|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: March 20, 2014

Location: Kinda near Phoenix, AZ

Posts: 1,254

|

Multiply by 3, then divide by 4?

Note: I've only been reloading for 13 months. Calibers I've reloaded: .223 rem, 38 spl./.357 mag, .40 S&W, .44 spl./.44 mag, and .45 acp. I reloaded my 4000th round about a month ago.

The reason I'm posting this thread is that after a year of reloading I've come to realize that though I feel I've learned a lot, the more I learn the more I realize how little I really know. Anyway . . . A much more experienced reloader I met awhile back introduced me to this equation for starting loads and I just wondered how many of you used it as well and what you might think of it. In case some of you aren't familiar, the way it works is pretty straight forward: take the starting charge weight, for example, for a 55 grain .223 rem FB using IMR 8208 XBR, the starting charge weight is 21.5 grains, according to Hodgdon's data center. Subtract that from the maximum charge weight of 23.0, giving you 1.5 grains. Multiply 1.5 by 3 to get 4.5, then divide that by 4, to get 1.12 or rounded down to 1.1 grains. To get your starting charge weight, simply subtract 1.1 from 23.0, giving you 21.9 grains. Begin making test loads here instead of at 21.5 grains, thus saving you from making 4 test loads, which for me is at least 20 rounds. I've used this formula for several different calibers to find my most accurate loads and it seems to work, while eliminating some of the cost in materials and time when working up test loads. So, is anyone else familiar with this formula and is there some obvious reason not to do this that I'm missing? Thanks in advance for your replies. Last edited by Rangerrich99; January 17, 2016 at 04:02 PM. Reason: I can't add . . . and I used the wrong word |

|

|

|

|

#2 |

|

Member

Join Date: July 20, 2015

Posts: 62

|

Is this just a method to basically eliminate the bottom quarter of the load range? I'm curious as to Where this came from. Like you said it could save some material.

|

|

|

|

|

#3 |

|

Member

Join Date: October 22, 2008

Posts: 73

|

If ya gots a calculator, just take the first number (the min/max spread if I'm reading this right) and divide it by 0.75. Gets you the same value, shorter steps thanks to the marvels of math, easy thanks to electrons.

Or, flipping the equation in a sense, just multiply the first number by 1.333. The result from either approach would then be subtracted from the max load to bring what the OP has been told is a reasonable way to get a "don't start all the way at the bottom" charge. It's not the same as the old standard start at 10% below max approach. I seem to remember finding some published loads that listed the minimum as something more than 90% of the max. Never heard of it, but if it works for you... |

|

|

|

|

#4 |

|

Senior Member

Join Date: July 10, 1999

Location: High Desert NV

Posts: 2,850

|

I always just eyeballed it.

|

|

|

|

|

#5 |

|

Senior Member

Join Date: January 5, 2009

Location: Just off Route 66

Posts: 5,067

|

I've always started half way between min and max and worked up from there.

Stay safe. Jim

__________________

Si vis pacem, para bellum |

|

|

|

|

#6 |

|

Senior Member

Join Date: August 18, 2009

Posts: 826

|

This is a "rule of thumb" developed by somebody, perhaps the "more experienced" hand loader in question. But, it has NO scientific validity. It MIGHT happen, by pure coincidence, work to find good loads for SOME firearms with SOME combinations of components, but there isn't a chance in heck that it would work every time. Baloney.

The "experienced" hand loader probably got that from somebody (more experienced) HE knows/ knew.....and has just stuck with it. Since nothing bad has happened, he thinks it "works every time". About as scientifically valid as flipping a coin. |

|

|

|

|

#7 |

|

Senior Member

Join Date: October 21, 2007

Location: Between CA and NM

Posts: 858

|

>In case some of you aren't familiar, the way it works is pretty straight forward: take the minimum charge weight

Forgive me, but where do folks get these ideas? There is NO minimum charge weight, except maybe for 296/H110. There is a STARTING load. If there is no start load, meaning that they are showing the MAX load, that means you drop the max load by 10-12 (i.e., multiply the max charge by 0.89 to get the start load). It is called a starting load because that is where you START loading and you work up. Do any of your MANUALS discuss any freaky equation or do they also say to START at the START load and work up, watching for pressure signs? The Hornady 9th manual, which spends all its time talking about their toys that they they want you to buy and about loading for rifles (and all the toys you can buy for that activity), still say to take the max charge weights in the manual and reduce by 10% for a starting charge (despite the manual HAVING start loads). Obviously the writer hasn't really reviewed the manual. |

|

|

|

|

#8 |

|

Senior Member

Join Date: February 13, 2002

Location: Canada

Posts: 12,453

|

There is no such thing as an equation for starting loads. If there is no start load, you just reduce the max load given IN A MANUAL by 10%.

