|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#26 | |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

Quote:

You don't really need gauges or even measuring tools, although they can make it easier. A sharpie and witnesses marks caused by the rifling will tell you when your at "zero" and most dies are 7/8-14tpi. So you can figure them out mathematically. 1/8th turn-.0089" 1/4 turn-.0178" 1/2 turn-.0357" 1 full turn .0714" Where the tools become much more helpful is to nail down the finished product that "works" so you can reproduce it down the road vs working everything back up. |

|

|

|

|

|

#27 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

'Briandg',

I pretty much agree, to a point... If you can bend it back to fit one paticular firearm, you are off to the races with minimal fuss & equipment. It's when you have a problem or questions about doing 'More' than just bending it back enough to fit in one particular chamber... That's when you need to start getting an advanced education and some gauges to figure out where you are, and where you need to go. Mr. Morris, I'm puzzled now, you origionally said 0.010", no tolerance give/take, Now are you saying that it's 'About' 0.010", more or less? Not that it works any better or worse for you, just clairifying. I guess I'm what they call 'Old School', So I can reproduce a working load, I note EVERYTHING in a load book, To do that, I have to use a 'Standard' starting point, And be able to gauge changes from that common standard, That requires some basic, but precision measuring tools. My 'Standard' is deviation from SAAMI. Its the one basic standard that everyone can work from since it's in most of the better loading books. Arguing to use a different 'Standard' than SAAMI doesn't make sense, simply because most of us have load books with the SAAMI specs in it, And its the same 'Standard' the firearms manufacturers & ammunition manufacturers use as a base line. Apples to apples kind of thing. The hardest thing I had to learn was restoring to SAAMI specs, Since a lot of the shaping dies weren't SAAMI back then, And no common die I've ever seen resizes the bottom of the case. Between the funnel shaped bottom in the die, and the shell holder covering bottom web and up, you simply can't get that brass restored to SAAMI... SO! The learning curve gets steep FAST! Case roller to get the bottom of that case sized back to SAAMI, comparable to brand new brass. A case roller also restores minor imperfections in the extraction groove/rim. Most cases get SHORTER when fired (which makes case trimmers funny for most die stamped resized brass), Rolling the case, then sizing gets the case back to SAAMI/Factory New cases. Just learning case spring back (memory) and how to control it was a steel learning curve... When I started producing brass from scratch, another steel learning curve in heat treating, annealing, not just the pressure required to form brass, but the application of that pressure! My first attempts were complete disasters, but when I started with the .22LR production, I pretty much had everything worked out. That's why opted for a mechanical scroll press rather than hydraulics, easier to control. The entire time I was looking for a SAAMI 'Perfect' case, and got very close, As close as the better quality .22LR brass/rounds were. I know why the big factory stuff has the +/- tolerance it does, Its virtually impossible to remove any more variance... Right now, the .458 SOCOM brass production is very close to happening. There is only a very few brass a guy can make on small scale and still make a reasonable profit. This will be my first attempt at production levels of brass, and to be quite frank, SOCOM brass is easier to produce than bottle neck cases. This might allow me to go after bottle neck cases next, Or it might be a one time thing. I've got the heat treating/annealing down, I can match Rockwell numbers precisely, and the first run reloads well, no problems with case splitting like the 'China' manufacture does... Right now, cutting the extraction groove really quickly is my big hold up. I just don't have CNC/robot to move cases to/from cutting tools fast enough yet. Last edited by JeepHammer; October 7, 2016 at 05:32 PM. |

|

|

|

|

#28 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

There is always a tolerance with anything assembled from components that also have tolerances. They can also stack for or against you as well. Why some sort rounds after manufacture, no matter what process was used.

