|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Primers vs pressures , how much of a difference

I had some 308 LC-12-LR cases that had been sitting around for a while . I was saving them for a new load that may come along . Last year I found a pretty good deal on 168gr Hornady BTHP bullets . I thought what the hay this is a good time to pull out the LC-12-LR brass . I had also just bought some Federal GMM primers .

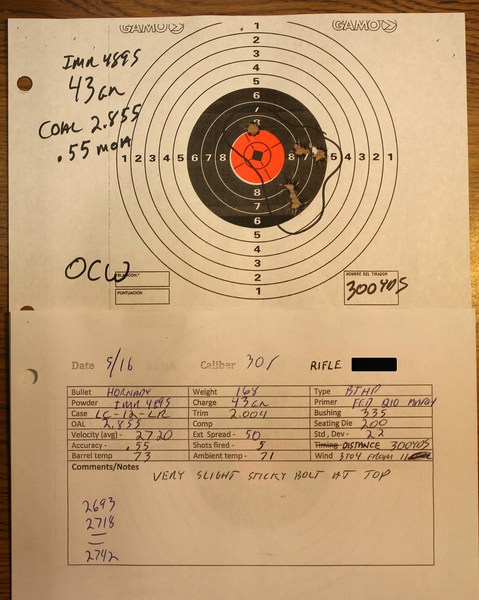

I go ahead and work up a load doing the OCW method . I find I get great results doing so with the final load being 168gr Hornady BTHP 43gr IMR-4895 LC-12-LR , H2o = 55.2gr average Coal 2.850 Max possible COAL 2.855 That load is really good but then I thought I should try to run a new load development . This time I'll use standard LC-14 brass and Win LR primers . I have many more of each . So I go ahead and work up a load from scratch with the new brass and primers but still use the same bullet and powder . On this load I did a ladder test as apposed to the OCW method . Now doing the ladder test I was getting sticky bolts at 42.2gr and real brass flow at 43.0gr . Big time pressure signs 1.5gr less then I tested to with the other load . I tested to 43.4gr with no issues in the OCW test but could not get past 41.8gr with the new primers and brass with out sticky bolt lifts . At that point I found that interesting but did not feel it to be odd . I just figured the brass volume must be lower along with the primers putting out much more flash/energy . How ever last night I decided to check the volume difference of both cases and found there to be very little difference with the LC-14 cases having slightly more volume ( LR = 55.2gr the LC-14 = 55.4gr ). I don't know but can't imagine that .2gr being a big factor which leads me to conclude the Win LR primer alone is the reason for the extra pressure . I'm just having a hard time wrapping my head around the idea that just changing the primers caused such a big difference as far as pressure signs showing up . FWIW the loads were the same , OK not exact . The LC-14 cases had the shoulders bumped back .001 more the the LR cases but other then that they were the same . Same COAL , Bushing , flash holes de-burred , case pep as a whole was the same . Is it really possible the primer alone is pushing me past max pressures at well below all manuals max loads ? Or am I over looking something ?

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; June 6, 2016 at 03:42 PM. Reason: Changed powder grain amounts of the pressure sign loads |

|

|

|

|

#2 |

|

Senior Member

Join Date: August 23, 2014

Location: Nevada/Ariz/CA

Posts: 1,753

|

You no doubt have the Lyman 49th or 50th. In either check the table on page 57 showing pressure difference between five primers used with identical .308 loads. The Winchester primer produced the next to highest pressure, only exceeded by the CCI 34. The primer could account for your pressure increase.

