|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

So I bought a few green mountain blanks...

After looking for "uppers" for one of my TC contenders for my Daughter and not liking the prices I decided to build them.

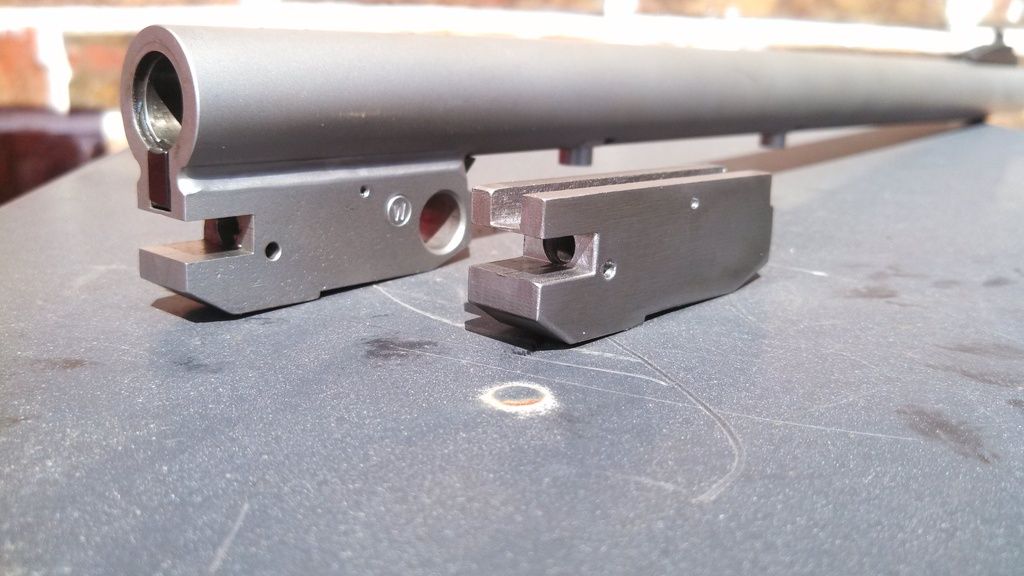

Started with the .22 blank and turned it down and threaded it for a suppressor.  While I was at it, I went ahead and machined a thread protector if it ever didn't have one on or a QD adapter on the threads.  After a little searching, I couldn't find any weld on lugs (one source for threaded) and machined my own just averaging the measurements from the TC barrels I do have.  Welded the first one together yesterday, chamber reamer is on the way now and after that will have to machine the slot for the extractor, finish and test. If it is a "winner", will do the next one the same way.

|

|

|

|

|

#2 |

|

Staff

Join Date: November 2, 1998

Location: Colorado

Posts: 21,847

|

This is inspirational.

__________________

Vigilantibus et non dormientibus jura subveniunt. Molon Labe! |

|

|

|

|

#3 |

|

Senior Member

Join Date: September 28, 2013

Posts: 3,834

|

Nice machining. I wish I have a lathe and a welder as you do.

But I am not sure welding a barrel is a good idea, as the heat will alter the heat treat. It is generally a no no according to the teaching at the school I go to. Same concern on the lug as it is a critical part bearing the blunt of recoil force. I wouldn't do it for myself, let alone giving to my daughter. It was a 0.22 blank, but you didn't mention the exact cartridge type. It may be OK if it is a low pressure round like .22lr, but a TC usually does a much higher power round. Well just be careful and good luck. -TL |

|

|

|

|

#4 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

That 3rd pic shows a factory TC welded barrel, that's just the way they do it. Weld then ream the chamber. That one is going to be .22LR.

