|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#51 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Unclenick, I'm familiar with polished chambers increasing back thrust of cases. I asked about polishing the lower half of the chamber. That's where a lot of folks think the cartridge rests when it's fired and wondered if that was part of the reason to polish that area. I thought someone might reason that way.

Last edited by Bart B.; June 24, 2014 at 05:17 PM. |

|

|

|

|

#52 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

That hadn't occurred to me, and may be worthy of an experiment. The idea I was focused on was just to introduce slipping over that greater length from head to mid chamber, instead of just over the sixteenth of an inch or so that we normally see as the length of a pressure ring. With the front half of the cartridge gripped, the pressure ring stretch will happen over that whole polished portion, more where the brass is thinner and less where it's thicker, but generally just more distributed. Assuming you set shoulders back 0.002", that much stretch is 3.2% of that sixteenth of an inch. But if the stretch is spread over 1 inch, it is only 0.2% of the stretching length. Since the yield of half hard cartridge brass is at around 0.3%, you may do no significant permanent pressure ring thinning of the brass at all if at least the lower half of your chamber is polished.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#53 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Cohesion of friction: If 75% contact is better than 50%, Why isn't 100% better than 75%? I want all the contact I can get between two surfaces. If I want it to slide and glide I add oil, when I want something to stop I go with dry.

I want nothing between the case and chamber but air, not a lot, a lot of air gets into the 'time as a factor' thing. Then there is the 'scribe the case' and skid marks, I have a few friends that built rifles with speed bumps in the chamber, even then, no skid marks. F. Guffey Last edited by F. Guffey; June 26, 2014 at 10:35 PM. Reason: change finds to friends |

|

|

|

|

#54 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

One other thing about case stretching non-uniformly around its back end causing the case head to be a bit out of square when it smacks the bolt face.

A squared bolt face helps keep case heads square; I don't think there's any doubt about that. But the further the case head moves back as the case body stretches unevenly all around it, the more the case head will be out of square. Couple that issue with head clearance; the distance from the bolt face to the case head when the round fires. If it's absolute minimum, such as only a few ten thousandths inch, the head won't be very much out of square when it stops against the bolt face. But sizing cases to that small a tolerance is virtually impossible. Keeping that spread to .001" requires the fired case to be cleaned well and have the same amount of lubricity when sized. Plus, the case head has to stop at the same place relative to the sizing die's shoulder each time; a shell holder of the right height or a die with the right headspace for a standard shell holder. Then the shell holder would stop against the die's bottom and the most consistant sized case headsapce would be attained. But they'll still have a small spread. No fired case sizing method or tool setup I know of will square up a fired case head with its body axis. So, square up your bolt faces (with the chamber axis, not the bolt axis), uniformly lube cases then use a shellholder-die combination that sets the fired case shoulder back as little as possible for reliable loading. With minimal sizing with the right die, the shoulder can be set back quite uniformly .0005" to .0010". Otherwise, with more commone tools and chambers with unsquared bolt faces, set it back .002". That's typically enough to prevent the bolt binding and its out of square face won't bind on an out of square case head. If it does bind, set the shoulder back more. Last edited by Bart B.; June 26, 2014 at 09:53 AM. |

|

|

|

|

#55 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

F. Guffey |

|

|

|

|

|

#56 | ||

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Quote:

Good summary here: http://www.firearmstalk.com/forums/f...11/index2.html It is very hard to roll a handload that equals, or beats, Federal Gold medal match, and Mr Sciuchetti shows the effort it takes to do so. Quote:

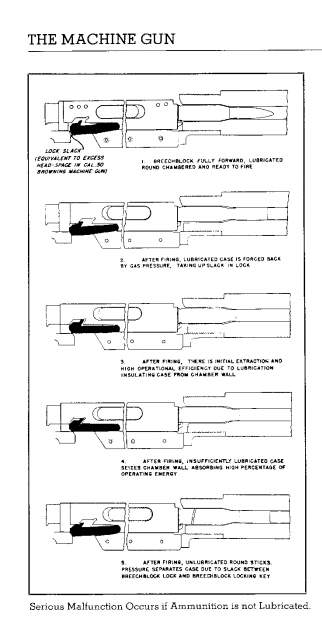

Secondly, I want to know just when I hit a maximum load: I don’t want case to chamber friction disguising a maximum load. I want the bolt fully loaded and I want sticky bolt lift when I hit a max load. People develop loads with dry cases in dry chambers and they are very surprised when the slightest bit of oil, water gets on their cases and they have over pressure indications. Well guess what, their loads were over pressure from the get go. I don’t trust primer indications, but at least when I lube the cases I see the transition from rounded to flat primers, something that is sometimes disguised by dry cases in dry chambers. I found early on that if I lubed my 308 cases in my M1a, I got rounded primers, but the same load in dry cases gave flat primers. Now I develop my loads with lubed cases and I look for that primer transition and I look for hard bolt lift, for I am very sure that when I see these signs when I near or at a max load. I am also of the opinion that eliminating case binding increases accuracy. Your rifle, your action was designed to withstand the full case head thrust, having an inconsistent case head thrust, due to variable case to chamber friction, is just going to load the action inconsistently. That is just another variable that you can eliminate, or reduce its effect. Match 22LR ammunition is greased so heavily that it feels like the rounds were rolled in bacon fat. I don’t believe this an accident: I believe the heavy grease layer was found to be necessary for the best accuracy, and it helps extraction function. For semi autos, you want the least friction between case and chamber as friction will cause failures to extract. It also defeats the residual blow back effect built into the actions.   These charts from Chin’s Vol IV Machine Gun. A book series that everyone, but no one, seems to read, or even download, though it is free : http://www.milsurps.com/content.php?...ge-M.-Chinn%29 To figure out why M16’s had an extractor lift problem, the Army had to grease the cases. Understanding Extractor Lift in the M16 Family of Weapons www.dtic.mil/ndia/2003smallarms/din.ppt None of this makes the slightest impression on those who believe in the inerrancy and infallibility of Hatcher and also believe the 1921 Army cover up of the pressures problems with their tin can bullets. For those who forgot, this all started 93 years ago when the Army made ammunition that had a tin coating on the bullet. This coating cold welded to the case neck creating a god awful bore obstruction. However, since the Army never admits they are ever wrong, they told the shooting community the rifle blowups that occurred were caused by greased bullets. Of course, this is/was a total lie, greasing bullets was common because bullets of the period fouled horribly. The shooting public has a memory slightly longer than the life of a fruit fly and has totally forgotten the oilers, the greased rounds, that were used prior to WW2. Paul Mauser’s M1916 carbine required greased rounds and this was an 8X57 cartridge, not some pop gun round: German Military Rifles and Machine Pistols, 1871-1945, Hans Dieter Gotz The Mauser Self Loading Carbine (M1916) , page 174 In the operator’s manual for the Mauser self-charger it is said specifically: “The chamber and receiver surfaces must always be lubricated with the grease that is provided. Likewise it is absolutely necessary that the cartridge cases be light greased in their entire extent” History is something ignored by Hatcherites Of course the public has forgotten the 20 mm Oerlikon. This was a blow back cannon, used by the Navy from WW2 all the way through Vietnam. One reference states that 150,000 of the things were made and were in service during WW2. Hatcher should have been very familiar with the things as they were in all Army Air Corp fighter planes (with cannons) and his Ordnance Department bought the things. The WW2 era cannons required greased ammunition to function or it would rip the case in half. You can see at exactly 2:14 on this WW2 video a Sailor’s hand painting grease on the 20 mm ammunition loading machine for the Oerlikon anti aircraft machine guns. http://www.youtube.com/watch_popup?v=9dR3h2HdnBQ Figure from The Machine Gun Vol V Hispano-Oerlikon page 358 http://www.milsurps.com/content.php?...ge-M.-Chinn%29

__________________

If I'm not shooting, I'm reloading. Last edited by Slamfire; June 27, 2014 at 04:33 PM. |

||

|

|

|

|

#57 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Is it very hard to roll a handload that equals, or beats, Federal Gold medal match? I don't think so.

Many folks have taken brand new Winchester, Remington or even Federal cases, uniformed their necks with an expander ball or Lyman M die, put in a good primer, loaded IMR4064 under Sierra 168, 175, 180, 190 or IMR4350 under 200 grain HPMK"s seated to touch the lands. They've shot as good as, sometimes better than, the best lots of Gold Medal Match ammo. Same for IMR4895 or Varget loaded in decent cases over good primers under Sierra 155-gr. Palma bullets. Last edited by Bart B.; June 28, 2014 at 09:49 AM. |

|

|

|

|

#58 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

I look through the barrel with a light at the muzzle, I look for rifling, I look for shinny, when the chamber looks as smooth as glass with reflection, for me that is good as it gets.

