|

|

|

#1 |

|

Member

Join Date: September 2, 2012

Location: Sierra Vista, AZ

Posts: 30

|

Cylinder Chamfering

I have a .31 Colt Pocket pistol that I'm having issues with loading. The ball has a tendency to slip back out past the front of the cylinder causing the cylinder to jam. Near as I can tell from making a few measurements with calipers, the mouth of each chamber is .003 to .004 smaller than the inside diameter. I'm thinking chamfering the mouth would resolve the problem. I know there are tools for some various caliber cylinders but I'm not finding anything for any of the common BP pistols sizes let alone a .31. If anyone knows a source for such a tool or can suggest another method, I'd like to hear about it.

Thanks, Craig |

|

|

|

|

#2 |

|

Member

Join Date: November 17, 2012

Location: Minn

Posts: 60

|

I'm no expert, but did you try a bigger ball that is .001 bigger than the opening of the cylinder ports????

|

|

|

|

|

#3 |

|

Senior Member

Join Date: October 24, 2008

Location: Naples, Fl

Posts: 5,440

|

Not picturing this...

You said that the mouth of the chamber measures smaller than the inside of the chamber. Unless I am mistaken (which frequently happens) it should be the other way around.

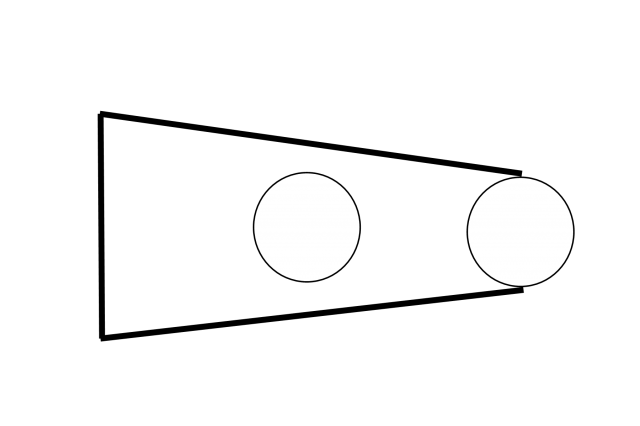

Most cylinders (I think probably all cylinders) are chamfered from the factory. The diameter at the very rim or mouth of the chamber should be slightly larger than the diameter of the chamber further into the chamber, You should see a notable chamfer in the chamber which extends into the chamber by about a sixteenth inch. I think the typical chamfer angle is 11 degrees but others on the forum will need to check me on that number. When I bought my first mold for my .31s I went by the recommendations in the various catalogs and selected a .315 diameter round ball mold. Bullet was too small and did not seat well in the chambers. I had the same problem you are having in that the bullets in the non-battery chambers were moving forward upon discharge. I went to a larger mold (I think it is .320) and solved the problem. I must hasten to add this note of extreme caution. The seating of the bullet on the powder is established at loading. There can be no air gap between the bullet and the powder lest you risk failure of the cylinder upon discharge. If the bullet moves forward in the chamber you might assume that an air gap has been created. Very dangerous.

__________________

Seek truth. Relax. Take a breath. |

|

|

|

|

#4 |

|

Senior Member

Join Date: November 19, 2009

Posts: 3,287

|

Before modifying your cylinder, I'd try the suggestion of using a larger size ball. You should be getting some "shear" - i.e. a small circle of lead when seating the ball in the chamber. And Doc points out a very good safety issue in regards to the balls moving forward and not being steed tightly against the powder charge.

You might try one of the suppliers and see if you can get a bag of 50 balls in a larger size to try. What are you using for a charge? Have you tried cutting that back a little to see if you are still having ball movement?