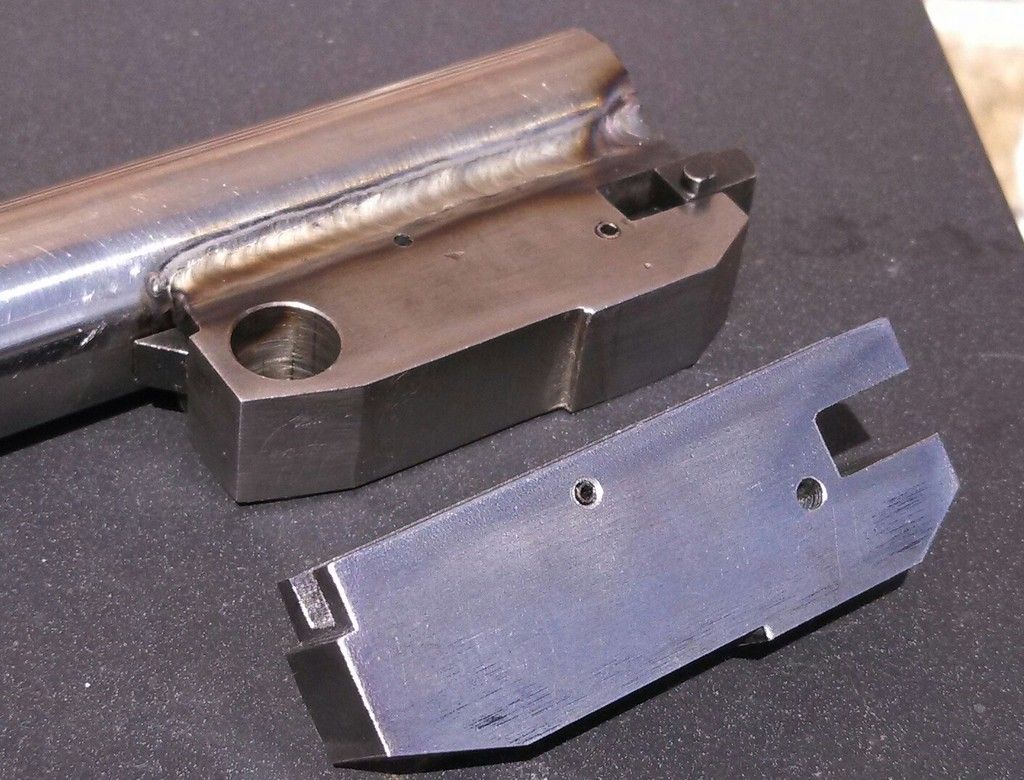

There are some out there that have a radius machined into the lug then they fusion weld the lug to the barrel. They had the best intentions in that that wouldn't heat the barrel/lug as much as a "real" weld. Problem is that they don't get any penetration and things like this happen.  Silver solder would have been a better idea than that. But not sure your understanding what the lug is actually doing, if it were recoil force opposite of the bullet leaving the barrel the breech face against the frame would take care of that. The lug is there so the breech face remains in contact with the frame instead of going down range. Last edited by jmorris; March 5, 2016 at 09:50 AM. |

|

|

|

|

#5 |

|

Senior Member

Join Date: September 28, 2013

Posts: 3,834

|

I see. I thought the picture was your finished work. Perhaps 0.22lr is OK to weld. But at least I would draw back the steel to blue in case the weld has made the steel hard and brittle.

-TL |

|

|

|

|

#6 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

None of the contender barrels are machined from one piece, they are not the only firearm that has multiple parts to the barrel either.

Even the 300 win mag barrel for the encore uses a welded on lug.  Same thing with the handi rifles.

|

|

|

|

|

#7 |

|

Senior Member

Join Date: September 28, 2013

Posts: 3,834

|

Reheat treat after weld is how they are made.

I was incorrect about the function of the lock lug. It is not for bearing the recoil force directly, but to keep the action from opening while projectiles is traveling down the barrel. It is critical part in a pivot barrel gun. -TL Last edited by tangolima; March 5, 2016 at 10:37 AM. |

|

|

|

|

#8 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

I was with you on the first two pics.

I have threaded a Green Mountain muzzle in the lathe. But at the 3rd pic, welding on the lug, you lost me. I have $2k in TIG welding gear here and so far put one useful spot on a overground Mauser trigger. I need to learn how to weld. Jmorris says Silver solder. I have that stuff. The flux is corrosive. I should try again. I drilled and tapped blind holes into the barrel, then fastened to the lug, with an epoxy to improve fit.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#9 |

|

Senior Member

Join Date: October 20, 2006

Posts: 687

|

nice job jmorris,,,,looks good

so before you ream the chamber are you planning to send it somewhere and get it normalised before you ream,,,to get the stress out where you welded?? ocharry

__________________

The felon does not fear the police, and he fears neither judge nor jury. Therefore what he must be taught to fear is his victim." - Lt. Col. Jeff Cooper, USMC |

|

|

|

|

#10 |

|

Senior Member

Join Date: August 25, 2008

Location: In the valley above the plain

Posts: 13,427

|

Sweet.

