|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Search | Today's Posts | Mark Forums Read |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: October 10, 2010

Posts: 317

|

people who melt and cast lead bullets

im currently using an iron pot over the stove with a ladle. im thinking about buying an electric melter with the bottom pouring spout. what are you thoughts on using the gas or electric methods?

|

|

|

|

|

#2 |

|

Senior Member

Join Date: January 14, 2011

Location: on the north side of DFW

Posts: 970

|

I have always used electric. If you prefer ladle casting, you can find some really nice pots that will allow that.

I imagine it is easier to control the temp with an electric heat source, rather than gas. Using a gas (turkey fryer) source to melt/smelt down large quantities of lead is probably the best choice, but for casting, I'd go electric. edit: Look at the Lee brand 20# capacity... best value. |

|

|

|

|

#3 |

|

Member

Join Date: October 2, 2009

Location: Ballinger, Tx.

Posts: 47

|

people who melt and cast lead bullets

If its working for you, why not. I would be more concerned about doing the

melting process away from inside the house itself. Would be better to do that outside somewhere more secluded and away from any dis-tractions a body would have in a kitchen area....Kids wife etc. Not only that but you have fumes to deal with. Better to cast during the winter months and shoot during the hot days if you can stand to do so. Too many things can go wrong , best to concentrate alone with no one around to complicate matters.

__________________

I Dont know you....but I have met you 1,000 times before. |

|

|

|

|

#4 |

|

Senior Member

Join Date: July 3, 2011

Location: S.E. Texas Gulf Coast

Posts: 743

|

There are lots of lead casters here but you may get more specific information on a site dedicated to casting such as "Cast Bullets". I still use a pot over a propane flame so I can't help you on this one.

http://castboolits.gunloads.com/ |

|

|

|

|

#5 |

|

Junior member

Join Date: October 6, 2010

Location: Michigan

Posts: 1,080

|

Hello, beex 215. I learned how to cast on an old cast-iron wood stove, with a little 10lb. cast iron pot & Lyman ladle. Now stove was in a barn..not a cooking stove in kitchen! If that is where your doing your casting..I would be very concerned with lead contamination! Moved on to 20lb. electrics..but out in garage, with all windows and doors open..still using the ladle though!

|

|

|

|

|

#6 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,882

|

Electric.

I may cast sinkers with a burner, but I need controlled temp for sharp mould fill-out/quality bullets (and that temp's different for pure lead vice various alloys.) BTW: I started casting back in the late 60's on the kitchen stove. My wife still talks about the lead splatters on that Wherry Housing ceiling.  She laughs... now.

|

|

|

|

|

#7 | |

|

Senior Member

Join Date: September 8, 2007

Location: Mississippi

Posts: 16,188

|

Quote:

The Lee bottom pour is really fast and neat but it does have a tendency to get clogged and leak. The Lee bottom pour is really fast and neat but it does have a tendency to get clogged and leak.

|

|

|

|

|

|

#8 |

|

Senior Member

Join Date: December 9, 2008

Location: Massachusetts

Posts: 283

|

Hope you know that casting lead inside a room without proper ventilation can cause lead poisoning.If you do,.........never mind.

|

|

|

|

|

#9 |

|

Senior Member

Join Date: September 8, 2007

Location: Mississippi

Posts: 16,188

|

You'd have to heat lead almost to boiling to get poisonous fumes off of it. You can get lead poisoning by ingestion by eating before washing your hands, etc.

