|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: March 19, 2002

Location: Nashville

Posts: 1,117

|

Case rupture - What did I do wrong???

[IMG]

[/IMG] [/IMG]Bullets: Hornady 180 JFP 10mm Powder: Accurate #7 11 grains (max for this combo is 12 grains) Primer: CCI Large Pistol Primer #300 Brass: Unfired Starline C.O.L. 1.260" Pistol: S&W 1076 4.25" barrel (first time I've shot this gun) Can anyone tell me what I did wrong? I double checked several rounds and they weren't over charged and my bullet seating is correct as specified. I didn't go over the max and the brass was brand new. I thought maybe the rounds weren't head spacing right so I included a picture of them fitting in the chamber. They look about right to me. There is no visible flaws in the chamber and the diameter of the fired brass (the ones that didn't burst) is a couple thousandths of an inch narrower than the brass that was fired in my Glock 20 (which I no longer have) so I assume the chamber is a littler tighter. Take a look at where both cases failed, they failed in the same place. I shot about 25 rounds and the last two were the ones that failed. The second to the last ejected and I had no idea that it had split. The last one ejected only the last half of the case and left the first half in the chamber. I couldn't fully chamber any more rounds which is how I knew it had failed. Any suggestions? Did I do something wrong? Could it be a bad batch of brass?

__________________

"The loudest sound you'll ever hear is a "bang" when you weren't expecting one." -Jimro Last edited by Ocraknife; August 22, 2016 at 08:31 PM. |

|

|

|

|

#2 |

|

Senior Member

Join Date: May 4, 2010

Posts: 5,468

|

Puzzle.

__________________

None. |

|

|

|

|

#3 |

|

Senior Member

Join Date: September 2, 2010

Location: Plainview , Long Island NY

Posts: 3,863

|

Did you measure the case length ? Even new cases should be checked & cut to the same length. Also checked in case headspace gage.

|

|

|

|

|

#4 |

|

Senior Member

Join Date: July 26, 2011

Location: USA

Posts: 1,730

|

10.7 is max for the xtp on Accurates website. http://www.accuratepowder.com/load-data/

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

That is weird. I can't recall seeing straight wall cases torn in half, most unusual.

In my opinion, your load is too hot. If the breech pressure at unlock is high, and the case front is sticking to the chamber during extraction, that could be the problem. Two ways to approach this, firstly cut your loads. Secondly, shoot some rounds with the cases dry and some lubricated. Take an oil bottle and put a drop of oil on every second or third round in the magazine. This will break the friction between case and chamber at normal pressures. I do this all the time shooting Bullseye Pistol with the loads in my 1911. Allows my pistol to cycle more reliably with light loads.

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

#6 | |

|

Senior Member

Join Date: March 19, 2002

Location: Nashville

Posts: 1,117

|

Quote:

__________________

"The loudest sound you'll ever hear is a "bang" when you weren't expecting one." -Jimro |

|

|

|

|

|

#7 |

|

Senior Member

Join Date: March 21, 2013

Location: Idaho

Posts: 5,522

|

Very Similar Loading

With Hornady's 180 XTP, using *-* brass (new, in some instances), and CCI 300 primers, I have run up to the full 12.0 grains of AA#7 with no trouble.

Both Hornady 9th and Speer #14 maxes out at 12.0 grains. I settled on 11.7 grains as my set recipe only to have some safety margin - the 12's shot fine without any pressure signs. And I have since loaded and shot several hundred of the 11.7's through my G20sf & G29sf with no trouble at all. It's a fine shooting round. I load them to an OAL of 1.255". But that's kind of apples n oranges as we're using slight different bullets and guns. I'm not going to guess at the problem. A bad batch of brass is a possibility, but I'm not saying it is. I'm only chiming in to let you know there's a guy out there who's loading a very very similar round with no trouble at all.

__________________

Gun control laws benefit only criminals and politicians - but then, I repeat myself. Life Member, National Rifle Association |

|

|

|

|

#8 |

|

Senior Member

Join Date: December 10, 2014

Posts: 1,965

|

New brass from Starline should be good to go. They have been very consistent for me.

I think you should consider the 11.0 gr charge of AA#7 to be in no man's land. Might want to call the max charge for your gun to be 10.5 gr AA #7. From the attached photo, your rounds passed the plunk test just fine. Remember, what works in a test gun at the ballistics lab won't necessarily be OK for your gun, and vice versa. |

|

|

|

|

#9 | |

|

Senior Member

Join Date: March 19, 2002

Location: Nashville

Posts: 1,117

|

Quote:

__________________

"The loudest sound you'll ever hear is a "bang" when you weren't expecting one." -Jimro |

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: March 19, 2002

Location: Nashville

Posts: 1,117

|

Quote:

__________________

"The loudest sound you'll ever hear is a "bang" when you weren't expecting one." -Jimro |

|

|

|

|

|

#11 |

|

Senior Member

Join Date: March 19, 2002

Location: Nashville

Posts: 1,117

|

When you look at the unfired primer vs the fired primer, is it just me or does the fired primer look like it is flattened, as if it were subjected to overpressure?

