|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Junior Member

Join Date: July 11, 2009

Posts: 4

|

Form 1 question and integral suppressor idea.

I would like to start with a pistol-caliber carbine (probably the Kel-Tec Sub2000 for me). Starting at about 5" from the breach, drill holes completely through the barrel at various intervals all the way to the muzzle. Details (hole size, number, and spacing) could vary quite a bit, with the primary concern being letting enough of the pressure waves enter the suppressor chamber, without letting them simply rush back out other holes, but that isn't the main point for now.

Then, using a drill bit of perhaps ~.4" (13/32 is .406" diameter, for example), I could drill into the bore from the muzzle end, to the last port hole, again roughly 5" from the breach. This effectively gives it a 5" barrel, though for all legal purposes it is still a 16", rifle-length barrel. The ideas behind removing so much of the effective barrel length are both to get more usable suppressor volume without increasing OAL, and to ensure that factory ammunition originally loaded to be subsonic will stay subsonic. Now for the suppression: The simplest way to complete the suppressor part of it would be to use a closed-ended steel tube of 1/16-1/8" thickness, whether round or square (square for easier optics / rail / foreend mounting), perhaps of 2" diameter / width. Even rectangular tubing that is like 1.5" x 3" or something could be used to flow a little better with the Sub2000s orignal lines, but it would be largely personal preference and have relatively little effect on its performance. While this obviously wouldn't make for the most efficient design, the actual materials cost and time would be very low (like $10 and a couple hours) heh. Still, though, its sheer mass and volume would still likely make it reasonably effective. Most likely I would go a few steps further to add some simple internal baffles (probably a series of discs inside the suppressor), make it at least partially servicable, and not weld directly to the barrel to avoid any warping or annealing. Basically since I already will have to pay like $230 or so (tax stamp plus fingerprint fees, etc), the small increase in time and money to give the suppressor significantly more quality would surely be worth it. So, what do you guys think of that? One concern I had was that due to the significantly shorter barrel length, cycling might be a problem? I know this can happen with the Ruger 10/22 action if the barrel is cut significantly shorter than stock, so I thought I'd see if it was still a concern with the 9mm. If you guys think that would be a problem, would there be a way to fix that (shorter / softer recoil spring, perhaps)? Also, as far as the Form 1 goes, I have some questions: 1) Would this design it would be the same as building a stand-alone suppressor, in that I could not legally start the project until the tax stamp is received? 2) Would there be any differences since the suppressor would be integral to the firearm? 3) I would have to submit a design, correct? And after that design is submitted and accepted, I could not legally make any internal modifications or alternations to the design, correct? 4) Is my assumption that the barrel modifications themselves would not require SBR registration correct? It would not be legally any different than adding recoil-reducing barrel porting, right? 5) Would the ports in the barrel be considered part of the suppressor, if the suppressor itself is made to be removable (except its mounting system)? If the ports in the barrel are not considered part of the suppressor, and the answer to question (3) is "no," then I could start with a small number of ports and slowly increase that number during testing until the amount of suppression stabilizes. BTW, I am in Oklahoma for those that wonder. Lastly, I know it seems suspicious to start asking questions like this in my first post on the forum. It's just that nearly everytime I Google something firearm-related, I end up reading (typically useful) threads on TFL, so it seemed like a good place to come  . . Thanks! Last edited by Lindenwood; July 11, 2009 at 04:20 PM. |

|

|

|

|

#2 | |||||

|

Senior Member

Join Date: March 5, 2009

Location: Uh-Hi-O

Posts: 3,006

|

Quote:

Quote:

Quote:

Quote:

Quote:

__________________

"9mm has a very long history of being a pointy little bullet moving quickly" --Sevens |

|||||

|

|

|

|

#3 |

|

Senior Member

Join Date: December 23, 1999

Location: South Sioux City, Nebraska

Posts: 704

|

Barrel ports just damage the rifling and make swiss cheeze out of the accuracy. Cut the barrel short, weld the silencer on the barrel so that the barrel/silencer combo is over 16" and good to go. You will loose the barrel folding latch on the sub2000

|

|

|

|

|

#4 |

|

Junior member

Join Date: July 20, 2008

Location: WA, USA

Posts: 447

|

I think drilling the barrel like you propose will ruin it. Even if you take the barrel off and mount into a lathe then start drilling, it will not work. The drill bit is likely to drift off center and make a crooked hole. The chamber and crown are the two most important parts of the barrel. Using a drill on the crown (the new one you are making inside) is going to ensure it is off center and the bullet will probably rattle down the bore then tumble and keyhole into the target. Key holing bullet will probably give you 12 inch groups at 25 yards.

