|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Search | Today's Posts | Mark Forums Read |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

Mauser 98 bolt lugs case hardened or through hardened

I have a Persian mauser k98 circa 1935 in 8x57. The bolt had been changed when I bought it, plus I noticed a small setback on the recriver's lug recess. I took the barrel apart and lapped the lugs but it went more than what it should. Nearly 8 thou" .

The good thing is that it seems all that lapped material are gone from bolt lugs only and not from the recriver's. I say this because the headspace is increased the same amount as what it is removed from the back side of the bolt lugs.

Another good thing is that bolt lugs back surface still pass the file scratch test and are hard as what they were brfore lapping.

In short the whole process was like this:

the chamber was .012' longer than standard go guage, the first step.

Took the gun and barrel apart.

lapped the lugs by 0.008'

I had nearly 0.02" excess headspace now, both from the chamber being long and lapping process.

I cut about 0.01' from the chamber's end of the barrel on my lathe.

turned another 0.12 from the outer shank of the barrel but kept yhe chamner area intact (only to make the barrel enable to turn 1/6 turn more into the recriver) to compensate for breech to barrel distance that was increased

Cut 0.02' from recriver's face snd trued the C ring.

assembled the whole thing

Everything seems ok now, the chamber passed the go nogo guage test, the distance between bolt face protrusion and barrel face is 0.006 inch, and barrel is torqued and snug, But I am still worried about the hardness of bolt lugs.

do you have any idea on this , I know that the bolt and receiver are case hardened on mausers , but I got the idea that the lugs are probably hardened all through.

Thanks

Mike

|

|

|

|

|

#2 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

They are not hardened through, or should not be. You are dealing with production guns from the 30's. The heat treating results will vary some what. Your initial test with the "GO" gage may have been off. I don't know if I ever checked a Mauser with SAAMI spec gages that passed. The Europeans had different specs for their guns and it will sometimes not crossover to ours correctly.

|

|

|

|

|

#3 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

thanks for your reply, do you think this gun is safe to shoot?

|

|

|

|

|

#4 |

|

Staff in Memoriam

Join Date: November 13, 1998

Location: Terlingua, TX; Thomasville, GA

Posts: 24,798

|

Safety? The "tire test" has been around longer than I have.

Get an old tire from the tire shop. Set the butt into it, forearm laid across the opposite side and tied to the tire. Load it. Use a ten- or twenty-foot length of cord to pull the trigger. Or fishing line. Whatever. Rinse and repeat if you want. |

|

|

|

|

#5 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

I don't know about your process. Are you saying you lapped the bolt lugs outside (Separate) of the receiver? If you noticed setback in the receiver ring, why are you worried about the lugs on the bolt? Either way, if one or the other is too soft now it will show. Using American made factory rounds to start would be a good idea. I would keep an eye on the fired brass. If the setback continues, the brass will slowly be getting longer. Someone brought me a .257 R that did that. By the time he fired the 6th round it was noticable on the brass OAL with a dial calipers.

|

|

|

|

|

#6 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

Thanks for your help gentlemen, I lapped the lugs while bolt inside the receiver, but the setback area is still there though it had become smaller. I can only feel a small click sound when I open the bolt and the bolt handle is 45 degrees up, it is at he very beginning of the so called ramp if I am not mistaken.

I will try shooting it tied yo a tyre, here id two pictures before and after lapping |

|

|

|

|

#7 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

As a reminder the setback had happened only in upper lug recess of the receiver, in fact it is where the split lug seats. Where the ejector slide inside. The upper bolt lug has most effect on the recess , people had the same problem in this area, I think lapping a mauser bolt lugs is a bad idea, the manufacturer has made those lugs so the there is no contact in this area, people lap the lugs to make more surface contact area and it will ruin the receiver

God bless |

|

|

|

|

#8 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

Uneven contact of locking lugs is common in military rifles, actually pretty much the norm. That is why lapping the lugs came about. Soft steel holds up better than most people think, although it will compress quickly when firing a few rounds. The strong receiver debate is in cases of catastrophic failure, which would be heavy overload, wrong ammo, blocked barrel, and so on. From what I have seen, the third lug on a Mauser won't stop the bolt dead, but it will slow it down before it can go too far.