If we could make everything identical we wouldn't have to average group sizes or velocities for that matter. Even if you sort a group of cases and projectiles to the tenth of a grain (there is still a tolerance to the hundredth) and powder charges to the kernel and shoot them in a tunnel from the same firearm, you still won't get identical results. Do the differences matter? Well, that is why we test. That said there are a bunch of rifles and many more people that won't be able to tell, on target, charge weights that vary .02 grains (or more) or even projectile run out by .005". I have also seen projectiles that had even more runout, then chamber them and eject without firing and they have less runout that they did out of the press. That adds even more variables to sort through. There are many other variables, some even out of our control, we just try to minimize variation, going after accuracy. In the end the "what works for you" part is really the end of the line for the individual. No reason to waste time if your happy. This is why, if your shooting a pistol at 15 yards, what matters to you will be a lot different than a precision rifle shooter shooting at 1500 yards. |

|

|

|

|

#29 | |

|

Senior Member

Join Date: December 16, 2013

Location: Eastern NC

Posts: 3,047

|

JeepHammer:

Quote:

I simply stated some facts and showed some evidence. You're still insisting your way is the only "correct" way, but you're still incorrect. There are many ways to reach the same end results. Like I said, I've seen all this before on different sites, and none of it is new. It's just you being you. When you're not a reloading/firearms expert, you moonlight as an "automotive engineer"  Pretty busy for a "trucker"

__________________

One shot, one kill Last edited by Snyper; October 8, 2016 at 07:30 AM. |

|

|

|

|

|

#30 | |

|

Senior Member

Join Date: December 16, 2013

Location: Eastern NC

Posts: 3,047

|

Quote:

Your gun is the only "gauge" that's needed when working up loads and fitting brass. Returning everything to SAMMI specs is counterproductive unless you want to use the rounds in multiple firearms.

__________________

One shot, one kill |

|

|

|

|

|

#31 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

that just do it. There is one that is the fan of the running start, he want the bullet to have 'that jump'. He does not tell those long and boring stories about .005" or .010 off the lands and to him there is nothing entertaining about sticking the bullet into the lands. He wants his bullets past the lands before the bullet realizes they are there. that just do it. There is one that is the fan of the running start, he want the bullet to have 'that jump'. He does not tell those long and boring stories about .005" or .010 off the lands and to him there is nothing entertaining about sticking the bullet into the lands. He wants his bullets past the lands before the bullet realizes they are there.I am the fan of transfers and standards, and then there is verifying. F. Guffey |

|

|

|

|

|

#32 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

Its 'Bending' metal, there will be tolerances,

When you have spent time polishing dies with newspaper to get them 'Just Right', its a different ball game entirely. This is completely different world than the cut-bend-weld I'm used to. Its real good of my boss to pay for the inspection equipment! I haven't talked him into moving all his stuff out so I can move my stuff in and use the shop full time!  'Snyper', A machinest is a machinest, building things, not talking about things that have already been built... Engineering comes with the territory. You can't build what you don't understand... When you conceive, design, build, test & refine your work, You have to find race tracks... Yes, I drag race cars to and from race tracks, that makes me a 'Trucker', hauling racing fuel makes me a 'Hazardous Material Hauler'... Along with the on site 'Track Engineer'. Another skill set I had to master to do the job, and a crap load more rules & restrictions & regulations I have to comply with. I still don't see your point, while you continue to prove mine... Last edited by JeepHammer; October 8, 2016 at 09:10 AM. |

|

|

|

|

#33 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

Mr. Guffy,

I see what you mean, VERY difficult to teach the concept of 'Zero'... A nothing that is everything doesn't seem to be easy to grasp... |

|

|

|

|

#34 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I guess I will jump in. You are correct. Some people are unteachable. Are you not the poster that suggested that an oversized neck area in a chamber is "An easy fix" by moving the barrel back? Now you wonder why a sizing die does not touch the head of a case? Talk about the pilot that never got off the ground. Have you ever reloaded ammunition? Typical SAAMI spec for case body diameters is .008. That is a LOT. You can pick up factory ammo, mic the head, and get all kinds of readings between the different manufacturers.

|

|

|

|

|

#35 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

The builder of these very fine rifles said there was nothing suspect about the accuracy so I offered to correct the problem with loose necks. It was about this time I said I had "An easy fix". When it comes to cases there is no shortage here or there so I took my forming dies. I am the one that uses a case lube with 'no-name', the builder is one of those that will not use anything in the way of lube but Imperial and or Dillon in a can or bottle. When I form cases for him in his shop I sometimes struggle because I have a tuff time making Imperial and Dillon lube look good. Anyhow, I formed 400 Lake City Match 30/06 cases to 308W. By forming the cases I reduce the clearance between the case neck and chamber neck by .007". And that made everyone happy, and then there was no one that understood what difference the .007" made. The proud owner of the very accurate rifle did not see an improvement in accuracy. The builder has close to 5.000 30/06 LC Nation Match cases. There is nothing like cases with case heads that match. F. Guffey I am the one that suggested reloaders purchase R. Lee's book on modern reloading, I am also the one that suggest the reloader read the book by R. Lee after purchasing it. |

|

|

|

|

|

#36 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

I do move barrels back, then rechamber, only if the rifling is still viable.