__________________

"The loudest sound you'll ever hear is a "bang" when you weren't expecting one." -Jimro |

|

|

|

|

#12 | |

|

Senior Member

Join Date: July 26, 2011

Location: USA

Posts: 1,730

|

This -

Quote:

|

|

|

|

|

|

#13 |

|

Senior Member

Join Date: July 26, 2011

Location: USA

Posts: 1,730

|

The fired primer looks like it may have primer wipe. The firing pin is in contact with the primer as the action is opening. Normal on some guns. Other wise, it looks ok Primer wipe" is a teardrop-shaped firing pin impression, accompanied by a drag mark (scratch or gouge) following the "point" of the teardrop and leading away from the primer, sometimes into the brass. This is because the firing pin does not fully retract after the round has fired and the slide is traveling back during ejection, causing the case to drag across the firing pin as it is thrown clear. It is not in any way harmful, except sometimes to the case if the primer pocket edge is gouged. Kahr will tell you it is a normal condition for their pistols, even saying so in the owner's manual.

|

|

|

|

|

#14 | |

|

Senior Member

Join Date: March 19, 2002

Location: Nashville

Posts: 1,117

|

Quote:

__________________

"The loudest sound you'll ever hear is a "bang" when you weren't expecting one." -Jimro |

|

|

|

|

|

#15 | |

|

Senior Member

Join Date: July 26, 2011

Location: USA

Posts: 1,730

|

Quote:

|

|

|

|

|

|

#16 | |

|

Senior Member

Join Date: March 19, 2002

Location: Nashville

Posts: 1,117

|

Quote:

__________________

"The loudest sound you'll ever hear is a "bang" when you weren't expecting one." -Jimro |

|

|

|

|

|

#17 |

|

Senior Member

Join Date: May 4, 2010

Posts: 5,468

|

I'm not convinced that it's pressure related. Rough chambers are found on a whole lot of pistols. The amount of pull that was needed to neatly rip that off in that ring would have been incredible, it should show as a gouge in the rim, I think.

It's not at the base of the bullet. Why would it have torn off so perfectly in the exact place, twice? The way there are fine shreds of brass on the tips of all cuts surprised me. I am having a really hard time putting this to load error, because I'm just not seeing problems serious enough to cause it, and brand new brass should have been too strong to pull apart like that unless there was already a weakness. I can't explain it, but I don't think that pressure and a dirty chamber combined would have done it. I can't imagine what sort of flaw in the brass could have caused it. You should, IMO, inspect all of the remaining cases as carefully as you did these. Take a really good look at your chamber, as well. Have you used the gun very much? Imo, you MUST contact starline and have them look T this. If there is a problem with the cases, they need to know.

__________________

None. |

|

|

|

|

#18 |

|

Senior Member

Join Date: May 4, 2010

Posts: 5,468

|

It's important to note that when a bottleneck case is stuck, has anyone pulled off the case head? I'm sure that it could happen with old brass, but this just doesn't look right.

I've even got a paranoid feeling that he made this story up to keep us up all night.

__________________

None. |

|

|

|

|

#19 |

|

Junior member

Join Date: July 23, 2016

Posts: 85

|

I concur about measuring case length after resizing, see where you are relative to specs.

Is it possible to get a closer pic of your crimps? What type crimp are you using? Normally the plunk test in the barrel is good enough, but in your situation a case gage may be a good idea. Agree with backing off max load for testing a new set of reloads. |

|

|

|

|

#20 | |||||

|

Senior Member

Join Date: December 10, 2014

Posts: 1,965

|

Quote:

Quote:

Myself would drop maybe 0.5-1.0 gr. and give it a try. Quote:

Quote:

Quote:

You only had two cases that created a problem. I don't think that would indicate the whole batch of brass is defective. Measure the cases, maybe every 5th or 10th one and get a feel for the brass. One thousandth is not going to create any problem. I have loaded over 100,000 handgun cartridges spanning a 54 year career in the hobby and I can honestly say that I have never trimmed even one and I have never owned a case gauge of any sort. I haven't destroyed any guns either. Just reduce your charge by an amount that makes you feel comfortable and give it a try. Just remember, don't reduce too much. The only thing really to worry about is if the cases have more separations, take care of it as the gasses will eventually cut the chamber. |

|||||

|

|

|

|

#21 | |

|

Staff

Join Date: March 11, 2006

Location: Upper US

Posts: 28,817

|

Quote:

This does not look like other case separations I have seen. This was not caused by brass that had been fired too many times and just failed. Look at where the brass failed, Check your other cases for a thin spot! This LOOKS like defective brass to me, and Starline is the people to talk to about it. Your load is within published data , I wouldn't worry about reducing it (at this point) unless you want to... Check with the maker, let us know how they respond. (and put that batch of brass, loaded, unfired and fired aside for now, until you know more. The flaw could only be in those two cases, OR it could be in many more, that haven't been found yet. Play it safe.)