__________________

Ouch, the dreaded "M-1 thumb", you just know it will happen eventually, so why not do it now and get it over with?? |

|

|

|

|

#3 |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

The current military primer mix is the FA 956 mix,

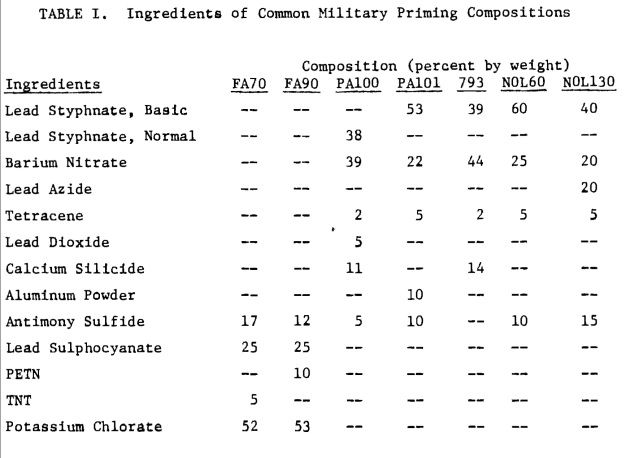

PATR 2700 Encyclopedia of Explosives Vol 8 gives the composition FA 956 Lead Styphanate 37.7 +/- 5% Tetracene 4.0 +/- 1% Barium Nitrate 32.0 +/- 5% Antimony Sulfide 15.0 +/- 2% Aluminum Powder 7.0 +/- 1% PETN 5.0 +/- 1% Gum Arabic 0.2% There are plenty of primer compositions for there are many applications for primers other than small arms. This is a list of military priming mixtures, FA 70 is the old corrosive primer, I was able to identify PA101 as a fuse primer composition. All of the compositions to the right of FA90 are more sensitive than rifle primer compositions, so these are probably used on a variety of explosive or propellant devices.  So given that primers are a mix of materials, all of which vary by percentage in the mix, and the purity of the starting chemicals also varies, and that primer mixes are proprietary to the manufacturer, it is a wonder that switching primer brands does not cause more problems.

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

#4 |

|

Senior Member

Join Date: June 15, 2008

Location: Georgia

Posts: 10,811

|

I've always read that Winchester LR primers were among the hottest, approaching magnum primers. I primarily use them, but have also used CCI and have only noted a very slight increase in speed. Less than 10fps, and no noticeable difference in pressure.

You are well under max for IMR4895, right on the edge for H4895. In my experience a load right at max might be effected enough by different primers to push it over the edge. But you say you're getting pressure signs at only .4 gr over a starting load. Without chronograph numbers I don't trust any traditional pressure signs. I think the primers MIGHT be PART of the issue, but you have something else going on here. Any guess is just a stab in the dark without actual muzzle velocity. |

|

|

|

|

#5 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

My notes say the 43gr LC-LR load has an average velocity of 2717fps with slight sticky bolt at top . I remember that now and changed the COAL from 2.855 to 2.850 to back it off the lands a tad . 2.855 is right up touching the lands . I went back to the range to test the new COAL but only got 10 rounds down range before my scope died . No chrono data was recorded at that time .

The LC-14 41.6gr load I don't have an average velocity because the scope died before I could get to it . I do have the ladder test numbers though . They were very erratic and after testing I concluded that was do to the bullets just touching the lands . I had similar results as far as erratic velocities with the other load as well with that same 2.855 COAL 40.6gr = 2549 41.0gr = 2613 41.4gr = 2497  Those three shots hit the 300 yard target with very little difference in vertical stinging . There was a total of 1/2" between the three . At 300yds that's not to bad . 41.8gr = 2609 42.2gr = 2734 42.6gr = 2717 this is where the sticky bolt got much more pronounced and I started to see extractor marks on the case heads 43.0gr = 2597  but still had sticky bolt but still had sticky bolt 43.4gr = 2682  big time sticky bolt big time sticky bolt 43.8gr = 2779 had to really force the bolt open The last three charges had clearly defined extractor and ejector marks on the case heads . I wish I had better data for you guys on this load . All of those velocities are only one shot each from the ladder test . I got similar erratic numbers with the other load at the same 2.855 COAL during load development . I tested COAL's from 2.815 to 2.855 . only the 2.855 had erratic velocities in both test . During the seating depth test of the OCW method 2.845 and 2.855 both shot real well but the 2.855 had those velocity issues so I went to 2.850 to see if splitting the difference would help . unfortunately my scope broke before I could complete the final testing . I did send it back and got a new one free ( got to love Vortex ) Either way I've shot the 43gr charge with the Fed primers with out issue enough to know the load with the Winchester primers is definitely different . I will add that I'm glad I keep pretty good notes because my memory told me there was a 2gr difference in the loads . How ever my notes have it just over 1gr really being the difference . I corrected those numbers in the OP .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; June 6, 2016 at 12:44 PM. |

