|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#26 |

|

Senior Member

Join Date: January 4, 2015

Location: Perryville MO

Posts: 426

|

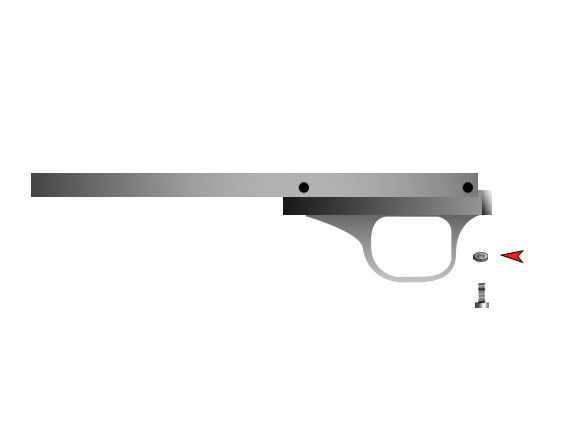

Pic of the disconnector pin where it rides on the action bars

|

|

|

|

|

#27 | |

|

Senior Member

Join Date: January 4, 2007

Location: pelican lake, WI

Posts: 414

|

Quote:

I will disassemble one of my 1962 model 100's later this morning and take some pictures. If I understand your statement correctly, the rails are tight up against the upper receiver? Is it possible they are binding. How much play is there between the receiver and recoil block. You said you didn't remember if there was any play before you replaced the extractor. This is a shot in the dark, but try cutting one or two shims out of a coke or beer can and place them temporarily under the recoil block, this would be less than .002". See if this corrects the problem. Who knows - old stock, oil soaked wood; may be the recoil block after you tighten the rear trigger guard screw compressed the stock and is sitting a little lower in the stock causing the receiver play. About five years ago I posted a re-print on how to glass bed a Winchester Model 100. It is done in four steps and really helps the accuracy of these guns. My 100 carbine shoots 1.5 to 2 inch groups as a result of this bedding. The first step read, "1.) The first step is to bed the recoil block in place - in a separate operation. This is done with the recoil block screw VERY loose. This screw just has to be there to locate its permanent location in a way that won't allow the recoil block to flex the action when your finished." According to this the recoil block could be raised a little and the gun would still function. This could eliminate your play in the receiver and block. |

|

|

|

|

|

#28 |

|

Senior Member

Join Date: November 19, 2002

Location: Mississippi

Posts: 963

|

Just look'en at the Pics,

The recoil block and group assembly should be tight, it looks like I can see a little chatter of the two over the years. What does the recess of the screw hole shoulders look like. Would a thin washer used with the screw tighten things back up??? |

|

|

|

|

#29 |

|

Senior Member

Join Date: January 4, 2015

Location: Perryville MO

Posts: 426

|

There is no binding in the action bars. They slide well. As far as the rear block. I thought about putting a shim under it but that may tighten the looseness but will pull the receiver farther away from the trigger assy making the problem worse. That's what I cant figure out is why this is now a problem. I guess I know what the problem is just cant figure out why it happened or how to fix it. Possibly bedding the around the barrel screw forcing the receiver down a little. I a afraid that will cause other problems.

|

|

|

|

|

#30 | |

|

Senior Member

Join Date: January 4, 2007

Location: pelican lake, WI

Posts: 414

|

Guess I don't understand the play issue if raising the recoil block will create more play between it and the receiver. But do not bed the barrel screw. Here are the instruction for glass bedding a model 100. This is off track but this bedding procedure reduced my 100 groups by half. I'm going to dis-assemble a 100 now.

Quote:

|

|

|

|

|

|

#31 |

|

Senior Member

Join Date: January 4, 2015

Location: Perryville MO

Posts: 426

|

It would not create more "play" but would create more clearance between the receiver and trigger assy. That's what I meant to say.

|

|

|

|

|

#32 | ||

|

Senior Member

Join Date: January 4, 2007

Location: pelican lake, WI

Posts: 414

|

Dissembled an early Mod 100, Serial number 75089; and mine doesn't have the dis-connector in it. I purchased mine used after it had the firing pin corrected. It may have been removed during the repair. I recall reading somewhere Winchester removed that part in later productions. Mine just has the trigger lock at the back of the trigger. Numrich diagram for the model 100 does not show the dis-connector.

