|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

So Many Seating Depth Questions On Bottle Neck Cases...

I keep seeing a TON of seating depth questions...

This *SHOULD* make some basics clear. ----- Since there are SO MANY ammo manufacturers, And since so many of those manufactures are out of the country and don't care about NATO or SAAMI specifications, You have NO IDEA what anyone will try and run through any given firearm... The firearms manufacturers have to COMPENSATE & COMPROMISE when it comes to chambers. They have no idea if the owner is going to run short 35 grain bullets through is new .223/5.56 rifle, Or he's going to buy some of those LONG, HEAVY 75 Grain bullets on the market, They don't know *IF*... It's going to be a 5.56x45mm NATO chambering, A .223 Rem chambering, Or something from the 'Surplus' market of unknown construction materials, Some 'Surplus' military ammo from unknown countries, The 'Dump' ammo that both China & Russia produce to make hard currency, which NEVER comes up to any US specification... And 99.9% of firearms owners won't know the difference, They only bought the firearm to ward off 'Zombies' or some 'Mystery Threat' that's being touted by the far right wing types... "End Of The American Way Of Life"/"End Of The World" (This makes them both scared and stupid, a dangerous combination where firearms are concerned! They have no idea if their ammo will function, or if it's even safe to run through the firearm!) SO! With that in mind, The manufacturers MUST make these stupid long freebore chambers... ----- With that in mind, Some of us are going back to the 'Short Chamber' and final finishing the chamber on new barrels... SAAMI specifications of 2.260" for .223 Remington, NATO specifications of 2.550" for 5.56x45mm The common 'Short' chamber is now being called 'Wylde' After a successful service rifle shooter named Bill Wylde. The 'Wylde' chamber is 2.445", No stupid long freebore to accommodate stupid long or mis-shapen bullets with low BC. Since this is a RELOADING forum, everyone here knows how to check COAL/Cartridge length, But not everyone knows how to determine freebore... This will let you know how to check your chamber for Free Bore and determine if you need to open it up, or close it up, Either by re-cutting the chamber, or changing bullets/seating depth for consistency/accuracy. ----- FIRST! You *SHOULD* know how your chamber is cut. Some people CAST their chambers, There is a fairly easy way to know how your chamber is set up... Simply POLISH some bullets/cases WITHOUT POWDER OR PRIMER. CRIMP the bullet into the case so it can't slip back and screw up your readings. Make your rounds about 0.010" longer each time. Then when you zero in on the chamber, you can do 0.002" at a time until you identify EXACTLY where the throat is relative to COAL/Shoulder of the chamber. ---- Drop the rounds in your chamber and ROTATE them. Since rimless/non belted bottle neck cases usually SEAT on the front shoulder/taper of the case, The distance from the shoulder of the case to rifling THROAT is your set point. Once you know where that throat is with any given BULLET, (bullets are longer/shorter by manufacturer/type) Do this with your 'Favorite' bullet and you will know EXACTLY the COAL where your bullet hits the throat... Then you can back the bullet into the case for what ever free bore you want, (Free flying space between case and rifling throat, or funnel that compresses bullet into rifling) ----- AR 15 and other 'Hooded' chamber shooters, Simply slip a piece of rubber tubing over the bottom of the case. This will allow you to turn the bullet/dummy in the chamber to produce that rub mark on the bullet where it meets the rifling throat. ---- Some guys like virtually NO freebore, They want the bullet knocking on the throat/rifling when it's touched off. Some guys like to give the bullet a little 'Head Start' in velocity before it hits the throat/rifling... ------- Another way is to do the same thing with a 'Dummy', NO CRIMP, But very carefully scribe a line in the bullet right at the top of the case, where case meets bullet. When you start pushing that scribe line into the case, you have found the chamber throat. Not as accurate, but it will get you there. ----- Some guys find they need bullets with canalure moved forward or backwards (different nose design/manufacturer), Some guys find they are seating WAY too short, Some find they are butting the bullet right up against the rifling throat... Once you find a bullet that loads well in the magazine, Has a reasonable amount of freebore, You will usually find accuracy/consistency goes up. This is the 'Long Way Around The Barn', but it doesn't require any specialty tools to do, Just your press, favorite bullets/cases, and a caliper which if you are asking about COAL, then you already have... Most of you with dual chambers, (5,56 NATO/.223 Rem) chambers will find you have WAY TOO MUCH freebore. You can't possibly make the bullet long enough to close up that freebore and still get the rounds to feed from the magazine. It will let you know what you CAN get away with for length, And it will let you know EXACTLY what bullet profile will do best to close that freebore gap up. Some guys will find they are TOO CLOSE to the rifling throat... This means the cartridge isn't settling on the shoulder of the case like it's supposed to, But the bullet is hitting the THROAT of the chamber. Not enough to keep the rifle from firing, But enough to screw up your accuracy. A bullet setting right on the throat will be INCONSISTENT. Freebore allows the pressure to build to EXACTLY the correct amount to get that bullet formed to the throat/rifling, While trying to force the bullet into the rifling with primer pressure will produce inconsistent results. (Yes, the primer WILL move the bullet into the rifling, before the powder starts to burn) 'Playing' with freebore will produce some suprising accuracy/consistency changes! That's why there are so many different approaches to freebore, throat shape, throat angles, ect. Put 10 guys in a room and ask what the 'Correct' Freebore & Throat design *SHOULD* be, and you will get 25 opinions, So I'm not going there. I'm just trying to give you a way to check YOUR freebore with EXACTLY your favorite bullet/case... ----- To CORRECT the barrel, Find a gunsmith with a lathe. Cut the barrel for some extra threads, the depth you need to move the barrel/chamber backwards to get what you want. Thread the barrel, Then use a chamber reamer/throat reamer to get EXACTLY what you want. You *MAY* have to cut some off the back of the barrel to maintain headspace to the bolt... This is simple while it's in the lathe since the amount you cut off is EXACTLY the same as the amount of threads you added. MAKE THE BARREL CHAMBER FIT YOUR FAVORITE BRASS/LOADED ROUNDS! Ordering custom dies to fit your chamber, Annealing brass to resize in those custom dies is a pain in the butt! It's better if the rifle is modified to accept your rounds than to modify the rounds to fit your chamber. I would also argue against any chamber that wouldn't fit 'Factory' rounds... Once the chamber/freebore/throat fit your rounds, you will gain consistency and accuracy. Last edited by JeepHammer; March 31, 2015 at 11:25 AM. |