|

|

|

|

#6 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Sounds like you have multiple variables in play. I've seen data for 223 Remington showing the equivalent difference to that of about 5% increase in powder charge in terms of pressure (about 11% peak increase). German Salazar's Rifleman's Journal had some large primer pressure and velocity difference data, but he's closed that off to any who are not invited, so we can't link to it any longer to let you see the numbers.

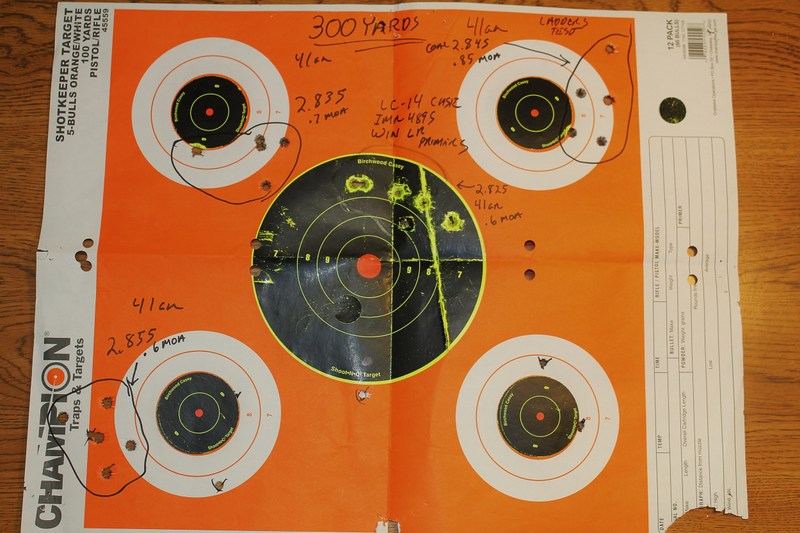

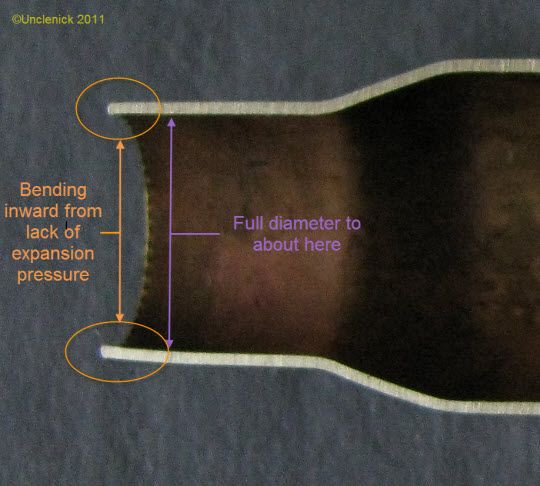

Another board member said in 2012 ATK switched Lake City over to commercial type conformal pressure test equipment to improve compatibility with commercial ammunition. I know Federal makes the Mk.316 m.0 brass, but don't know about the M118 LR brass. That may have been old Lake City, while the new brass may have been post-modernization LC. I would take an automatic centerpunch and see if it indents any more easily and deeply than the 2012 brass. It could conceivably be softer. With kind permission from Jim Ristow at RSI, the plot reproduced below showed that moving the bullet back from the lands by 0.030" dropped pressure 20%, though it's not your chambering.  This older data is, at least, 30 cal. It has less drop (just 10%) and it takes moving a quarter inch back from the lands to get that. The reason is that it's a round nose bullet, so the sides taper very slowly and open the gas bypass annulus with the throat much more gradually with seating depth than happens with a pointed nose bullet. It's the gas bypass change that causes the pressure change.  What's important about that second image to your situation is the shape of the curve. Note that the first five thousandths would not do much to pressure on either curve. The difference would still be inside normal shot-to-shot variation. I've measured that much variation in bullet ogive-to-case-shoulder distances on loaded rimless bottleneck ammo before, which means the actual bullet position in the throat portion of the chamber is varying that much. So I consider it to be inside the noise of bullet-to-bullet variation. Some measurement of that variation is eye opening. Even on Sierra Match bullets I've measured an extreme spread in bullet base-to-ogive contact point of 0.008". In the 1995 Precision Shooting Reloading Guide, the late Dan Hackett described a 40X in 220 Swift that he could not get shooting under about half an inch (5-shot groups) and that typically was more like three quarters of an inch. Then one day when he was loading for it he switched bullets to a Nosler 50 grain bullet and in so doing adjusted his micrometer seating