|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

Changed my COL...little nervous

I went from my safe 1.165" COL and started reloading at 1.100" as stated by Hodgdon's. Well after the first round I just kinda stared at it. Even though I'm within spec I am still nervous from going factory COL spec to 1.100"

Am I okay...just never seen them so small and I know that bullet is resting on the powder now. The 1.100" is top cartridge.

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. Last edited by Silver00LT; July 3, 2013 at 09:12 AM. |

|

|

|

|

#2 |

|

Senior Member

Join Date: June 18, 2004

Location: Minden , Nebraska

Posts: 1,407

|

if the 1.165 oal length works in your pistol use it. the 1.100 oal is set so it will work in all pistols

|

|

|

|

|

#3 |

|

Senior Member

Join Date: January 25, 2009

Location: Liberty Twp, OH

Posts: 283

|

Silver, Standard protocol dictates that you drop back down to starting charge weights when changing the OAL, hopefully you have done that and are planning to work back up.

Based on your picture, I think you may have that particular bullet seated slightly short as the case mouth looks to be beyond the shoulder where the ogive/taper starts -IMO. 9mm cartridges are subject to pressure spikes. I would encourage you to look at the following two older posts that provide some good info. http://thefiringline.com/forums/showthread.php?t=360959 http://thefiringline.com/forums/showthread.php?t=421138 Happy loading. |

|

|

|

|

#4 |

|

Senior Member

Join Date: November 8, 2007

Posts: 2,001

|

Silver00LT,

Looking at your picture, I see a few things that concern me. First, the data that you are using is for a LEAD round-nosed bullet, but your pictures show that you used a bullet that is either plated or jacketed. IF it is jacketed, that will increase pressure above what is shown in the data table, which is already pretty high at max loads. Second, there are a LOT of shapes called "round nose bullet" for the 9mm cartridge, and that results in different RN bullets with the same weight that have substantially different lengths. Seating all of those bullets to the same over-all cartridge length will result in substantially different peak pressures with the same powder charge. Because the bullet in your photo appears to be one of the longer ones, and it appears that you have seated the top one down into the case so far that the case mouth is on the ogive, I suspect that you have seated this particular bullet deeper than the bullet that was used to produce the data that you are using. Both of those issues could make your cartridge produce substantially higher peak pressure than your data indicate. And, the case mouth getting over the ogive could also cause feeding problems. Using QuickLOAD to estimate what your pressure could become, I turned a 9mm load that uses the max charge of 4.8 grains of W-231 under a 115 grain FMJ RN bullet from the nominal 32,000 psi load to a 46,000 psi load simply by changing the COL from 1.169 to 1.095, which makes the bullet "rest on the powder" as you indicated in your post. SAAMI spec for maximum peak pressure is 35,000 psi, or, for "+P," it is 38,500 psi. So, 46,000 psi is about 20% over "+P" pressures, which is approaching proof load level for a "+P" gun, and getting above proof load level for a standard-pressure gun. And, that is just an estimate based on a computer model, which may or may not accurately predict the real pressures. Based on that, I suggest that you NOT shoot the shorter (1.100" COL) loads unless we can establish that the pressures are probably within standards. It would help if you would tell us what bullet and how much powder you are using. In particular, we need to know the length of the bullet itself, as well as whether it is jacketed or plated. And, please tell us why you want to decrease the COL from what you started with. Have you been shooting the longer (1.165" COL) loads? Was there any problem? SL1 Last edited by SL1; July 3, 2013 at 07:48 AM. |

|

|

|

|

#5 |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

4.4GR W231 and its a 115GR Rainier Ballistic PRN.

Haven't shot any. The 1.100" alone is what had me stop the entire session. I think I will go back to the safe and proven 1.165" COL as I know how that groups and performs with these rounds. It's just one round I did and no crimp so a few heavy hits with the puller will remove the round.

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. |

|

|

|

|

#6 |

|

Senior Member

Join Date: February 17, 2013

Location: South Louisiana

Posts: 432

|

From the photo it looks like they're seated too deep...especially the top one

|

|

|

|

|

#7 |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

The top one is 1.100", Bottom one is a round I pulled out of one of my factory ammo boxes.

As stated until I find out the exact pressures for this round and Powerbond jacketed RN I will not be using this COL. I'll be going with the safe and proven method I've reloaded with so far.

