|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: March 4, 2009

Location: Varying between 1 and 3 hours from Chicago

Posts: 152

|

Hardness on a Checked Bullet

So I am planning on loading 45/70 in the near future, and am going to put a GC on it. From my understanding, the gas check's job is to simulate that of a copper jacket and allow the use of cast at higher pressure loads.

Would the alloy used need to be very hard if a GC was used? Obviously hardening the bullet to what it would be without a gas check isn't required, as that would defeat the purpose of the check, but logic would dictate (mine atleast, and it has proven to be lacking on more than one occasion  ), that the sides of the bullet would shear off from the stress of the rifling. Any thoughts? Anybody worked with the hardness in a checked bullet at high vel. rifle loads? ), that the sides of the bullet would shear off from the stress of the rifling. Any thoughts? Anybody worked with the hardness in a checked bullet at high vel. rifle loads?For that matter, if the check is doing a good job of keeping the bullet from leading in higher velocity loads, couldn't I just check pure lead bullets for use in my 9mm loads rather than alloy my lead up to the proper hardness (at a cost to me of about $10 per 500 rounds of 124 gr). Any help is greatly appreciated as always!

__________________

Rev 5:13 "To him who sits on the throne and the Lamb be praise honor and glory and power, for ever and ever" Last edited by Shane Tuttle; August 24, 2011 at 07:22 AM. Reason: BULLET, not boolit |

|

|

|

|

#2 |

|

Junior member

Join Date: October 6, 2010

Location: Michigan

Posts: 1,080

|

Hello, studman..Your giving that little copper cup way more credit than it deserves. The gas check could be thought of as a wrench..giving additional purchase on the rifling than just the soft surface skin of a lead bullet. And while it does protect the vulnerable lead base from hot powder gasses, the sides of the bullet are still very much in contact with the bore & using a too soft alloy..even with a check will give you a bore full of lead. The best you can expect is a bit over 2000fps. with lino & gas checks plus a very good lube. If you want high velocity with pure or nearly so lead..you'll have to paper-patch. This acts just like a jacketed bullet..a barrier to friction between lead & bore.

|

|

|

|

|

#3 |

|

Senior Member

Join Date: August 1, 2007

Location: Tabor City , NC.

Posts: 1,969

|

To add to Ideal Tools comment , the bullet still has to be hard enuff to grab the rifling & start spinning ,the check helps this to happen but only after it enters the throat far enuff. The checks main job is to protect the base from deformation from pressure distortion.

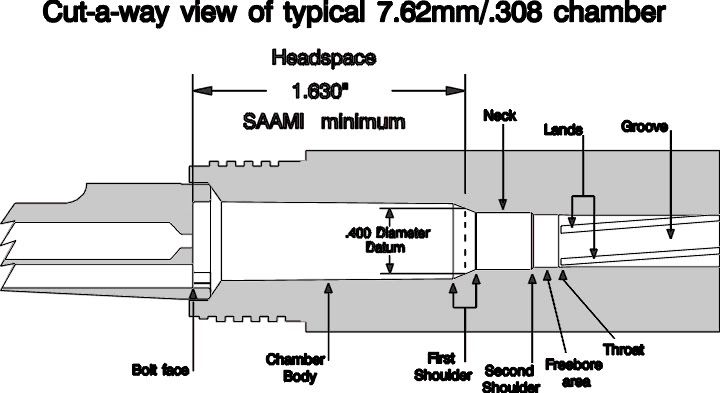

Here`s a pic of a typical chamber throat ,barrel . The free bore is the area we have to work with , some seat to it some seat off of it . Typically we tend to think we need to seat to it ,but not always !!

__________________

GP100man

|

|

|

|

|

#4 |

|

Senior Member

Join Date: October 13, 2009

Location: nw wyoming

Posts: 1,061

|

I've noticed that if I use straight WW alloy with a plain base boolit, I can go to about 15000-16000psi before leading the barrel and losing accuracy.