die to compensate for its base-to-ogive length being shorter than the previous bullet he was loading. The problem was, he turned the micrometer thimble the wrong way and ended up with the bullets way back at 0.050" off the lands. He had 20 rounds loaded before he noticed the error. He considered pulling them and reseating, but decided just to shoot the 20 up as practice rounds. To his amazement, the long jump bullets produced two quarter inch groups and two true bugholes in the ones. Bottom line here is that each gun's preferred bullet jump has to be tested. I wouldn't assumed jammed or a few thousandths off the lands will be best. It could be a good bit further back, just depending what your gun likes.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#7 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Thanks condor for pointing out pg 57 in the Lyman book . It does show for what ever load they used a 1600psi difference in the two primers I'm using . That having the Win LR primers creating more pressure then the Fed match primers . Now that we know the WLR primers are hotter . can we assume they are the lone cause of the higher pressures .

I guess if the 43gr charge with Fed primers are right on the edge of max pressure . I can see the WLR primers pushing it way over the top . I do have the bullets pretty close to the lands so there is no real blow by as far as gasses escaping around the bullet before hitting the lands . This is generally going to spike the pressure anyways right ? I just had another thought . If the ignition of the WLR primers push the bullet into the lands before the powder can really get going . Maybe that's the issue . If that is happening that cartridge/load would act more like the bullet started out jammed into the lands rather then being .005 off . hmm , Interesting

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; June 7, 2016 at 01:02 PM. |

|

|

|

|

#8 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Again, look at the second plot. Contrary to popular mythology, making contact with the lands does not cause a sudden big jump in pressure. It's a steady change as you back away from that contact point. Even if the change is more rapid than for the round nose bullet that data came from, it will still be the case a change as small as 0.005" is unlikely get you outside the span of normal shot-to-shot variation in peak pressure. Make bigger steps if you want to see clear change.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#9 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Thanks UN . I did do a fare amount of seating depth test and found the closer I got with this bullet the better they grouped