|

|

|

|

|

#9 | |

|

Senior Member

Join Date: October 28, 2006

Location: South Central Michigan...near

Posts: 6,501

|

[Re: Bolt lugs]

Quote:

Can someone shed some light on this? |

|

|

|

|

|

#10 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

Thank you gunplummer and all ,

dahrmit, At least it is what most people say on the net, I read in more than a few places that the metal is something in the range of 1020 or 1030 or 1330 low carbon steel. As I said in my first post the bolt lugs of my gun are 0.008 inch less on my dial and digital calipers after lapping but the lugs are still seem fine i.e they pass the file scratch test, I feel they are hard ad they were before lapping, I heard that if they pass the file test they're fine. In the other hand I read some where that only bolt lugs and recriver's lugs are hardened through. |

|

|

|

|

#11 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

Gunplummer said:

From what I have seen, the third lug on a Mauser won't stop the bolt dead, but it will slow it down before it can go too far. ############## Gunplummer, do you mean that the third lug can not keep the shooter from being unsafe in case of a catastrophic accident, can you please elaborate on this. God bless |

|

|

|

|

#12 |

|

Senior Member

Join Date: March 11, 2010

Location: South East Pa.

Posts: 3,364

|

If it is a massive screwup, enough to split the receiver ring, then the bolt will probably come back. I am not saying leave the rifle, but it will back up. This was proven in tests by P.O. Ackley. Most rifles will handle overloads, blocked barrels, blown primers. Some of the worst cases are wrong ammo. That is asking a lot from a rifle and the results can be hit or miss as far as end result.

**Mausers are low carbon steel. You can grind the thin case off and re-heat treat until you pass out and they will not reharden without adding carbon. I am not really a student of Mausers, but allegedly there was one model made from tool steel. This was the Chech or the the Polish model. According to rumor, there was a royalties fight between Carcano and a Mauser producer over a steel recipe. It may have been a special model. Someone else on here may know. |

|

|

|

|

#13 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

Thank you, your post is very interesting.

John Lee of Lee precision once told me that they heat treat their dies with the same method( carbon case hardening). God bless |

|

|

|

|

#14 |

|

Senior Member

Join Date: August 23, 2008

Location: East shore of Lake Michigan.

Posts: 714

|

Side note/question about the actual bullet diameter...are you sure

about the proper bullet diameter of your 8x57 ?, as in 8x57S (.323) vs 8x57J (.318).

__________________

Sent from my Tandy 1000 |

|

|

|

|

#15 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

Yes Sir! Sure it is .323 version I slugged the bore. Besides my impression is that only the early versions were.318

|

|

|

|

|

#16 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

Lug setback on an old Mauser means that headspace will continue to grow with every trigger pull.

Lapping the lugs also laps the lug recesses, and you've worn away the case hardening on both the bolt and receiver, which will make lug recess deformation only go that much faster. You can handload down to low pressure rounds which will extend the life of the reciever, but the only real solution is to have the action and bolt gas carbeurized to restore the case hardening. Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#17 |

|

Member In Memoriam

Join Date: March 17, 1999

Posts: 24,383

|

I don't know about a catastrophic failure of both front lugs, but the safety lug on a Mauser 98 definitely will hold for normal shooting of service ammo.

I once was asked to check out a late war Mauser (Czech, IIRC) and found that the front lugs did not bear at all. There was no contact and no evidence that there ever had been. The safety lug was the only thing keeping the bolt locked. Yet the rifle passed the gauge tests. Further, it had obviously been fired extensively, though the owner, the vet who brought it back, said he had not fired it very much. The safety lug and seat showed no setback and, as I said, the headspace was good; cases showed no sign of stretching. Jim |

|

|

|

|

#18 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

James K is correct, it is entirely possible to get good headspace with only the safety lug engaged. When you have a pile of rifles and a pile of bolts, it is easier to just try swapping the bolts until you find on that has correct headspace than any other method for getting the rifles "re-arsenaled" and ready for sale.