I want nothing but air between the case and chamber, not a lot of air, just a little and I want clean air. I know the case is embeddable but when the case body is imbedded with dirt, grit and grime I must prevent the case from moving/skidding, because the dirt, grit and grime can dull my shinny chamber. I have no problem with those that grease the case and or chamber, they know what they have to do to make it work. I am not the fan of hammering the bolts lugs and or the front of the chamber. F. Guffey Add: I am the fan of the running start, I believe in bullet jump. I am not the fan of the case head running start, I do not want my case head hammering the bolt face. He said he know something about pigeons, I know something about case heads, cutting down on the distance they travel reduces case head crush/upset. Does anyone add MPH? Case head crush, who measures? Last edited by F. Guffey; June 28, 2014 at 10:03 AM. |

|

|

|

|

#59 | ||

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Slamfire's comments:

Quote:

Quote:

Nobody I know of ever had a failure to extract one of those fired cases in all the thousands of rounds so fired. I shot over a thousand myself as did others at the same matches. Flawless functioning and excellent accuracy with dry cases and chambers with very hard grip of case wall to chamber wall at peak pressure. Last edited by Bart B.; June 29, 2014 at 09:38 AM. |

||

|

|

|

|

#60 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Bart,

Revolver cases operating below pressures needed to stick the brass to the chamber often show no primer flattening before starting to cause sticky extraction. Since primer flattening happens during reseating of a primer cup bottom that has been bulged by pressure, I'm thinking his lube got the case to back up before the bottom of the primer bulged out to be flattened, just like the aforementioned revolver rounds. Slamfire, Have you double-checked that there are no current copyrights in force on the illustrations you copied?

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#61 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Unclenick, I've seen well flattened rifle primers in hot loads with .243 Win cases long enough in headspace that the bolt binds on the case head when closed. Case head barely moved off the bolt face when the firing pin struck the primer. The resized 7.62 NATO match cases had .001" shoulder setback at most as tested with primed cases in that rifle. I don't think that's enough to let a primer back out far enough to matter when peak pressure bulged its cup out as much as possible. I didn't check its firing pin spring strength to see if it was 23 (24?) pounds; spec for Win 70's springs. But I doubt a .243 Win case shoulder will set back as much as a .308 Win case will with all other things that matter being equal.

I must admit, sometimes my reasoning's been off. Your comments are welcomed. |

|

|

|

|

#62 | |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Quote:

Copywrit on Government Publications: (from Wikipedia) http://en.wikipedia.org/wiki/Copyrig....S._government A work of the United States government, as defined by United States copyright law, is "a work prepared by an officer or employee" of the federal government "as part of that person's official duties.".[1] In general, under section 105 of the Copyright Act,[2] such works are not entitled to domestic copyright protection under U.S. law. I am very unhappy with you deleting my images, including ads by Speer bullets, (no copyright protection on advertisements) and taking an extreme and overly limiting interpretation of the "fair use" doctrine of images and quotes that I use.

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

|

#63 | |||

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Quote:

We both understand that the primer is backed out early in combustion, the primer is hanging out by the clearance between base and bolt face, which is basically the cartridge headspace relative to the chamber. It is my guess that as pressure increases, the dry case is still stuck to the chamber walls but the primer cup is expanding. By the time pressure has increased enough to stretch the case sidewalls, the pressure inside the case is enough to bulge the primer cup to a muffin appearance, or square the ends. However, a lubricated case slides back to the bolt face much sooner in the pressure curve, stuffing the primer back in the pocket before it expands. This is assuming a load below max. At max loads, the primer in lubed cases does flatten out and looks indistinguishable from a max load in a dry case. In a gas gun, with the 0.003” clearance that I put between shoulder and chamber, I see the transition clearly. My theory could be bogus, but my observations in the physical world show that in my gas guns (Garand/M1a/AR15) non max loads that cause flat primers in dry cases will give rounded primers in lubricated cases. Science is built on observations in the physical world, theories are wrapped around the observations, but theories can be wrong, and are modified/dumped as better experimentation with better observations are created. Anti science is built on the unquestioning authority of some respected figure, such as Hatcher and the US Army. When my observations conflict with Hatcher’s authority, I conclude that Hatcher/Army are wrong. The anti science crowd stand with their authority figure regardless of what real world phenoma shows. Quote:

This bolt is on its third barrel of lubricated cases. It will be a long time till I put a fourth barrel as I seldom shoot the thing in competition. Once I got my Distinguished and gave up the chase for a Pres 100 patch, I prefer match rifle sights.  Now as an example of what happens with increasing case friction, just plug up the flutes on a roller bolt. Or, shoot that ball ammunition issued to M16 carrying troops in Vietnam. That stuff was so hot it ripped the rim of the case and left the case in the chamber. You can find accounts where Colt representatives advised troops to lube their cases to prevent case sticking. The Army did not like this and this was not the proper answer as what was needed was ammunition that was not over pressure for the operating characteristics of the rifle. The Army of course, covered this up too, but the declassified documents can be found on DTIC. http://www.dtic.mil/dtic/index.html Report of the M16 Review Panel Appendix 4 Appendix 4 Ammunition Development Program. Report of the M16 Rifle Review Panel Volume 7 Appendix 6 review and analysis of M16 System Reliability. Report of the M16 Review Panel Appendix 5 Procurement Report of the M16 Review Panel Appendix 7 Vietnam Surveys Report of the M16 Panel appendix 10 the small arms program Report of the M16 Review Panel Summary Report

__________________

If I'm not shooting, I'm reloading. |

|||

|

|

|

|

#64 |

|

Senior Member

Join Date: June 1, 2008

Location: Lone Star State

Posts: 295

|

So did the OP find his magical load? It seems he abandoned this thread the day after he started it. Inquiring minds would like to know......

|

|

|

|

|

#65 |

|

Junior Member

Join Date: June 10, 2014

Posts: 12

|

Well had no time to get back to this but I am still trying.. to get the accuracy..

Went to the range and got back disappointed again. Here what I learned so far one thing which I found interesting: I tried the suggestion from uncle nick who suggested to partially pull a bullet and reseat.. Here a quote " One test for the above issues, collectively, would be to partially pull and then reseat some GMM rounds and see if they still producing the same velocity and are still grouping as well as before. If loosening the neck grip drops velocity and precision, the neck bond may be an issue as may the graphite." I liked the idea since it would not touch the primer and would not change the powder amount of the original GMM. So here the results: I fired several groups with original GMM and the one with partially pulled bullets that were reseated to original depth. Results is clear the groups opened up from 0.5 MOA to 0.8 MOA every time I used the partially pulled rounds that were reseated. I find this interesting since it clearly shows that the problem/solution is going to be in the neck region! So I have been waiting for more dies.. A reeding type S competition neck sizing die and a forrester bench rest bullet seeting die. They arrived today. I tried the reeding type S competition neck size on once fired FedGMM and am again disappointed by the runoff.. It is not better than what I get with the LEE collet die.. I am clearly out of luck on this .. It measures .004'. The bushing I got is 0.336. Not sure what I do wrong on this one? I do not think that I should proceed loading these since the runoff is too large. Anyone knows a trick on how to get the runoff to where it should be using these dies. They are supposed to be great! I also got some new out of the box lapua which measures 0.001' reaching what I was hoping for. I think I will try to use those and (re)load 20 rounds for Friday. So I would not need to touch the neck. Just prime and seat to same depths as original GMM and hope that I get the 0.5 MOA that Original GMM delivers.. Thanks for a all the help and suggestions it is so much more than I could ever try. Anyway, will post again if I get any closer.. |

|

|

|

|

#66 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

I doubt a Redding bushing neck die will make sized case necks as straight on the case and shoulder axis as Redding's full length sizing die with a bushing. The die's shoulder and body have to be held in perfect alignment with the neck when they're all sized down in diameter. The last die used to make those new cases out of a sheet of cartridge brass was a full length die without an expander ball that made them a bit smaller than commercial full length dies do.