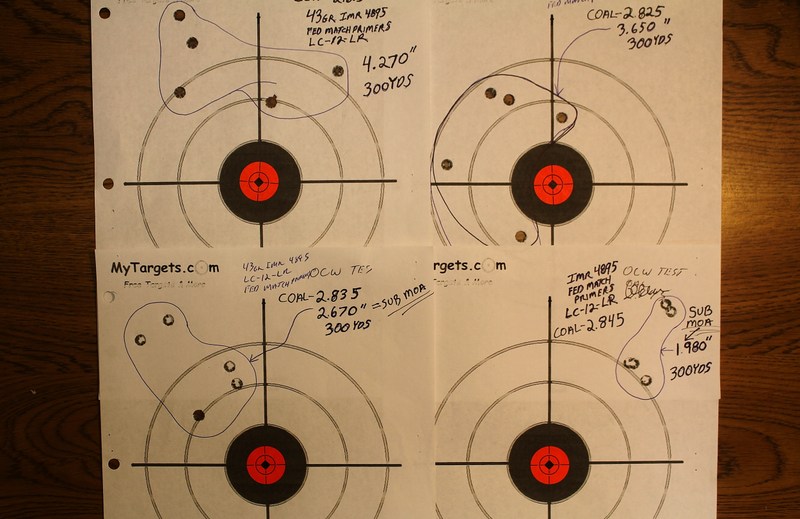

These are my 300yd targets after I found that 43gr was my OCW using the LR brass  As you can see I moved closer to the lands in .010 increments resulting in the groups consistently getting smaller as I went . That last bottom right target is a 2" group or 2/3 moa at 300yds This target was shot at a later date with the bullet right at the lands . 300yds and again 1/2 moa  I've tested that load from 2.815 to 2.855 . With 2.855 by fare being the best . Now what I may have done was incorrectly assumed the new load would also prefer to be close to the lands . That ladder test was done at 2.845 or .010 off the lands . As you can see the other load of 43gr has no problem shooting well at that same COAL with no pressure issues . Quote:

My issue is , why is the WLR primer rounds showing pressure signs at 42.2gr but the Fed primer loads don't show pressure signs at 43gr with all other things being equal except the primers .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; June 6, 2016 at 04:46 PM. |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Here is the seating depth test target for the WLR primer load after I concluded 41gr was the best charge after the ladder test .

As you can see the groups shrunk as I get closer to the lands . Center target is 2.825 , bottom left is 2.855 . All are sub moa  I think the fact this load is 41gr and the other is 43gr is where I came up with the loads being two grains apart pressure wise .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#11 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Perhaps I misunderstood. I thought you had also changed the case lot at the same time as the primer. My thought, given the changes made at Lake City in this time frame, is that you might also have softer brass, which would stick at a lower pressure.

There are two consequences to changing seating depth. One is that the peak pressure and barrel time change. If, for example, you seat the bullet significantly deeper and then re-fire the Audette ladder you can find your load is no longer quite in the middle of the flattest spot of the ladder's vertical POI curve. This means, with a different seating depth you may need to retune the charge weight. For that reason, a better seating depth may remain disguised until you've rerun your OCW round robin again. One way of dealing with that is with the help of a chronograph. As you change seating depth, watch for velocity change. Adjust the charge weight to get the same velocity you had before the change and that will be close to the same barrel time. It won't be exact because a circumstance in which a greater charge produces the same velocity in the same gun will have a slightly lower peak pressure and slightly higher muzzle pressure. That increases barrel time. A velocity match just means the average pressure behind the bullet was the same, but whether that average comes from lower peak and higher muzzle pressure (longer barrel time) or a higher peak and lower muzzle pressure (shorter barrel time) doesn't change the final velocity. This all assumes, as the Audette theory does and as Chris Long's OBT theory does, that matching barrel time is critical. However, Varmint Al's FEA analysis suggests it isn't necessarily that simple and that much of the muzzle deflection that moves the bullet up an Audette ladder is actually due to the effects of steel deformation under pressure and the magnitude of the recoil moment. Nonetheless, I would take it under advisement that a change in seating depth may be moving your Audette tuning around. If the load is a true OCW load it will move a lot less than a ticklish load does. Nonetheless, if you are seeking maximum accuracy, refiring the Auddette ladder after the adjustment may reveal a charge tweak is needed. I should add that you may have found your best seating depth in that gun already. I'm just wanted to be sure you don't miss the possibility another good one exists. A lot of guns seem to have two seating depth sweet spots, and occasionally you can find three. Also, it's important to note you and the gun are already shooting very well and that squeezing out further improvement may take a lot more additional effort than getting it this far did. To me it's just fun to try, but there are certainly no flies on how it's shooting now.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#12 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Good info to think about there UN . I had similar thoughts about the pressure changing as seating depth changed while doing the OCW test . Dan never talks about that so I stuck to his directions . The 43gr load in theory should have an .8gr cushion to work with +/- .4gr . The idea of maybe dropping my charge a tad to compensate for the extra pressure I get from moving the bullet closer to the lands is interesting . I'll try that as well as trying some shorter COAL's .

