|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Junior Member

Join Date: March 14, 2011

Location: Murfreesboro, TN

Posts: 3

|

Lake City Brass rupture

Gentleman: I am new to this site and need some input on Lake City Brass, headstamp 07/08. I had 3 (three) 7.62 308 Win brass rupture @ the extractor grove while firing 2 new Thompson Center firearms, ICON bolt action and T.C Pro Hunter 15 1/2 SS Fluted 308 Win pistol, loaded with 44.5 grains Varget, CCI primer and CT Ballistic Tip 150 grain, B.C .435 to a COL of 2.810. As you can see, nothing out of the usual, low powder charge etc... I bought both firearms from the same dealer the same day, both factory new. I have 1000 of the L.C. Brass and just really use it for paper shooting and nothing else. I hate to trash all of the brass, but I also like my two eyes and ten fingers. No damage to the firearms, well blew the mag into many pieces on the Icon, cost $35.00 to replace it

. Any suggestions, input on powder change (type) would be appreciated . Any suggestions, input on powder change (type) would be appreciated Thank you for your time and knowledge in advance. Thank you for your time and knowledge in advance.Ken, The Bushmaster Kid Last edited by kwduff; March 14, 2011 at 08:43 PM. Reason: spelling error |

|

|

|

|

#2 |

|

Senior Member

Join Date: August 31, 2009

Location: New Mexico

Posts: 1,033

|

Headspace issue? The load sounds OK and I can't think of anything that should cause this. LC brass is thicker at the web if anything and should be stronger than commercial brass. Anyone else??

|

|

|

|

|

#3 |

|

Senior Member

Join Date: November 13, 2006

Posts: 8,286

|

I honestly do notknow enough about the TC guns to comment much.I do know of a Contender 14 in 7-30 Waters and an Encore rifle in .338 Win hat have had case head separation issues but any number of factors could be at play.However,perhaps some action spring could be part of it.

Running the brass all the way in the die,bumping the shellholder,is not a good way to go.It typically over shortens the brass,causing excessive case stretch. It is common for LC 7.62 brass,and other mil 7.62 brass,to have been run through a machine gun.This can cause problems. I suggest you take a few pieces of brass and section them with a hacksaw,then file the burrs off to examine the inside of the cases.You may find a stretch ring inside.I Also suggest getting a chamber type case checking bushing.I have found the Wilson to be a good one.It will tell you if the brass is sized to original specs. The brass may well be junk if it is excessively stretched. While LC brass is popular with NRA HiPower shooters,it is not known for having uniform neck thickness. You are shooting single shots,and I assume you are pursuing accuracy. Norma cases are expensive.They are also precise,require little or no prep,and they are durable. For your application,100 rds of brass,maybe 200 will do a lot of good shooting. |

|

|

|

|

#4 |

|

Senior Member

Join Date: December 29, 2008

Location: Granville, IL

Posts: 153

|

LC brass is stronger to a point that point is it's thicker so it will most likely last longer at mid loads, but at the same time has a thicker structure equaling less case capacity. In most load manuals they state "if using military brass reduce loads by X amount" usually 3-5% but If you work up your loads from starting data there is no need to. The problem starts if you load military brass with full power civilian brass data, then that "stronger" LC brass turns into a an equivalent 3-5% overcharged civilian case.

__________________

Μολὼν λάβε |

|

|

|

|

#5 |

|

Senior Member

Join Date: August 25, 2010

Posts: 782

|

A small suggestion. I have always made a practice of checking for any cracks developing on the inside of the case in that area. I use a paper clip that is straightened with a 90 degree bend about 1/8" long and leave a little bend on the other end for a handle. You can feel a crack developing.

This problem sounds like a headspace or chamber defect of some kind. If you haven't done so, I would double check all of the loading data, and the steps that were used to load. I would even check the bullet diameter to see if it's .308" I would even check the bore grove diameter. Good Luck, and Welcome to the forum. |

|

|

|

|

#6 |

|

Senior Member

Join Date: August 25, 2010

Posts: 782

|

Iv'e another thought. If the case is to long or the necks to thick, that could do it.

|

|

|

|

|

#7 | |

|

Senior Member

Join Date: August 25, 2008

Location: In the valley above the plain

Posts: 13,424

|

Quote:

If the new rifles have tighter chambers than the others the brass was fired in, it could be an issue that was unnoticed before.

__________________

Don't even try it. It's even worse than the internet would lead you to believe. |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: May 20, 2001

Location: Oshkosh wi.