"...IMR 8208 XBR, the minimum charge weight is 21.5 grains..." Only for a solid copper bullet.

__________________

Spelling and grammar count! |

|

|

|

|

#9 | |

|

Senior Member

Join Date: January 24, 2009

Location: Anchorage Alaska

Posts: 3,341

|

Quote:

Write down the minimum charge (that you want to test) at the top of a page write down a charge a little bit heavier on the next line continue like that down the page until you reach the charge where you want to stop testing. Use those charge weights for your testing. What weight is "a little bit"? That's where the "eyeballing" comes in. Large enough that you will not produce too many tests to do in a session. Small enough that you figure you will not skip over a good load. I tried to make this easier/simpler to read than the OP. Not sure how well I did at that. Lost Sheep |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: March 20, 2014

Location: Kinda near Phoenix, AZ

Posts: 1,254

|

Okay fellas, sorry about the incorrect word usage. I just fixed it in the OP.

Anyway, thanks again for all the replies so far. |

|

|

|

|

#11 | |

|

Senior Member

Join Date: September 27, 2004

Posts: 4,811

|

Quote:

I check several manuals, select the lowest HIGH & then Highest LOW then split the difference. This is (theoretically) an absolute median from which I can go up or down as needed.

__________________

Allan Quatermain: “Automatic rifles. Who in God's name has automatic rifles”? Elderly Hunter: “That's dashed unsporting. Probably Belgium.”

Last edited by wogpotter; January 18, 2016 at 05:11 PM. |

|

|

|

|

|

#12 | |

|

Senior Member

Join Date: March 20, 2014

Location: Kinda near Phoenix, AZ

Posts: 1,254

|

Quote:

@noylj: And I probably should have mentioned that I did in fact begin my reloading career by working up loads from the START loads suggested by whatever manual or data center I was using for a given cartridge. Every single time. When I was introduced to this 'formula,' me being me, I decided to work up loads both ways just for safety's sake. Now I know full well that 20 or so work ups aren't anything close to a scientifically acceptable proof, but as I said before it does seem to work. As to the comment about whether or not I read any of the three manuals I own, that's specious at best, and as such I refuse to offer a reply one way or the other. As it sits, it seems no one has heard of the formula, which answers my original question. @grump: Thanks for the hack on the formula; that simplifies things a bit. @T. O'Heir: Of course you're right; that is the starting charge weight for a solid copper bullet. I just grabbed that data for the purposes of a theoretical example since it was the first one listed and the math was easy. I actually used the data listed below that one using a Speer soft point when I did my work ups on an actual test cartridge. @KBrun: I don't know what the origins of the formula are; I admit I never asked him. I do know that the other gentleman that was there during our conversation also was aware if it. I remember this other gentleman expressed that he used it for working up rifle cartridges but not for handgun loads. I can't remember why he didn't use it for handgun loads though. Continue . . . Last edited by Rangerrich99; January 17, 2016 at 08:41 PM. |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: January 14, 2000

Location: Southern California

Posts: 1,089

|

That's the strangest thing I've heard about reloading in the last 47 years and more than 600,000 rounds later. Why not ask Hodgdon, or any powder maker, if they recommend it? I would find a new source of information like http://reloadersnest.com/forum/default.asp.