Will the silencer tube extend past the muzzle? If it is limited to covering the barrel, then I think the suppression level will suck. Not all of the gases will make it through the barrel ports and vent into the can. You need an open space beyond the muzzle enclosed by the can containing baffles to do a decent job of suppressing this carbine. How will you deal with the front sight? Square baffles will be hard to make. 9mm pistols will shoot standard ammo through five inch barrels at supersonic speeds. Your five inch barrel will too. The only good way to reduce velocity is to load the ammo lighter and use a heavier bullet like a 147 grain. The barrel is not considered to be a silencer part by the ATF, so you can do anything to it you want as long as you keep it 16 inches or longer. You can chop to less than 16” if you make it a short barreled rifle (SBR) on an ATF form 1. Do not make any silencer parts until you get your ATF form 1 back approved. The ATF form 1 is the same for any silencer. DO NOT submit a design for silencers. Do not put the length of the silencer or barrel on the ATF form 1, enter “N/A” instead. There is no need to lock yourself into any certain design before you start making it. Your barrel modifications do not matter as long as you keep it 16” or longer. In fact you can chop the barrel down then weld the silencer to it to make it 16 inches long and avoid paying another tax for the SBR. You can not make any replacement parts after silencer construction is done. You must send the silencer to a class 2 for replacement parts, it they are willing to do it. Since the barrel is not a silencer part, then you can modify it anyway and anytime you want. There is nothing wrong with discussing silencer construction here as long as you do not imply or say you are doing it illegally. Ranb |

|

|

|

|

#5 |

|

Senior Member

Join Date: April 25, 2006

Location: Amerika's Doyleland

Posts: 809

|

Sounds like you want to make sn SD type of can. Sounds pretty cooll, and given the design of the sub2K, would still let you fold it up. Since it's a blowback rifle, it should work with a vented barrel.

|

|

|

|

|

#6 | |

|

Senior Member

Join Date: December 15, 2001

Location: Winter Haven, Florida

Posts: 4,303

|

Quote:

I also have a Ciener manufactured suppressor on my Walther PPK. It uses a longer barrel (about 4" longer than normal) that is perforated and threaded. This supports the suppressor while still using the entire length of the suppressor to dissipate the gases.

__________________

NRA Certified Instructor: Pistol, Rifle, Shotgun, Home Safety, Personal Protection, Range Safety Officer NRA Life Member |

|

|

|

|

|

#7 |

|

Junior Member

Join Date: July 11, 2009

Posts: 4

|

Thanks for the pointers!

With good bits and decent machines, it is not difficult for a drill bit to cleanly and evenly follow a pilot hole. When I made .410 slug molds, I did just that; drilling a 7/32 hole, and then drilling a 13/32 hole behind it stopping about half an inch short. The smaller diametered part of the cavity was tapped 1/4-20, and a threaded plug was used to form the center cavity of the slug when casting. I never had a problem with bore concentricity. Still, with a .4" overbored diameter, any loose tolerances should be more than covered, and if I am still concerned I would just go to ~.45" or even .5" on the overbore. However, I will be sure I can do this before I try (including measuring bit and chuck run-out), and if I am not comfortable I would take it to one of my machinist friends who I know could just pop it on a lathe and be done with it in a few minutes. I would likely do that if I did not feel the .4" overbore would allow enough clearance. True, the cross-drilling would damage the rifling initially, but after overboring there would be no rifling anyways. And the overboring would take place after the cross-drilling so as to also remove any internal burrs from the process. As far as the crown goes, you are probably right about that also. However, I have a 10/22 that would, with a stock barrel, shoot under 2" at 100 yards with bulk ammo. I cut the barrel down to about 16.375" with my bandsaw, then used a file to even it out, taking it to about 6.25". I used a cone-shaped grinding bit, originally made for a dremel, with my hands to reform the "crown." Accuracy did not suffer at all, and I know it is not as even around the circumference as it would be with a good drill bit. And, if worse comes to worse, I could have a gunsmith redo the barrel boring and shorten the effective barrel length down to perhaps 4.75" or whatever, giving it a satisfactory crown. As far as 9mm ammo not being subsonic out of a pistol, there is plenty of factory 147gr ammo that is: http://www.cheaperthandirt.com/33416-5.html http://www.cheaperthandirt.com/33979-5.html http://www.cheaperthandirt.com/34829-5.html RAnb, you say the suppressor would not work well if it is not passed the muzzle. If the effective inside diameter of the suppressor being .4" (AFAIK, the same as most other 9mm suppressors), how would it be any different than a large suppressor mounted on a 5" barrel. I do see what you mean about the expansion chamber part, and I would need to work that into the design, though it does not look difficult. And likely the sights would be removed completely, with a red-dot being used instead. |