Everyone that I have seen successfully weld lugs to barrels (Handi-Rifles, in particular), has encountered enough warpage to be problematic unless they pre-heated the parts, TIG welded the lug/block on, and then put the assembly back in the oven to slowly cool. But... I'm not a metallurgist. So all I know is what I've seen others do ... and the few failures people have been willing to share on the GBO and MO H&R/NEF forums. I have been wanting to build a few barrels for my Handi-Rifle frame, for a few years now; and I'm not a fan of the ever-so-popular 'stubbing' methods (mostly due to the fact that an existing barrel must be sacrificed). So new blocks/lugs was the direction I planned to go when the time comes.

__________________

Don't even try it. It's even worse than the internet would lead you to believe. |

|

|

|

|

#11 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I would like to think that the barrel is an undrilled bar before welding. Even a lot of the old S/S shotgun barrels were forged as one piece. I don't know, I have seen some dumb stuff come from the factory. Most barrels are 4140 that are pre heat treated to about 28 RC. When welding 4140, the parts should be heated up first. The problem with welding 4140 is it gets unstable. You cannot be sure what it will do. It may get softer, or it may get harder. I would not worry about a .22 or a low energy center fire. A round with some pressure would make me think twice.

|

|

|

|

|

#12 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

This article on barrel making is an interesting read. Douglas draws back barrels at 1100°F (just 12°F less than the 600°C mentioned by Kolbe, so, close enough). This is done in a controlled atmosphere oven to avoid oxidation. I would be doing that after welding to stress-relieve the steel. You can wrap the thing in heavy stainless foil to prevent much oxygen getting at the surface, and then put it into a knife oven or kiln that has proper temperature controls and let it soak in there for an hour.

How much the welding will affect the properties of the barrel, I can't say. If you can at least rough the chamber in before welding, then pump a coolant like anti-freeze through it while you weld, that will go a long way toward keeping strength integrity around the bore and chamber. The cold bore and chamber surfaces will then cause a temperature gradient to develop between the bore and the weld site that will stay below 1100°F for some portion of the thickness to the weld. If the steel is half an inch thick around the bore, then about 0.2" will stay below that value. For 1/4" thickness between the bore and the weld, it will be about 0.1". In other words, about 40% of the thickness, whatever it is. On the assumption the barrel was drawn back at 1100°F originally, you should then not affect the temper inside that thickness around the bore and chamber. If you don't at least rough the chamber first, though, you may end up cutting through the preserved temper when you chamber.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#13 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

1100 degrees sounds about right. That would take it to 33 RC even if it was up at 57 RC to start, and all they are doing is stress relieving. The use of coolant while welding is a little dicey. The 4140 series of steel is oil hardening. Quenching it in water could bump it up to 70 RC. I have seen it done accidentally by people wanting to cool something off after welding.

|

|

|

|

|

#14 |

|

Senior Member

Join Date: October 20, 2006

Posts: 687

|

thats what i was thinking,,,i have done some welding of 4140,,,and the weld sight does get kinda hard,,,,without stress relieving or normalising you might wreck the reamer

good thought about roughing the chamber before the weld,,,,just make sure you leave enough to finish ocharry

__________________

The felon does not fear the police, and he fears neither judge nor jury. Therefore what he must be taught to fear is his victim." - Lt. Col. Jeff Cooper, USMC |

|

|

|

|

#15 | |

|

Senior Member

Join Date: February 16, 2006

Location: IOWA

Posts: 8,783

|

My compliments !!!

Quote:

Be Safe !!!