Added. Here is the discussion from post: http://thefiringline.com/forums/showthread.php?t=272094 Quote:

Quote:

Last edited by wachtelhund1; January 7, 2015 at 12:35 PM. |

||

|

|

|

|

#33 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Yes, that is what is called the trigger lock lever, and as you can see, if the bolt is not forward, and mashing this down, it wont fire. As was mentioned, they later discontinued this, and it could be taken out of this gun, and it would assuredly drop the hammer every time. My guess is that it is not working correctly, and freeing the trigger when the bolt closes. The action bar would be what hits the cam surface, and depresses it, when the bolt is forward. If there was too much slack in the bar, (up and down movement), then it might not push the lever all the way down when the bolt is forward. Winchester must have evidently decided that this safety feature was not needed, and removed it.

This is why I was concerned about the extractor being proud on that rim, and maybe holding the bolt back just enough that this would catch the trigger, and block it. It is a really close tolerance part for it to work correctly. Any new slack or wear can most assuredly cause a malfunction. Since they took this out of the later models, you could too, and I will guarantee it will work, but you will loose that safety feature. |

|

|

|

|

#34 |

|

Senior Member

Join Date: January 4, 2015

Location: Perryville MO

Posts: 426

|

If I took it out the hammer would follow the bolt back down when firing? That's what it looks like to me. There is nothing to hold the hammer back?

|

|

|

|

|

#35 |

|

Senior Member

Join Date: November 19, 2002

Location: Mississippi

Posts: 963

|

No, no, You put the washer on the screw...

|

|

|

|

|

#36 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

No, it can't do that, because you're holding the trigger back, like you would when firing.

The disconnector, or hammer hook, is the rear spring loaded hook on the trigger, and you'll notice another hook at the front but lower, and that is the sear hook. These keep that from happening, and I doubt you would be fast enough to fire it, release the trigger, and pull it again, before the bolt closes. This works about the same as the trigger is a Browning Auto-5 shotgun. |

|

|

|

|

#37 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

I'll add this. The trigger lock lever was a safety device to keep the gun from firing if the bolt was not completely closed, even if the bolt was not totally turned as far as it could go. If it did, the excessive headspace could cause a case rupture. However, Winchester chose to do away with this safety feature, as I would say, that when the guns eventually loosened up from age and firing, the thing would get to where it would do just what your's did.

I'll tell you one other thing to check. See if the bolt in the stock is loose, which holds the recoil block in pace. Take off the butt plate to get to it. That bolt should be tight, so the recoil block has no movement in it. Movement could allow the receiver some slack, and thus the action bars. |

|

|

|

|

#38 |

|

Senior Member

Join Date: January 4, 2015

Location: Perryville MO

Posts: 426

|

I will look at it again when I get home later tonight.

I also want to thank you all for your help. This rifle has been in the family since new and I would love to get it working again. My grandpa claims he even killed a elk with it. He is no longer with us. Its a .243 |

|

|

|

|

#39 |

|

Senior Member

Join Date: January 4, 2015

Location: Perryville MO

Posts: 426

|

Took the "extra" parts out. rifle functions fine cycing the bolt. hammer does not follow bolt down when holding trigger. Now for the weather to warm up a bit and I will go to the range and live fire test it.

Once again I want to thank you all for helping me with this gun. ESP Dixie Gunsmithing |

|

|

|

|

#40 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

You're welcome, and let us know how it works.

|

|

|

|

|

#41 |

|

Senior Member

Join Date: October 9, 2009

Location: North Alabama

Posts: 8,314

|

hats off

Dixie Gunsmith,

Hats off to you for a comprehensive and apparently knowelegable set of posts, and a desire to see the issue through. Big fan of the M88, and its semi brother the M100. |

|

|

|

|

#42 |

|

Senior Member

Join Date: January 4, 2015

Location: Perryville MO

Posts: 426

|

Shot the model 100 yesterday. It cycles now most of the time. About once per magfull it would cycle but the trigger would not pull. Not sure what its was doing. If the disconnect was not releasing or if the hammer was not going all the way back. It ejected and had a new round in the chamber. I shot it 15 times and this happened twice. I would cycle the bolt and it would work again. It still is giving me fits. lol to top if off I put a different scope on it and it wont adjust high enough to be on at even 25 yards.

|

|

|

|

|

#43 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

If the hammer wasn't going all the way back, it would follow the bolt forward. If so, you would be able to see the hammer behind the bolt, thought the operating handle slot in the receiver. Also, it would probably dent the primer on the cartridge, but not enough to fire it.

