|

|

|

#1 |

|

Junior Member

Join Date: April 9, 2008

Location: Virginia

Posts: 6

|

Casting time

How long does it take to cast 100 bullets, from start to finished product?

|

|

|

|

|

#2 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

No simple answer.

Might want to put this question in the bullet casting sub-forum. Link is at the top of this forum's page and here.

The answer to your question depends on the variables, so you might want to figure out what they will be to include the information in your question? How big are the bullets? How many cavities does your mold have? What method are you using (bottom pour or ladle). Are the bullets conventional lube groove design you will put through a lubrisizer or are going be unsized and tumble lubed? Are you planning to heat treat them? Also, there's time overhead: getting the alloy into ingots; letting the pot heat and melt the alloy, then fluxing it initially; getting the mold blocks up to casting temperature. If you cast 500 bullets in one session, that overhead gets a lot smaller per bullet than casting just 100. So, having three hours for a casting session gets you disproportionately more output than having half that time does.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle Last edited by Unclenick; March 21, 2010 at 01:52 PM. |

|

|

|

|

#3 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

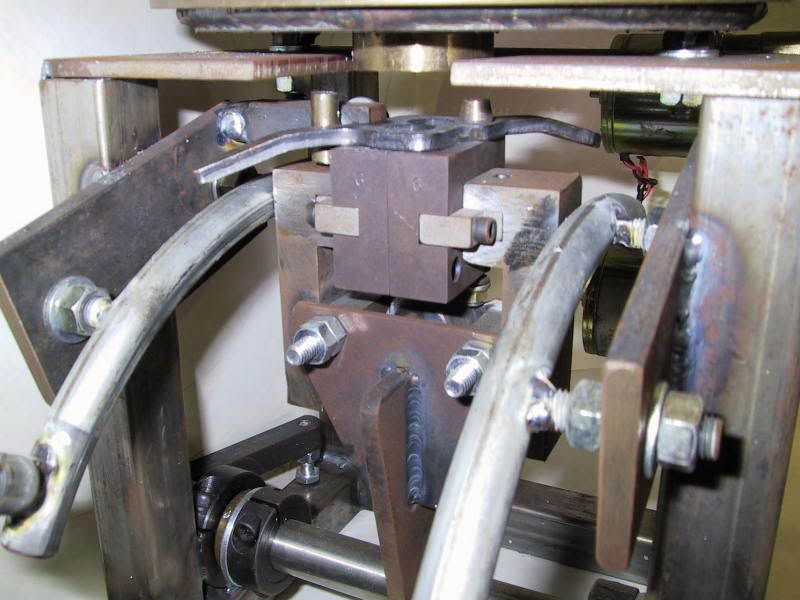

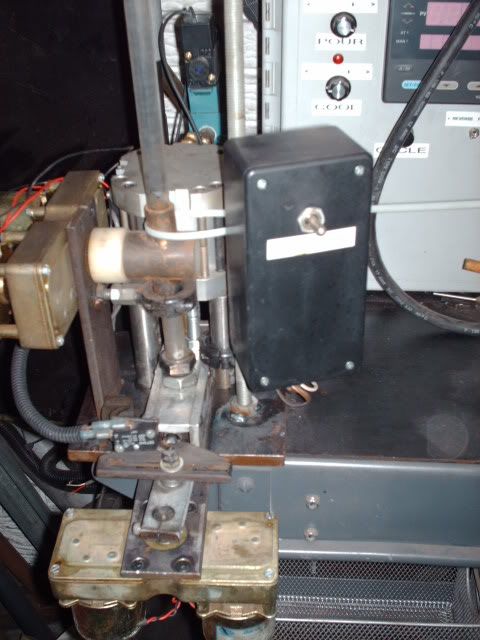

I have an automated casting machine (2 bullet mold) and an automated sizer and dip lube the sized bullets. Not counting heat up or drying time it takes almost 14 minutes to make 100.

|

|

|

|

|

#4 |

|

Senior Member

Join Date: December 23, 2008

Location: Southern Illinois

Posts: 1,527

|

With a Lee 6-cavity mold I can very easily pour 2-3 molds per minute. That is 18 bullets per minute. So about 5-6 minutes to make 100 bullets (give or take). It does take time to heat up the pot though...maybe 15-20 minutes. Once the bullets are cast and cool to the touch, I can begin running the bullets thru my Star lubrisizer. The Star is one of he fastest lubrisizers out there. I can lube 100 bullets in 3 to 4 minutes going at a comfortable pace. BUT....most guys do not go about it this way. We cast a bunch of a given bullet or 2 in a casting session. Molds can get really hot and the hotter they are the longer it takes for the bullets to solidify. Thus, once a mold gets too hot, it is best to start casting with another mold. Some guys have 2 molds of the same caliber and swap them out when they get too hot. I like to cast 2 different styles of bullets in a given casting session. Each session will yield 750-1000 bullets. That is about all I can do (I get tired)...especially if I am using 2 cavity molds. Once you have all these bullets cast, then you get to lube them. This may be immediately after casting or a couple months later...doesn't really matter. I like to lube all the bullets in one go so I have them ready when I need them. If you go start to finish each time you want to load 100 bullets it will not be very time-efficient. Hope this helps.

__________________

~~IllinoisCoyoteHunter~~ ~NRA LIFE MEMBER~ ~NRA CERTIFIED INSTRUCTOR~ |

|

|

|

|

#5 |

|

Senior Member

Join Date: August 23, 2008

Location: SoCal

Posts: 6,442

|

I've never really timed myself per 100 bullets. I cast outdoors, so there's the set up time added to the other overhead already mentioned. My casting sessions are long and infrequent. Like ICH, I keep two LEE 6-cavity molds and two pots going. I find it interesting that ICH's manually operated 6-cavity molds can do 100 bullets in less time than the machine of jmoris. Sizing is another matter, I use an old Lyman with a Midway heater.

|

|

|

|

|

#6 | |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

Quote:

|

|

|

|

|

|

#7 |

|

Junior member

Join Date: January 1, 2007

Location: Idaho

Posts: 2,282

|

I'm thinkin with a two cavity mold maybe 100 in 1/2 an hour...never timed it. I use a wet towel to cool my molds when they get too hot or to solidify a sprue, and I dip my metal. That's a good question, I will have to time myself next time. Oh yeah, and I'm told if you don't plan on doing a lot of shooting you can get by with a lyman or rcbs lubersizer.

|

|

|

|

|

#8 |

|

Member

Join Date: October 11, 2008

Location: N.E. Missouri

Posts: 31

|

I cast at around 2400 an hour, so not to long

|

|

|

|

|

|