|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: August 24, 2014

Location: Minnesota

Posts: 639

|

Clasic 4 hole turret for Xmas

So Ms. Santa let me buy, I meen gifted me a new 4 hole auto indexing turret press. After a bit of setup trial and error I cranked out an astonishing amount of 9mm ammo today. Got me thinking about loading rifle ammo through it. In thinking through the prosses I got hung up on how to remove the sizeing lube. If the effency of the turret is that I dont handle the brass as much, how should I remove the lube. I suppose I could wipe them down with a rag after running them through the press, but that would take a while to do 300 or so. I have read some where that some people tumble their loaded rounds. That doesn't seem like a good idea for a number of reasons.

|

|

|

|

|

#2 |

|

Senior Member

Join Date: January 25, 2009

Location: Liberty Twp, OH

Posts: 283

|

Congrats on the new present. First, you don't have to lube pistol brass when using carbide dies. Second you don't have to remove the lube. If you want to, you can tumble it, no harm will be done. If you want to manually clean it off, my preferred method (for rifle rounds) is to lay out rounds in multiple rows on a micro fiber cloth then cover with a second cloth and push back and forth to roll between the cloths several times.

|

|

|

|

|

#3 |

|

Senior Member

Join Date: February 9, 2005

Location: Owego, NY

Posts: 2,000

|

Congrats on the new press. I use one myself for both pistol and rifle (40 S&W, 221, 223, 25-06 and 45-70).

Since I have to pull the rifle brass off the press to trim to length after sizing I don't find it a big deal to wipe off the lube before going back onto the press. I use Imperial Die Sizing Wax. If you haven't already done it, do yourself a favor and pick up a Lee Auto Drum. They work great on the Classic Turret for charging cases. Just be aware you will need the rifle charge die in addition to the Auto Drum. I use the Auto Drum with both the long and short charge dies.

__________________

,,, stupidity comes to some people very easily. 8/22/2017 my wife in a discussion about Liberals. Are you ready for civil war? |

|

|

|

|

#4 |

|

Senior Member

Join Date: December 10, 2015

Posts: 265

|

I love my Lee turret press the best thing is to change calibers just slip out the turret and put in the other one. No recalibration needed. I have a turret set up for each caliber

|

|

|

|

|

#5 |

|

Senior Member

Join Date: February 9, 2005

Location: Owego, NY

Posts: 2,000

|

Regarding the easy turret swap, I picked up a second Classic Turret and outfitted it to a stand that I take to the shooting range for portable load development. All I do is swap out turrets from the portable station to the bench station. Very easy.

__________________

,,, stupidity comes to some people very easily. 8/22/2017 my wife in a discussion about Liberals. Are you ready for civil war? |

|

|

|

|

#6 |

|

Senior Member

Join Date: September 21, 2014

Location: Somewhere in the middle

Posts: 629

|

I don't use the self index for rifle ammo. Too much off the press case prep to do.

__________________

"The day you stop learning SHOULD directly coincide with the day you stop breathing." |

|

|

|

|

#7 |

|

Senior Member

Join Date: August 23, 2008

Location: East shore of Lake Michigan.

Posts: 714

|

This is a nice addition to the Lee Classic Turret Press when using

a powder throw. http://www.ebay.com/itm/EXTENDER-for...AAAOSwstxVCuEB

__________________

Sent from my Tandy 1000 |

|

|

|

|

#8 |

|

Senior Member

Join Date: February 9, 2005

Location: Owego, NY

Posts: 2,000

|

S & R - do you know if that adapter will work with the new Classic Powder Measure?

__________________

,,, stupidity comes to some people very easily. 8/22/2017 my wife in a discussion about Liberals. Are you ready for civil war? |

|

|

|

|

#9 |

|

Senior Member

Join Date: January 16, 2011

Location: North Bend, OR

Posts: 743

|

If the new classic is case activated, then no. If the new classic is manual operated, then yes.

Sorry, Just went to lees website and looked at the classic. It looks like the mounting threads are different sizes between the 2 measures. So, no it won't work. Last edited by Vance; December 20, 2015 at 11:07 PM. |

|

|

|

|

#10 |

|

Senior Member

Join Date: May 3, 2009

Location: Central Texas

Posts: 3,930

|

I have been tumbling loaded rounds for years. Never had a problem with any that I have. Lots of progressive press users have to.