|

|

|

|

#2 | |||

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Quote:

Best example was when over a hundred Lapua 185 FMJRB match bullets were so seated in .308 Win cases and the all shot under 2 inches at 600 yards. Several 10-shot groups ranged from .7 inch to 1.5 inch and a 40-shot test group was 1.92". Proof to most folks that seating bullets back into the case is a big advantage. And that extremely consistant results happen. Quote:

Quote:

Last edited by Bart B.; March 31, 2015 at 12:36 PM. |

|||

|

|

|

|

#3 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

For Example,

.223 resized cases, 55 Grain V-Max ballistic tipped bullets, LONG taper on the bullet, so the bullet contacts the bore further back towards the case... From case SHOULDER to the throat/rifling, ZERO FREEBORE Check Chambers, 5.56mm NATO, 2.425" (Military Barrel), Wylde chambered AR barrel, 2.325" Middle of the cannelure crimp, 2.250" Freebore with the bullet seated to the middle of the cannelure, 5.56mm Nato, 0.175" of free bore when crimped at the cannelure, almost 2/10s of an inch! .223 Wylde, 0.075" of freebore with the when crimped at the cannelure, considerably closing up freebore. ----- For example, With Hornady 55 Grain FMJ, ZERO FREEBORE, the bullet doesn't have the long taper the V-Max rounds do... Using a crimp to the center of the cannelure as your 'Standard'... NATO 5.56mm, 2.335" (military barrel) Wydle chamber, 2.330" Bullet crimped in the middle of the cannelure, 2.220" Again, this closes up the freebore between bullet and rifling, when seating in the middle of the cannelure. NATO freebore 0.115" freebore, Wydle freebore 0.110" freebore. ---- Your COAL (Cartridge Over All Length) should consider your freebore. If seating a little more shallow, or a little deeper will give you 'Optimum' freebore, then you might consider it. Most bullets I use have a cannelure, which I crimp into. There is a limited range of seating depth in that cannelure, so making the chamber fit my favorite rounds is an option, Since I don't plan to run stupid long, heavy bullets... I'm using .223 for an example, but the same is true for all cases that use the bottle neck shoulder to set bullet depth/freebore. |