While I was running the tests I had two different threads going on two different forums . I was posting the results after each range trip . Neither were TFL  . I had many guys telling me to try several different things that were outside the directions Dan puts forth on his web page . I tried to stay true to the original method as much as I could . I did how ever change the original start distance to 200yds rather then 100yards . It just seemed like it would be easier to see the definition of the groups better at 200yds . . I had many guys telling me to try several different things that were outside the directions Dan puts forth on his web page . I tried to stay true to the original method as much as I could . I did how ever change the original start distance to 200yds rather then 100yards . It just seemed like it would be easier to see the definition of the groups better at 200yds . I did change the brass as well and read what you posted about that , sorry forgot to address it in my post above . That again is an interesting thought and one I had not considered . Do you have a home brew test I can do to check there hardness ?

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#13 | |

|

Senior Member

Join Date: July 26, 2011

Location: USA

Posts: 1,730

|

Quote:

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

No the H2o volume is pretty much the same only .2gr difference . The actual brass weight was around the same as well 185gr +/- a few tenths .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#15 |

|

Senior Member

Join Date: August 23, 2014

Location: Nevada/Ariz/CA

Posts: 1,753

|

Metal:

If we are still on the issue of the pressure increase, have you looked at the table on page 57 of the Lyman manual showing higher pressures created by the Winchester primer with .308 loads? That could provide at least a partial answer.

__________________

Ouch, the dreaded "M-1 thumb", you just know it will happen eventually, so why not do it now and get it over with?? Last edited by condor bravo; June 7, 2016 at 10:21 AM. |

|

|

|

|

#16 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

MG,

The only home-brew test I can think of is the one I suggested in the first post. Take an automatic center punch to a sample of each lot of brass it at several locations. If you have one of the Lee lead hardness test kits, the handheld microscope it comes with would let you compare the indentation diameters. If you don't have one and don't need one, this appears to be the same microscope in a different color.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#17 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Condor

I did look at that and posted a response in post # 7 . The primers I'm using are in that data and show a 1600psi difference with the load they used . It was helpful in so much as knowing that they at least have some impact on the issue . UN I went back and looked at the second pressure chart and although I understand the whole of the chart . I don't understand how it applies here . It seems to show pressures as you move the bullet off the lands but it is already at or over max pressures throughout the chart . It also seems to show HUGE jumps rather then the .030 to .040 I'm working with . Are you saying there is very little pressure difference in the bullet being at the lands or .040 off the lands . I've always believe there would be a big difference in that example . Quote:

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; June 7, 2016 at 07:05 PM. Reason: Changed the whole concept of the post hoping UN had nt read it yet |

|

|

|

|

|

#18 |

|

Senior Member

Join Date: August 23, 2014

Location: Nevada/Ariz/CA

Posts: 1,753

|

Oh, I must have overlooked your post 7. Interesting as to how much difference primers can make. Never considered that. I always use the Winchesters along with the CCI 34s and standard CCI 200 large rifle. Where do you do your shooting in the San Diego area? San Diego along with Phoenix are second homes. Otherwise up the coast a ways at Ventura.

