|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Member

Join Date: July 5, 2009

Posts: 20

|

Controlling and adjusting bullet runout - concentricity

What methods do you use to control runout when seating long rifle bullets? One trick I learned was to get the bullet started and seat it about half way then rotate the case 180 degrees and finish seating. Even with this method I still get some bullets that don't seat straight.

I was thinking about getting a competition seating die, but I'm not sure that will really help. Anyone use the NECO Cartridge Alignment Tool? http://www.neconos.com/shop/?cart=237249&cat=28 |

|

|

|

|

#2 |

|

Member

Join Date: March 15, 2009

Location: Gloucester, MA

Posts: 47

|

I eliminated most of my run out by reaming the inside of the neck with a RCBS die/reamer and than trimming the outside of the neck with a home brew neck trimmer. I was able to reduce a .009” run out to less than .001”.

__________________

.222 rem-Sako, .204 - Savage, 6 mm BR - Savage, 7-30 Waters - T/C, 270 Weatherby - Custom Muser, 22-250 - Savage, .222 rem - T/C, 204-T/C, BP .44 & .36 Bob

|

|

|

|

|

#3 |

|

Senior Member

Join Date: December 1, 2002

Posts: 2,832

|

duplicate post

|

|

|

|

|

#4 |

|

Senior Member

Join Date: December 1, 2002

Posts: 2,832

|

Ditto.

Last edited by wncchester; August 21, 2009 at 07:47 AM. |

|

|

|

|

#5 |

|

Senior Member

Join Date: December 1, 2002

Posts: 2,832

|

"What methods do you use to control runout when seating long rifle bullets?"

You may not realize it but you just asked us to write a book. There are several books already available that address the topic. I'd suggest you find a copy of Precision Shooting's "Reloading Guide". "One trick I learned was to get the bullet started and seat it about half way then rotate the case 180 degrees and finish seating. Even with this method I still get some bullets that don't seat straight." Yeah, that's a common "trick". Problem is, it doesn't work. Any bullet that gets seated half way into a crooked neck isn't going to get any better just because it's rotated, the seater stems we use aren't tight enough for that. (anyone wanting to argue that point needs to check it out on a concentricity gauge first, not just give hopeful opinion!) "I was thinking about getting a competition seating die, but I'm not sure that will really help." Good idea. It will work IF your cases have straight necks. Most don't. "Anyone use the NECO Cartridge Alignment Tool?" Sorta, kinda. I mean, it's a gage, not an alignment tool. But, it probably overkill when you first start chasing concentricity. Start with a Sinclair gage, easy to use, a lot less expensive and may be all you ever need. Last edited by wncchester; August 21, 2009 at 08:19 AM. |

|

|

|

|

#6 | |

|

Senior Member

Join Date: April 16, 2009

Location: Utah

Posts: 209

|

Quote:

|

|

|

|

|

|

#7 |

|

Senior Member

Join Date: June 6, 2009

Posts: 113

|

Seating

The RCBS Comp seating die works for me. It has a floating line up sleeve that straightens the bullet and the Mic for seating depth control. I find this to increase the consistancy of POI to a degree that makes it worthwhile - that is if your other procedures are precise, as well. Also, have to prep the brass and measure/trim/finish well as others have described herein to ensure uniformity.

Once you get your cases finished to your understanding of "Perfection" use this method to fine tune your load and seating depth. (link courtesy of UncleNick) http://optimalchargeweight.embarqspace.com/ Consistancy is the real secret. |

|

|

|

|

#8 |

|

Senior Member

Join Date: May 20, 2001

Location: Oshkosh wi.

