|

|

|

#26 | |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Quote:

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

|

#27 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Gunplummer,

I am not quite sure what steel was used on receivers back then, but when you calculate the longitudinal force that the cartridge applies to the bolt, it does not take much to hold it to be honest, and as I mentioned earlier, a lot of as-annealed steels will hold it without a drop of hardening. They may have used something like 1040 or 1045, which have a decent yield strength, around 60,000 psi for 1040, and around 45,000 psi for 1045. The 41xx series, I think, came about around or maybe just before WWII. I think they use that as a sales pitch any more. |

|

|

|

|

#28 |

|

Member In Memoriam

Join Date: March 17, 1999

Posts: 24,383

|

Everyone thinks of rifle pressures in the 45,000-65,000 psi range. But that is pounds per square inch inside the case. The actual thrust on the bolt (or on the bullet) is a lot less because the areas under pressure are only a fraction of a square inch. The thrust on the bolt face is that on the inside rear of the cartridge case, which is around .1 square inch. So for a 50,000 psi cartridge, the thrust on the bolt is about 5000 pounds. A .30 bullet has a base of about .07 square inch, so the pressure on it is about 3500 pounds.

Those are not insignificant pressures, but far from the usual "50k psi pushing on the bolt" we usually hear. So where does all that 50k psi go? Most of it is wasted trying to push out the chamber walls. Jim |

|

|

|

|

#29 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Jim, you hit the nail square on the head. From what I have found, especially on large frame guns, is that receivers hardly ever have any heat treatment that I can find. One can easily see this when drilling and tapping one for rings, etc. The only places that they might spot harden would be the major wear areas, where a bolt, etc., does a lot of sliding, but I doubt they do that much, especially if they use the right steel. If they didn't wear out, they wouldn't be able to sell a new one. When you get into pumps and semi-autos, you really start seeing wear.

Now, like you said, on barrels, there is a very big outward pressure difference. I was shown how they developed those, and then tested them. They calculate the barrel, especially around the chamber for minimum outside diameter at proof pressure, and they make a test barrel, in the form of a bull barrel, so they can drill into the bore about every two to three inches, and tap the holes. They install pressure transducers into these holes, all the way down to within maybe two inches of the muzzle, and connect them to a recording x-y graph, and fire a round in the barrel fixed in a jig. They record the peak pressures all the way down the bore, and use the dropping pressures to calculate or check the needed taper. |

|

|

|

|

#30 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

Thank you Cowtowner for starting this thread.

Thank you Slamfire for the pics. Thank you William for reminding me My 49 year Mauser addiction has been a money pit. Thank you tobnpr for coming through with the stock and bolt handle. Thank you Gunplumber for the kind words. Thank you Bart for 22 years of great posts. Thank you Waffenfabrik for sending me the pdf of your FFL. I ordered a quantity of these actions today. They will probably arrive while I am gone hunting ~ a week. But maybe I will get to see them before hunting.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#31 |

|

Senior Member

Join Date: October 17, 2007

Location: Cowtown of course!

Posts: 1,747

|

For my part Clark, you are most welcome.

__________________

NRA Chief Range Safety Officer, Home Firearms Safety, Pistol and Rifle Instructor “Today, we need a nation of Minutemen, citizens who are not only prepared to take arms, but citizens who regard the preservation of freedom as the basic purpose of their daily life......” President John F. Kennedy |

|

|

|

|

#32 |

|

Senior Member

Join Date: October 25, 2001

Location: Alabama

Posts: 18,535

|

I looked and looked but could not find another integral scope dovetail like the one shown here.