__________________

If a pair of '51 Navies were good enough for Billy Hickok, then a single Navy on my right hip is good enough for me . . . besides . . . I'm probably only half as good as he was anyways. Hiram's Rangers Badge #63 |

|

|

|

|

#5 |

|

Senior Member

Join Date: December 27, 2010

Posts: 211

|

I use Hornady double ought buckshot in my Wells Fargo model. They measure .330" and are reasonably priced when bought in bulk. The Wells Fargo model has no loading lever so I load off the gun. Works great!

|

|

|

|

|

#6 |

|

Senior Member

Join Date: October 24, 2008

Location: Naples, Fl

Posts: 5,440

|

Yes...

Hope I was not misunderstood. I am not suggesting chamfering the cylinder.

I actually think they already are although I did have a Pietta in whch the chamfering process was omitted in manufacture. It was darned difficult to load. But that was only one. I wouldn't do that even to my own pistols. Use bigger bullets

__________________

Seek truth. Relax. Take a breath. |

|

|

|

|

#7 |

|

Member

Join Date: September 2, 2012

Location: Sierra Vista, AZ

Posts: 30

|

Thanks, everyone. The balls I have right now are .315. It seems odd to me as well that the mouth would be smaller than the inside dimension of the chamber but that was what I had found. The balls I have now do shear when I lever down, but then they flop in and out causing the gun to jam up.

I'll try a larger ball. Not sure how that would change anything but I'm game for it. I'm still thinking that camphering the mouth of each chamber so the mouth is slightly larger than the inside diameter is the solution. I'll let you all know what happens after I try a larger ball. Thanks again. ~Craig |

|

|

|

|

#8 |

|

Member

Join Date: November 17, 2012

Location: Minn

Posts: 60

|

If we're talking ORIGINAL COLT,, I put that in a glass case and buy a repro. to have fun with..

If that is a repro, then call VTI parts and see if they have a cylinder... probably be cheaper in the long run..???? |

|

|

|

|

#9 |

|

Senior Member

Join Date: September 8, 2007

Location: Mississippi

Posts: 16,188

|

How did they bore a hole with the entrance smaller than the hole itself?

|

|

|

|

|

#10 |

|

Member

Join Date: September 2, 2012

Location: Sierra Vista, AZ

Posts: 30

|

Springfield, it is a repo. Cute little thing. Buying a new cylinder would be easier but where's the fun in that? lol

Hawg, trust me, I've asked myself that question but I've measured each chamber 3-4 times with calipers and keep coming up with the same numbers. You got me on that one. One would assume, if nothing else, that it would be same through out. ~Craig |

|

|

|

|

#11 |

|

Senior Member

Join Date: April 24, 2010

Location: Ohio

Posts: 581

|

It is virtually impossible to get an accurate internal diameter measurement with dial calipers. You really need to measure the internal diameter with a half ball guage and micrometer.

|

|

|

|

|

#12 |

|

Senior Member

Join Date: September 16, 2007

Posts: 712

|

robhof

I chamfered the cylinders on my Walker clone, because it wasn't. I've had no problems with it since. I used a tapered stone mandril on my drill press and just tapered the edge enough to make loading easy. I don't know what the degree is, but it shoots fine and loads much easier with no creap of the balls upon firing.

|

|

|

|

|

#13 |

|

Senior Member

Join Date: November 18, 2008

Location: Rocky Mountains of Montana

Posts: 292

|

Yep chamfering the cylinder is easy and a good idea in most cases. Sounds like you need to chamfer and go with a larger ball.

Chamfer can reduce chain fire and make loading cleaner and easier...most guns come with the chamfer, it is just so little that it is hard to see. I just used the little hand chamfer tool that RCBS sells for brass reloading. It worked just fine and now balls get swaged into the cylinder and don't shave the big ring. A much better seal. If you chamfer too far/much, accuracy will be harmed. A bigger ball will increase the size/length of the "flatspot" that is formed on the side of the ball. This will increase surface area friction..so a larger ball is also good advise. A .457 is way more accurate and 200fps faster than a .454 out of one of my Remingtons 58's..(but it has other issues)