Posts: 3,055

|

TC icon is a bolt action rifle;

http://www.tcarms.com/firearms/icon.php The pro hunter is an encore pistol; http://www.tcarms.com/firearms/proHunter.php How I read the OP is the brass was rupturing at the EXTRACTOR GROOVE! This is no where near the web area, where case head separations usually occur. The case web is the thickest at that point, BUT is also completely unsupported by a bolt action rifle chamber at that point! The encore pistol should support the case web better than a bolt rifle. Ken, we should have fun batting this one around till we figure out what's happening. Have you fired any factory rounds or loaded any "civilian" brass?

__________________

The more people I meet, the more I love my dog They're going to get their butts kicked over there this election. How come people can't spell and use words correctly? |

|

|

|

|

#9 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,894

|

Kwduff, welcome to the Forum. `Sorry it had to be over such an issue.

Normally, case separation is as shown below:  Could you upload a picture of one of the cases? (I'll be honest, I've never seen a case separation actually at the extractor groove) |

|

|

|

|

#10 |

|

Junior Member

Join Date: March 14, 2011

Location: Murfreesboro, TN

Posts: 3

|

Lake City Brass rupture

All the info I read in your replies leads me to think it is a brass issue, I always inspect each piece of brass before loading or "reloading" it. The rupture is inside the ring "grove" where the case is rebated to form the "extractor grove". Several people at the rifle range and Gallatin Gun Club has confirmed the area I am talking about. Maybe 44.5 grains is too much for a LC brass

, but that is bottom end load for 7.62 in he Nosler Reloading Guide 6, page 371, 2771 fps MV @ 97% case capacity using Varget powder. I "unloaded" pulled the bullets and reworked some Remington new brass and reloaded them, just have not fired any yet. There were no signs of excessive pressure on the case, the range safety officer RSO has been reloading for 50 years, former Marine Sniper. He also said pressure was not an issue insomuch as over charging. I'll drop the pin on a few Rem brass and see. I appreciate all your input and knowledge, the fourm seems to be a great place for a lot of trusting info. Thank you gentlemen, I appreciate it: , but that is bottom end load for 7.62 in he Nosler Reloading Guide 6, page 371, 2771 fps MV @ 97% case capacity using Varget powder. I "unloaded" pulled the bullets and reworked some Remington new brass and reloaded them, just have not fired any yet. There were no signs of excessive pressure on the case, the range safety officer RSO has been reloading for 50 years, former Marine Sniper. He also said pressure was not an issue insomuch as over charging. I'll drop the pin on a few Rem brass and see. I appreciate all your input and knowledge, the fourm seems to be a great place for a lot of trusting info. Thank you gentlemen, I appreciate it:Ken- The Bushmaster kid

|

|

|

|

|

#11 |

|

Senior Member

Join Date: January 20, 2010

Location: Central Arkansas

Posts: 1,074

|

I'd be interested in dropping a few of the LC cases unsized in a Wilson cartridge case gauge, you may find the cases will not enter the gage fully. It has already been mentioned much of the 7.62X51 cases may have gone thru machine guns. If you have a mic handy check the diameter of several of the fired LC cases about a 1/4" above the extraction grove, if they measure .473" or more I wouldn't use them, (unfired/new 308 brass measures .465-.4663). Another quick check (maximum) case length is 2.015", trim to length (minimum) is 2.005". Of all the calibers I load for the 308 has been a difficult round for me, currently I don't have one, I have given some thought about purchasing a Ruger Hawkeye in 308 and have another go at it! William!

Last edited by William T. Watts; March 16, 2011 at 12:11 AM. |

|

|

|

|

#12 |

|

Senior Member

Join Date: November 13, 2006

Posts: 8,286

|

Given the OP has clarified the failure:A separation of the brass between the primer pocket and the minor diameter of the extractor groove,

Thats a new one on me. Thinking about it,that spot ,it seems to me,would be under a compressive load from pressure rather than a tensile one.I do not think pressure,even extreme overpressure,could cause it. The only force I can imagine causing it would be a very robust extraction system and very violent extraction while the case was still obturated. In any case,if I had a lot of 1000 brass and had two case failures in two different guns with a book spec load,I'd kick it to the curb,maybe take it up with the supplier. |