|

|

|

|

#4 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

Like I said Bart,

You take 10 guys and ask their 'Opinion' about what a 'Correct' seating depth/freebore/throat profile is, And you will get 25 'Opinions'... Each and every guy will have 'Statistics' or 'Articles' or 'Stories' they will point to as 'Proof' of what they believe... That means NOTHING to me since we are talking my rifle here, not what they used to have, once read, once saw done, ect. Personally, I don't really care what people do, it's up to them and the results they get. I've dinked around with several barrels (and ruined a few) in my day, trying this or that... Some shot well, some didn't, about every one 'Liked' something different. That's why I'm NOT recommending something specific and radical. Just recommending the folks working up a reasonably accurate load for their particular rifles consider, And check for, freebore... I'm trying to demonstrate how to check 'Freebore' without a bunch of costly equipment, And let guys know how to correct if necessary... ---- I'm not a fan of having the BOLT set the bullet depth, And how do you explain the 'Squibs' that do get into the rifling and solidly stuck? Not EVERYONE shoots YOUR rifles, A bolt that's slow to unlock, or a bolt rifle WILL jam the bullet in the bore, ----- And further more, I don't believe for a second that you, or anyone else, HAS SEEN ANY GAS OPERATED, LOCKING BOLT SEMI AUTO RIFLE KICK THE CASE OUT ON THE PRIMER ONLY. Since the bolt is LOCKED, And the gas can't reach the gas port in the barrel to UNLOCK the bolt, The bolt will NOT unlock and eject the case. Blow-back bolt, maybe... Locking bolt, NEVER. It's just simple phsyics of the gas operated locking bolt design, it just can't happen... Unless you have a primer that not only drives the bullet past the gas port on the barrel, AND has enough remaining energy to operate both the bolt lock and move the bolt/bolt carrier group to the rear far enough to eject the round... I would believe that to be VERY unlikely, And you would STILL have the bullet jammed in the barrel... So unless you MIS-TYPED what you were trying to get across, and would like to correct, I'm not going for it... No offense, I'm just pointing out how it came out, And YES, I do the same thing, Brain ahead of fingers! No harm, no foul. ----- Most of us aren't running UNCRIMPED cases, Some are, It's up to you. Personally, I don't care for my 'Plinkers' (ARs) to knock the bullet back into the case, spilling powder in my rifles, So they will be getting enough crimp to keep them in them SOLIDLY seated in the case until I pull the trigger... That's my PERSONAL PREFERENCE, And with a medium crimp my AVERAGE rounds are more accurate with a crimp. (Your experience and results may vary, every rifle is different.) I'm sure you have yours, feel free to express it WITHOUT attacking me... I find my ammo to be more CONSTANT with a medium crimp, but I also shoot the same ammo in several different rifles, all having different chambers. It's been a while since I had a hand load hanger queen, Multi-purpose rifles are what I shoot now, and they are mostly for FUN, Not Extreme Competition. ------- Now, the PURPOSE of this post was to give a reasonable way to check freebore, To make a decision on how deep to set the bullets, And maybe try some new things. From seating SUPER SHALLOW, and letting the rifling push the bullet back into the case, then measure it, (A good way to lightly lodge your bullet in the bore, and the case comes out without the bullet) To finding EXACTLY where your CHOSEN bullet profile meets the rifling, And making adjustments to see if you group better... Personally, I find a reasonable seating depth that fits the mags so I don't have failure to feed issues, Then working on the chamber to match the seating depth so I have accurate rounds... Some won't want to mess with changing the chamber, Some will try to see if accuracy/consistency improves, Some won't care at all... It's just information, do with it what you will... Just don't kill the messenger! |

|

|

|

|

#5 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

I thought everyone knew a powderless round had to be manually ejected from all center fire rifles if its primer fired. That's been my observations with several from .222 Rem to .300 Win Mag; bolt guns and semiautos.

Jeep, you need to know I never worked up a load for any cartridge except for two new bullets there was no data for. I just used the same recipe the winners and record setters used. All my barrels shot the same loads as accurate as theirs did. Last edited by Bart B.; March 31, 2015 at 08:52 PM. |

|

|

|

|

#6 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Seating depth: I am the fan of the running start, I want my bullet to have 'the jump start', I do not want my bullet setting still at the lands when everything behind it gets very serious. I want my bullet past the beginning of the lands before my bullet even knew it was there.

And then there is that spike, WHAT SPIKE? I do believe it is important the reloader understands free bore and knows where the lands are located as in thousandths from the lands to the bolt face. F. Guffey |