__________________

Maker of Horse Tack and Cowboy Gear. www.7xleather.com Mister, why do you carry a 45? "Cause Sam Colt don't make a 46." |

|

|

|

|

#14 |

|

Senior Member

Join Date: September 7, 2012

Location: Crockett, Texas

Posts: 363

|

I don't know who the manufacturer of your gun was,but I have an ASM .31 and ended up going between .319-.321 and it worked cool, I tried the .315's like it said to and had the same problem as you. I got a Wells Fargo, so no rammer, but I pound the balls into the cylinder with a small wooden mallet and finish it with a piece of dowling I got in the arts and crafts aisle at wall mart. It's cheap chinese pine or somethin, so you have to make a new one every now and then, but a couple ft. of that wood rod is like less than a dollar, and you get quite a few pencil lenght pieces out of it. It's so reliable now, I carry it from time to time.

__________________

"I'm your huckleberry, it's just my game" |

|

|

|

|

#15 |

|

Senior Member

Join Date: October 12, 2012

Location: Wyoming

Posts: 351

|

champfering

please go back and read what you wrote?

You stated the mouth of chamber is smaller than the chamber dimensions farther in. The balls work forward jamming the revolver. If you were to champfer the opening (make bigger) would this not in turn exacerbate the problem? Yes it would. Almost all BP revolvers are designed with an opening smaller than the rear of the chamber. The smaller opening, causes the ball to be squeezed and compressed into the cylinder. Causing a friction fit. Thus causing pressures to build up when firing to then expell the ball out at great force. When seating the ball you should be shaving a nice ring of lead from all around the ball. If not, then the ball is too small. Are you sure you have a .31 and not a .36 (of any model) Measure the opening of chamber. You want a ball anywhere from 2 to 6 thousandths larger in diameter. But no, you do not want to champfer the opening with the condition you wrote about. you wrote: Cylinder Chamfering I have a .31 Colt Pocket pistol that I'm having issues with loading. The ball has a tendency to slip back out past the front of the cylinder causing the cylinder to jam. Near as I can tell from making a few measurements with calipers, the mouth of each chamber is .003 to .004 smaller than the inside diameter. I'm thinking chamfering the mouth would resolve the problem. I know there are tools for some various caliber cylinders but I'm not finding anything for any of the common BP pistols sizes let alone a .31. If anyone knows a source for such a tool or can suggest another method, I'd like to hear about it. |

|

|

|

|

#16 | ||

|

Senior Member

Join Date: October 8, 2006

Location: Northern Michigan

Posts: 2,772

|

Quote:

Quote:

IF the openings were actually smaller than the throats, which they aren't, the ball would be swaged to the diameter of the opening and then be LOOSE further down inside the chamber where the diameter would be larger. Lead balls don't expand to fill up the extra space available in a larger diameter cylinder. There would be no 'friction fit' because the ball diameter would be smaller than the diameter of the cylinder throat. Because the loose ball would not seal the chamber, expanding gas would escape around the ball resulting in low velocity.

|

||

|

|

|

|

#17 | |

|

Senior Member

Join Date: September 8, 2007

Location: Mississippi

Posts: 16,188

|

Quote:

|

|

|

|

|

|

#18 |

|

Senior Member

Join Date: March 19, 2008

Location: High & Dry in Missouri Ozarks

Posts: 2,113

|

Craig, get some .319 or .323 balls for your pocket model. You will no longer have he problem of the balls creeping out. .315 is way too small to work properly.