That's why Sierra Bullets uses full length Redding bushing dies on cases used to test their bullets for accuracy. And why a few years ago, most benchresters switched over to full length sizing dies with necks the right size from neck only sizing. While the smallest groups with either type remains the same, the biggest groups with the full length version are a lot smaller. Those new Federal GMM cases are smaller than most any full length sizing die will shrink fired ones down to. So having smaller diameter cases is not detrimental to accuracy. I've never got any version of a neck only sized case to shoot as accurate as new ones nor properly sized ones in a full length sizing die. Last edited by Bart B.; July 1, 2014 at 10:05 PM. |

|

|

|

|

#67 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Wrong standard

Then there is 'THE' fan of bullet hold, I want all the hold I can get, I would go with the flow but I can not measure neck tension, I do not have a gage that measures tensions. tensions as in more than one. I can measure bullet hold, I did notice the OP moved away from neck tensions to grip.

And I am still 'the' fan of the "LEAVER POLICY', when it works I leave-er the way I found-er. Long before we started rediscovering everything there were reloaders that get no credit. One reloader/shooter purchased 500 cases, out of the 500 he narrowed his selection down to 47 cases as being accurate. He did not say the other cases were not accurate, he did say he could index the cases of culls to improve accuracy. F. Guffey Quote:

F. Guffey Last edited by F. Guffey; July 2, 2014 at 10:55 AM. |

|

|

|

|

|

#68 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

My statement has no value?

That's rediculous. Neither are yours, then, for the same reasons. |

|

|

|

|

#69 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Slamfire, the USAF and USN armourer's maintaining those Garands shooting hot loads saw no more parts wear or failure issues than those shooting standard service ammo. The part that was stressed the most was the op rod. There were only two men in the shop in San Diego that could fit them right to withstand higher port pressure.

Many civilians took their Garands with bent op rods from such use to the Navy van at the Nationals to have them refitted if the rest of the rifle was good enough to support it. Last edited by Bart B.; July 2, 2014 at 02:58 PM. |

|

|

|

|

#70 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Bart,

Your reason is actually an extension of mine. Your example is high pressure, which flattens any primer, and, for that reason, I don't believe rounded primers can be had at high pressure. I am, therefore, assuming Slamfire's ammo that produced rounded primers with lubrication were not maximum pressure loads. That left me looking for a mechanism whereby a moderate pressure load still might produce a flattened primer when dry, while lubed ones did not. But of course I was just speculating. It might be something utterly unrelated. Here's another mechanism that might explain it: I once took some NM LC '64 and ran it through several club Garands with the powder positioned forward in the case while firing. I then shot more, but with the powder back over the flash hole in the case. The forward and rear powder positioning was accomplished by tipping the chambered gun's muzzle down or up, respectively, before settling the gun slowly to level for firing. The forward positioned powder yielded rounded primers in all the guns, while the rearward positioned powder yielded flat primers ones in all the guns, because the resulting faster ignition increased the peak chamber pressure. This difference was made possible by the poor case fill of 4895 in that ammunition. If Slamfire's ammo had a powder charge that left enough extra empty space in the cases, perhaps the oiled case simply wound up chambered with the powder positioned further from the breech end of the case than was the case without oil. In this instance, the mechanism would be that the oiled cartridges stripped from the magazine and slid forward faster and more easily than dry cartridges do, slamming them home harder and throwing the powder forward inertially. But, again, I am speculating. And it would be easy to prove by using dry cartridges and the tipping the muzzle down before leveling to fire to see if effect on the primer shape was the same as oiling cases produced.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#71 | |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Unclenick, your method:

Quote:

http://www.saami.org/specifications_...wnload/206.pdf the section titled "4. Handling of Ammunition." I did a similar "twist" on a friends chronograph with a .308 match rifle with WCC58 match cases. Those 150-grain, thin wall cases had enough airspace with 42 grains of IMR4895 under Sierra 165 SBT bullets that rounds with the powder at the back end of the case shot bullets out noticably faster. The American Rifleman and other print media has oft times mentioned the importance of 100% loading density for best accuracy. Anything less can produce excellent results if the round's handled the same way from storage to 'positioned for aiming' chamber for every shot fired. In the few muzzle velocity tests I've done, each round was twisted the same for each shot. It was chambered in the rifle when held vertical when the second hand on the clock was at 45. Rounds fired at the 60 second mark. All done to have powder at the same position and temperature each time. Last edited by Bart B.; July 3, 2014 at 02:01 PM. |

|

|

|

|

|

#72 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Yes. Exactly. The SAAMI standard is designed to make a worst case pressure, and powder over flash hole is one of those factors. The "twist" works to achieve that in the universal receiver. which is mounted solidly and cannot practically be tipped up or down after closing the chamber. The reason I used the tipping approach with the Garand is that the spring-powered feeding does tend to throw powder forward, regardless of where it started out, same as with about any self-loader. It's the primary reason people often report lower velocities with the Garand than the same ammo gives them in 24" bolt rifles.