If you are going to do semi progressive loading for rifle I would suggest the rifle charging die it does speed things up.

__________________

No matter how many times you do it and nothing happens it only takes something going wrong one time to kill you. |

|

|

|

|

#11 | |

|

Senior Member

Join Date: January 5, 2009

Location: Just off Route 66

Posts: 5,067

|

Quote:

Stage 1 - powder measure. Stage 2 - powder check die. Stage 3 - Seating die. Stage 4 - Factory crimp die. Stay safe. Jim

__________________

Si vis pacem, para bellum Last edited by Jim243; December 21, 2015 at 01:02 AM. |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: February 9, 2005

Location: Owego, NY

Posts: 2,000

|

Jim243, how do you like the Lee Press Mounted Trimmer? Is yours the standard or deluxe model? I will guess standard since you have the Lyman system close at hand.

__________________

,,, stupidity comes to some people very easily. 8/22/2017 my wife in a discussion about Liberals. Are you ready for civil war? |

|

|

|

|

#13 |

|

Senior Member

Join Date: August 23, 2008

Location: East shore of Lake Michigan.

Posts: 714

|

@ flashhole,

The extender that I pointed out works only with the Lee Perfect Powder Measure...of which the threads that accept the measure are 5/8-11, as the threads on the Classic Measure are 7/8-14. I did invent an adapter in order to use my RCBS Uniflow measure with my Lee Classic Turret, but found that it was why to heavy to allow the turret to rotate properly.

__________________

Sent from my Tandy 1000 |

|

|

|

|

#14 | |

|

Senior Member

Join Date: January 5, 2009

Location: Just off Route 66

Posts: 5,067

|

Quote:

It works well, I use it only for 5.56 & 223 cases. It is the deluxe model, and yes I know it chamfers as well as trims, but I like the cutters on the Lyman case center and it let's me do the primer pockets as well as clean the inside of the necks. I guess I am just anal that way on doing the cases. I also have the Lyman universal trimmer for other caliber cases, so the case center works double duty for all other cases as well. At the time the Frankfort trimmer did not do chamfering as well as trimming, and I think I would have gotten that instead. Just my view on it, stay safe. Jim

__________________

Si vis pacem, para bellum |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: February 22, 2014

Posts: 868

|

I personally would rather wipe the lube of the cases with a rag and a little solvent. Running the rounds through the tumbler will only gum up the media.

As stated earlier get a carbide die and you won't need to use the lube. |

|

|

|

|

#16 |

|

Senior Member

Join Date: February 9, 2005

Location: Owego, NY

Posts: 2,000

|

The carbide die works great for straight wall pistol cases but they don't make carbide dies for tapered/bottle neck rifle cases. Even the 45-70 has a mild taper.

One thing I started doing with my rifle cases on the turret press is just neck size, not FL size. The Lee Collet Neck Die does not require lube. For those bottle neck cases where I don't have a collet neck die (221 Fireball) I use the conventional neck die and dry lube it with powdered graphite before putting it in the press. No need to clean the small amount of residual graphite. So long as I'm not pushing things too hard I can get by with a few neck size sessions before having to bump the shoulder back.

__________________

,,, stupidity comes to some people very easily. 8/22/2017 my wife in a discussion about Liberals. Are you ready for civil war? |

|

|

|

|

#17 |

|

Senior Member

Join Date: February 7, 2009

Location: Southern Oregon!

Posts: 2,891

|

If you're using the turret press semi-progressive for rifle ammo, then just toss the finished rounds in a wobbbler/tumbler for a few minutes to clean off the lube (I 'spose this will bring up the old "No don't tumble finished reloads you'll shoot yer eye out! vs. Yes it's OK to tumble finished reloads" arguement

). I have no need to run my turret press in auto-indexing mode as I batch load for everything; handgun and rifle ammo (even 30-06), so I disabled the auto-index many years ago... ). I have no need to run my turret press in auto-indexing mode as I batch load for everything; handgun and rifle ammo (even 30-06), so I disabled the auto-index many years ago...

