|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Search | Today's Posts | Mark Forums Read |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: January 7, 2012

Location: Auburn, AL.

Posts: 2,332

|

Rainy? Stuck indoors? Build a PID!

I had built one last year using a small PID from Auberins.com and it works really great, but I almost immediately wanted one with a bigger display, just to have larger numbers and buttons. I use PID's for 3 or 4 things and it's also handy to have one for each task so I don't have to reset the values or wait for it to retrain when I switch appliances, so another one will be useful.

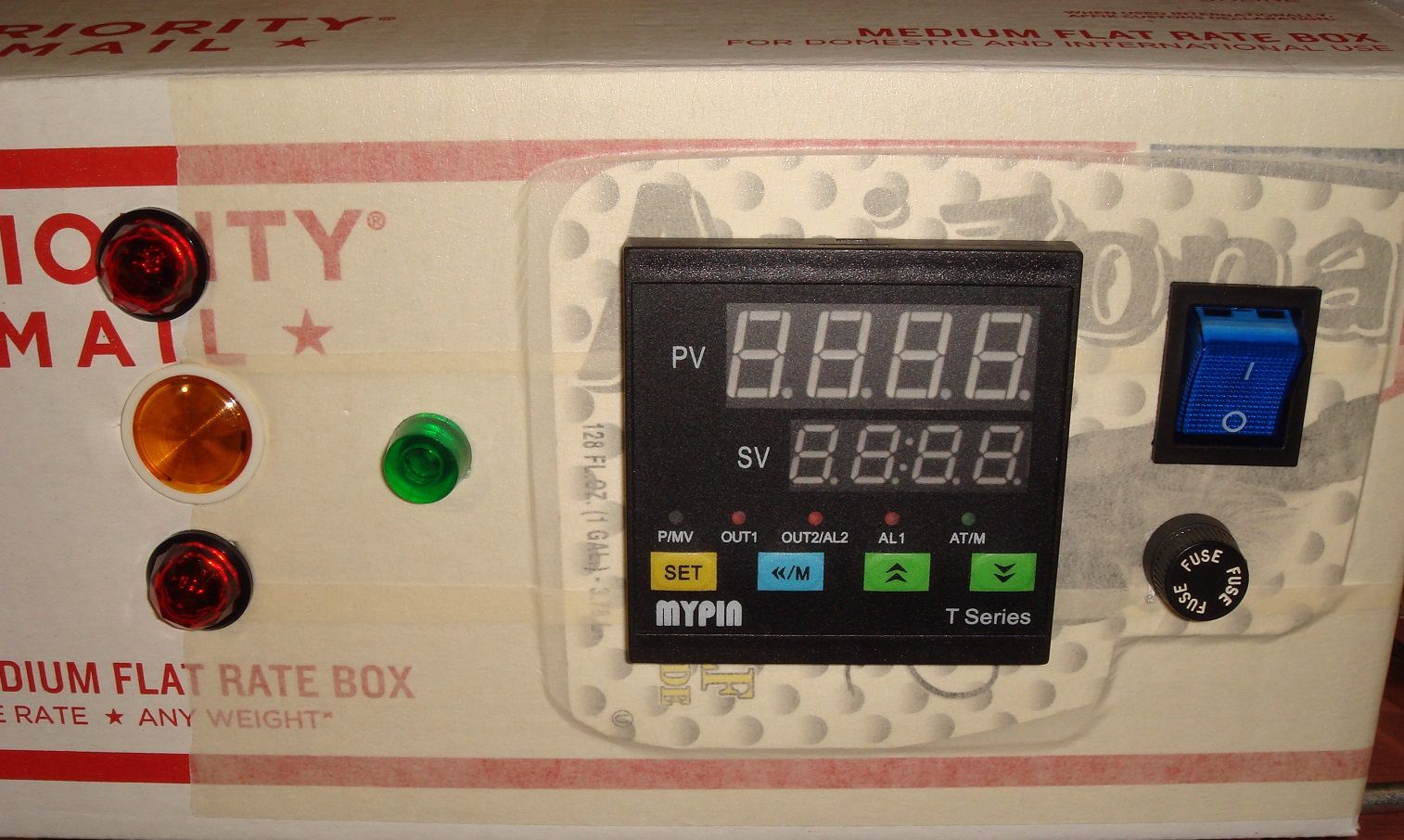

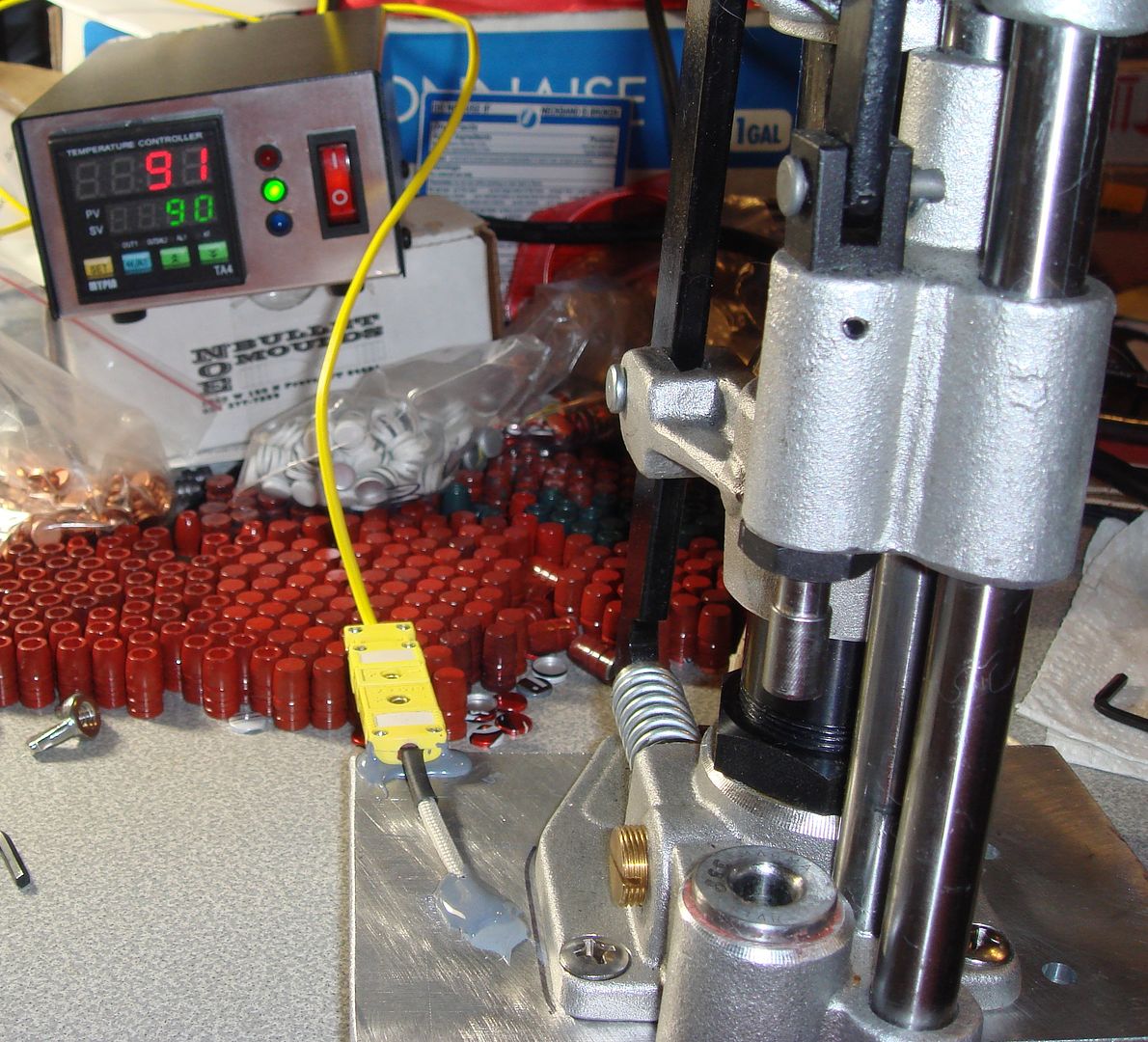

This was the first one I built..... using the Auber 1/32 DIN-sized PID.  And this is the one I made today.. using a Mypin TA7 PID. (4X bigger)   It's not more "powerful" or smarter, it is just bigger and easier to see and use the larger buttons. It also shows both the set value and actual temp at the same time. My original model requires switching back and forth to see one or the other. This one is the "Easy Reader" version!  I like building them in the cardboard box because it is just a nice roomy size to work in and very lightweight. I don't work very well in tiny places (big fingers and thick glasses)

__________________

. . . Have a Colt and a smile.

|

|

|

|

|

#2 |

|

Senior Member

Join Date: October 28, 2006

Location: South Central Michigan...near

Posts: 6,501

|

Now, if I just knew what a "PID" was, I would be all set.

|

|

|

|

|

#3 |

|

Senior Member

Join Date: August 25, 2008

Location: In the valley above the plain

Posts: 13,423

|

I'm surprised there weren't more replies to this by now.

Anyway... How good was the wiring diagram and technical information that came with the PID, Beagle? I've come across the Mypin PIDs a few times, but everyone talks about them like the data is pretty sketchy and hard to interpret. Was that your experience, or have they improved their reference material? I ask mostly because I can't figure out if I need a separate relay for switching the 110V supply for my pot, or it the relay in the PID can handle it...

__________________

Don't even try it. It's even worse than the internet would lead you to believe. |

|

|

|

|

#4 |

|

Senior Member

Join Date: January 7, 2012

Location: Auburn, AL.

Posts: 2,332

|

A PID is just a "smart" thermostat that "learns" what it is controlling. I use it for my lubesizer heater, my lead pot, my mold pre-heating hotplate, and my powdercoating toaster oven.