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. |

|

|

|

|

#8 | |

|

Senior Member

Join Date: February 17, 2013

Location: South Louisiana

Posts: 432

|

Quote:

|

|

|

|

|

|

#9 | ||

|

Senior Member

Join Date: June 12, 2010

Posts: 479

|

Quote:

With various 9mm 115 gr RN bullets, I usually use 1.125" - 1.135" OAL. Rainier Ballistics recommends we use lead load data for their plated bullets when specific load data can't be found (Vihtavuori load data lists Rainier plated bullets). Here's current Hodgdon load data. Although the load data lists 1.100" OAL, it doesn't mean that's the OAL you should use for your pistol/barrel. You should use the OAL that works well in your pistol/barrel. Quote:

Last edited by BDS-THR; July 3, 2013 at 10:06 AM. |

||

|

|

|

|

#10 |

|

Senior Member

Join Date: November 8, 2007

Posts: 2,001

|

As I wrote in my earlier post, we would need the actual length of the bullet (in addition to the loaded length of the cartridge) to calculate an estimate of the peak pressure.

Also, whenever you do decide to change the COL of a short auto-loader cartridge, it is best to do it at reduced powder charge weight and just in small steps. While 0.065" may SEEM like a small step, it is really quite a lot in the context of what matters. It reduces the space available for the powder by about 17% with bullets similar to yours. Reducing the powder space by some percentage usually raises the peak pressure by something like 2 or 3 times that percentage, depending on a lot of variables. QuickLOAD indicates a 34% peak pressure increase for loads like yours, which is "only" a factor of 2 over the powder space reduction percentage. And that is only an estimate based on a computer model. There is a discussion on page 349 of the old Speer Manual #10 that says they MEASURED a peak pressure increase from 28,000 CUP to 62,000 CUP with a bullet seating depth increase of only 0.030". (But, they did not specify what the load was and I have nver been able to calculate such a large change with QuickLOAD. Still, I'm not going to argue with actual pressure measurements on the basis of a computer simulation.) So, making cartridge length decreases (= seating depth increases) in steps of 0.010" or less at a time seems prudent, and then only when well away from maximum powder charges. Shooting batches with each reduction step will allow you to see if recoil, case ejection, primer condition, case condition, etc. show any signs of abnormally high pressure. But, those signs are not a fool-proof way to determine that pressure is within SAAMI standards. They are just likely to occur before more dangerous results, at least in cartridges that work in the 35,000 psi peak pressure range. (If we were dealing with old, low-pressure cartridges like .45 Colt in the guns originally designed for them, there would be NO pressure signs like those before pressure became high enough to explode the gun.) SL1 |

|

|

|

|

#11 |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

Lengths:

Powerbond Jacketed RN - 0.555" Rainier Plated RN - 0.565"

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. Last edited by Silver00LT; July 4, 2013 at 11:41 AM. |

|

|

|

|

#12 |

|

Senior Member

Join Date: November 8, 2007

Posts: 2,001

|

Silver00LT,

I want to try to give you some guidance on the pressure effects of seating depths for your bullets using QuickLOAD. But, I need you to understand that QuickLOAD comes with a warning NOT TO USE ITS RESULTS IN PLACE OF PRESSURE-TESTED DATA from loading manuals. In order to use the program effectively, it is best to adjust it first to match your gun, brass, etc. as closely as possible, then chronograph your loads and readjust the program. Without putting you through all that, all I can really do is see if the program can match the published data and then, IF it does a reasonable job of matching that, try to interpolate and extrapolate that data to other bullets and seating depths. That means that the QuickLOAD results will still require a work-up in your charge weights and a work-down in your seating depths, just like manual data, but with even more caution because it really is NOT manual data. So, for starters, I tried to match the Speer Gold Dot data in your photograph with QuickLOAD calculations. Here is the "match" I settled on: Code:

Start Max

charge velocity pressure charge velocity pressure

Published 4.7 1077 25,300 5.1 1167 28,100

QuickLOAD 4.7 1086 25,295 5.1 1153 30,089

Now before using these settings to calculate results for your two bullets with W-231 powder, I want to check one thing with you. You listed the lengths of your bullets as 0.555" for the Ranier and 0.565" for the Power Bond. But, my QuickLOAD database showes 0.565" for a Ranier and does not list the Power Bond. So, before I do a bunch of calcs, please assure me that you did not switch the numbers for the lengths of your two bullets. SL1 |

|

|

|

|

#13 | |

|

Senior Member

Join Date: February 20, 1999

Location: home on the range; Vermont (Caspian country)

Posts: 14,324

|

this is never true

Quote:

I have found OAL in 9x19 matters most for feed reliability. I am not (as) concerned with over pressure.