|

|

|

|

#7 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

I seems Bart wants to argue semantics,

Missing the point entirely, which was seating depth and how to check it on the cheap. And he missed the point entirely about closing up the excessive freebore once you know how much you have. I *Think* what he was trying to say/do when he fired primers was form the case to the chamber without a full power round, Or was just practicing with primers instead of 'Snap Caps', Then MANUALLY ejected the cases. His throat was tight enough the bullet didn't enter the rifling, so the round ejected MANUALLY. He wasn't clear on that, so I'm not sure, just trying to make sense of his posts... ---- F. Guffey My bolt rifles seem to like very little freebore, While the semi-autos like a short freebore. When the freebore starts getting closer to 1/4', they get inaccurate, and sometimes have 'Running' issues. The V-Max round was an example, Seated at the cannelure, which most of us do, The freebore was HUGE! 0.175" is just TOO MUCH, no wonder it wouldn't group well. By checking and closing up that freebore, the barrel came right in to sub MOA. The same barrel with less tapered bullets, less freebore & same weight (55 Gr.) FMJ it shot sub MOA. Still crimping on the cannelure on both rounds, The tighter chamber shoots BOTH at sub MOA now. That's why I intentionally run 'Short' chambers. Less freebore works FOR ME, Don't know what anyone else is going to experience... Or what bullets/weights they are going to run in their rifles, This is subject to weight, length and throat/forcing cone on the rifling... I'm NOT going to run 90 Grain .223 bullets through my ARs, hand loading a semi-auto sucks, And I'm not silly enough to try a 1,000 yard snap shot at a fleeting target out here in the sticks... I'm going to stick with reasonable rounds for what I do, Coyotes out to about 500 yards. I can't see any farther than that anymore (aging isn't for wimps!), So it works fine for me. I'm not going to 'Recommend' anything, It's up to whom ever owns a rifle to decide if it's 'Accurate enough' for what they are doing, Or if they want to mess around with it a little to squeeze a little more out of it. "If the women don't find you handsome, they should at least find you handy" --Red Green. In that vein, I have the bathtub faucet chucked up in the mill... The 'Little Woman' wants more water volume, and these 'Low Flow' faucets are a pain in my butt! My new AR top end is on hold until she can fill the bathtub in 5 minutes flat! I'd like to use the fire hose on her sometimes when she wants these things during garden planting season and I have an AR to mess with! Last edited by JeepHammer; April 1, 2015 at 12:39 AM. |

|

|

|

|

#8 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Jeep, those rounds I fired that kept the bullet in place had no powder in them at all as I said. They were issued to me and shot in a 1000 yard match. I had to load and fire over 40 rounds to get 22 that shot bullets out of the barrel. Inspection of others of the 60 rounds issued to me showed about half of them to have no powder in them. The man in the support unit's loading room didn't put powder in all of those handloads.

I was not trying to form the case to the chamber without a full power round, nor was just practicing with primers instead of 'Snap Caps.' |

|

|

|

|

#9 |

|

Senior Member

Join Date: January 16, 2010

Location: Minnesota

Posts: 3,577

|

I Have noticed each rifle will like it's own. My 308 ( stock Savage FVSS ) Likes a running jump, On the other hand my 6BR likes them nice and tight. I do not crimp any rifle rounds, never seen a need to ( if your neck tension or for Guffy neck hold) is good there is not need to crimp. I am one that did send my Die along with 5 cases back to Forester to have my die customized to my rifle. I now seat my rounds long enough that when I close the bolt it actually seats the bullet back farther in the case. As for finding seating depth there is a easier way. Seat a bullet to long, start chambering bullet, set bullet back .002 at a time till bolt closes to your liking, all done. Is it perfect-NO. Does it work-Yes.

__________________

NRA Certified RSO NwCP- Performance Isn't Optional |

|

|

|

|

#10 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

WOW!

50% failure rate! They NEED a new loader in the worst way! You are more dedicated than me, I would have given up. The potential for damage to the rifle and my face wouldn't have been worth the potential points. Glad you didn't have any damage and could continue, And DIDN'T GET HURT in the process! ----- I was at a service rifle meet a long time ago, ammo supplied, AR-15s. The guy squeezed his first round off and the upper receiver split, the bolt split the carrier, the mag blew apart... I never did hear what the official report was about failure cause, but it happened two more times during the same shoot, just not as catastrophic of failure. The first time it happened, the guys thought it was an obstructed barrel, but after it happened twice more, They called the shoot off. (Good Call!) It was just by the grace of God that no one lost an arm or eye... I'm OBSESSIVE about my loading. The cases get checked at least 4 or 5 times during the deprime, cleaning, inspection process, I watch the powder checker like a hawk, Every single loaded round gets a TWO final checks, EVERY SINGLE ROUND in a case gauge before I buff them, And a second hand inspection after being buffed going into the boxes or stripper clips. I don't want a repeat of what I've seen happen with other loaders. Factory rounds (From US companies) are pretty reliable, But I don't shoot 'Surplus' from foreign manufacturers, and I don't shoot 'China' or 'Russia' anything. I won't consider those 'White Box' reloads at the gun shows either. The only 'Squibs' I've ever had was handgun ammo from a gun show in a 'White Box'... Stacked two rounds up in a 1917 .45 Cal service revolver, I was 16 years old, no idea in the world how to 'fix' the situation, and ruined a nearly PERFECT specimen of 1917 revolver I saved up all summer to buy. Throwing hay bales and digging fence post holes is a hard way to make enough money to buy a revolver, and the FIRST box of ammo I tried to run through it ruined it. The second failure was some .45 Colt rounds loaded locally, 'White Box', Blew the top of the cylinder and the top strap off an original Colt single action revolver. Not 'Squibs', but WAY over power rounds for that old, original single action. And I'll not have that happen again if humanly possible. |