__________________

Fingers (Show Me MO smoke) McGee - AKA Man of Many Colts - Alter ego of Diabolical Ken; SASS Regulator 28564-L-TG; Rangemaster and stage writer extraordinaire; Frontiersman, Pistoleer, NRA Endowment Life, NMLRA, SAF, CCRKBA, STORM 327, SV115; Charter member, Central Ozarks Western Shooters Cynic: A blackguard whose faulty vision see things as they are, not as they should be. Ambrose Bierce |

|

|

|

|

#19 |

|

Member

Join Date: September 2, 2012

Location: Sierra Vista, AZ

Posts: 30

|

Thanks everyone for your input. I ordered some .320 balls this weekend and with a little luck, they'll be here next by next weekend. {{{knock on wood}}} In the meantime, I am going to campher the chamber mouths as a couple of people suggested. It only makes since that if the ball is shearing going in but not making a tight fit inside the chamber, that camphering would be the option. That would open the mouth just a bit to allow the ball to make a tight fit into the chamber.

I'll post again once I get the new balls and have a chance to try them out. Thanks again to everyone for your input. This is a great place.  ~Craig |

|

|

|

|

#20 |

|

Senior Member

Join Date: October 12, 2012

Location: Wyoming

Posts: 351

|

champfering

haven't figured out how to quote

Quote: Almost all BP revolvers are designed with an opening smaller than the rear of the chamber. This is what I said in first post. No, they aren't. Is what somebody said in response Quote: This is part of what I said The smaller opening, causes the ball to be squeezed and compressed into the cylinder. Causing a friction fit. this is what you said. Nonsense. IF the openings were actually smaller than the throats, which they aren't, the ball would be swaged to the diameter of the opening and then be LOOSE further down inside the chamber where the diameter would be larger. Lead balls don't expand to fill up the extra space available in a larger diameter cylinder. There would be no 'friction fit' because the ball diameter would be smaller than the diameter of the cylinder throat. Because the loose ball would not seal the chamber, expanding gas would escape around the ball resulting in low velocity. I did not say all. But most are. If you will remove your cylinder. Then look down into it. Most of them (not all) you will see a distinct line about 3/16" or so in. This is where the powder area has been bored slightly larger than the opening. Some are a gradual enlargement and thus no distinct line. Some are the same size all the way down. I know this from personal observation and the use of a split ball gage, because over the years I have owned many different types and models and brands. Many of them I have bored the powder area larger myself on my lath / boring machine. We are not talking about the throat / forcing cone at the beginning of the barrel right in front of the cylinder. On the cylinder regardless of caliber size. the opening needs to be 2 to 6 thousands smaller than the ball you are using. Or reverse that. The ball needs to be 2 to 6 thousands larger than the cylinder opening. When pressing a ball down into the opening several things occur and are accomplished. 1. the ball is squeezed to fit the opening thus elongating it. 2. a thin ring of excess lead is shaved from the largest diameter of the ball 3. this causes a friction / pressure fit. 4. this friction fit, causes the gas pressures to build up to a point where Newtons law comes into effect. Since the pressure fit of the ball is a weaker point than the rest of the cylinder, the gases push the ball out of the cylinder and down the barrel. In normal loading the greatest diameter of the ball does NOT go below the narrower area of the opening. Many shooters use small powder loads and then fill the chamber with filler (corn meal, fiber wads, etc). But a properly loaded cylinder will keep the ball in the immediate opening area. recessed just below the surface. In my 44 Remmington (35 years old), I can load as little as 20 grains FFFg and the ball will be in the constricted area. I can load a max of 35 grains FFFg and the ball will be below the surface. 38 grains and the ball protrudes. Less than 18 grains and the loading lever stops before it seats the ball on the powder. To continue seating does place it too far down and out of the restricted area. I know this, because I deliberately did this, in the past, seeing what would be a minimal and max for my gun, volume wise. If for some reason the ball is too loose, then the gases will escape around the ball. then the ball either won't go down the barrel at all, or maybe only part way, or maybe go any distance. Or if the ball is stuck and can't move. excessive pressure build up COULD cause the hammer to be pushed back off the nipple and the gas and pressure to escape back out the nipple. Or the cylinder itself could burst. In any event before you jump on me and say NO as in your reply. Take into account I said MOST not all cylinders are bored this way. Maybe I should of said MANY instead of MOST. |

|

|

|

|

#21 |

|

Senior Member

Join Date: November 19, 2009

Posts: 3,287

|

O.K. . . . not to get in to a big debate or duel . . . but when I read this originally and posted . . . I neglected to ask what Hawg and several others have already mentioned. I have a machining background and am still scratching my head . . .