Properly set up, the safety lug has a few thousandths of clearance and no contact with the lug recess. But, since the OP is experiencing lug setback, the safety lug still has clearance to allow the setback to happen. Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#19 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

That's very interesting,

but for this mauser the third lug is not hardened I can scratch it by a small file easily. God bless |

|

|

|

|

#20 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

uneven case hardening is a sign they were reusing the pack material on areas that weren't critical, pretty common to save money. Only the receiver ring and front lugs were "critical" to the M98 design for case hardening.

Jimro

__________________

Machine guns are awesome until you have to carry one. Last edited by Jimro; July 13, 2015 at 01:18 AM. |

|

|

|

|

#21 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

Anyone knows why it is only half of the lugs surface that are engaged with the receiver s recess, it is by design of course.

Bless |

|

|

|

|

#22 |

|

Senior Member

Join Date: May 4, 2001

Posts: 7,478

|

To learn the fine details of Mauser rifles, I recommend buying the Jerry Kuhnhausen Shop Manual.

These manuals were written as training aids for new gunsmiths, and get way down deep into the details you can't usually find elsewhere. The manual specifically addresses in detail the locking lugs, case hardening, and includes pictures of lugs with the case hardening lapped away If you're working with a Mauser this is money WELL spent. It has information that's usually not available elsewhere. http://www.brownells.com/gunsmith-to...prod25715.aspx |

|

|

|

|

#23 |

|

Staff

Join Date: April 13, 2000

Location: Northern Virginia

Posts: 41,380

|

"The "tire test" has been around longer than I have."

Except when you were a kit, it was "tie the gun to a stone wheel..."

__________________

"The gift which I am sending you is called a dog, and is in fact the most precious and valuable possession of mankind" -Theodorus Gaza Baby Jesus cries when the fat redneck doesn't have military-grade firepower. |

|

|

|

|

#24 |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

The case, as applied in case hardening, is primarily a wear hardness surface. Case is still applied for modern alloy steels, such as nitriding, salt bath, etc for wear hardness. The habit of grinding off case layer in the shooting community to make parts "fit better" is a total folly and is an example of how foolish ideas become doctrinal behavior within a society. Once that case is removed you are down to a soft metal surface that will gall, wear, etc.