Rehabilitates mostly off center chambers and way too long/blown out shoulder or throat areas. Can't imagine moving the barrel back far enough to re-cut the neck, since the neck is a straight bore, the entire thing would have to be removed to install a smaller bore... Moving back 0.020" to 0.030" to clean up free bore, erosion of throat, ect is one thing, moving back 1/2" to 3/4" is something else entirely... I can't tell what you are talking about in particular, But I have recommended a few times for guys to hone out the neck of a SIZING die that is way to small to begin with. Some die WAY over work the brass, compressing it way too much, Then expanding it out to accept a bullet. The over compression isn't required, the die neck doesn't need to crush that brass excessively, overworking the brass and hardening it... When cracks result with just one or two reloadings, it's usually a neck that is being over compressed, so I suggest MEASURING how much expansion you have when firing, Then pulling the expanding ball, size that brass to see how much compression you are getting... Honing the die out a little helps stop some of the working of the brass... Honing the die is for ONE firearm that has a 'Generous' neck in the chamber, Saves you from Re-Barrling the rifle since taking 3/4" out of the chamber area isn't such a good idea... To make it work better with common dies... |

|

|

|

|

#37 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

Mr. Guffy,

I saw a post recently and didn't even suggest forming brass with thicker neck walls. Didn't need the heartache that was bound to happen. |

|

|

|

|

#38 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

Maybe you should take the time to read some of the replies to your rants. You most certainly did say it was an "Easy fix" to move a barrel back in the "IT WORKS FOR ME" thread. What thread pitch allows a complete turn to move ".020-.030"? Hone out the neck of a die? Where do you get this crap? I have a factory RCBS 7.62x39 die set. It came with a .308 expander ball and a .311 expander ball. Think I will have to ream the die out to use the .311 ball? I made an 8MMx54R chamber and used a factory RCBS 7.62x54R die with an 8MM expander ball to form the brass. I have mixed and matched dies to make wildcats more than once. Maybe there are die sets out there that squeeze the neck area like an orange, but RCBS and LEE don't.

|

|

|

|

|

#39 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

'works for me' I could give a crap less,

Since you weren't paying attention, its for PROBLEMS... I don't guess, I actually find the problem and fix it. I can't help if that offends you, that's one problem I can't fix. |

|

|

|

|

#40 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

The only problem on this forum is people handing out bad advice to new shooters and reloaders. Explain to me just how you hone the neck on a die. I will usually try something new just to check, but there is nothing there. I got into reloading late, but had a good background in guns. I could pretty soon tell when someone was blowing smoke at me. People just starting out in shooting and reloading don't need the B/S to confuse them.

|

|

|

|

|

#41 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

The same way you hone any bore, with a bore hone.

Anything from a stick with lapping compound to a micrometer adjustable bore hone. Crushing, then expanding the neck is hard on the brass. Period. No one can argue that point. Not even annealing (softening) will completely remove the compaction/expansion (thick/thin/stress) stress. Simple metal working/metallurgy. SO, Since you can't or won't do anything about your favorite brass getting blown out way too far... Instead of WAY overworking the brass, you simply don't crush the crap out of it in the first place... It's common sense. It DOES take use of somewhat precise measuring equipment (accurate caliper), and we all know what the 'No Gauges Or Measuring' guys think about calipers & gauging your work, so they are lost right there... ------ Cutting length on a chamber depends on the barrel, it simply gets shorter overall length. A full size barrel profile from chamber forward to muzzle could concevably be cut from say 24" to 2". Tapered profile barrels have less area that is safe to cut into since wall material gets thinner as you move chamber forward. I have no idea about your 'One Turn' argument... Dove tail front sight cuts are the only restriction that require full turn cuts... and since you weren't paying attention, you missed the 'Problems' part, 0.070" throat errosion, and only if the bore is still any good, misaligned chambers, chambers seriously screwed up when you get them... Usually, when someone advocates using WAY blown out brass to get any semblance of accuracy, without admitting the obvious, they have a way blown out chamber that could benifit from rehab, if the rifling is salvagable... Instead, they continue to blow out brass. entirely their choice. |