__________________

My Anchor is holding fast! I've learned how to stand on my own two knees... |

|

|

|

|

#18 |

|

Senior Member

Join Date: August 24, 2014

Location: Minnesota

Posts: 639

|

My original half-baked idea was fl size in station 1, press mount trim on 2 remove brass ch and db, reinsert and prime, powder drop on 3 and seat and crimp on 4. Thinking through the idea 1st was lube removal, and I think the one that kills it is their simply isn't enough room on the tool head. I like the idea of neck sizing in a progressive manor, but my ar brass should be fl sized right? Guess ill keep doing the batch brass prep work and not sell my single stage just yet. how well does the auto disk do with stick powder like imr 4895? Would probably need to weigh and trickle for my 556, 308...?

Vibe tumbling loaded ammo wouldn't break down the powder granules some and create some inconsistency? I doubt they could bounce around enough to strike and ignite the primer but still a concern I guess. Last thought on the matter. The tool head seems to have a small amount of give to it compared to a solid piece of steel like a single stage. would this cause some inconsistency for bench rest loading? Thanks for the input as usual. Happy holidays every one. |

|

|

|

|

#19 |

|

Senior Member

Join Date: June 23, 2013

Location: Central Taxylvania..

Posts: 3,609

|

Congrats on the new press!!

I love my 4 hole turret!! I reload 380, 9mmLuger, 38 spec, 357mag, 45ACP, (soon hopefully 45 Colt), 243Win, 308, 7mm-08, 7mm-08AI, 30-06, 7mm Rem Mag.. Oh, and 257 Roberts. With the rifles I don't full length resize except for 30-06, that I load for 2 different pump action guns. I use the Lee Collet Sizer. No lube needed. |

|

|

|

|

#20 |

|

Senior Member

Join Date: February 7, 2009

Location: Southern Oregon!

Posts: 2,891

|

Jes my opinion; tumbling live ammo won't break down powder and affect burn speed.

Yep the turret plate will move (there has to be clearance or the turret wouldn't turn), but it moves the same every time the ram pushes it up, so there is no variation. I'm able to keep .002" variation in bullet seating quite easily on my old turret press. While I batch load on my turret, I trim separately, off press. For my method is easy for me; inspect, lube F/L size and deprime mebbe 100 cases. Often at this point I'll clean the brass in my tumbler, easier to handle lube-free brass. Then trim and deburr. Back to the press for priming (I have a ram prime installed station 2.). I like to charge off press, but in station 3 a powder measure could be installed, and seat in 4, and possibly seat and crimp here. (I don't crimp my Garand ammo so I could get away with charging on press, but normally I charge off press and have the 4th station open for a collet crimp die, if I choose to use one.).... I'm sure you can find a method/process that works for you, just experiment with different "set-ups" and methods.

__________________

My Anchor is holding fast! I've learned how to stand on my own two knees... |

|

|

|

|

#21 |

|

Member

Join Date: May 5, 2015

Posts: 16

|

Started out about 3 years ago with a Lee Classic Turret press and love it. I use it to load .380, .38 Special, .9mm, .40 S&W, .44 Magnum, .45 Long Colt, and just starting to reload .223 rifle.

The thing is just simple and dependable, although I have had issues in the past with the Lee Perfect Powder Measure (the one that uses the disks). Some powders simply don't meter well with them, so I invested in a RCBS Chargemaster and except for .40 S&W & .9mm I meter all my loads. I use a Lee Auto Drum for these rounds and it's never off more than 0.1 grains. I keep thinking about upgrading to a Dillon, especially since they're about 1/2 hour from my house, but outside of speed I just don't see the need. |

|

|

|

|

#22 | |

|

Senior Member

Join Date: May 19, 2004

Location: SC

Posts: 2,743

|

Quote:

|

|

|

|

|

|

#23 |

|

Junior member

Join Date: February 2, 2010

Posts: 6,846

|

I turned my standard 4 hole turret press into a "sequential"(takes one case through 4 operations) vs. a "progressive"(does operations on all 4(5) cases simultaneously) for loading prepped .223 cases.