Posts: 3,055

|

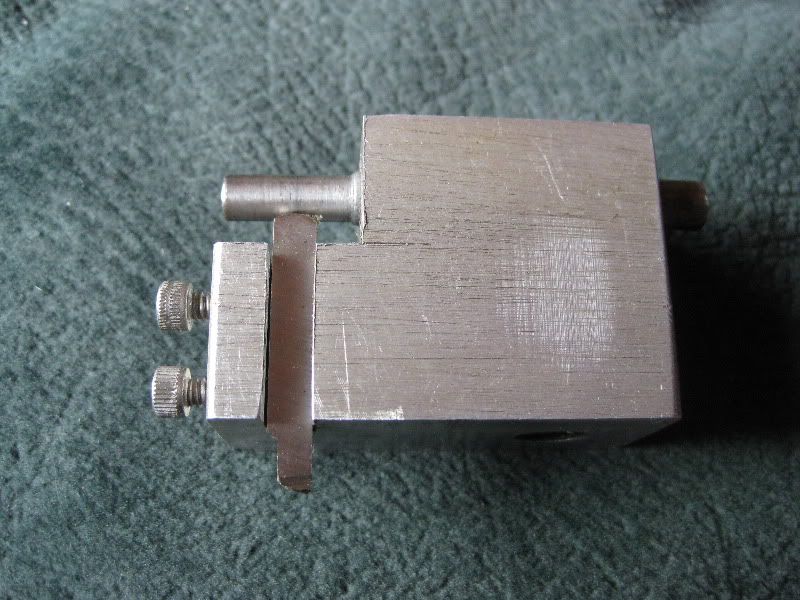

You need something to measure with so you KNOW just what your runnout is. Here's my answer to that question.

You can clearly see there's .002 runnout on that match .223 round. I recently ran the gamut on precision seating for the .223. I was given the opportunity to do a load work-up on a buddy's custom built match AR .223. Finally a match rifle to work with! I got this one first; http://www.midwayusa.com/viewProduct...tNumber=665744 That's the RCBS competition seater. With the cute little window to toss the bullet into. Results were no better than with a lee, or a hornady standard seater. Runnouts of as much as .008! Oh and you have to fiddle around with a special long shell holder,(it comes with the die). Next I got the /forester.Made my first mistake this year! http://www.midwayusa.com/viewProduct...tNumber=665744 Finally, runnouts of .001 to a high of .003! Now some would say "your brass is no good". This was all new lapua empty brass. I checked each neck with the RCBS gauge, they were all less than .0005 runnout. Checking the neck runnout on a .223 case.  This is how you check the neck thickness and uniformity.

__________________

The more people I meet, the more I love my dog They're going to get their butts kicked over there this election. How come people can't spell and use words correctly? Last edited by snuffy; August 22, 2009 at 04:13 PM. Reason: I meant forester NOT redding. |

|

|

|

|

#9 |

|

Senior Member

Join Date: April 16, 2009

Location: Utah

Posts: 209

|

Excellent post snuffy. Thanks for the tutorial. It's already on my "wishlist" so maybe I'll have to hint to the wife what a fine Christmas present it would be.

|

|

|

|

|

#10 | |

|

Senior Member

Join Date: May 20, 2001

Location: Oshkosh wi.

Posts: 3,055

|

Quote:

When sizing or converting brass from a larger caliber to a smaller one, like .308 to 7mm-08, necks can and do become thicker. Sometimes too thick. So outside neck turning is the best bet, because it evens out the thickness variation problem. I've never heard of reaming or neck turning doing anything for bullet runnout. The case itself has to have very little runnout to start with for the completed round to have low runnout.

__________________

The more people I meet, the more I love my dog They're going to get their butts kicked over there this election. How come people can't spell and use words correctly? |

|

|

|

|

|

#11 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Freedom-First,

I first got Redding's Competition Seating Die back about 1990 or so for .30-06. I also owned of Forster/Bonanza concentricity gauge back then. In Lake City brass my TIR (total indicated runout) dropped from 0.008" worst cast, to 0.002" worst case, seating 168 grain SMKs. Rotating the bullet 180° while using a Redding standard seating die did very little good. Might have reduced 0.008" to 0.006", but I don't recall clearly. In any event, it didn't take care of the problem. The 0.002" runout that remained after switching to the Redding Competition die for seating turned out to be due mostly to 0.002" difference in case neck wall thickness on the cases which exhibited that TIR. If I sorted cases for uniform neck walls using a ball-end micrometer, I usually could detect no more than a half thousandth of runout, and that was probably still the fault of the case, its neck not being perfectly coaxial with the rest of the case body. So, yes, the competition seating die is worthwhile. It certainly does a lot more than rotating with a standard seater. I don't know how the different brands compare for quality? I was so impressed with that first Redding I got that I've been a loyal purchaser of their product for all my rifle calibers ever since. The RCBS Case Master is a good tool from what I've seen and heard, though I don't own one. I own the NECO case gauge, instead, which is another good one. It also lets you check for banana shaped cases with an anvil that gives your TIR of the case wall way back near the pressure ring. I don't know the RCBS unit does that or not? It's more of interest to benchrest shooters.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle Last edited by Unclenick; August 22, 2009 at 03:06 PM. |

|

|

|

|

|