You might contact Conetrol, they make a number of Daptar bases for different integral bases and they never throw away a blueprint. Of course you could just screw a Weaver down on top of them since they considerately provide the screw holes, but that would not be as classy. |

|

|

|

|

#33 | ||

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

Quote:

Quote:

http://www.eaw.de/assets/files/09_SM_Ring30.pdf And http://www.rivolier.com/mont-eaw-o-3...in-a-2000.html  and http://www.acp-waffen.de/downloads/p...talog-2004.pdf

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

||

|

|

|

|

#34 |

|

Senior Member

Join Date: October 17, 2007

Location: Cowtown of course!

Posts: 1,747

|

Awesome work, Clark. Boy do they make some pretty rings/mounts.

I don't suppose there are any U.S. based sources for the mounts?

__________________

NRA Chief Range Safety Officer, Home Firearms Safety, Pistol and Rifle Instructor “Today, we need a nation of Minutemen, citizens who are not only prepared to take arms, but citizens who regard the preservation of freedom as the basic purpose of their daily life......” President John F. Kennedy |

|

|

|

|

#35 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I have never worked on a Mauser that did not have a heat treated receiver. P.O. Ackley had Mauser receivers checked by a lab and they are in the 1018-1020 range. Most military actions are case hardened. The exceptions I have seen are the Arisaka and MAS 36. The Arisaka is proven to be 4140 or very close and is heat treated accordingly. I never heat treated an MAS 36, but it machines the same as an Arisaka. I have a section of a '99 Savage receiver(Somewhere) and have been meaning to heat it up to test it. I suspect it also is in the 4140 range. The difference between trueing up a receiver that is case hardened and one that is a constant hardness through the section is understandable. You can true up the 4140 or tool steel receiver and nothing will change in regards to strength unless you really start removing metal. The cased receivers are weakened when you remove only a few thousandths of material. I have seen the result of underloading and overloading and the "Setback" caused by it. I have heard about some people sending a receiver out to be heat treated after truing up. Sounds like a waste of time. The receiver will warp again.

|

|

|

|

|

#36 |

|

Senior Member

Join Date: October 17, 2007

Location: Cowtown of course!

Posts: 1,747

|

My Google-Fu must be getting weak. I'm unable to find those European made mounts here (U.S.) anywhere. Does anyone know of a source?

__________________

NRA Chief Range Safety Officer, Home Firearms Safety, Pistol and Rifle Instructor “Today, we need a nation of Minutemen, citizens who are not only prepared to take arms, but citizens who regard the preservation of freedom as the basic purpose of their daily life......” President John F. Kennedy |

|

|

|

|

#37 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Gunplummer,

That's the whole thing about heat treating, in that is warps the part. Generally, the piece is made slightly over-size, hardened, and then ground, or sometimes machined, but grinding is the best. I've tried turning hardened pump parts, and it isn't any fun. Case Hardening can warp one, too, and you have to brace the piece to try to hold its dimensions when doing it. However, they have to be very close to final dimensions, as if you remove the surface, its soft again. Generally, a little stoning is all that can be done, to smooth a working surface. Spot hardening, that they do now by using RF coils and immediately hitting the spot with oil or water, is about the best they have, and is what they use on gear and sprocket teeth, along with other parts. Of course, the old rifles would not have had this done. Most all modern guns, even bolt actions I have noticed, when drilling and tapping, are easily done, and those are the front holes at the bolt lugs and barrel threads. However, they have access to a lot better steel now, that wasn't available when some of the old bolt actions were in military service. I am like you on case hardening and not thru-hardening on them, or not hardening at all. What I've read about the 4xxx steels, is that they first appeared around the end of WWI, and it was invented for thin walled structural tubing, in Germany, for use in aircraft, and it later became popular here for landing gear, etc, then engines. That was more, though, at WWII, and after our bolt actions were falling from military favor. When you calculate the locking pressures, like Jim and I mentioned, and multiply that to 1.5 to 2 times, it is still way under the yield of modern steels. Here, they can make the parts the same thickness as the old ones, but they are strong enough, that no case hardening, or thru-hardening is necessary, and that saves some big money. If you order the steel with a little lead, or resulphurized, it machines easily. |

|

|

|

|

#38 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

I picked up the receivers at the FFL.