__________________

. "all my ammo is mostly retired factory ammo" |

|

|

|

|

|

#14 |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

Rainier is .565" Should've wrote it down to double check my post. Thought I entered it correctly, but QuickLOAD is correct on the length of the Rainier bullets.

I'm going to stick with the OAL I currently have as it works for my weapon and groups good. I'll start fine tuning when I get more details. Would the Lyman reloading manual list "plated" or "jacketed" RN? Powerbond recommends using LRN formulas for their Jacketed RN. Rainier I have to further research since they are listed as plated IIRC. 1.169" Feeds correctly into my Glock, I actually get around 1.163-1.165 as to not go more than the 1.169" stated as maximum OAL. It's been proven in my Glock for several hundred rounds so why change it.  Thanks SL1 for using QuickLOAD to check for me!

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. |

|

|

|

|

#15 |

|

Senior Member

Join Date: February 7, 2009

Location: Southern Oregon!

Posts: 2,891

|

Lots of info extended. One thought that may help you; the info in a reloading manual is the specifications the techs used and the results for a particular cartridge at a particular time. The loaded dimensions at within SAAMI suggestions, but not hard, fixed formula. If you vary from the formula, the Reloading Police aren't going to fine you or take away your "license" to reload

It's better to shoot loads in your gun that you know are safe and accurate, than worry about a spec./load you saw that differ from your tried and true specs./loads... It's better to shoot loads in your gun that you know are safe and accurate, than worry about a spec./load you saw that differ from your tried and true specs./loads...

__________________

My Anchor is holding fast! I've learned how to stand on my own two knees... |

|

|

|

|

#16 | |

|

Senior Member

Join Date: June 12, 2010

Posts: 479

|

Quote:

|

|

|

|

|

|

#17 | |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

Quote:

I dropped down to 4.4GR due to going with a shorter COL. Powerbond states to use LRN formulas on the bullet I have. Rainier is "plated" IIRC.

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. |

|

|

|

|

|

#18 | ||

|

Senior Member

Join Date: June 12, 2010

Posts: 479

|

Quote:

As I posted previously, Rainier recommends we use lead load data when we can't find load data listing Rainier plated bullets. As far as I know, PowerBond doesn't suggest which load data to use. Based on my experience, when I pushed Rainier plated bullets too hard, my accuracy fell and I ended up using lead load data or start-to-mid range jacketed load data. With thicker plated PowerBond bullets, I have used jacketed load data with good results. BTW, I only use flat to light taper crimp with plated bullets to not cut through the plating and Rainier Ballistics states: Quote:

|

||

|

|

|

|

#19 | |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

In reloading world is "jacketed" on listed formulas only specifically talking about an actual jacket?

Like this FMJ:  I've seen people speak of powerbond as jacketed, but its an entire covering just like the Rainier. If this is a terminology error I need to know so I can correct this and avoid using improper terminology again. As far as Powerbond I've seen reloaders post this response to their e-mails. Quote:

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. |

|

|

|

|

|

#20 |

|

Senior Member

Join Date: June 12, 2010

Posts: 479

|

As far as I know, PowerBond sells plated bullets that are completely covered with copper plating, including the base.

Those in the picture are definitely jacketed bullets with exposed lead base. |

|

|

|

|

#21 |

|

Senior Member

Join Date: November 8, 2007

Posts: 2,001

|

"Jacketed" used to mean that a gilding metal cup was formed separately and placed over a carefully weighed, but unformed lead core, and then they were swaged together to final shape in a set of dies. That often allowed the jacked to separate from the core when an animal was the target. So, engineers worked-out ways of making the core stick to the jacket. Some used a form of soldering for the two seperate parts, while others actually built-up copper alloy jackets around pre-shaped lead cores by electro-plating the cores. And, bullets made with both methods often are worked extensively after the core and jacket are mated so as to form hollow-pointed bullets that would expand well while still not shedding their jackets.