|

|

|

|

|

#10 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

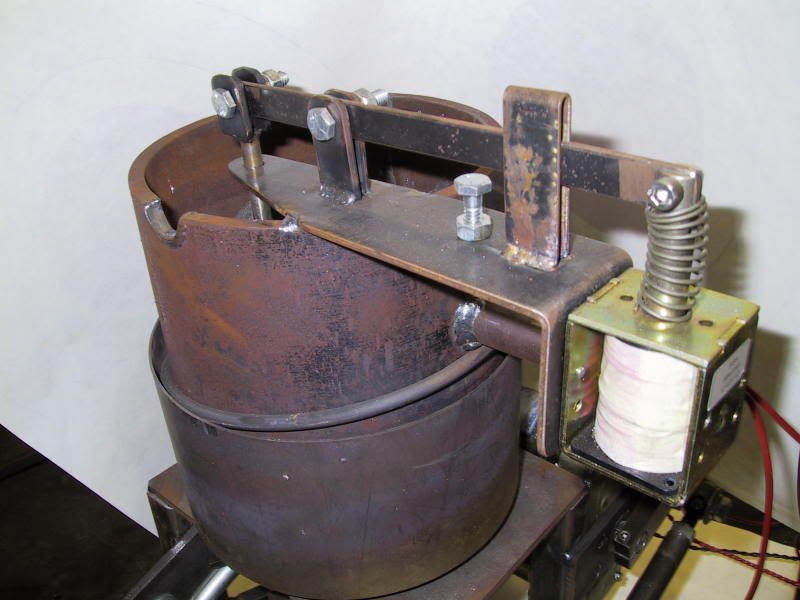

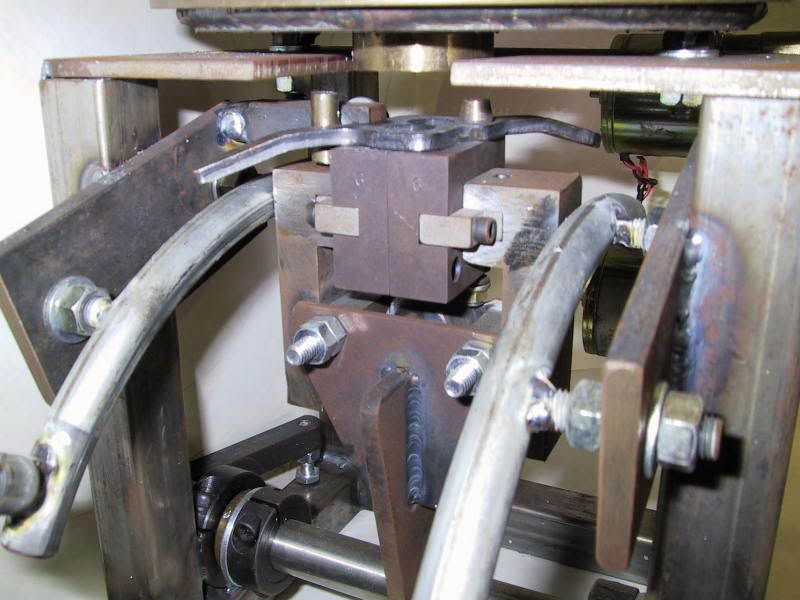

I built a melting pot out of 3/8" thick pipe and a 3500 watt oven element, that I later converted into a bottom pour pot for my automatic bullet casting machine. A new element cost $9 or so and has worked for a number of years.

|

|

|

|

|

#11 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,882

|

I've got both the Lee Production Pot (smokeless alloys) and RCBS Pro Melt (big pure lead stuff). I plugged the bottom-pour spigots on both of them long ago and have gotten best/most consistant results out of using the Lyman/RCBS lead ladles

|

|

|

|

|

#12 |

|

Senior Member

Join Date: April 23, 2008

Location: Medina, Ohio

Posts: 273

|

I'm assuming from your brief statement that you are casting from the iron pot and also melting your bulk lead alloy (wheel weights, pipe, etc) in the same pot. If that works for you, keep it up. If you want to use an electric melter with the bottom pour spout (like the Lee 20# pot) for your bullet casting, you should continue do your bulk lead processing/melting/fluxing separately in the iron pot and pour the cleaned lead into ingots. For the electric melter, you want the lead alloy (the ingots) to be as clean as possible so your pot and pour spout do not get covered/clogged with trash from the lead and so you get bullets without includions (trash).

__________________

God Bless America US Army, NRA Endowment TSRA Life, SASS |

|

|

|

|

#13 |

|

Senior Member

Join Date: August 6, 2010

Location: mountain view ,ar.

Posts: 184

|

in my humble opinion electric is the way to go ,,,

i only ladle pour but have a lee bottom pour which leaked /dripped so i put a screw up in it and ladle i also have a lyman mag smelter,, but it hasn't got any heat control but keep a constant 700* the lee has the temp control. just my 2c,,,

|

|

|

|

|

#14 |

|

Senior Member

Join Date: February 16, 2006

Location: IOWA

Posts: 8,783

|

Smelting and Casting

I smelt in cast iron pot over a fish fyer propane burner, outside, mostly in the fall. Sometimes I ladle out for decoy weights and some sinkers.

I cast out of an electric bottom pour unit, again, outside, in the spring and fall. Be Safe !!!

__________________

'Fundamental truths' are easy to recognize because they are verified daily through simple observation and thus, require no testing.

|

|

|

|

|

#15 | |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,882

|

Quote:

Keep smelting & casting separate to isolate the trash in the scrap metal |

|

|

|

|

|

#16 |

|

Senior Member

Join Date: June 4, 2006

Location: West Virginia

Posts: 2,258

|

I smelt WW's in a cast iron pot over a propane burner. I cast with an electric bottom pour pot. It works best to keep smelting and casting separate.

__________________

I don't ever remember being absent minded. |

|

|

|

|

#17 |

|

Senior Member

Join Date: September 27, 2008

Posts: 121

|

lee for me

had the pot--a pain. lee bottom pour-works great. i do 45acp, 45-70 and soon to be 44mag. also use lee molds--2 and 6 cavity. very pleased and save a ton of $$.

|

|

|

|

|

#18 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

Here is the one I built. You can see the remains of the pour spout in the center of this photo and the "ears" of at the side.

Then build a bit more   And it gets easy. |

|

|

|

|

#19 |

|

Senior Member

Join Date: January 14, 2011

Location: on the north side of DFW

Posts: 970

|

now that setup is just fascinating. I've been toying with the idea of building a casting setup that will bring the mold up to the optimum temp so that each cast fills out the same. I had hoped to minimize the number of casts needed to bring the mold up to temp.

Can you describe how yours works? |

|

|

|

|

#20 | |

|

Senior Member

Join Date: May 20, 2001

Location: Oshkosh wi.

Posts: 3,055

|

Quote:

There are no gas fired casting pots out there. Now, I'm not talking about using a cast iron pot over a makeshift propane burner. The excess heat generated will make the coldest blooded person sweat. AND there is no way to control the heat. By that I mean to make the flame heat to a desired temperature. Temp. control is the basis of good boolits. Without good temp control, you'll get inconsistent fill-out and weights.

__________________

The more people I meet, the more I love my dog They're going to get their butts kicked over there this election. How come people can't spell and use words correctly? |

|

|

|

|

| Thread Tools | Search this Thread |

|

|