__________________

Ouch, the dreaded "M-1 thumb", you just know it will happen eventually, so why not do it now and get it over with?? Last edited by condor bravo; June 7, 2016 at 02:23 PM. |

|

|

|

|

#19 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Most of my shooting is at South bay rod & gun club http://www.sbrgc.org/ . Pala just up north a ways is good but very limited as to when there is open shooting . There is some BLM land around but it can get a little scary at some spots with other shooters around .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#20 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

MG,

That chart was done in a lab in the 1960's and they weren't working to SAAMI standards. The reason you have to move back 0.25" in the second chart where you only had to move back 0.030" in the first chart to see a big difference is the first chart is a pointed bullet and the second chart is round nose. The round nose has an extremely gradual taper from the bullet shoulder to the start of the radius of the round tip, so it has to be moved back pretty far to open the gap between the bore and the sides of the bullet much. That gap is what the bypass gas flows through between the time the neck expands away from the sides of the bullet and the bullet moves forward to obturate (plug up) the bore. The gas bypassing has the same effect as reducing start pressure. A pointed bullet, by comparison, opens the gap much more with much less seating depth change because of the greater angle along the sides of the ogive. Assuming you are using a Spitzer nose bullet, you're going to see something closer to the first graph in terms of the seating depth and pressure change relationship. The reason I put the second graph in was just to show that the increase in pressure isn't a sudden jump that occurs when your bullet is seated to contact the lands, as some folks think, and that your 0.005" gap probably won't reduce the pressure much from land contact pressure as compared to an 0.020-0.030" increase in seating depth will.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#21 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

UN

What's your thoughts on my theory that the Win primers are pushing the bullet to the lands faster then the Fed primers before the powder really starts to burn . Therefore treating every load with Win primers as if the bullet was jammed in the lands compared to the Fed primers . So as a whole that combination of components will show higher pressures at any given charge weight or seating depth then a duplicate cartridge using the Fed primers ? I'm just wondering if I should just move away from that train of thought .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#22 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

So today I went to the range and thought I'd run a new test . This time I loaded 42.6gr in the LC-14 cases . I loaded 10 with the Win primer and 10 with the Fed primers . Everything was the same except the primers . Keep in mind I had pressure signs at this charge using the Win primers and this brass .

Winchester primer load 2648fps 2650 2641 2679 2666 Avg 2657fps ES-38.6 SD-15.39 Moderate sticky bolt at top Fed primer load 2617fps 2637 2645 2641 2623 AVG 2632fps ES-28 ? SD-11 Kind of a stiff complete bolt lift with it being even harder at the top Interesting isn't it . but wait I also took that 43gr load out that uses the Fed primers and LC-12-LR brass . That had a smooth bolt lift with NO binding at the top . So as Uncle nick was suggesting . It appears that the issue is NOT the primers and actually the brass that is causing the pressure issues . I have one last thing to test to confirm that . That is load some Win primers in the LC-12-LR cases at 42.6gr and see if the pressure signs go away . I'll do that next time out . EDIT : Now that I think it's a case issue . I had a thought about something I observed a couple weeks ago that may have something to do with why the LC-14 cases get sticky bolts and the LC-LR do not at the same charges . That is the portion of the LC-14 case body that is directly above the extractor grove and slightly above measures .470 while the LC-LR measure .4685 . I usually don't measure this area but I had one cartridge when I was at the range that chambered a bit tight as if I'd only neck sized it . How ever I know this specific batch of brass was sized to the length of my GO GAGE . That's .0015 shorter then I normally size my cases for this rifle . So that had me thinking why am I getting a little resistance when closing the bolt . I did not fire that cartridge so I could inspect it when I got home . After checking COAL and case head space and them both being correct . I went ahead and colored the whole case with a sharpie . It was only then I saw the case was rubbing down by/at the web just above the extractor . These are all FL sized cases using the #6 comp shell holder . after measuring I found that area of the cases measured .471 maybe .4715 . I then went and checked all the cases that measure over .470 . I had 40 out of 420-ish FL sized pieces that measured over .470 with a few at .472 . Of those 40 I only checked a couple but the ones I did had the same tight fit in my chamber . The rest of that lot of brass measures right at .470 with a few a little less . At .470 I do not feel the bind when I chamber the case or loaded cartridge . Long explanation I know but that leads me to my question . Is it likely that's my problem ? There is just not enough clearance at the base for the cases to be able to take the stronger charges ? The next obvious question is , Will a small base die fix this issue ? I assume that's the very reason they're made for . If so and I'm sure I find this out my self but will the small base die only need to be used once seeing how I'll only be using the brass in my bolt guns ? Well that ended up being a little more long winded then I planned . What do you guys think .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; June 12, 2016 at 01:25 AM. |