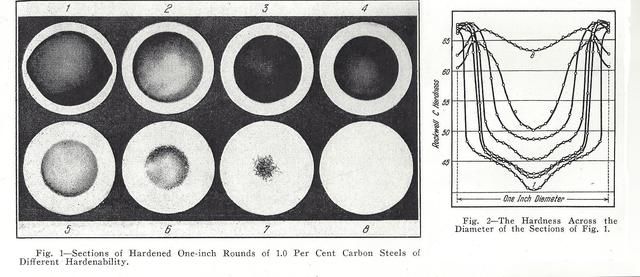

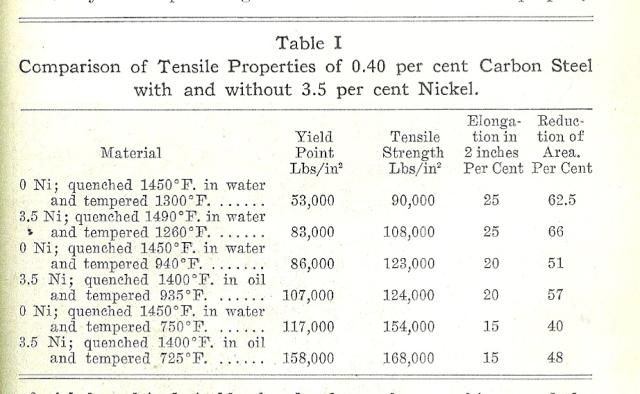

Case hardening is not meant to effect the heat treatment nor the "through hardness" of the steel. Carburizing requires hours of exposure to a carbon rich environment. Pre WWII it was common to pack parts in boxes that had bones, leather, etc, and heat the box and parts for hours and hours to develop a case surface. Around that time other more precise methods were developed, but all involve exposing steel to a carbon rich atmosphere and letting the carbon diffuse into the surface making the surface carbon rich and hard. From all the data I have read, pre WW2 Mausers were made of plain carbon steels just like all of the other military firearms of the era. Plain carbon steels are inferior in all properties to alloy steels but they were state of the art in 1890, manufacturers are slow to change and legacy systems tended to use the same steels that they always had. The steels used in your Mauser would have been heat treated to withstand a 45,000 psia 8mm load. You could heat treat the material to a harder material, thus raising ultimate and yeild properties, but the material would be less tough. Toughness is a much more desired property in an environment where the load is basically a shock or impact load. The material would be heat treated just to the level needed to support the load and not more, as toughness would decrease. Plain carbon steels were commonly used on parts prior to WW2, but metullurgy in the 1920's and 30's advanced so quickly that by the time you get to WW2 it is obvious that plain carbon steels are only a good choice if cost is the number one criteria and the loads are not high or safety critical. The steels used in pre WW2 rifles are now used as rebar, rail road ties, applications where the low load justifies the low cost. The American metallurgist Edgar Bain, http://www.nasonline.org/publication...in-edgar-c.pdf in 1932 published conclusive experiments on carbons steels. Bain heat treated identical plain carbon steel coupons under identical conditions and examined the coupons afterwards for hardness depth. The black chemical etching, which I assume is the unhardened steel, show that plain carbon steels have erratic hardening depths, given that all else is equal. These steels were called in WW2 era text books as “shallow hardening”. This was meant not as praise but as a pejorative. As is shown on the right of the diagram, the hardness of these coupons varies by depth. This is not good as consistent hardening provides consistent material properties. It is undesirable to create parts some of which will be hard through and through but others soft below the surface even though the heating processes are the same for all parts. But use plain carbon steels, and you will create such inconsistent parts, just by the nature of the material.  Therefore, you would expect even properly forged, properly heat treated plain carbon steel parts to vary considerable in hardness depth, which then affects the properties of the end part. Yield is an extremely important material property, for above yield, the part deforms. Once a steel part yields it is no longer safe to use. What happens after yield is unpredictable, often it takes less load to cause more deformation, ultimate load is the load it takes to break the part. In this early 1920’s chart, for the same essential heat treatment, the nickel alloy steel always has a higher yield, a significantly higher yield in all cases, than the plain carbon steel. Nickel steel versus plain carbon steel  What is not shown in these charts is a material property called toughness. For a device, such as a receiver, which is going to be subjected to impact loading, toughness is a highly desirable property. Toughness is directly related to fatigue lifetime, which is the number of loading cycles to failure. Assuming the yield is sufficient for the load, the tougher material will have a longer service life. Alloy steels have a greater toughness than plain carbon steels. Alloy steels take more energy to shear, Charpy impact tests are a direct predictor of a steel’s fatigue lifetime. It is a revelation to see just how shear energy decreases with temperature, and at low temperature, alloy steels take several times the energy to shear as do plain carbon steels. Therefore, old plain carbon receivers are a very significant unknown quantity. We know that the material varies considerably in properties after heat treatment, and that the service life of the part will always be less to one made out of a good alloy steel. Just how many service lives have these old receivers been though? How many more load cycles will they take before failure? How will they react in an overpressure situation? The fact that you have receiver set back in your rifle is of a great concern to me. The material has yielded indicating that an excessive load or loads have been fired in that rifle. Once a material yields, it takes less load to make it yield again (typically). It is your choice, but if you shoot the thing you better check the headspace to see if it is growing, and regardless, understand you are behind something that is less strong than it was when it was new. If that receiver had gone through a rebuild program, it would have been discarded if lug set back had been found.

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

#25 |

|

Member

Join Date: January 30, 2014

Posts: 26

|

Thank you for your invaluable help. interesting information.

I found many old mauser receivers suffer from the same setback in upper recess area, I think ( or I would rather hope in fact! ) that it is mostly a design failure rather than material failure. The reason for this kind of setback is that the split lug on bolt had a very sharp edge that instantly attack the recess upon firing. What do think about it, of course it is only an idea nothing more and I am not an expert by any means in this field. Again many thanks for interesting write up and the time you put on this God bless |

|

|

|

| Tags |

| lapping bolt lugs , mauser bolt lugs hardness , mauser98 |

| Thread Tools | Search this Thread |

|

|