|

|

|

|

#42 |

|

Senior Member

Join Date: November 13, 2006

Posts: 8,288

|

Lets not import Jerry Springer to TFL

There are those who appear on Jerry Springer as guests.There are those who sit in the audience,and there are those who watch.

Last night I declined to comment on this thread.I chose to not participate in the drama. We have a new member who posted a different thread asking about "Blanks with no powder" This gentleman bought a 9mm handgun and was asking about dummy rounds for safe familiarization. Jeephammer,you chose to comment on that thread,you lead your comment with "I don't want to start a crapfight" Why bring the drama?? You opened this thread with a semantics question Reloading vs remanufacturing...but it quickly transformed to a venting session about drama on another forum. Why bring it here? Then you have a little spat here with Snyper,and another with Gunplummer.... When you yourself come to the point you have to begin your posts with "I do not want to start a crapfight" Ask yourself this,Mr Jeephammer,What one person do all these crapfights have in common??? Hmmm??? Please let the drama that occurs on other forums stay on other forums,and lets not turn TFL into the Jerry Springer show. |

|

|

|

|

#43 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

I didn't want to start something because it was already suggested the question was in the wrong forum.

Didnt need it turning ugly just because I posted... Apparently its upset someone since it got dragged to another thread entirely. Did you follow everyone that posted in that thread and rebuke them? And while we are discussing that very thing, This started out as a thread on case conditioning, particularly in volume. Volume doesn't suggest loading for ONE particular, out of specification chamber. It seems any suggestion of specifications, measuring equipment/gauges, ect. Really seems to set some folks off... The single comment shows that, "The only gauge you need is the chamber". I guess if you have ONE chamber, you already have things figured out and simply don't need/want to explore anything else. I would like to continue learning, and continue to make the best cases/rounds I can muster... I don't know what others are doing, it's not real clear from their postings. |

|

|

|

|

#44 |

|

Senior Member

Join Date: November 13, 2006

Posts: 8,288

|

There are many approaches and definitions.

A lot of folks used to get started with a mallet and a Lee loader.They only needed 15 rounds a year and strived for minute of deer.Lyman tong tools,etc. Today,a lot of folks get their needs met with a single stage press,a scale,and a loading manual.Pretty much,the "need" might be moderate quantities of hunting and practice ammo.These folks can be justifiably minimalist."Don't try to convince me I need to spend money" They really CAN do just fine without a chrono,gages,etc.No argument. And,there are other folks who need quantity economic ammo for games,matches,etc. Those divide between those who need quantity,and those who require match accuracy. Three gunners and cowboy shooters might have different priorities than High Power Shooters. Oh,but wait,there was Harry Pope making special dies for his rifles,and the benchrest and 1000 yd folks,and the crow hunters...Farrel powder measures,neck turning,concentricity gages,Wilson straight line dies. So somewhere in here we find The Handloader. The loader who is pursuing ammo that somehow outperforms what can be bought at Sportsman's Warehouse. There is the guy who has a Dillon 1050,and aSquare Deal,with feeders,etc because he enjoys engineering efficiency into feeding his 3-gun habit. Some are tailoring a load to one rifle,and optimizing brass life with minimal setback,etc. Several different tools and systems can be used. Many folks only shoot their own reloads ,never anyone elses. Some commercial remanufacturers,like Black Hills,are held in high regard. A brother had some commercial reloads wreck his Les Baer 1911. The M-1 A and Garand shooters have some important considerations . Oh,lets not forget the Wildcatters!!,forming,trimming Ackleying...And those cast bullet wheel gun guys Two or three shooting buddies can cover different degrees of all of these groups.They learn,grow and share A cowboy shooter might be a benchrester.A three gunner might be a prairie dogger. It can make for a pretty rich pot of soup. Last edited by HiBC; October 10, 2016 at 06:24 AM. |

|

|

|

|

#45 |

|

Senior Member

Join Date: April 16, 2011

Location: Georgia

Posts: 1,599

|

It seems as though you have more issues than just with ammo reloaders.