You may have something fouling the trigger spring. It is under the trigger at it's front. If it was to foul, it may not let the trigger be pulled back far enough to release the sear. Another place could be some debris in the safety, which would foul the trigger being pulled far enough back too. The gun looked pretty clean to me, but something could get into it. |

|

|

|

|

#44 |

|

Senior Member

Join Date: January 4, 2015

Location: Perryville MO

Posts: 426

|

There was no dent on the primer. I had the whole trigger assy apart so it is clean other than the slight chance of something falling in there. I will have to try it again. I was just agrivated about the scope deal also. lol

|

|

|

|

|

#45 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Since you had the trigger assembly apart, then you can see how it works. It may be possible that the hammer loses enough force to indent a primer, if the hammer follows the bolt, but you'll have to fire it until it does it again, to catch that, by looking through the cocking handle slot at the end of the bolt. If it does do this, it sounds like it could be a gas problem, etc. In other words, there's not enough pressure to force the piston back hard enough to fully push back the bolt. That could be a leaky piston seal, or the gas hole in the barrel may be dirty.

Mounting scopes has made many a man curse their gun |

|

|

|

|

#46 | |

|

Senior Member

Join Date: November 19, 2002

Location: Mississippi

Posts: 963

|

Dixie, I think we got off into two different areas, I am still think’en ,

Quote:

This would accomplish the squeeze 98 220 was doing, would it not??

Last edited by TATER; January 20, 2015 at 05:26 PM. |

|

|

|

|

|

#47 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

It could be from that, but it also sounds like it could be the action bars binding, if not the gas system. I always check the gas system first, before I start looking for binding.

If the receiver to recoil block was a little loose, I would think the bars would have slack in them. That's why I believe he was having problems out of that trigger lock. The cam on the one bar was not pushing the lock all the way down, due to the slack or wear. I think that was why Winchester quit using the lock in later rifles. |

|

|

|

|

#48 |

|

Senior Member

Join Date: January 4, 2015

Location: Perryville MO

Posts: 426

|

I can't see how the washer would help. I have assembled the rifle out of the stock and the block is very tight against the trigger housing. To me its just a bad design.

I looked at the rifle last night the trigger "cocks" its self long before the bolt is fully back. Too short to pic up the next round from the mag. So It can't be "short stroking". I will need to get some more ammo and try again. |

|

|

|

|

#49 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Being that the case, if it does it again, before pulling back the bolt handle to eject the round, look through the slot in the receiver at the back of the bolt, and see if the hammer followed the bolt. If it did not, then you'll see the end of the firing pin, but if it did, its hard to miss the hammer.

For the hammer to follow the bolt, the rear disconnector hook would have to not catch the hammer after firing. Check to make sure the hook spring is good, and that it works freely. Also, check the teeth on the hook, and the notch in the top of the hammer that the hook catches, for being rounded over, etc. It's job is to catch the hammer, with the trigger pulled, and not allow the hammer to follow the bolt. The front hook is the sear, which is used to fire the gun. When the gun fires, and the bolt goes back, the hammer is mashed down, and the rear disconnector hook supposed to catch the hammer, at the rear. When you let off on the trigger, the sear hook at the front, catches the hammer, as the disconnector hook releases it. Then, it is cocked, ready to be fired again. |

|

|

|

|

#50 |

|

Senior Member

Join Date: January 4, 2015

Location: Perryville MO

Posts: 426

|

Update

Took rifle out yesterday to sight in scope. Put in two rounds pulled trigger both rounds shot off. Tried again same result. I have not done anything since last time out other than put scope in different mounts. Did not even remove stock. Trigger works fine if dry fire and work bolt manually.

It is time to throw in the towel. I guess I will need to find a gunsmith that can fix this rifle. |

|

|

|

|

|