|

|

|

|

#8 |

|

Junior member

Join Date: July 20, 2008

Location: WA, USA

Posts: 447

|

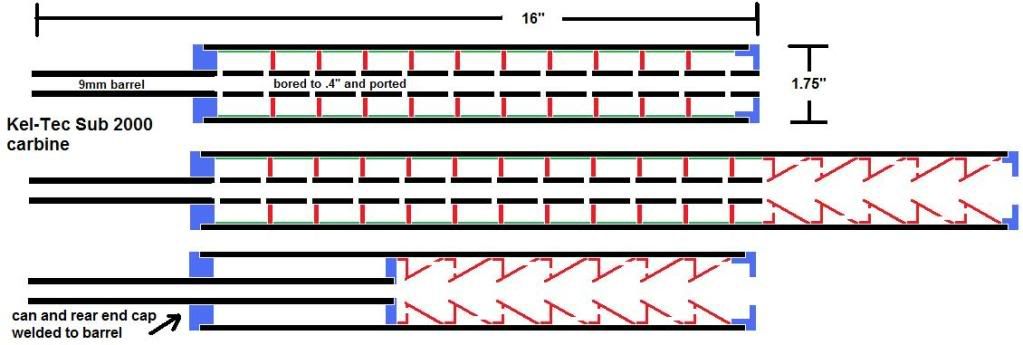

I drew up what I thought you were talking about, then added two other designs. I think the best way to go about this is to chop the barrel down to about 8 inches and weld the can in place to avoid the SBR tax. Fill it with aluminum baffles (steel blast baffle) and use a screw-on front end cap.

Ranb |

|

|

|

|

#9 |

|

Member In Memoriam

Join Date: March 17, 1999

Posts: 24,383

|

There is a rumor, which may not be true, that with the right combination and size of holes, there is no need for a "can" on or over the barrel. There is another rumor that the old Mossberg .22's with the full length stock sometimes became very quiet without any muzzle attachment.

Jim |

|

|

|

|

#10 | |

|

Senior Member

Join Date: March 5, 2009

Location: Uh-Hi-O

Posts: 3,006

|

Quote:

It's ok... I'll wait...

__________________

"9mm has a very long history of being a pointy little bullet moving quickly" --Sevens |

|

|

|

|

|

#11 | |

|

Junior member

Join Date: July 20, 2008

Location: WA, USA

Posts: 447

|

Quote:

No rifle shooting the 22lr cartridge is quiet. Even those equipped with a good silencer are over 100 decibels. Ranb |

|

|

|

|

|

#12 |

|

Junior Member

Join Date: July 11, 2009

Posts: 4

|

This is kinda what I'm thinking. Go even simpler with the baffles:

The ID of the overbore is actually ~.5" on that drawing, just for the empasis (could not really see the difference at only .4"). The OD of the suppressor is two inches. The effective barrel length is 5" and the suppressor itself is 11". As far as the depiction itself goes, baffle thickness and baffle / port numbers can vary (based on input). I don't want to do much welding on the barrel itself as I am pretty sure it would warp, and I don't know if the extra tolerance of the overbore could compensate. Perhaps having them TIG-welded would prevent too much heat from getting into the barrel during welding (as opposed to my OxyAcetylene torch setup), but Ill have to research that a bit. However, I have started to devise some ways to allow the entire suppressor to be completely removable and user servicable without having to do any welding directly to the barrel. I really do want to keep the barrel as one piece, as the barrel walls will sort of serve as part of the baffles shown above. They effectively create the horizontal part of "L"-shaped (in cross-section) baffles, helping to avoid the need to fabricate much more complicated one-piece baffles (only the flat baffles would need to be created, which would obviously be very easily). Additionally, it will guarantee concentricity, which could be a problem with cutting off the barrel and then welding on a separate piece. Finally, it will increase strength, perhaps preventing any bending or cracking should the firearm ever be dropped. This is as opposed to the can only being supported at the 5" mark. What do you think? Last edited by Lindenwood; July 13, 2009 at 08:12 AM. |

|

|

|

|

#13 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,077

|

Others have suggested precisely what I did on my build. I just shortened and re crowned the barrel and TIG welded the tube to the barrel so with the end cap off its 16.125” oal. There are two rings welded to the barrel spaced apart so concentricity was easy to achieve. 1 4140 blast baffle and 5 K’s + the end cap. It’s silly quiet.

|

|

|

|

|

#14 |

|

Senior Member

Join Date: May 19, 2009

Location: Auckland NewZealand

Posts: 350

|

Suppressor

I would be more inclined to make the components out of stainless steel rather than mild steel, easier to clean and and more resistant to corrosion (rust). My own one has stainless body and baffles and aluminium spacers and end plugs. The whole suppressor unscrews off the thread by the receiver and the rest of the silencer is easily dismantled for cleaning.

|

|

|

|

|

|