If it was a "bored through" cylinder (i.e. as for cartridge) I can see how the chamber could be machined so that the mouth of the chamber (end towards the barrel) could be tapered to a smaller I.D. - a fairly simple mating process with the right tools. But we're talking a BP cylinder - bored from the mouth end (barrel end). How on earth can you machine it so that the mouth is a smaller I.D. than the lower portion (nipple end) of the chamber? I just don't see how it can be done unless you bored the chamber and then went in with an expandable hone of some sort that expanded after inserting. I really don't think they go to that extent. So . . . I'm not casting doubts on what the OP has stated or questioning him . . . and yes, it's possible that his end measurements may be off due to the difficulty in taking them . . . but that still doesn't explain the balls moving forward. If he's getting a good shear of lead . . . they shouldn't be doing it. Or am I missing something? I've never shot a "49 Pocket (although I'd love to have one). I'm assuming you are using about 12 grains of BP. Doesn't seem to me like that would force the balls in the unfired chambers forward unless there was a problem. Is it possible that the chambers are "out of round" - i.e. enough that you might get a shear and it look O.K. but off enough to allow movement? Just asking . . .

__________________

If a pair of '51 Navies were good enough for Billy Hickok, then a single Navy on my right hip is good enough for me . . . besides . . . I'm probably only half as good as he was anyways. Hiram's Rangers Badge #63 |

|

|

|

|

#22 |

|

Senior Member

Join Date: October 24, 2008

Location: Naples, Fl

Posts: 5,440

|

When I was looking into a situation....

....requiring the measring of the chambers, I looked unsuccessfully for gages small enough to fit inside a .31 caliber chamber.

Actually the situation was very similar to this one. I could not get balls to fit my 1863 Remingtons. Having bought the .315 mold, I was getting the same problem that Craig is having. Anyway, I tried several places looking for gage sets that would work inside a .31 and found nothing at anything like a reasonable price. Any leads, tips or suggestions? Tnx,

__________________

Seek truth. Relax. Take a breath. |

|

|

|

|

#23 |

|

Senior Member

Join Date: February 25, 2009

Posts: 643

|

If you get to the point of still wanting to chamfer your chambers, reach for a Lee tool produced to chamfer the mouth of cartridges. It is a hard steel that will cut you chambers easily. A couple of twists will break the sharp edge and solve your problems. Unless you grind on it with both hands you cannot do any damage to the gun.

Just go lightly until the desired configuration is reached. |

|

|

|

|

#24 | |

|

Senior Member

Join Date: October 8, 2006

Location: Northern Michigan

Posts: 2,772

|

Quote:

This is not my experience. I have owned over 70 black powder revolvers, mostly Italian replicas of Colts and Remingtons, over the last 35 years. I have restored and repaired several more for friends. NONE, repeat NONE, have had this 'step' machined in the cylinder chambers in the so-called 'powder area'. (What is the 'powder area' anyway? Machining a 'powder area', essentially larger diameter in the chamber expressly for powder, implies that there is a specific powder charge intended for use in that chamber, and no manufacturer of either original or replica ball and cap revolvers makes that known to the users. Why would they go to an extra, and certainly an expensive, machining operation in every chamber and then not tell the user that the gun was designed for a specific powder charge?) |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: February 25, 2009

Posts: 643

|

If anything the powder area is smaller than the throat of the chamber. There is no logical reason for an enlargement. You would have to assume that the ball would compress then expand to fill the hole?

Now, a cartridges revolver has such a line between the cartridge area and the throat. And as mykeals say none of mine including an 1862 manufactured 1851 style colt have such an enlargement. |

|

|

|

| Thread Tools | Search this Thread |

|

|