It will regulate anything to within 2± degrees of the set temperature. That means no fluctuations of 50° or more with your lead pot while you are casting, or no over/under cooking of the powdercoat (or biscuits, if that's what you decide to bake), or no fiddling around with the lube heater on the sizer (notorious for either leaving the lube hard and difficult to apply, or so warm that it drips out the bottom of the die.) It learns how fast whatever you are using will heat up and how fast it reheats. Let's say you set a regular thermostat at 700°..... when your thermostat gets there, it clicks off, and your coils are still glowing red hot and your pot of lead ends up at 730°, then it begins cooling down and your thermostat lets it cool down to 680° before it kicks back on for a heat cycle. Your lead cools on down to 675° before the coils get red again and start transferring heat through the metal pot and the temp will climb back to 700°+ and the cycle will start all over again. This thing will "learn" (autotune) as to how much it takes to get your pot to exactly 700° and start "slowing down" or "coasting" before it gets there. It anticipates how much heat it will take to get back to set temp and doesn't go full power all the way to it. It eases up to the set temp and then it knows how much to intermittently apply to keep it at 700° by using short bursts and pulses instead of getting the coils glowing again, so it adjusts it in tiny increments now and the lead (or oven or whatever) stays right at perfect temp. It will also learn how much it takes to keep it hot with whatever load you are heating, and so your pot won't get hotter and hotter as the lead level drops, like most pots will do. And if you add more lead to the pot or change the tray of bullets baking when powdercoating, it won't just apply full power and overshoot, it'll hit it hard for a minute or so and then slow down as it approaches the target temp again.

__________________

. . . Have a Colt and a smile.

|

|

|

|

|

#5 |

|

Senior Member

Join Date: September 27, 2004

Posts: 4,811

|

The whole PID (proportional-integral-derivative controller) story, unexpurgated version.

http://en.wikipedia.org/wiki/PID_controller We used them for tank temperature control on film processors. Basically they "learn" how much current changes how much volume by how much temperature. Then they steam up fast to a learned point & progressively back of power or go on/off to sneak that last bit into the set aim. It prevents "Poropising" of temps as the element retains energy as heat even after the power is cut as with a conventional thermostat.

__________________

Allan Quatermain: “Automatic rifles. Who in God's name has automatic rifles”? Elderly Hunter: “That's dashed unsporting. Probably Belgium.”

|

|

|

|

|

#6 |

|

Senior Member

Join Date: January 7, 2012

Location: Auburn, AL.

Posts: 2,332

|

I bought this one on Amazon and there were no instructions. But there are instructions on the web that can be downloaded. There is enough information in the casting equipment section of castboolits now to cover any installation of the Mypins and there are plenty of folks to help you through any build if you should get stuck. There are several examples of builds now on there, from start to finish, and if one doesn't mirror your situation exactly, just start a thread and lots of folks will guide you to the finished product and are really a lot more helpful than a set of instructions. If one isn't an electronics-friendly person (such as me!), you can simply take pics as you build and post them and the guys there will actually walk the builder through the steps, one connection at a time.

All three of my PID's use a separate Solid State Relay to control the power. The PID just provides the switching signal to the SSR. There are some with internal relays, but I do not know their limitations. I have seen it discussed on the CB forum in the casting equipment section though. You should be able to find a PID, a separate 25A SSR and a thermocouple for about 35-50 bucks. (depending on where you shop  ) )I just used a flat rate postal box as the container because it is free, it's big and roomy for my clumsy hands, and nobody else had done it! But beware, the safety Nazis will flame you quite a bit for building an electronic thingy in a paper box. I only cast and powder coat outdoors though, so it doesn't really matter to me. I do use my lubesizer indoors, but I have one model that I bought from Frozone that is a commercial PID and is in a metal box.  (I don't lube powdercoated bullets..... I just keep a messy bench and those were on the bench the day I first mounted/tested the lube heater.)

__________________

. . . Have a Colt and a smile.

Last edited by Beagle333; January 6, 2015 at 11:39 AM. Reason: spellin |

|

|

|

|

#7 |

|

Senior Member

Join Date: September 27, 2004

Posts: 4,811

|

SSR's (solid state relays with no "points" or moving parts) are way better!

Mechanical relays are actually pretty poor for rapid on/off cycles such as this would require. One of the BIG upgrades we did was replacing every mechanical relay with an SSR.

__________________

Allan Quatermain: “Automatic rifles. Who in God's name has automatic rifles”? Elderly Hunter: “That's dashed unsporting. Probably Belgium.”

|

|

|

|

|

#8 |

|

Senior Member

Join Date: August 25, 2008

Location: In the valley above the plain

Posts: 13,423

|

Thanks for the replies.

Electronics are not foreign to me, so handling the situation isn't a problem. It's just trying to find information on these Mypin PIDs that was proving difficult. I'll probably order some parts soon and then dig a little deeper at castboolits...

__________________

Don't even try it. It's even worse than the internet would lead you to believe. |

|

|

|

| Thread Tools | Search this Thread |

|

|