I got about 80 fps average difference in powder-forward/powder-rearward testing of the Garand I did. The '64 NM load was an even 46.0 grains of IMR 4895 under the 173 grain M1 Type bullet. It worked out to about 81% case fill. Despite that modest charge weight for the big case, 1964 gave 2669 fps at 78 feet from the test barrel (fairly fast bulk lot of 4895), with powder over the flash hole, which means it would have been about 2758 fps at 15 feet from the muzzle where I was measuring. Faster than anything I got, but that's not unusual with fresh ammo and this was 30 years old by then. My tests gave anywhere from 2495 fps at 15 feet, powder forward against bullet in the slowest of the well-worn club guns, to 2611 fps at 15 feet, powder forward in the fastest club gun. I got 2578 fps and 2689 fps for powder rearward in the same guns, respectively. That was measured by an Oehler 35P at 15 feet from the muzzle. At 78 feet those powder rearward loads should have been about 2492 fps and 2602 fps, for the slow and fast rifles, respectively. That puts the faster gun a good 68 fps below the LC test barrel, but that's not an unusual thing, in and of itself.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#73 |

|

Senior Member

Join Date: December 4, 1999

Location: WA, the ever blue state

Posts: 4,678

|

I saw one guy shoot sub moa 15 years ago with FGMM 223 ammo in Win70.

I say another guy shoot sub moa 15 years ago with FGMM 308 ammo in an M14 with original TRW barrel. But when I put FGMM 308 ammo on the Sinclair concentricity gauge, the ammo is not the best. I can make ammo a little straighter with a Lee Collet neck die. The best ammo I have tested for concentricity is Greek surplus 303. I can't load that well. I think PMC target 223 is a little better than I can reload as well.

__________________

The word 'forum" does not mean "not criticizing books." "Ad hominem fallacy" is not the same as point by point criticism of books. If you bought the book, and believe it all, it may FEEL like an ad hominem attack, but you might strive to accept other points of view may exist. Are we a nation of competing ideas, or a nation of forced conformity of thought? |

|

|

|

|

#74 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

The ammo loaded on two Dillon 1050 progressives had 3 mils runout, 3/10 charge spread and new cases first used with Sierra's then new Palma bullet. It shot 1/2 MOA at 600 yards in several rifles.

|

|

|

|

|

#75 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

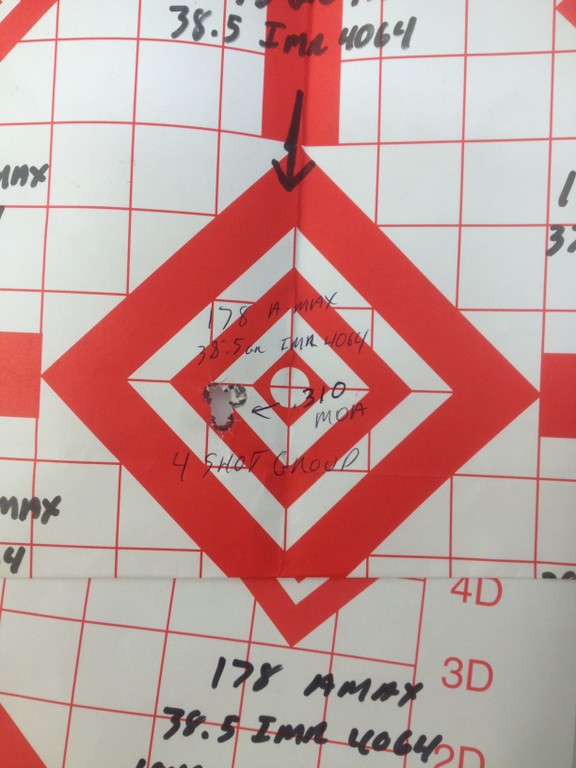

My savage shot Federal GMM like this at 100yds when the rifle was new

Now it shoots them like this at 100yds 1500 rounds later Get your self some IMR 4064 or 4895 with 175gr smk or 178gr A-max and find YOUR best load and stop trying to find someone else's

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; July 8, 2014 at 09:32 PM. |

|

|

|

|

|