

Posts: 909

|

Do you have a fired case that has not been resized? How does that go in? Have you checked to make certain that you have the correct die? I have a 708 with a very tight chamber and a 300 WSM with a short chamber. Using a 450 or 600 grit sandpaper I just took a small amount off of the top of the shell holder. This will set the should back a little farther.

|

|

|

|

|

#12 |

|

Senior Member

Join Date: January 26, 2009

Posts: 654

|

I had the same problem with 223 rounds. Turned out that I had RCBS dies with a Lyman shell holder. Changed over to a RCBS shell holder and all was good. Universal shell holders ain't so universal.

|

|

|

|

|

#13 |

|

Senior Member

Join Date: July 4, 2010

Posts: 134

|

mehavevey,

I dont have a cam over press its a Lee turret press. and the die is screwed all the way down so when the ram/shelholder is at up its pushing the FL sizer up if I screwed it in more it would be to far. I called Lee today about this, they gave me explanation that summed up to "not our problem" |

|

|

|

|

#14 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I use a cam-over press and am not sure what yours does, but on the cam-over models, if the expander bulb is too far down it will hit the bottom and feel as though it went all the way. Rare, but does happen to people.

|

|

|

|

|

#15 | ||

|

Senior Member

Join Date: November 9, 2005

Location: Ohio, Appalachia's foothills.

Posts: 3,779

|

Quote:

Quote:

|

||

|

|

|

|

#16 |

|

Senior Member

Join Date: December 26, 2004

Location: Louisville KY

Posts: 13,806

|

Forgive my newbie ignorance, but wouldn't it be better if he used a Lee neck sizing die instead, since he's using a bolt action?

|

|

|

|

|

#17 |

|

Senior Member

Join Date: July 4, 2010

Posts: 134

|

chris,

I hate Lee neck sizer dies for my own reasons. I use RCBS neck sizers they work alot better |

|

|

|

|

#18 |

|

Senior Member

Join Date: July 4, 2010

Posts: 134

|

mr. awsome,

I just tried that and it didnt work, you owe me 5 bucks haha. the problem is the lee FL sizer doesnt size cases to SAAMI spec. they work fine in all my other rifles. but for precision rifle with very close chamber tolerences you will need a different die or maybe take 1mm of the bottom of the one you have. Last edited by midnightrider; July 20, 2010 at 08:33 PM. |

|

|

|

|

#19 |

|

Senior Member

Join Date: July 5, 2007

Location: Pacific NW

Posts: 1,310

|

Generally, once-fired cases will rechamber in the same rifle they were fired from, "precision" or not.

Unless something funny is going on with the expander button and the shoulder is being stretched a little as the case is withdrawn... I can't prove this, but it's about the only thing that makes sense. You might try lubing the inside of the neck a little and see if the case will chamber after resizing.

__________________

.30-06 Springfield: 100 yrs + and still going strong |

|

|

|

|

#20 | ||

|

Senior Member

Join Date: November 9, 2005

Location: Ohio, Appalachia's foothills.

Posts: 3,779

|

O.K., I owe 'ya... I'll pay 'ya in beers? Cool?

Quote:

Quote:

I know if this were my rifle, I'd gently explain to my wife, over dinner at her favorite restaurant, that I need custom die!

|

||

|

|

|

|

#21 |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

The set up instructions given with sizing dies assume a lot of things. And seldom following the instructions do you ever get the brass sized to the correct length. If possible you would like to set back the case shoulder about .003” from the fully expanded condition it comes out from the rifle. In no circumstance do you ever want to size it more than .006” as you are likely to get a case head separation on the next firing. There have been instances where I followed the instructions and I got a crush fit in the rifle chamber because the sizing die did not set the shoulder back enough. In those instances I have had to grind material off the bottom of a sizing die to get sufficient case sizing. If the sizing die is too long, you have to shorten it. Why is that a difficult concept for some?

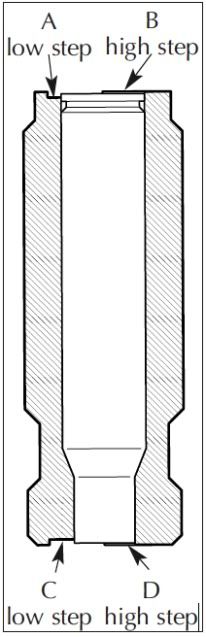

To properly size cases to a correct length you will need a new piece of equipment that has not been mentioned: case gages. I really like the Wilson type case gage. You size your round and drop it in the gage. This gage measures the distance between shoulder and base. It is a "go" and "no Go" gage. And they are calibrated, as I have dropped my chamber headspace gages in my wilson gages and found perfect agreement between them. You want to size your case between “go” and “no go”, and for my match rifles, I size everything to gage minimum. This allows my ammo to fit all of my rifles of a similar caliber.   If you want to try an experiment, size the case following the factory sizing die instructions. Then measure the sized case length with your case gage. If the case is between the “go” and “no go” of the gage, go buy a lottery ticket. Because it is your lucky day and you are going to be a millionaire. This picture shows the length difference between go and no go on my Wilson gage. I don’t see how anyone randomly turning the die is ever going to be between these marks.

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

#22 |

|

Senior Member

Join Date: August 19, 2007

Location: Montmorency Co, MI

Posts: 1,551

|

Factory ammo shot and chambered!!

If you are not lubbing the INSIDE of the necks-then when you raise the press haddle (Lower the die) and the expander ball comes out of the case-the neck/shoulder is stretched. Check cases after sizing in the rifle or get a Wilson case gage as may have been mentioned. Check each case after sizing and after seating bullet on every round you reload regardless of gun it is for. Following added after reading a post above about a half dozen. A previous posted said the same thing in a different way: Generally, once-fired cases will rechamber in the same rifle they were fired from, "precision" or not. Unless something funny is going on with the expander button and the shoulder is being stretched a little as the case is withdrawn... I can't prove this, but it's about the only thing that makes sense. You might try lubing the inside of the neck a little and see if the case will chamber after resizing. |

|

|

|

|

#24 |

|

Senior Member

Join Date: July 4, 2010

Posts: 134

|

slamfire,

I uderstand your method of making the die shorter by taking material off the bottom. but I dont have the tools to accuratly do this. If I did I would do it. I am in a very busy part of my life I barely have time to sit down and load up ammo to go to the range once a month. maybe when I get the time I will do it. demazer I always lube the inside of the necks with powdered graphite, and its a very easy pull on the expander step of the stroke. Mr. awsome thanks for the idea! I will have to talk it over with the GF |

|

|

|

|

#25 |

|

Senior Member

Join Date: June 9, 2010

Location: NEPA

Posts: 909

|

You don't need tools to remove 0.001 off of the bottom of the die or from the shell holder. Flat table 400 grit sand paper. One of two swips over the sand paper and test it. I like doing it to the shell holder since they can be replaced for a few bucks. RCBS sells a set of competition shell holders that have different thicknesses so you cna do this adjustment.

|

|

|

|

|

|