So here is how it works, go to the powder makers website, get the minimum weight and maximum OAL. For rifle, the OAL is pretty much fixed, and all rifle loads pretty much fill the case. Start at 21.5, move up .5 grains to 23, done. You don't need 20 test rounds, only 5 rounds. Run it for accuracy thru the chrono because it will never be the same as shown Somewhere in that test lot of 20 rounds will be a group better than the others. Ok, so lets say 22.5 is best, 23 next best. Go .25 grains for 5 rounds, then dial in the last tenth. In this case who runs a 24" .223Rem with 1/12 twist for 55s? For pistol, same deal, but OAL can very by over .100" depending on bullet weight and shape and powder type. Hot pistol powders fill the case 3-4 times. Same deal, .5 grains at at time, but don't try to go any closer than +/- .1 on a pistol, the powder throwers are not that accurate, plus certain powders measure like corn flakes others like corn sugar. Then start shortening the OAL if the particular bullet doesn't feed well by .020" at a time. Here are 4 different bullets, all 125 grains, and all at 4.2 grains of TiteGroup, from 1.170" OAL to 1.050" OAL. 3rd from left is actually a .357 revolver bullet that I plan on using in my Glock 31 (.357SIG) to get over 1,600 fps. I just dropped in a 9mm case to see if it would feed. And there is a difference for whats important in competition action pistol and hunter silhouette. For my Thompson Center Contender in .35REM, I would buy new brass and resize, clean the primer pocket, trim the case, weight the cases, weight each bullet, final charge weight by a dripper to .1 grains, weigh the loaded round, and measure the OAL's and sort them, all on a single stage press, course you only need like 40 rounds every other month. For action pistol, out of the tumbler into the reloader, 400 rounds in an hour on the progressives.

__________________

Sometimes my Glock forgets where to look..... Last edited by 9x45; January 17, 2016 at 08:02 PM. |

|

|

|

|

#14 |

|

Senior Member

Join Date: July 8, 2013

Location: Littleton, Colorado

Posts: 1,121

|

Rangerrich, Mind boggling.

|

|

|

|

|

#15 |

|

Senior Member

Join Date: February 22, 2014

Posts: 868

|

It looks to me that your friend is a want to be mathematician. For a person to come up with some thing like that. I am far from or farther from that. Although I don't think it is a good formula without a PI in it.

The manuals are the way to go. If you don't like one buy another one. Read a dozen or so over and over. Then take make your opinion from that. With a Gr. of salt. That's my opinion. |

|

|

|

|

#16 |

|

Senior Member

Join Date: February 7, 2009

Location: Southern Oregon!

Posts: 2,891

|

No offense meant, but the "formula" mentioned sounds like much ado about nuttin'. Someone trying to establish his own reloading formula/following? Going through all that figgerin' and the difference for the charge example is .4 gr? Perhaps if you can see a difference in a less than half grain starting load, this formula may be of some benefit (have you tried to find a noticeable difference between 21.5 vs. 21.9?).

I've been reloading for a couple decades and have never found a need or benefit for not use my manuals' starting loads. But then again I'm not shooting competition benchrest...

__________________

My Anchor is holding fast! I've learned how to stand on my own two knees... |

|

|

|

|

#17 | |

|

Senior Member

Join Date: July 10, 1999

Location: High Desert NV

Posts: 2,850

|

First of all, for some people, reloading is more of the hobby than actual shooting, and there is nothing better than tinkering with different powders, and charge weights, and seating depths to try and eek out the best possible performance from your load and rifle.

I am not that person. I want to work up a load with acceptable accuracy and velocity for the gun in question, as quickly as possible. That usually means, I come up with 4 or 5 test loads in the published range, and call it good. I tend to stick with powders I have had good results with in the past. One of those will normally give acceptable accuracy. Yes, I generally leave at least some accuracy potential on the table, but for me at least, the time involved is not worth the potential for shrinking the groups by a little bit. Perfect is the enemy of good. Quote:

For a pretty narrow range like you are talking about, published starting of 21.5 and max of 23, I would probably do .3 grains, and work backwards from the max for my steps. I also do more than 5 rounds, try to reduce the chances of blind luck making a good group. Ten rounds would be great, but I normally use 7. Load 7 at 23, then 7 more at 22.7, 22.4, 22.1, and 21.8. Shoot them from low to high of course, watching for pressure. If you get pressure signs, stop, that is what a bullet puller is for. The last load I worked up was for 8mm Mauser, where the minimum and max published were pretty wide, starting at 40.9, with a max of 47 (that would be 61 different loads, 305 rounds and about 2 lbs of powder using your .1 steps). In that case, I also went backwards from the max load, but in this case went by one full grain steps, and skipped the max load completely (no real reason to push max loads from a ~75 year old rifle). I shot 7 round groups at 43, 44, 45, and 46 grains. 46 did the best group, but I was not satisfied with the accuracy, so I narrowed it down a bit, and made up some test loads centered around 46 grains, with 7 rounds each at 45.5, 45.8, 46.1, and 46.4 grains. In this case, 45.5 and 45.8 tied for the best group, and they were tight enough I am satisfied with the accuracy of the load and rifle. My next range trip with that gun, I may just split the difference, and use 45.7, if it still groups fine (and I expect it will) I will load there. For OAL, in rifles I ignore the OAL listed in the manual, and set to about .020" jump to the lands, assuming I can get that long and still fit in the magazine. If I can't, I use the max that will fit the magazine and still feed reliably. I also do ladder tests to work up loads that are tolerant of slight variations in powder charges, but that is beyond the scope of this thread. |

|

|

|

|

|

#18 | |

|

Senior Member

Join Date: February 17, 2009

Posts: 1,089

|

Quote:

Heck... there isn't even a easy way to convert PSI to CUP !!! Learning the physical burn characteristics of a specific powder is a VERY complicated thing. IMHO... leave the powder charge weight info to the professionals. |

|

|

|

|

|

#19 | |

|

Senior Member

Join Date: January 24, 2009

Location: Anchorage Alaska

Posts: 3,341

|

Quote:

Lost Sheep |

|

|

|

|

|

#20 | |

|

Senior Member

Join Date: August 9, 2011

Posts: 1,293

|

Quote:

Last edited by TMD; January 19, 2016 at 02:35 AM. |

|

|

|

|

|

#21 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

If you look at any manual you will see the charge weights correlate to a specific numbered velocity in 100fps increments . It's why you see 21.2gr rather then 21.0 . Why bother with that when loading for rifle loads . If it says 21.2 , I'll start at 21.5 then 22 , 22.5 , 23 etc . If there is a huge amount of grains between min & max . I'll start at or very close to minimum and load two rounds working up in whole grain increments loading two of each for about 1/3 the load ladder then 3rds in 1gr or .5gr increments for the next 1/3 then 5rds in .5gr increments for the final 1/3 of the ladder .

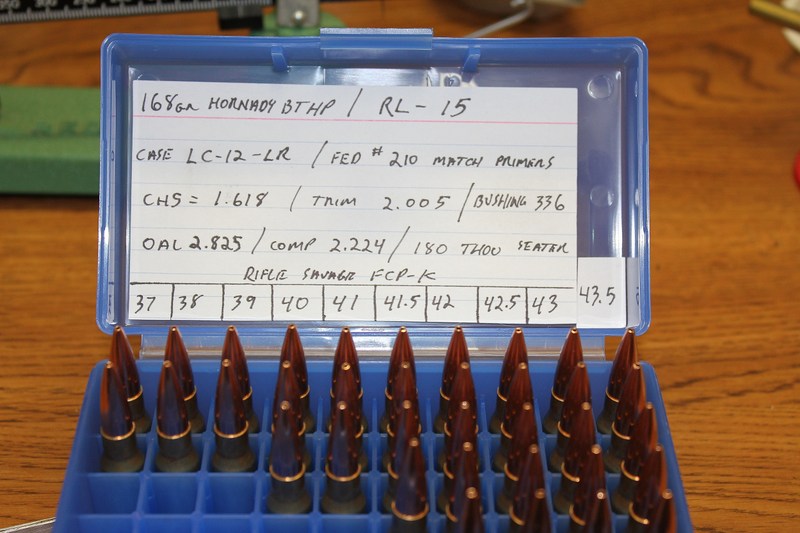

The first third is only for checking pressure and is why I only load two rounds at each charge . The second third is with 3rds also really only keeping an eye on pressure but looking for a group just in case I shoot something real tight I can go back to it . The last third is where I'm expecting the loads to shine and is why I start loading 5rds per charge . I generally load in .5gr increments from around minimum . That usually is 5 to 8 different charges . I don't have my notes in front of me be I think RL-15 and Hornady 168gr BTHP had quite a large gap between min and max loads . If I recall , if I would have done the .5gr increments I would have had to load 13 or 14 different loads to hit all charges from min to max . That to me just seems to be a waist of components . I did those test with ten different loads saving 14 bullets , primers and powder . Hey found a pic of that very load development .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; January 20, 2016 at 12:39 AM. |