I run mostly range brass which often requires more sizing force than I feel the turret press is capable of on a long term basis. I full length size and tumble to remove the lube. Then trim, swage, and prime separately since those operations are mostly handwork(for me anyway). For me, there are just too many things going on to consider taking rifle brass from fired to finished in one circuit of the loading press. |

|

|

|

|

#24 |

|

Senior Member

Join Date: February 9, 2005

Location: Owego, NY

Posts: 2,000

|

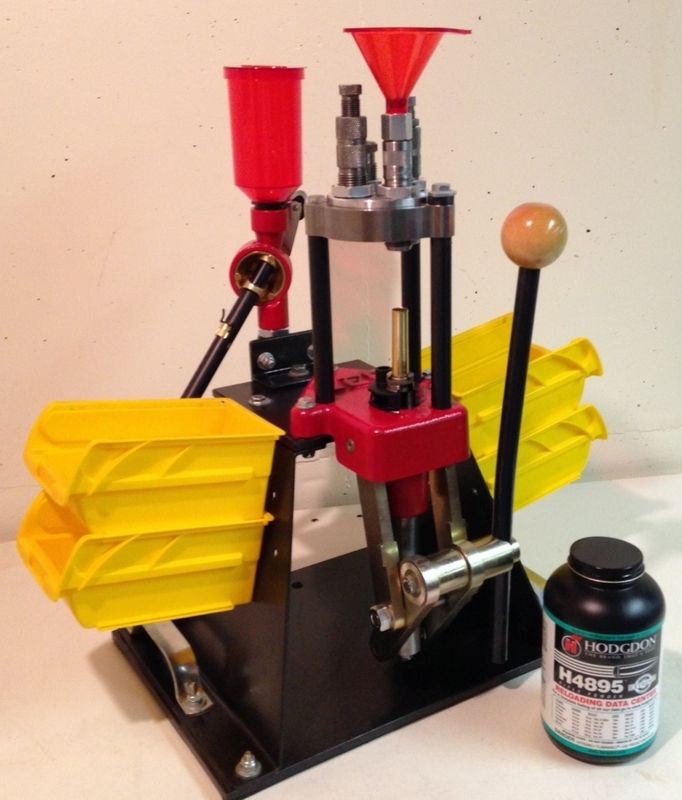

A couple of years ago I started a project for a portable reloading setup I could haul to the range for load development. Finally got it completely finished with the two powder measures I got for Christmas.

First pic shows the Classic Powder Measure and a Funnel on the Powder Through Expander Die along with the Classic Turret press. The adjustable chamber on the Classic Powder Measure is graduated in cc. Checking a few different powders against the Lee data that comes with the Lee Dipper Cups showed it to be quite accurate with dropped charges measured using a precision scale. Knowing the amount it drops at particular settings avoids having to haul a scale to the range.  Second pic shows the same setup with the addition of a Lee Auto Drum in place of the funnel. This is set up for 45-70. I had to make a small bushing to get the Auto Drum to work with the 45-70 Powder Through Expander Die but it works great. Lees claim that each flat on the powder chamber adjustment key represents 1/10 grain is accurate, at least for the powders I tried.  About the setup. I used Dillon Strong Mounts and attached them to a 3/8 steel plate. The press deck is also 3/8 steel. I put handles on it to make it easy to tote. There is a rubber pad on the bottom that helps keep it in place. I took advantage of the pre-drilled holes in the Strong Mounts. The lower Akro Bins are drilled and I use 1/4-20 nuts, bolts and washers to hold them in place. I can stack as many as I need. I bolted the bench mount from a Redding 3-BR powder measure to the stand to hold the Powder Measure. The press stays bolted to the mount during transport but everything else gets toted in a tool box for safer keeping. Once back from the range I simply put the turret in the bench mounted press and make ammo. Anyway - My Christmas gifts are already in service and I have two range trips planned this week. Merry Christmas and Happy New Year. FWIW - I really like the Lee Auto Drum.

__________________

,,, stupidity comes to some people very easily. 8/22/2017 my wife in a discussion about Liberals. Are you ready for civil war? |

|

|

|

|

#25 |

|

Senior Member

Join Date: August 24, 2014

Location: Minnesota

Posts: 639

|

my auto drum should be here today

. looking forward to cranking out some 9mm. auto drum sounded better than auto disk, can any one confirm? . looking forward to cranking out some 9mm. auto drum sounded better than auto disk, can any one confirm?

|

|

|

|

|

|