|

|

|

|

#23 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

I'm guessing the pressure difference is just due to primer start pressure difference. A primer pressurizing a case that size can't move the bullet forward faster than the powder builds pressure. The proof is that if you look at sectioned .308 Win cases you see a slight inward curl at the mouth. This proves the case didn't let go of the bullet until the neck had expanded off the bullet most of the way forward. Primers don't make enough pressure to do that and so they unseat a bullet comparatively slowly in the large case. A little case is another matter. Primers beating the powder to unseat the bullet happens in tight space pistol cases and in small rifle cases like the 22 Hornet.

Regarding fit, take a look at the SAAMI drawings and see how the cases compare and how well your chamber matches. Keep in mind that the cartridge linear dimension numbers are all maximums with a minus tolerance and the chamber linear dimension numbers are the other way around. The exception is where a range is given. Look, too, for the diameter tolerances to learn the range. Also worth doing with the tight cases is to try rotating them around the clock to see if that affects how easily they chamber. This is just to double-check that you didn't get a chamber cut off-axis with the bore. It happens. Otherwise, though, I think the softer brass is just flowing under pressure. The way to check is to measure the diameter both before and after firing a case that's still a good fit to see if your load is producing case head expansion. If so, it's too warm for that particular lot of brass.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#24 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

SAAMI shows the max case diameter of .4703 and the minimum chamber diameter of .4714 with a difference of .0011 . So my cases that measure .471 to .4715 can easily be binding in the chamber even more so when you consider I'm using a $45 set of calipers to measure that . To be clear I'm able to chamber the rounds they just feel tight , Which apparently they are just not in the way I expected . I just measured a once fired LC-14 case I bought yesterday at the range It seems most are .472 with a few measuring as much as .4745 . When I FL size the .472 cases they are sized down to .470 but the cases measuring .4745-ish only size down to .472 . Bummer I just bought 500 more . Great deal $20 bucks for 500 but now I know why . I'll go play with all those and see what chambers easy and what binds up . SIDE NOTE :These LC-14 cases are disappointing . I have LC-09 , 10 , 12 and all size down to around .4685 or so . The LC-14 I can only get to .470

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|

#25 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

I think I might be more confused now then ever . I just finished measuring , sizing to different case head spaces and chambering multiple cases to find what is binding up . I have one case sized .0005 longer then my GO GAGE that has a web measurement of .4705 that binds up so much I need to knock the bolt back with the palm of my hand . While I have another case with what appears to be the same measurements chamber and extract with ease .

I sooted  up the case with a candle that sticks real bad and it does show some rubbing at the base . Turning it and chambering again multiple times does not seem to make a difference . Nor does it with the case that has the same measurements but chambers fine . up the case with a candle that sticks real bad and it does show some rubbing at the base . Turning it and chambering again multiple times does not seem to make a difference . Nor does it with the case that has the same measurements but chambers fine . All the cases I was just testing were sized to GO GAGE lengths or less . and trimmed to 2.005 of the 20 cases tested 7 of them have some resistance to closing the bolt with 2 being pretty hard to chamber and extract . Yet they are at most +/- .0005 in diameter at the base ( .4700 to .4705 and at most .0005 longer from datum to head then my Forester GO GAGE that chambers freely . Other bras I have that chambers fine measure .4680 to .4690 . The confusing part is I have two seemingly same sized cases . One binds up and the other does not .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|