|

|

|

|

#11 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

4 Runner,

My home built version of M40 in .308 likes TIGHT case necks, no crimp, Boat tail bullets, next to ZERO freebore. For some odd reason it likes 178 grain bullets instead of the usual 168 grain everyone else in the world gets to run... For variance in the press (Progressive) It gets about 0.002" freebore just to make sure the bolt works SMOOTHLY. My 'Varmint' .223, a Ruger M77 MKII, likes a light crimp, but no free bore. Most small bullets (.22) rifles seem to like a little crimp, And I don't know why, it's just one of those mysteries of the universe I have noticed... While the .30 cal work just fine without any crimp at all most times. The Exception is my AR-10s, both .300 WSM and .308 Win like a little crimp, not much, just enough to keep the bullet in the case during cycling, While my M1A doesn't need a crimp and doesn't like a crimp at all, just a tight case neck... The chamber in my CMP M1A was spot on. The chamber in my .309 AR-15 had 0.210" freebore and continued to tighten up groups as it closed up, The AR-10 in .300 WSM had about 0.0120" freebore, And again, groups closed up as freebore was removed. The AR-15s in .223 & 5.56mm are a different story. They like somewhere around 0.010" freebore, And they like a medium to hard crimp. The problem was, my .223/5.56 AR barrels came with nearly 0.200" to 0.230" freebore! Not good for light weight, short rounds that I normally load and shoot for reasonable money... Instead of trying to make a 'Favorite' round for each rifle, I cut the chambers to make my rounds fit the rifles. It's easy to load for ONE rifle, but when you have several rifles or top ends, it's just a ton more simple to close the chambers up ONCE to fit the rounds you like to crank out... This is just MY RIFLES, your approach and results may vary. |

|

|

|

|

#12 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

I'm a firm believer that a dozen people will have different test results with a given load in a given rifle. Proved that years ago with a match rifle shot by a dozen people with ammo whose 5-shot test groups were about 1/4 MOA at 100 yards. Their test groups ranged from 3/4 to near 2 MOA.

|

|

|

|

|

#13 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

I had a 'One Hole' bench rifle years back,

The guy saw me shooting, and just HAD to have the rifle. Way more dollars than sense, and since his opening offer was about 3 times as much as it would take to build a new rifle... I'm always up for a new project, it got a new home. I sent it along with the ammo I had at the range since the new rifle would have a new chamber and probably a new caliber, So I get a call about a week later, The guy is SUPER upset. He is shooting 1-1/2 to 2 MOA, all over the place, And he can't find ammo built to the specifications I had on the box labels... It wasn't the rifle, and I told him on the outset the rounds would have to be made (or reloaded) for it, the chamber wasn't 'Standard' anymore... He was still all up for owning it, I even threw in the dies I was using to make those rounds. About six months later, that rifle was at the local gun shop for sale for about 1/3 what the guy paid for it... One of the local guys getting into bench shooting knew where it came from, Called and ask me about it (not telling me it was at the shop), And ask me about rounds, which I explained, and offered my load book data, ask him if the dies were included with the rifle (They weren't)... So the guy buys the rifle, we get some dies running for it again, And back down to one hole shooter again... Nope, you can't count on anyone getting the same results. The opinions will differ about what the 'Problem' is, In this case, I got blamed for the guys lack of skills, Called every name in the book by him, And there was nothing wrong with the rifle... The guy that purchased the rifle at the shop was VERY happy with it, and I think he still has it 25 years later. I know he still had it up to about 5 years ago, when we still shot some together... ----- While in the military, I heard a 3 week running argument about how to throat the next production of Palma rifles. Nothing more than a throat change... They crapped on each other, argued, nearly came to blows several different times, and generally thought each guy that DIDN'T share the same opinion were 'TOTAL IDIOTS' in every way... Now, these guys were capable of building the most accurate service rifles in the world, But any one TINY change would throw them into a tailspin, And all being Alpha Type A personalities, You either agreed with them 100%, or you were an idiot trying to sabotage them. NOTHING IN BETWEEN! It got REALLY personal... I was a young pup, just learning my trade, so I did my very best to be invisible... Everyone of them had forgot more than I would be able to learn in my time there, And I wanted to absorb as much from them as I could, So NOT getting on the bad side of any of them was my goal... And trust me, it was DIFFICULT! After the Palma rifles were done, and won as usual, They all got drunk together and the differences seemed to be left in the past, But believe me, they weren't! Every time the subject came up, the crap fight started all over again! Those boys can carry a grudge like a hormonal woman! |

|

|

|

|

#14 |

|

Senior Member

Join Date: September 2, 2010

Location: Plainview , Long Island NY

Posts: 3,863

|

WOW, Good thing it's a slow day at work. Covers soup to nuts

|

|

|

|

|

#15 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Jeephammer,

Quote:

Long story, I checked a rifle that had been checked and rechecked and had a bore scope test etc. Then I was asked to check it. I made test cases for determing the length of the chamber from the rifling to the bolt face. I pushed the bullet out of the case first then the bullet skidded down the barrel and finally hit the rifling. The bullet travel exceeded .250", I was asked how that could happen. I suggested someone misunderstood Weatherby and then gave the rifle an additional .250"+ free bore. F. Guffey |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: December 23, 2005

Location: Minnesota

Posts: 2,952

|

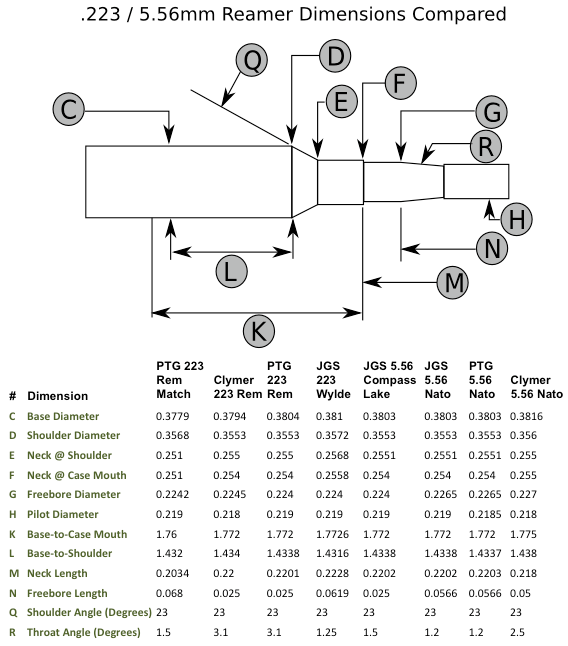

Your chamber dimensions are incorrect.

http://www.combatsimulations.com/ar1...ls/223-556.pdf http://www.luckygunner.com/labs/5-56-vs-223/ |

|

|

|

|

#17 |

|

Senior Member

Join Date: March 27, 2014

Location: southeastern Vermont,USA

Posts: 325

|

i have as usual a simple answer.rifle and ammo manufactuars have SAAMI so that ammo you buy for your 30-06 wont seat into the grooves.SAAMI and gun makers work extensively to get all the kinks out for basic safe factory ammo.

experimentation is the only answer for reloaders because you never know how a load will work in your gun untill you try. i would seat .035 off the grooves for soft spitzer type bullets and .050 for bonded core or pure copper bullets.if you dont like the accuracy start moving them toward the grooves .005 at a time.if that does not work go back to .035 or .050 and back away and see if that helps. if nothing helps rebarrel it. young reloaders think they will get sub moa ammo tommorow but it does not work like that.try and try and try and you will get good results but not overnight |

|

|

|

|

#18 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

Steve,

The chamber dimensions I gave are from SAAMI, NATO, Bill Wylde- Respectively. The dimentions given in your post are for particular REAMER MAKERS, their versions of each chamber. Because the two don't match perfectly, doesn't mean they are 'Wrong', just 'Different'. A chamber reamer gets you 'Close', accuracy of the chamber is up to you and your SKILLS & MEASURING EQUIPMENT. The second point is FREEBORE, Freebore depends ENTIRELY on the BULLET SHAPE, A longer taper on the bullet will produce more freebore, While a shorter bullet that's more rounded will produce less freebore in most cases. Reamers are sold as GENERAL tools, While you are looking for something SPECIFIC for your chamber... Which is why chambers are often cut for the case first, Then a 'Throat' reamer is used to get EXACTLY the free bore you are looking for with a SPECIFIC bullet, Not a 'General' freebore to support everything from 35 grain bullets to 90 grain bullets. The other part of a 'Throat', (The 'Forcing Cone' in correct terms) Is the radius/angle when the bullet is compressed into the rifling. Some are a simple angle cut, a 'Funnel' shape, Some are rounded, a radius, to compress instead of 'Shave' the bullet into the rifling... There are good arguments for both types, I'm not getting into that discussion... This is to CHECK your freebore, where the bullet is seated in the case currently, And how far it has to travel to hit a 'Compression' point, no matter what type of compression cut is in the chamber currently. Just the freebore distance, when not excessive, usually improves accuracy... Once you check freebore, you can correct your COAL to close up freebore, Or you can modify the barrel to close up freebore so it's not excessive. Just a little experimentation a hand loader can do on the cheap to see *IF* accuracy improves. My point was: If your rounds become too long to fit in the magazine before freebore closes up, But accuracy improves as freebore closes up, Then consider cutting the barrel and re-chambering. It's not worth the trouble/expense to cut a barrel that doesn't shoot better with less freebore... AND, If you have several rifles that shoot the same caliber (your favorite round to build) And your rifles respond to closing up the freebore, Then consider making your barrels MATCH the round you are building, So the round interchanges and is ACCURATE in all your barrels... If you do a LOT of shooting, And have several rifles that shoot the same caliber, It's well worth the effort to make a STANDARD round, Have the rifles all shoot it well. Interchangeability is a wonderful thing when ALL the rifles benefit, and FEED CORRECTLY, off the same rounds. |