The holes seem to be on 0.86" centers in the front and 0.504" in the rear, or close to those old Weaver standards for centers. They are flat. The closest flat bases would be #29 Weaver in the rear .504" center 0.292" thick, and #61 or #161 in the front .860" centers .361" thick. If it is 4" between bases a difference of .069" in thickness would be inverse tan .069/4" = .98 degrees = 60 moa in the wrong direction [pointing the barrel low]. I can't get 6-40 nor 6-48 to fit. It takes a .121" pin gauge as minor diameter of the holes. It might be an M3.5x.5 or M3.5x.6 metric thread. Or maybe I need to try harder with the 6-48. I made a drawing of the dovetails. The look like 16mm in the front and 14mm in the rear.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#39 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Clark,

That screw size sounds like an M4 x 0.7, as 0.121" for a tap drill does not show up on my inch chart for a #6 screw, but it's close to a 3.3mm drill or a #31 drill 0.120". The tap drill for a #6 screw is a #33 at 0.113". The tap drill for a M4 x 0.7 is a #30 in the inch chart, or 0.1285". A #31 bit might work for a M4, but it would be a tight fit. |

|

|

|

|

#40 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

Whoops!

The Brownells stainless replacement pack 6-48 screw did not go in easily late last night, but the Weaver supplied Chrome moly screw 6-48 just went it  The point is, the scope base holes are standard American 6-48 threads. I am going hunting and will not work on these for a while.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#41 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

Been busy. I would check the angle on the dovetails. Europeans have a weird metric angle standard (Mauser sights, Russian extractors, ect.) It may be a standard American angle, but you never know.

|

|

|

|

|

#42 |

|

Senior Member

Join Date: August 1, 2010

Location: Tampa Bay

Posts: 4,556

|

Couldn't one mill off the dovetails, and then d&t the top of the action for whatever rings or mounts are desired?

__________________

Remington 700/Savage Rebarreling /Action Blueprinting 07 FFL /Mosin-Nagant Custom Shop/Bent Bolts Genuine Cerakote Applicator www.biggorillagunworks.com |

|

|

|

|

#43 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

tobnpr,

I'd say you could, easily, since that extra steel making the dovetails really does nothing for the receiver's strength. I don't know if it would hurt it's value though. To me, I would rather have it so standard mounts would work. |

|

|

|

|

#44 | |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

Quote:

The basic Morse taper was what made the old LC Smiths shoot well, they had an extra long choke bore created by standard Morse taper reamers. I have my old Elsie locked in my gun safe, ready to go at a moments notice. It's been one of the best guns I ever laid to my shoulder. Last edited by Dixie Gunsmithing; October 4, 2014 at 09:57 AM. |

|

|

|

|

|

#45 | |

|

Senior Member

Join Date: August 1, 2010

Location: Tampa Bay

Posts: 4,556

|

Clark, I know you're hunting and won't see this for a while, but...

I'm new to the machining game, so please forgive the ignorance...I'm self-teaching on a Sieg X2 and a mini-lathe for now. Quote:

Can't help but wonder, why even have them (the dovetails) in the first place? Do you think they add any stability to a mount, as opposed to just mounting a flat base on top of them?

__________________

Remington 700/Savage Rebarreling /Action Blueprinting 07 FFL /Mosin-Nagant Custom Shop/Bent Bolts Genuine Cerakote Applicator www.biggorillagunworks.com |

|

|

|

|

|

#46 |

|

Moderator Emeritus

Join Date: April 27, 2013

Location: Ohio

Posts: 1,923

|

I wont be able to do it until tomorrow, but I'll plug those numbers into my CAD program, and see what taper they really are. I'm hoping it's just a standard angle, however if not, you could have a cutter ground, though that would be pricey.