|

|

|

|

#13 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,061

|

Kwduff,

It seems likely to me to be one of three things, all to do with the brass. First, if this is, indeed, once-fired brass, then cracks could exist at the extractor groove from severe extraction force. Normally, that just bends the rim, but if the brass where weaker than normal, as from one of the two causes outlined below, it might happen. A second possibility is just exposure to (even very low levels) of ammonia fumes for any length of time. This causes season cracking in the necks of loaded ammunition, but could also weaken the head or any other part of a case that is just sitting around unloaded. The term "season cracking" refers to the days before necks were annealed and British soldiers in India found the necks of their unfired cartridges cracking and splitting during the rainy season (hence, the name). This turned out to be caused by brass weakening in the presence of ammonia in the air from composting manure and vegetation. That composting accelerates in the dampness of the rainy season. The stress of the brass stretched over the seated bullet would then cause it to split. But weakened brass might split anywhere a high stress is applied to it. A third possibility is a manufacturing defect. There are two approaches to case forming: one is from brass wire slugs (Lapua and Norma use this, I believe) and the other is from long cups drawn from brass discs punched out of brass sheet (what Hatcher's Notebook illustrates). I assume Lake City is using the disc method, just because the military arsenals used that traditionally. In this method, the drawn brass cups have to be forged down at the bottom to make the solid head, and I have seen sections of some foreign-made .40 S&W brass in which this process left folds in the head of the brass that were not fully fused by forging. Though this brass survived its original commercial load firing, it could not be reloaded and fired again without coming apart (mainly head separations, but it could happen anywhere there is a fold). So, I would follow the suggestion to section the brass and polish the edges and look at it under a magnification for signs of these problems. In any event, I think the problem will prove to be in the brass, unfortunately, as I am unable to think of any failure of brass in good condition that looks the way you describe (though a picture wouldn't hurt.) For future reference, in Lake City brass, the load you mentioned should be safe if the rifle's throat isn't short, but it's not a minimum load for LC brass. Most of the Lake City cases I have weigh 178 to 181 grains. That corresponds to about 56.1 grains of water capacity when fired in a SAAMI minimum .308 chamber. They should take about 1.5 grains less Varget than a Winchester case (Winchester has the most capacity among commercial cases), which weighs about 156 grains and has about 59 grains of water capacity when fired in a SAAMI minimum chamber. Hodgdon's load data, using a Winchester case and Federal 210M primer, lists 44 grains of Varget as a starting load under the Nosler 150 grain bullet seated to 2.800". (This assumes you have a standard .308 commercial chamber with 0.020" freebore.) That equates to about 42.5 grains of Varget as a starting load for the same bullet in LC brass. But as I say, that's just for future reference with LC brass that's in good shape.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle Last edited by Unclenick; March 16, 2011 at 02:09 PM. |

|

|

|

|

#14 |

|

Junior Member

Join Date: March 14, 2011

Location: Murfreesboro, TN

Posts: 3

|

Lake City Brass rupture

I cannot thank you fellows enough for all the vital information you have shared. I hae the next 2 days off from the hospital and looks like I am spending some time at the reloading bench. I'll take all info into consideration, printed off your suggestions to follow. Micrometer time, hacksaw and file time should answer the questions I have. Thank you all for the information. I have used other sites and just got a lot of BS from rednecks I would not trust loading a firecracker. You Gentlemen are true professionals and I greatly appreciate your input.

Thank you: Ken

|

|

|

|

|

#15 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Kwduff, you should question some of the answers as in the military case is safer than domestic cases and military cases being stronger because they are heavier than commercial cases. Then find out how many responses have actually measured a case, most are repeating something they have heard, read and are repeating this information as being fact. Then find out about measuring case head protrusion, I measure case head protrusion and do not believe the military case is safer and or stronger, why? Because I am one of the only case head protrusion measures around, and I measure cases, for example, rather than use deductive reasoning I use scales and micrometers, when I apply logic to the question I find the 30/06 military case like the LC I find the head of the case from the head of the case to the top of the web/cup to be .200 thousands, when I measure a commercial case like R-P I fond the case head thickness to be .260 thousands thick.

Back to case head protrusion, I measure case head protrusion, the Mauser case head protrusion is .110 + or - very little, when applying the logic of the military case being safer than commercial case does not hold up when one considers the added .060 on the R-P case is added to the supported case side. The case head is a support column and yields to pressure or hammering meaning when hit or hammered it shortens and at the same time increases in diameter, so with out head space it is possible to have case head separation (incipient) if the case body locks onto the chamber wall and the case head shortens. Back to case head protrusion, I measure case head protrusion, it is possible to have nothing before and nothing after but still have a problem, like the British 303 with rear locking lugs, measure before firing, no head space, measure after, again no head space (problem) but when attempting to get 40 firings the relaoder has to use 14 cases? It is possible the case head protrusion on your chamber, because of a different kind of an extractor, could be from the extractor groove back and the rest of the case could be supported leaving the case head from the extractor groove unsupported AND because of the work hardened case head can be compressed but not stretched. Your rifle could be one of those rifles that goes through contortions when fired, nothing before, nothing after, I have break open shotguns, three different categories, worn out from being fired, in three different pieces from being fired and tight ones from having never been fired. F. Guffey |