|

|

|

|

#19 | |

|

Senior Member

Join Date: December 23, 2005

Location: Minnesota

Posts: 2,952

|

Quote:

|

|

|

|

|

|

#20 |

|

Senior Member

Join Date: May 20, 2006

Posts: 925

|

good read

I have read this entire thread three times. The subject is something I have been trying to wrap my head around. It helped a lot. What I am taking from this is some people get good results with a jump and some people get better results with less. It depends on the individual rifle barrel and bullet shape. After reading the thread I now know how to measure it and find what works best for mine. No short cuts, just measure and observe results. Thanks to all and keep these informative thread coming.

|

|

|

|

|

#21 |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

SAAMI specifications of 2.260" COAL for .223 Remington,

LINK TO SAAMI: http://www.saami.org/pubresources/cc...0Remington.pdf NATO specifications of 57.40mm (2.2598") COAL, 2.550" to throat of barrel, Source, US Marine Corps. ----- With thanks and respect to 'Ammo Oricle', A link to Ammo Oricle's VERY GOOD page on .223 Rem vs. 5.56 NATO... http://ammo-oracle.razoreye.net/  The common 'Short' chamber is now being called 'Wylde' After a successful service rifle shooter named Bill Wylde. The 'Wylde' chamber is 2.445", Source, Bill Wylde and 'Wylde' chamber barrel/reamer makers. ----- This is what I'm trying to get across... THE POINT OF THE BULLET DOES NOT CONTACT THE RIFLING WHEN THE ROUND IS CHAMBERED. FREE BORE IS THE DISTANCE THE BULLET BETWEEN THE BARREL 'FORCING CONE' AT THE BEGINNING OF THE RIFLING, AND, THE POINT ON THE BULLET YOU ARE USING WHERE IT CONTACTS THE FORCING CONE. ----- A set back chamber, or lengthened COAL, CLOSES UP the FREE BORE. PERIOD. That is what this thread is about, COAL questions that keep popping up. The point between the EXPANDING TAPER OF THE BULLET NOSE TO THE CASE, And where the bullet YOU ARE USING contacts the forcing cone. It REALLY doesn't have a lot to do with 'SPECIFICATIONS', It has to do with where your chosen bullet actually IS when the round is chambered, AND, How far forward that CHOSEN BULLET PROFILE has to move forward before it hits the forcing cone. That is FREEBORE, No Rifling, No Restrictions on the bullet before it hits the forcing cone. Bullet contact point with the throat/forcing cone set too far forward, The bolt head spacing gets screwed up. Bullet contact point with the throat/forcing cone, set too far into the case, Excessive Freebore. THIS IS A THREAD ON SEATING DEPTH, FREEBORE, And an easy way to determine how much freebore you have... Last edited by JeepHammer; April 2, 2015 at 10:40 AM. |

|

|

|

|

#22 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

SAAMI's maximum spec for the .223 Rem cartridge length is 2.260" and minimum cartridge length is 2.215". None of SAAMI's specs for the round's chamber is 2.260" as can be seen in:

http://www.saami.org/PubResources/CC...0Remington.pdf SAAMI's specs/glossary also says freebore is a cylindrical length of bore in a firearm just forward of the chamber in which rifling is not present. It's the same for every round fired in a given chamber as it's part of the barrel, not the round itself. Depending on who made the reamer, it may well be different across all of them. http://www.saami.org/glossary/display.cfm?letter=F While freebore is associated with bullet jump, it stays the same for each round chambered. Bullet jump depends on how far back the bullet's ogive contact point with the rifling is from the chamber throat where it contacts it. SAAMI lists "bullet jump" in their glossary: http://www.saami.org/glossary/display.cfm?letter=B If I'm claimed to be arguing semantics, so be it. But we all would be better off if we all have the same definition for each term used describing anything about cartridges and/or chambers else that "failure to communicate" will lead to bad ju ju. I had called that part of the chamber immediately in front of the chamber mouth to where the angled throat (or leade) of the rifling starts the "throat" until I was recently corrected. In the SAAMI drawing above for the .223 Rem, it shows the freebore length to be .025" forward of the chamber mouth; the difference between the 1.812" and 1.787" lengths that are both .224" diameter at those points. SAAMI's definition of "forcing cone" has nothing to do with rifle barrels; only revolver and shotgun barrels. Last edited by Bart B.; April 2, 2015 at 10:55 AM. |

|

|

|

|

#23 |

|

Senior Member

Join Date: February 7, 2009

Location: Southern Oregon!