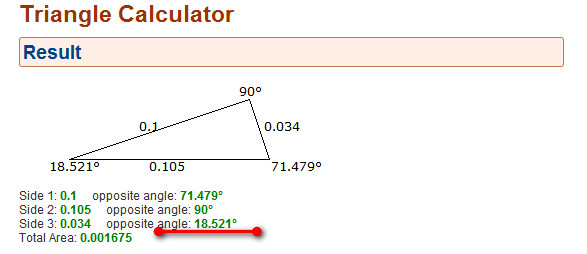

Edit: Using a calculator, the angle on a side came up to 18 1/2 degrees, or a 37 degree cutter. That is an oddball. I'll check it with CAD tomorrow, but it should be the same. I could have sworn those dovetails were tapered, too, so I must have looked at something else and thought that. After looking again, they were straight, so my bad   Cutter Ang by matneyw, on Flickr Last edited by Dixie Gunsmithing; October 5, 2014 at 08:35 PM. |

|

|

|

|

#47 |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

My current plan A is to use dovetails and 6-48 screws. I have been using dovetails as sight bases for several decades now, they used to be very common as scope bases back in the day when scopes were long and placed out on the barrel.

Bases generally had hole spacing’s of 0.860” and 0.562”. These don’t convert to nice round mm dimensions so I have no idea where this crazy convention started or why. The front holes on the square bridge are 0.860” apart, but the back holes are 0.500 from each other. At least that is my best guess for the back holes. Dovetails with half inch hole spacing are rare, I don't know a current source. This is a source for scope bases: Champion's Choice Single Step Bases http://www.champchoice.com/store/Mai...ions&item=A175 My standard Warne rimfire rings and B-Square rimfire rings will fit on these dovetails. The dovetails in the picture are 0.175 high, but until I have a barrel mounted, I won’t know what height of dovetail will allow the scope objective will clear the barrel. On my Anschutz rifles, I am using a 0.225” dovetail with my Redfield 3200 scopes. An Anschutz barrel has little to no taper. Since the rear holes are spaced 0.500” I can take a 0.860”dovetail and drill a hole up a half an inch from one hole and that should work. If I go this route, I will epoxy the dovetails to the receiver and attach with screws.   While this approach will work, will cost less than a $400.00 set of rings, I think a flat aluminum Picatinny rail, something I could drill properly spaced holes, would be a better way to go. I do see that flat picatinny rails are available, but these are pre drilled. http://www.rakuten.com/prod/picatinn...FSgS7AodxUYAOA The picture looks nice, but I have no idea if the rail is flat or contoured on the bottom nor how long it is. http://www.opticsplanet.com/evolutio...ope-mount.html I would prefer the Picatinny as I could use Weaver scope bases. I like Weavers, they lock inbetween the slots and the bases won’t move under recoil.

__________________

If I'm not shooting, I'm reloading. Last edited by Slamfire; October 14, 2014 at 10:44 AM. |

|

|

|

|

#48 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

If you have no access to machinery, Brownell's used to sell blank lengths of Weaver base material.

|

|

|

|

|

#49 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

I've had exactly one Mauser action treated, a Turk K.Kale. The steel was very soft and so gas carburizing seemed prudent to me.

Never felt the need with a commercial, German, or Czech receiver. Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#50 |

|

Senior Member

Join Date: October 17, 2007

Location: Cowtown of course!

Posts: 1,747

|

Perhaps something like this?

http://www.brownells.com/optics-moun...-prod1651.aspx Or perhaps something more like this? http://www.brownells.com/optics-moun...-prod9851.aspx

__________________

NRA Chief Range Safety Officer, Home Firearms Safety, Pistol and Rifle Instructor “Today, we need a nation of Minutemen, citizens who are not only prepared to take arms, but citizens who regard the preservation of freedom as the basic purpose of their daily life......” President John F. Kennedy |

|

|

|

| Thread Tools | Search this Thread |

|

|