GEEEE WHIZZZZZ! |

|

|

|

|

#46 | |

|

Senior Member

Join Date: November 21, 2011

Location: Southern Louisiana

Posts: 1,399

|

Quote:

Your cases are NOT perfectly round no matter what you do. If you think they are, you just need better measuring equipment. Using typical reloading dies, me and 99.999% of other reloaders are perfectly capable of getting our brass that has been shot through oval chambers and chambers with feed ramp bulges (I have no idea what a "dratamic" feed ramp is) round enough to function perfectly without rolling. So why should we? You seem to put a lot of value into meeting arbitrary dimensions which add no value to the final product. You have a lot of anger directed toward people who are more concerned with making functional ammo than meeting an irrelevant dimension. If it makes you happy, process and machine your brass until it is round out into the 10th decimal place. Just be careful not to measure it with something capable of measuring 11 decimal places ... |

|

|

|

|

|

#47 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

WOW!

'Rich Pot Of Soup' is exactly the point! What is the 'Best' way to make a 'Round' peg to go into a round hole? |

|

|

|

|

#48 | |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

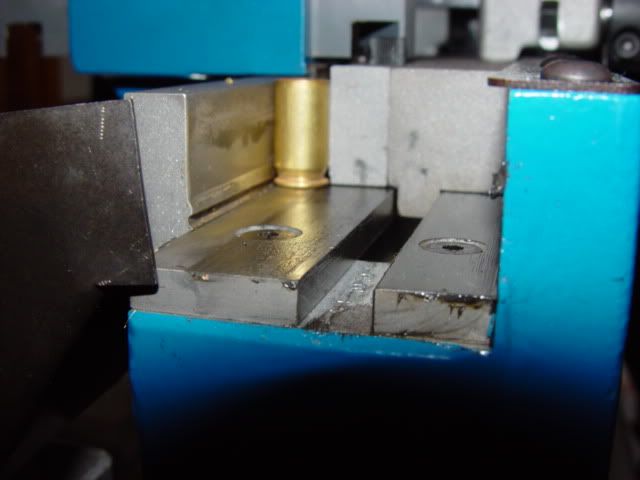

Quote:

It makes the parts of the case you cannot size with a normal size die perfect again. So dings in the rim/extractor groove and the rest of the case your size die cannot touch are back to original specs.  Is it a "must have"? No. Will it help you make better ammunition? Yes. |

|

|

|

|

|

#49 |

|

Senior Member

Join Date: November 21, 2011

Location: Southern Louisiana

Posts: 1,399

|

Nothing wrong with roll sizing. It's obviously a better process, but not necessary in the vast majority of cases. That's why I said "me and 99.999%".

You're the 0.001% of handloaders (I use that term very loosely in your case, probably take a company like Federal or Remington to compare to your operation!  ) that push the limits on equipment and processes. ) that push the limits on equipment and processes.

|

|

|

|

|

#50 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

Mine is purple, doesn't get used much since I built an automated version.

I could not care less about 'Bob' and his hand press reloads, The 'Bob .4671' that started out as .45 Auto. If 'Bob' is happy and not having issues, then I'm just tickled pink with his results! The entire point was 'WHY DO PEOPLE RESIST... Obviously because they can't look past their own particular situation. And why does 'Bob' think everyone should do things 'His' way when they are having issues and can't crank out a working round at all? Probably why 'Bob' thinks anyone doing something he's not is stupid & arrogant... The guy that sits down and cranks out 5,000 rounds is probably going to have a lube that works, name brand or not... The guy that has been using the same bottle of case lube for five years and still isn't to the bottom probably hasn't had much experence with anything else... That's why I ask questions, participate in debate, try to find out what others think, try and help when I can... Avoiding 'Bob' when I can, but 'Bob' is PERSISTANT, since he's not loading or shooting, he seems to have a lot of time to follow you around from post to post, forum to forum, espousing the same stuff on every thread possible, no matter if it applies to the conversation or not... Last edited by JeepHammer; October 10, 2016 at 07:31 PM. |

|

|

|

|

|