|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: January 7, 2012

Location: Auburn, AL.

Posts: 2,332

|

Sunday, with the Ranch Dog

Today, I got a Ranch Dog design from NOE to try out. It is the SC 311-165-RF in HP.

I do not know what the SC stands for..... They have a "TL 311-165-RF" also, that is tumble lube. I guess the "SC" stands for "traditional lube".  It looks pretty good on their website.  We shall see if I can make some of them. Here is the mold...... We shall see if I can make some of them. Here is the mold......

__________________

. . . Have a Colt and a smile.

Last edited by Beagle333; October 20, 2013 at 07:03 PM. |

|

|

|

|

#2 |

|

Senior Member

Join Date: January 7, 2012

Location: Auburn, AL.

Posts: 2,332

|

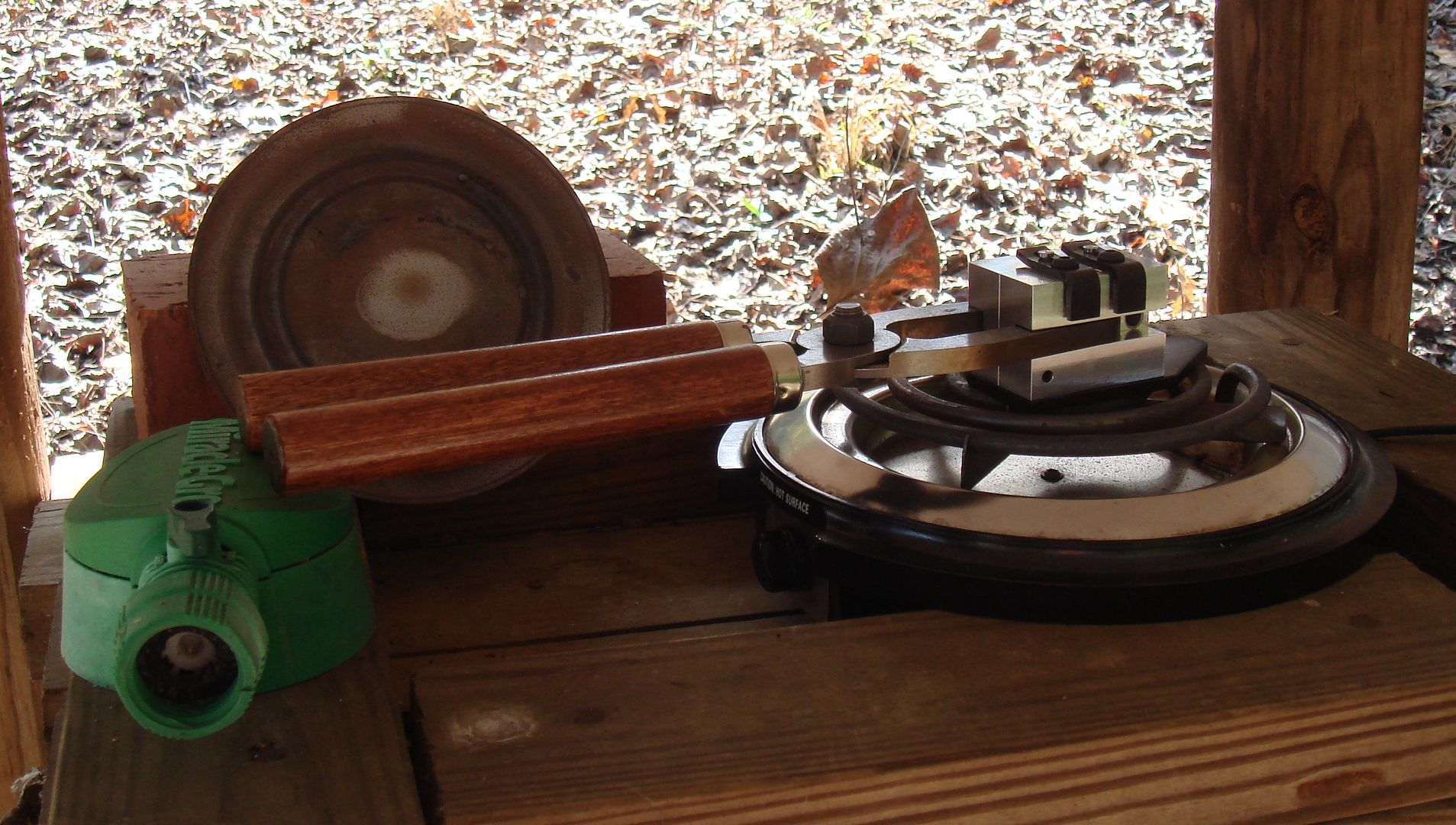

And here is a shot of the high-tech casting area.

And the mold prep station (as it is known.)

__________________

. . . Have a Colt and a smile.

|

|

|

|

|

#3 |

|

Senior Member

Join Date: January 7, 2012

Location: Auburn, AL.

Posts: 2,332

|

Here's the results. I like em.

I made enough for quite a while too. I was so amazed at how well this mold cast on the first time out. I usually have to use one for 2 or 3 castings before it works really smoothly. (Mike says I never show the rest of 'em.)

__________________

. . . Have a Colt and a smile.

Last edited by Beagle333; October 20, 2013 at 07:06 PM. |

|

|

|

|

#4 |

|

Senior Member

Join Date: April 8, 2000

Posts: 2,101

|

Hey those are PRETTY!!

Now get some slathered down with lube and show us how well they group. If they shoot as good as they look I might have to look into getting one myself.

__________________

LAter, Mike / TX |

|

|

|

|

#5 |

|

Member

Join Date: March 8, 2013

Posts: 22

|

As usual, some great pics of some really nice-lookin CBs there Beagle.

Would've really liked to get in on that run but the budget wouldn't let me play.  Looks like those run about .06" shorter than the (older? / 'standard'?) NOE 311-165"G" mould I've got, which would probably eliminate the very stiff lever-closing I run into when chambering those rounds. Looks like those run about .06" shorter than the (older? / 'standard'?) NOE 311-165"G" mould I've got, which would probably eliminate the very stiff lever-closing I run into when chambering those rounds.Those pics really make me want to send mine off to have a cavity or two HP'd now though, thanks for that!

|

|

|

|

|

#6 |

|

Senior Member

Join Date: January 7, 2012

Location: Auburn, AL.

Posts: 2,332

|

And.... to point out something that might be misleading.... in one of the pics

, I'm warming the mold on an open-coil hotplate... but note I have a piece of metal in the background that I was using over the coils when the mold blocks were on the hotplate (an old circular saw blade works great), and in this pic, I had it sprue-plate down to warm the top.... , I'm warming the mold on an open-coil hotplate... but note I have a piece of metal in the background that I was using over the coils when the mold blocks were on the hotplate (an old circular saw blade works great), and in this pic, I had it sprue-plate down to warm the top....Don't put your mold blocks directly on an open-coil type hotplate. It has the potential to warp the blocks. (it is too late to edit that frame, so I'm writing it here.)

__________________

. . . Have a Colt and a smile.

|

|

|

|

|

|