|

|

|

|

#22 |

|

Senior Member

Join Date: December 22, 2015

Posts: 887

|

Never heard of the times 3 divide by 4 practice referenced to establish a starting load. Nor would I practice it or recommend it.

The practice of starting about 10% below the max charge has been a common practice in many loading manuals for many decades. There have been some instances in the past where recommended starting loads with certain powders were 6% below maximum. And there have also been a few loads that were to be used exactly as published (no reduction in charge weight). Some manuals show loads that go significantly below a 10% reduction. That indicates to me that with that particular combination, you can safely reduce to those levels if it provides the velocity you are seeking. I guess I’m simply suggesting that if one wishes to work up to a maximum or near maximum load, the proper place to begin is the recommended starting point specified in the loading manual (usually a 10% reduction, sometimes a lesser reduction). Encountering high pressure signs well below the maximum powder charges listed in the manual (as I have) gives one a better appreciation for the published starting point recommendations. I know of no compelling reason to begin anywhere other than starting point recommended in the loading manuals. |

|

|

|

|

#23 |

|

Senior Member

Join Date: September 21, 2014

Location: Somewhere in the middle

Posts: 629

|

What happens when your most accurate load is in the bottom 4th of the load range?

I don't want to sacrifice accuracy for speed. EDIT - I changed the words accuracy and speed - I had them reversed and TOTALLY ruined the initial thought.............

__________________

"The day you stop learning SHOULD directly coincide with the day you stop breathing." Last edited by 849ACSO; January 19, 2016 at 05:12 PM. |

|

|

|

|

#24 | |

|

Staff

Join Date: March 11, 2006

Location: Upper US

Posts: 28,833

|

Quote:

The practical answer is that a handful of fps is also essentially irrelevant. Sure, the slower bullet drops more, but does "more" matter that much?? I say this, because if you know what your load's drop at a given range is, then how many inches it is doesn't matter. Take that .223 slug, 55gr BC .23 (in this example). MV of 3200fps it drops about 12" at 300yds. Same slug, MV 3000fps, it drops about 16" at 300yds. Some will look at this and say "that's 25% more for the slower round!!  " "Others know that if you can compensate for 12" of drop, you can just as easily do it for 16" (other bullets and speeds will of course have different numbers, but the point is still valid with any numbers, if you can do for one, you can do for either just as well) Most of the loading data I see is about a 200fps spread, often less, between starting load and max load. SO, if your best accuracy load is in the lower end of the velocity range, I don't think the difference in speed matters as much as how much difference there is between your best, and worst accuracy. If you need minute of prairie dog, and a min load gets you there, while the max load gives you minute of moose, the extra powder is wasted. And the opposite is sometimes true. Usually max loads don't group as well as slightly lesser ones, but some guns are the exception to that general rule. You just have to work with your own stuff and see what it does. As to the formula, never heard of it, anywhere other than here, today, and I've been handloading since the early 70s. It did make me wonder, since there is such a wide difference in powders and cartridges, how anything like that could work (and work safely) will all possible combinations, but then I realized that since ALL you are doing with it is using it to pick a random starting point within safe published data, that it really couldn't do much harm. Seems like you could throw darts at a list of possible starting points and do as well, though.

__________________

All else being equal (and it almost never is) bigger bullets tend to work better. |

|

|

|

|

|

#25 | |

|

Senior Member

Join Date: September 21, 2014

Location: Somewhere in the middle

Posts: 629

|

Quote:

Seems counterproductive to be less accurate, but do it "faster"...................

__________________

"The day you stop learning SHOULD directly coincide with the day you stop breathing." |

|

|

|

|

|

|