If the plating is thick enough, as in the case of Speer "TMJ", "Gold Dot", and "Deep Curl" pistol bullets and Federal "Fusion" rifle bullets, they act pretty much like regular jacketed bullets. So, many people just refer to them as jacketed. But, careful review of the loading data developed with those bullets suggests that they are a little different with respect to the peak pressures that they produce, so max charge values may differ because of that (as well as other differences) between Speer and, say, Hornady jacketed bullets. If the plating is not of similar thickness to a regular jacket, then the bullets are called "plated". Typically, that means that the plating can be cut by crimps or rifling under high pressures, exposing the lead and ruining accuracy. But, electro-plating can be done to almost any thickness, so different manufacturers make different products with different thicknesses. Some are cutting no costs to make the best bullets possible, while others are making the cheapest bullets that will work well enough for range practice. And, then we add "marketing" which tries to make us buy each manufacturer's bullet with a lot of hype that is not particularly informative and sometimes intentionally misleading. Sooooo, it is best to make sure you know how a bullet is made and what it is really good for, BEFORE you buy them. That often means reading reviews in magazines and web sites and asking on forums like this one. SL1 |

|

|

|

|

#22 |

|

Senior Member

Join Date: November 8, 2007

Posts: 2,001

|

QuickLOAD results

Silver00LT,

Using the same adjustments to QuickLOAD that I needed to make the match to Hodgdon's Speer God Dot data, as described in post my post on July 3rd, I get the following for your load of 4.6 grains of W-231 under the Ranier 115 grain RN bullet: Code:

COL velocity pressure 1.165" 1049 fps 22,050 psi 1.155" 1057 fps 22,276 psi 1.145" 1065 fps 23,582 psi 1.135" 1074 fps 24,435 psi 1.125" 1082 fps 25,356 psi 1.115" 1091 fps 26,353 psi 1.105" 1100 fps 27,422 psi 1.095" 1110 fps 28,616 psi Code:

COL velocity pressure 1.165" 1100 fps 25,200 psi 1.155" 1108 fps 26,064 psi 1.145" 1117 fps 27,015 psi 1.135" 1126 fps 28,030 psi The first is that Hodgdon's data stops at 28,000 psi for the Gold Dot bullet. And, second, looking at Speer's data for that same bullet, Speer stops at 4.9 grains instead of 5.1 grains of W-231. Why both data sources stop with charges well below what produces SAAMI max pressures is not stated. But, that is often an indication that the pressures get "spikey" beyond that point, producing wider ranges of peak pressure for a given charge weight, and perhaps greater pressure increases than expected for small steps in charge weight. Because QuickLOAD cannot predict spikey behavior, I choose not to extrapaolate with calculations into realms where people with pressure-measuring equipment have choosen not to go. Still, the calculations that I have provided will give you some idea of how sensitive your load is (or is not) to changes you might coose to make within the data you have, even if there is some diffeerence between calculation and what actually happens in your own gun. SL1 Last edited by SL1; July 5, 2013 at 12:10 PM. |

|

|

|

|

#23 |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

BDS - I just wanted to fix any terminology errors I was making.

Thanks for clearing out the error I made. |

|

|

|

|

#24 |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

Thanks SL1.

I have actually shot the power bond bullets into gel and retrieved them I'm on mobile so I can not access the photographs to show you the outcome. I wish QuickLOAD wasn't $160 bucks. I don't like spending a lot of money on software. lol |

|

|

|

|

#25 |

|

Senior Member

Join Date: August 23, 2011

Location: Phoenix AZ, Kealakekua HI

Posts: 100

|

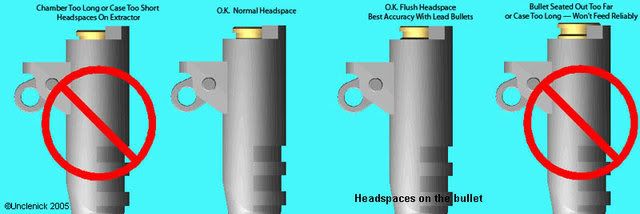

For most semi auto pistols this visual will give you a better way to gauge COAL that will better suit your gun.

|

|

|

|

|

|