If I use a gas check boolit with the same alloy and hardness, I can run it around 29000-30000psi. Everything may vary a little, but this is pretty close. I have a hardness tester, but I dont have a pressure tester, but it takes a certain pressure to make a certain speed, so with a chrono you can tell pretty close. This might not have anything to do with anything at all, but I've come to keep tabs on psi the last couple years and load this way, and it works pretty good for me. Some people that have been doing cast alot longer may find something completely different. I've still alot to learn. BTW, we've been running max loads in 9mm with air cooled WW and Bullseye powder. We use a plain base gas check on the boolit, and it works great. No leading and great accuracy. Before, it didnt matter what we tried, it leaded the barrel. Last edited by reloader28; August 24, 2011 at 08:31 AM. |

|

|

|

|

#5 |

|

Senior Member

Join Date: March 4, 2009

Location: Varying between 1 and 3 hours from Chicago

Posts: 152

|

Ideal Tool - Paper patching huh? I hadn't considered that. I'll have to do some research and see if it suits my needs. Do you paper patch? If so, can you give a bit of an explanation how it affects your casting process? Thanks!

thanks for the pic GP100man. reloader28 - I've been having leading problems in my 9mm with my first batch of cast boolits. I'm currently trying to work myself one of the freechex devices (making your own GC out of aluminum for a materials cost of about 5% of factory price) and plan on putting GC on my 9mm loads. you said plain base gas check, that would mean you're talking boolits from a mold that doesn't have a GC shank cut into it and crimping them on? What sizing & crimping method do you use? Thanks!

__________________

Rev 5:13 "To him who sits on the throne and the Lamb be praise honor and glory and power, for ever and ever" |

|

|

|

|

#6 |

|

Senior Member

Join Date: January 14, 2011

Location: on the north side of DFW

Posts: 970

|

First off, I'm not a ballistician.. (and I don't play one on TV

) )I DO read a lot, though, and I've read some enlightening things lately on shooting cast lead bullets (boolits, if you prefer). I will share them as I read them.. don't mean to start any shovin matches. A gas-check is just what the name implies... it is a "check", or a stop, for the hot gases created when firing the cartridge. It keeps the gases from blowing past the base of the bullet, melting the lead as it goes. It creates a flat, consistent surface, with a good seal to the bore to accomplish that. Leading is NOT caused by the base of the bullet melting. People have used "gas-checks" cut out of thin wax, then recovered the bullets with wax still intact, unmelted, on the base. If the gases don't melt the wax, it certainly won't melt the lead base. Leading is usually caused by (1) gas blow-by (2) incorrect, insufficient bullet lube Hardness of bullet alloy is not quite as important as most people think. Harder is NOT always better. Bullet alloy that is soft enough to allow bullet obturation (swelling to fit the bore) is highly desirable. If the bullet can't obturate, you get gas blow-by. Not good. Too hard an alloy is also usually too brittle to hold together for penetration, and will "shatter" or break up when hitting bone. Like I said, these are just a few of the things I've run across that punctured a LOT of the "fact balloons" I'd been told as I got into shooting cast bullets. Open for discussion...

|

|

|

|

|

#7 | |

|

Senior Member

Join Date: October 28, 2006

Location: South Central Michigan...near

Posts: 6,501

|

Quote:

|

|

|

|

|

|

#8 | |

|

Senior Member

Join Date: October 28, 2006

Location: South Central Michigan...near

Posts: 6,501

|

Quote:

|

|

|

|

|

|

#9 | |

|

Senior Member

Join Date: October 28, 2006

Location: South Central Michigan...near

Posts: 6,501

|

Quote:

|

|

|

|

|

|

#10 |

|

Senior Member

Join Date: October 13, 2009

Location: nw wyoming

Posts: 1,061

|

Studman, my mold is a plain base design. The gas checks are from aluminum pop cans.

Size and lube the boolit exactly like normal. Then put a check on it and run it thru one more pass and your done. Piece of cake. |

|

|

|

|

|