__________________

'Fundamental truths' are easy to recognize because they are verified daily through simple observation and thus, require no testing.

|

|

|

|

|

|

#16 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

A quench could cause distortion and hardening, but if you run coolant through the bore and roughed chamber of that thick barrel, cooling from the inside out will be slower than a quench is at the weld sight. Whether or not it is slow enough that the surface cools itself faster by thermal diffusion than heat flow to the inside can, I don't know, but suspect that will be the case. Perhaps our resident metallurgist, Mete, will see this and know the answer. I can set up an FEA model to see, if I get time. In any event, doing the draw afterward should bring it back closely enough. Matweb has 25 mm 4140 oil quenched round bar drawing back as:

Rc 34 1000°F Rc 30 1100°F Rc 27 1200°F Thinner stock will be harder after exposure to that temper because it is harder through and through to begin with as a result of quenching faster.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#17 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I welded up a set of pie jaws once and the kid helping me had grabbed a slug (of 4140) and turned it while I was boring the jaws. I welded them up and about 5 minutes later he put them in a bucket of water to cool down. Could not split them with a band saw. 4140 is funny stuff sometimes. Who knows what the coolant would do? I used a brass bar to align two halves of a receiver together one time when gas welding. The brass acted like heatsink and I could not weld it.

|

|

|

|

|

#18 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

It's a question of proximity and the thermal properties of the material and the ability of the welding system to supply Btu's fast enough. In this case I am counting on the thickness of the steel to have enough thermal resistance to allow heat build-up for the same reason you can weld a piece of steel without heating the whole piece.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#19 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

Instead of just talking about it, try it.

|

|

|

|

|

#20 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

I used LA-CO Block-it (same product I use when I TIG weld brazed heat exchanger cores to tanks without damage) when I welded the parts together and the reamer arrived yesterday so I was able to test fire it a dozen times today and it all works. After I get it drilled and tapped and figure out what optic I am going to put on it, I'll post back accuracy results.

|

|

|

|

|

#21 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

I can't weld well, but my brother has all the certificates.

He uses heat paste on welding Mauser bolts. On some things he uses compressed air for cooling between welds https://www.youtube.com/watch?v=PITNUV8ky_s

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#22 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

Clark, you are confusing the issue. Mauser bolts (Everyone I ever worked on) are mild steel and really will not change from a little heat. I saw photos of a Russian receiver you welded on and I bet the case is still hard near the weld. I have used heat sink and really do not care for it. A lot of the problems caused by heat are from years back when welding options were limited. I know guys that used to submerge the bolt in water to gas weld the bolt handle on. I have gas welded, but only when I wanted to use a rod of the same material so I could re-heat treat. I usually use an arc welder, Put a short bead on, stick the part of the bolt FARTHEST from the weld under running water, and then weld a small bead again. I have welded both receivers and bolts made of 4140 and have NEVER had a crack develop or lost a bolt handle. Welding is pretty much like heat treating. You have to understand what the properties are of the material you are working with.

|

|

|

|

|

#23 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Gunplummer, I agree. However, I did fabricate fixtures to hold parts from wanting to warp, if I thought that they had a good chance of it. But of course, it is how much heat you apply, and the amount of weld, that will cause it. A larger spot of weld, with pull at the piece with more force that a smaller.

Back when they had to gas weld everything, that put bookoos of heat into a part, but by using a TIG, you can put a sudden amount of energy and a small spot of metal pretty quick, so that smaller amount of heat dissipates quicker, and does not travel as far. If you let it cool between spots, then you can do a lot without warping. |

|

|

|

|

#24 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I never did tig welding, but from what I have seen and been told, it is not much more than really clean gas welding. I suspect that if you were to actually use a rod of 4140 to weld 4140, the heat would be a lot higher. You can see anywhere a weld (With standard rods) is on a gun part made of 4140 as soon as it is blued. You can re heat treat and draw back and that weld will show up when blued. It is not the weld that gets hard, it is right next to it. No matter how much you cool the area, or restrict the area from heat, that steel was a red hot liquid right next to where you laid the bead down. If it was not, you just "Tacked" it on. That is the area I would worry about, not the inside of the barrel. Take another look at that broken weld picture. That weld looks as if was barely tacked on. And it looks crystallized.

|

|

|

|

|

#25 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Gunplummer, Whatever they did, I've not seen that before on guns. I think that may have been flash welded, a type of resistance weld. They literally just mash the two pieces together, while applying a current, as the edges were all that welded along a thin edge. They weld the yokes on RR car brake rods that way.

|

|

|

|

|

|