|

|

|

|

#16 |

|

Senior Member

Join Date: February 9, 2005

Location: Owego, NY

Posts: 2,000

|

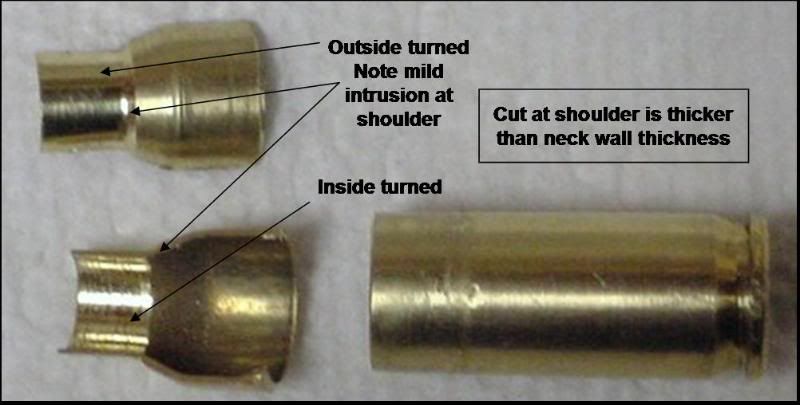

kw - when sectioning your brass, dragging it across a sheet of fine emery paper cleans the edges up nicely so you can see what is going on. Here's an example. I reform 223 to 221 and will disect one to see how my sizing/turning operations are behaving.

__________________

,,, stupidity comes to some people very easily. 8/22/2017 my wife in a discussion about Liberals. Are you ready for civil war? |

|

|

|

|

#17 |

|

Senior Member

Join Date: February 9, 2005

Location: Owego, NY

Posts: 2,000

|

Did you size the brass yourself prior to loading it? If yes, did you have good alignment of the ram to the die with no offset? Separation in that area of the case requires some serious stress or an overly brittle material. I'm not adding much but I am curious as to the cause of your problem.

__________________

,,, stupidity comes to some people very easily. 8/22/2017 my wife in a discussion about Liberals. Are you ready for civil war? |

|

|

|

|

#18 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,061

|

Just for those trying to follow the lingo, the brass intrusion Flashhole photographed so nicely is commonly referred to as the "dreaded donut" by the benchrest crowd. If not inside reamed, it can raise pressure if your bullet bearing surface is seated that far into the neck.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#19 |

|

Senior Member

Join Date: February 2, 2007

Location: Iowa

Posts: 2,676

|

Lake City brass ruptures are nothing new. I had a .223 blow gas and metal back in my face with a case head separation. Checking with a local re-manufactured ammo gent he immediately asked if it was by chance Lake City brass while we described the incident to him. Seems that they've had runs of brittle brass that may or not be corrected by annealing. His recommendation, toss it all away. We did.

LK |

|

|

|

|

#20 |

|

Senior Member

Join Date: June 14, 2004

Location: NY State

Posts: 6,575

|

I DID see a weird failure through the extractor groove.

I was actually able to discover the cause !! This was a 45acp case reloaded numerous times .The case is made by 'back extrusion' where a slug is put into the female die and the male die then pushes down and the brass of the slug flows up around the male die. The end of the male die should be very smooth so the brass will flow easily. In this case the end of the male die had a bit of a nipple with sharp edges.This caused a small tear in the inside of the case as the brass couldn't flow properly .That tear grew by fatigue as the case was used again and again and finally and finally extended to the extractor groove !! Find it as new case inspection ? No way.

__________________

And Watson , bring your revolver ! |

|

|

|

|

#21 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,061

|

LK,

Annealing is only done to neck and shoulder (the oxide stain there on Lake City is from the flame) because heads have to be harder and annealing down there guarantees blow-out. Hatcher points out that between the world wars there was actually separate brass for rifles and machineguns. The machinegun brass was softer to allow stretching under hard extraction. That was to prevent head separation, a problem that used to plague early machineguns like the Browning-designed Colt. A stuck case extractor was a required tool to keep them running with the old ammunition. But that brass just had to work once. It wasn't going to be reloaded so they didn't care how far it stretched, as long as it didn't break. The unsupported portion of the chamber in the 1903 Springfield rifle, on the other hand, didn't go well with soft brass and needed something harder to be sure to prevent rupture and for smooth manual bolt operation. The -R (for rifle) suffix ammunition had harder brass. Both types of case were the same 70:30 cartridge brass alloy, but they work the harder cases more. Steps as simple as impressing the headstamp deeper can make a significant difference in final hardness, as Hatcher describes having that done on cases he needed for high pressure failure testing, which the standard cases were not up to. Eventually, for the sake of ammunition cross-compatibility, the military reached a compromise that was workable in both rifles and machineguns, and that's what Lake City is today. In a well-supported chamber it is fine and it is less likely to jam a self-loader on the first firing. But with multiple firings you have to watch it. John Feamster put 4 reloads as the limit on LC .308 cases, IIRC, beyond which he considers them a hazard to the fellow to the right of an M1A. Military brass isn't made with the expectation it will be reloaded.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

|