__________________

All else being equal (and it almost never is) bigger bullets tend to work better. |

|

|

|

|

|

#22 |

|

Senior Member

Join Date: August 6, 2002

Location: SoCal PRK

Posts: 986

|

Maybe it's just the lighting but are those nickle plated? I see regular brass in the pics but the ones that are separated look like nickle.

I'm gonna have to agree with others that said its a case failure and to contact Starline to get their opinion. Look inside other fired cases in the same spot and look for a ring around the inside. If you see it, don't fire any more as you don't want to damage your pistol. Dufus summed it up pretty good, primers look good and don't show pressure signs. When people say that they will be flat, they'll be flat and fill out the primer pocket. That or they'll just fall out of the pocket from being flattened and the pressure trying to push them out. Also do like he said and reduce your charge but check your manual so that it's not to low. Back to nickle, I don't like using it as it doesn't spring back as much as brass and isn't as pliable either. Making it prone to being brittle and the way the cases look made me think of it. Even if they are new, the process of running them through the dies could've made a weak point weak enough to split.

__________________

I see the world thru bloodshot eyes Streets filled with blood from distant lies The dogs of war never compromise, No time for rearranging. |

|

|

|

|

#23 |

|

Senior Member

Join Date: June 14, 2004

Location: NY State

Posts: 6,575

|

Take a new case and carefully cut in half lengthwise . Check dimensions.

Clean and check the chamber dimensions.If the gun is unlocking while pressures are still high that might do it .

__________________

And Watson , bring your revolver ! |

|

|

|

|

#24 |

|

Senior Member

Join Date: January 27, 2014

Location: New Mexico

Posts: 204

|

Chamber

I am not an expert in this, but as we all know, that kind of case failure in straight wall pistol cases is very rare, and almost unheard of in quality new brass. I absolutely would contact Starline and get their thoughts on it.

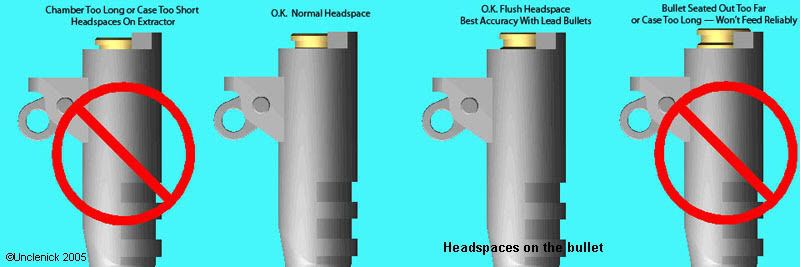

But if those are brand new cases, once fired, they look TERRIBLE to me. In a couple of the pictures, your chamber looks absolutely filthy - way too dirty for 25 rounds if the gun was actually clean when you started. And in the bottom left picture, the brass clearly shows physical damage from something pressing on it - looks kinda like three little punch marks. I would seriously consider having a gunsmith look at that chamber. Finally, the top middle picture looks like the fired brass is visibly ballooned in the bottom half, but not the top. It is probably a trick of the photograph, but if it is actually expanded significantly more on the bottom than the top, I would again be worried about that chamber. Maybe it is normal; I do not know. I have never had reason to measure my once fired brass that closely to compare it with what I think I see here. And Yes, headspace problems CAN cause this. Pistol cases headspace on the case mouth, and if they go into the chamber so far that there is significant room between the bolt and the case head, then the act of firing can cause the front of the case to "anchor" to the chamber walls while it is trying to release the bullet, and the rear of the case is pushed backwards into the bolt face. If that is what caused this failure in your gun, then it is an extreme problem, and I would not consider the gun safe to shoot. Your bottom middle picture looks to me that you have massively excess headspace - again this is quite possibly just a trick of the photograph, but it sure looks to me that the case head is WAY below the face of that breach (see the images below). Of course, it all depends on the actual shape of the bolt face. Once again, you need to find a good qualified gunsmith.   I doubt the problem is the brass, and I doubt it is the load. Whatever that gun is, I sure would not want it.

__________________

NRA Family Life members, TSRA Life member, USAF vet and American Legion member. Last edited by Mauser69; August 23, 2016 at 06:31 AM. |

|

|

|

|

#25 |

|

Senior Member

Join Date: December 31, 2011

Location: Vermont

Posts: 2,076

|

Listen to 44 AMP...

It's a thin spot in the brass... |

|

|

|

|

|