Posts: 2,891

|

Wow some long (and boring) posts. I'm gonna go with Bart on this one...

__________________

My Anchor is holding fast! I've learned how to stand on my own two knees... |

|

|

|

|

#24 | |

|

Junior member

Join Date: February 27, 2015

Posts: 1,768

|

Quote:

Some barrels are chambered for .223 while stamped 5.56, Some are the other way around, Some are a mixture of the two... Manufacturers have to anticipate the guy buying the rifle is an idiot, and will run what ever he finds laying around that will chamber... (Including idiots that run .222 Rem through a .223 chamber!) And guys running weirdly shaped bullet noses, extra long heavy bullets, and anything else they can scrounge up or read about and just 'HAD' to try through a factory made rifle... The maker HAD to anticipate that kind of 'Use' (I say 'Abuse') and cut the chamber to accommodate the rounds so they don't harm the user... ---- So now you have to HUNT DOWN what type of chamber you have, Short, less freebore, Or longer with a bunch of freebore. The guys that HAND BUILD RIFLES know exactly where their chambers are, Most guys are stuck with what came when they bought the rifle/barrel... ----- This was a thread that has gone HORRIBLY SIDEWAYS, It was simple enough in the beginning, To answer some of the questions about 'COAL' (Cartridge Over All Length), And that is determined by your FREEBORE, And what will fit in your magazine... By the time you close up 0.250" of freebore by making the Cartridge Over All Length (COAL) long enough to close up freebore, The round is too long to fit/feed in your magazine, Then you have a single shot... Not the 'Optimum' for guys with varmint rifles and auto loaders... ---- MY SITUATION is, I have SEVERAL rifles in .308 Win, .223 Rem, ect. I like to hand load ONE ROUND for every rifle. So the situation demanded I RE-Chamber all the rifles to shoot my most accurate rounds/favorite hand loads. (this IS a reloading forum, although we are getting into gun smithing a little here) --- The next demand for MY RIFLES was seating depth changes between Hornady BT FMJ, my 'Plinking' round, And my V-Max Varimint rounds. Since the taper to full barrel diameter on the BULLET ITSELF is in a different place (farther back), To cut down on freebore I had to set up a seating die to close up the freebore. BULLET NOSE PROFILE is different on EVERY type of bullet, So freebore changes. That's why I say use the bullets you like to build/shoot to determine freebore for each round you make. With me, it's FMJ and V-Max and not much else. The seating die for V-Max has to have a pusher with a HOLLOW inside, as not to damage the ballistic tip, So I have a RED strip on that seating die to tell the difference, Rather than mess around and try to change seating depth, cranking out 'Dummies' or 'Test' rounds each time I switch in the loader... Saves time and/or components when I make the switch from FMJ to V-Max. ---- The situation might be YOU just need to make LONGER cartridges to close up freebore in ONE rifle, Then just make LONGER cartridges for that ONE rifle, But you are still subject to what will fit/feed from the magazine. ---- The point here is, You simply won't know what your freebore is unless you check your chambers with the bullets you are loading. By checking chambers, and building your rounds to fit the chamber 'Better' you might just find out you can make that 2 or 3 MOA rifle into a 1 MOA rifle... ----- I didn't intend this to turn into a crap fight between 'One Shot' hand feeding guys, They are in an entirely different situation, and probably built the rifle from scratch... I was addressing the guys with 'Unknown' chambers, And the verity of questions about COAL... And the guys that want to load a magazine instead of hand loading each round... and still TRY to improve accuracy. This *SHOULD* have been simple, With the shoulder seated in the chamber, How far forward does the bullet travel before it hits the 'Throat' or 'Forcing Cone' of the barrel? That distance is how much longer the COAL can be before things get dangerous, So I gave a way to accurately measure it with a simple caliper instead of proprietary (and expensive) precision equipment you are only going to use once to a few times. This will get you three places behind the decimal point (0.001") instead of 4 or five places, But it's accurate enough to get you shooting better in most cases, and all it takes is some cases, bullets you like to shoot, and a caliper you should already have as a reloader. |

|

|

|

|

|

#25 | ||

|

Senior Member

Join Date: December 23, 2005

Location: Minnesota

Posts: 2,952

|

Quote:

From you original post. Quote:

Sorry, you are all over the board here and jumping back and forth between OAL (fit the Mag), chamber dimensions and reamer drawings. |

||

|

|

|

|

|